Professional Documents

Culture Documents

09 - 0046 - MJ-77 - Rivet Selection

Uploaded by

marian32Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

09 - 0046 - MJ-77 - Rivet Selection

Uploaded by

marian32Copyright:

Available Formats

Rivet Selection:

The following rules should govern your selection and use of rivets:

1. Replacements must not be made with rivets of lower strength material unless they

are larger than those removed. For example, a rivet of 2024 aluminum alloy

should not be replaced by one made of 2017 aluminum alloy unless the 2017 rivet

is a size larger. Similarly, when 2117 rivets are used to replace 2017 rivets, the

next larger size should be used.

2. When rivet holes become enlarged, deformed, or otherwise damaged, you should

use the next larger size as replacement.

3. Countersunk-head rivets should be replaced by rivets of the same type and degree

of countersink, either AN426 or MS20426.

4. All protruding-head rivets should be replaced with universal-head rivets,

either AN470 or MS20470.

5. Rivets less than three thirty-seconds of an inch in diameter should not be used for

any structural parts, control parts, wing covering, or similar parts of the aircraft.

6. Minimum rivet diameter is equal to the thickness of the thickest sheet to be

riveted.

7. Maximum rivet diameter is three times the thickness of the thickest sheet to be

riveted.

8. The proper length of rivet is an important part of the repair. If the rivet is too long,

the formed head will be too large, or the rivet may bend or be forced between the

sheets being riveted. If the rivet is too short, the formed head will be too small or

the riveted material will be damaged. The length of the rivet should equal the

sum of the thickness of the metal plus 1 1/2 times the diameter of the rivet, as

shown in figure 13-43.The formula for determining rivet length is as follows:

1 1/2 x D+G=L

D = the rivet diameter

G = the grip (total thickness of material)

L = the total length of the rivet.

Spacing and Edge Distance:

• Rivet spacing, also referred as rivet pitch, is the distance between the rivets in the

same row, and is measured from the rivet center to the rivet center.

• Transverse pitch is the distance between the rows of rivets, and is measured from

the rivet center to rivet center.

• Edge distance is the distance from the center of the rivet to the edge of the

material being riveted.

There are no specific rules that apply to every case or type of riveting. There are,

however, certain general rules that should be followed.

Rivet Spacing:

• Rivet spacing (pitch) depends upon several factors, principally the thickness of

the sheet, the diameter of the rivets, and the manner in which the sheet will be

stressed.

• Rivet spacing should never be less than three times the rivet diameter.

Spacing is seldom less than four times the diameter nor more than eight

times the diameter.

Transverse Pitch:

• When two or more rows of rivets are used in a repair job, the rivets should be

staggered to obtain maximum strength. The distance between the rows of rivets is

called “transverse pitch.” Transverse pitch is normally 75 percent of existing

rivets pitch, but should never be less than 2 1/2 times the diameter.

Edge Distance:

• The edge distance for all rivets, except those with a flush head, should not be less

than twice the diameter of the rivet shank nor more than four times the

diameter of the rivet shank.

• Flush-head rivets require an edge distance of at least 2 1/2 times the diameter. If

rivets are placed to close to the edge of the sheet, the sheet is apt to crack or pull

away from the rivets. If they are placed too far away from the edge, the sheet is

apt to turn up at the edge. NOTE: On most repairs, the general practice is to use

the same rivet spacing and edge distance that the manufacturer used in the

surrounding area, or the structural repair manual for the particular aircraft may be

consulted, Figure and edge distance.

You might also like

- Macramé for Beginners and Beyond: 24 Easy Macramé Projects for Home and GardenFrom EverandMacramé for Beginners and Beyond: 24 Easy Macramé Projects for Home and GardenRating: 4.5 out of 5 stars4.5/5 (7)

- Paracord Outdoor Gear Projects: Simple Instructions for Survival Bracelets and Other DIY ProjectsFrom EverandParacord Outdoor Gear Projects: Simple Instructions for Survival Bracelets and Other DIY ProjectsRating: 4.5 out of 5 stars4.5/5 (2)

- Under Armour Marketing MixDocument13 pagesUnder Armour Marketing MixSyahida AmirrudinNo ratings yet

- Design Guidelines - SheetMetal PDFDocument4 pagesDesign Guidelines - SheetMetal PDFsunilbhol100% (1)

- Ae6413 - Cad & Aircraft Component DrawingDocument52 pagesAe6413 - Cad & Aircraft Component DrawingDamo Daran G50% (2)

- MP II by RavindranDocument15 pagesMP II by Ravindranavijayakumar_1964No ratings yet

- L11 Mechanical FastenersDocument91 pagesL11 Mechanical FastenersSHADES 4 ALLNo ratings yet

- Sheetmetal Design GuidelinesDocument20 pagesSheetmetal Design Guidelinesbrpnaidu2157No ratings yet

- Bolted and Welded ConnectionsDocument2 pagesBolted and Welded ConnectionsKrunalsinh VirpuraNo ratings yet

- Aircraft Structurses - Part IIDocument17 pagesAircraft Structurses - Part IIhellenhse1No ratings yet

- Product DesignDocument36 pagesProduct DesignvkrishnarajNo ratings yet

- Product Design IntroDocument37 pagesProduct Design IntrokavinkumarjackNo ratings yet

- Design of DieDocument41 pagesDesign of DieKarthik ACNo ratings yet

- Design Tips For Sheet Metal BendingDocument2 pagesDesign Tips For Sheet Metal Bendingjitendertalwar1603No ratings yet

- Module 3 - Joint Types in Machine DesignDocument28 pagesModule 3 - Joint Types in Machine DesignMahmud HassanNo ratings yet

- Understanding Thread Forms and Lathe SetupDocument30 pagesUnderstanding Thread Forms and Lathe SetupAkulNo ratings yet

- Design of Permanent Joints RivetsDocument37 pagesDesign of Permanent Joints RivetsAmunyela FelistasNo ratings yet

- Aircraft HardwareDocument52 pagesAircraft HardwareMatthew Silab100% (1)

- Screw Thread PDFDocument45 pagesScrew Thread PDFPandurang Nalawade67% (3)

- Bend Relief Options for Accurate Sheet Metal ModelsDocument17 pagesBend Relief Options for Accurate Sheet Metal Modelsjohndesign123No ratings yet

- 7-Design of Riveted Joints - Introduction-03-Sep-2018 - Reference Material I - Module 4A - Rivetted JointsDocument62 pages7-Design of Riveted Joints - Introduction-03-Sep-2018 - Reference Material I - Module 4A - Rivetted Jointsakhil govindNo ratings yet

- AASHTO Table 10.32.1A Bds-Sec10cDocument20 pagesAASHTO Table 10.32.1A Bds-Sec10cWill McMullenNo ratings yet

- RIVETSDocument16 pagesRIVETSعبدالرحمن سيدNo ratings yet

- L - 9 Ah - SSBLF I (6.5)Document7 pagesL - 9 Ah - SSBLF I (6.5)Arjun SharmaNo ratings yet

- Welded Connections: Chapter Twenty OneDocument14 pagesWelded Connections: Chapter Twenty OnePaul RoqueNo ratings yet

- Plug and Slot Welds V.1Document3 pagesPlug and Slot Welds V.1sboergertNo ratings yet

- Threads and FastenersDocument89 pagesThreads and Fastenerstheleovn0% (1)

- Fillet Weld Effective Area and LimitationsDocument1 pageFillet Weld Effective Area and LimitationsErnesto MarinNo ratings yet

- M6 Hardware (Phase B)Document88 pagesM6 Hardware (Phase B)Moin IqbalNo ratings yet

- Built Up ColumnsDocument28 pagesBuilt Up ColumnsSuneesh PNo ratings yet

- DDSS Unit 2Document27 pagesDDSS Unit 2Alam Mohammad Parvez SaifiNo ratings yet

- RT187M Rivet GuideDocument2 pagesRT187M Rivet GuideConquest97No ratings yet

- Fasteners Guide - Threaded, Non-Threaded Types and Design for Fatigue StrengthDocument41 pagesFasteners Guide - Threaded, Non-Threaded Types and Design for Fatigue StrengthGcwalisile DlaminiNo ratings yet

- Chapter - 3 L-1 Bolt DesignDocument34 pagesChapter - 3 L-1 Bolt DesignBerihunNo ratings yet

- Sheet Metal DFMDocument3 pagesSheet Metal DFMNageswar ReddyNo ratings yet

- Screw Thread CalculationsDocument4 pagesScrew Thread CalculationsbagmassNo ratings yet

- How To Install Metal LathDocument2 pagesHow To Install Metal LathKfir BenishtiNo ratings yet

- Threads Design in SolidWorksDocument12 pagesThreads Design in SolidWorksRicky TerryNo ratings yet

- Aircraft FastenerDocument91 pagesAircraft FastenerPrasanthNo ratings yet

- Threads and Thread Cutting Operations: Arul R ApmechDocument22 pagesThreads and Thread Cutting Operations: Arul R ApmecharulsivagiriNo ratings yet

- Riveted Joint Design GuideDocument20 pagesRiveted Joint Design GuidegurdyalNo ratings yet

- ME137L 2 Threading Operations 2Q 19 20Document91 pagesME137L 2 Threading Operations 2Q 19 20Mj GaupoNo ratings yet

- Limits, Fits, Tolerance and GaugingDocument107 pagesLimits, Fits, Tolerance and GaugingHarsh Rana0% (2)

- Saw HandleDocument7 pagesSaw Handleانغي رحمنيNo ratings yet

- Tolerancies Generals EstampacioDocument2 pagesTolerancies Generals EstampacioAlbert SolsonaNo ratings yet

- Sheet Metal (C) FabricationDocument67 pagesSheet Metal (C) FabricationAl VlaerNo ratings yet

- HSFG Bolts RNGDocument34 pagesHSFG Bolts RNGSANDEEP DANGDANo ratings yet

- Thread and Thread CuttingDocument9 pagesThread and Thread Cuttinglyk zNo ratings yet

- LESSON 5. Riveted ConnectionsDocument12 pagesLESSON 5. Riveted ConnectionsAdarsh bhatNo ratings yet

- Field Inspection Procedure For Used GPDS Connections Revision 03 PDFDocument3 pagesField Inspection Procedure For Used GPDS Connections Revision 03 PDFJohn Dolan0% (1)

- 4 Die DesignDocument40 pages4 Die DesignNarendrareddy RamireddyNo ratings yet

- Pile CapDocument27 pagesPile CapHafeel Ahamed Ashraf AliNo ratings yet

- D Tension Members: StressDocument2 pagesD Tension Members: StressJerry M. Davila MartelNo ratings yet

- Damaging: Permanent JointsDocument16 pagesDamaging: Permanent JointsKrishna MurthyNo ratings yet

- Sheet Metal BasicsDocument16 pagesSheet Metal BasicsvittlevishnuNo ratings yet

- Thread Cutting, Tapping and Broaching: Nainik Shah - 171040075 Ajinkya Shah - 171040076 Ameya Iyer - 171040089Document87 pagesThread Cutting, Tapping and Broaching: Nainik Shah - 171040075 Ajinkya Shah - 171040076 Ameya Iyer - 171040089Kundan PatilNo ratings yet

- Screw Thread CalculationsDocument4 pagesScrew Thread Calculationsyauction50% (2)

- Table J2.4 Minimum Size of Fillet Welds: 2b. LimitationsDocument2 pagesTable J2.4 Minimum Size of Fillet Welds: 2b. LimitationsJen Tan100% (2)

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosFrom EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNo ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- Malwarebytes Report 5-11-2018Document8 pagesMalwarebytes Report 5-11-2018marian32No ratings yet

- Oscar Screener LeaksDocument41 pagesOscar Screener Leaksmarian32No ratings yet

- Officer Detailer Contact List: PERS-41 Surface Officer Distribution DivisionDocument6 pagesOfficer Detailer Contact List: PERS-41 Surface Officer Distribution Divisionmarian32No ratings yet

- P-51G Mustang Full-Scale Replica 11x17 RDocument4 pagesP-51G Mustang Full-Scale Replica 11x17 Rmarian32No ratings yet

- NZMEDocument2 pagesNZMEmarian32No ratings yet

- Joseph Borremans Tel: Cell: 2393008404 EmailDocument2 pagesJoseph Borremans Tel: Cell: 2393008404 Emailmarian32No ratings yet

- Mig 29 Construction Guide v3Document28 pagesMig 29 Construction Guide v3marian32No ratings yet

- MS-282 Neal V. Loving CollectionDocument14 pagesMS-282 Neal V. Loving Collectionmarian32No ratings yet

- James G. Vazzana, Esq. BioDocument2 pagesJames G. Vazzana, Esq. Biomarian32No ratings yet

- DLA Disposition Services: Defense Logistics Agency Defense Logistics AgencyDocument15 pagesDLA Disposition Services: Defense Logistics Agency Defense Logistics Agencymarian32No ratings yet

- John J. Perrone Jr.Document2 pagesJohn J. Perrone Jr.marian32No ratings yet

- Hank Stuart Bio May 2013Document1 pageHank Stuart Bio May 2013marian32No ratings yet

- GoodYear Vip instructionforMSDocument5 pagesGoodYear Vip instructionforMSmarian32No ratings yet

- SOLIDWORKS Educational Product. For Instructional Use OnlyDocument3 pagesSOLIDWORKS Educational Product. For Instructional Use Onlymarian32No ratings yet

- Supermarineaircraft © 2018Document5 pagesSupermarineaircraft © 2018marian32No ratings yet

- Florida Directory 2020 v9Document194 pagesFlorida Directory 2020 v9marian32No ratings yet

- Department Position Last Name First NameDocument2 pagesDepartment Position Last Name First Namemarian32No ratings yet

- Office of The Secretary 1000 Navy Pentagon WASHINGTON, D.C. 20350-1000Document27 pagesOffice of The Secretary 1000 Navy Pentagon WASHINGTON, D.C. 20350-1000marian32No ratings yet

- Disp Cah 160513Document29 pagesDisp Cah 160513marian32No ratings yet

- Kärcher Floor Cleaner RecommendationDocument5 pagesKärcher Floor Cleaner Recommendationmarian32No ratings yet

- Daikin CallDocument2 pagesDaikin Callmarian32No ratings yet

- Detailer Contact List: Pers-401 - Navy Diver / Seal / SWCC / EodDocument9 pagesDetailer Contact List: Pers-401 - Navy Diver / Seal / SWCC / Eodmarian32No ratings yet

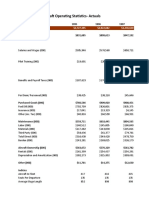

- American Airlines Aircraft Operating Statistics - ActualsDocument54 pagesAmerican Airlines Aircraft Operating Statistics - Actualsmarian32No ratings yet

- Call Center Candidates Contact ListDocument2 pagesCall Center Candidates Contact Listmarian32No ratings yet

- Department of The Navy: O C N O 2000 N P W, DC 20350-2000Document7 pagesDepartment of The Navy: O C N O 2000 N P W, DC 20350-2000marian32No ratings yet

- MCAGCC Telephone Directory Emergency NumbersDocument112 pagesMCAGCC Telephone Directory Emergency Numbersmarian32No ratings yet

- De Sti N Ation: The BestDocument5 pagesDe Sti N Ation: The Bestmarian32No ratings yet

- R. Thomas Flynn President Emeritus Monroe Community College Rochester, N.YDocument2 pagesR. Thomas Flynn President Emeritus Monroe Community College Rochester, N.Ymarian32No ratings yet

- GA Buyer June 2021Document56 pagesGA Buyer June 2021marian32No ratings yet

- leapfilesvsJUoMTVBxWim04bhb92eEHYlC7CF5TGGeV5zeTL Attachment - PDDocument2 pagesleapfilesvsJUoMTVBxWim04bhb92eEHYlC7CF5TGGeV5zeTL Attachment - PDJuan GonzalezNo ratings yet

- Animaccord v. Schedule A (Albright) - Order Granting PIDocument14 pagesAnimaccord v. Schedule A (Albright) - Order Granting PISarah BursteinNo ratings yet

- OpMan and TQM Chapter 1Document48 pagesOpMan and TQM Chapter 1Kadmiel CarlosNo ratings yet

- Internship Report RosheenDocument23 pagesInternship Report Rosheenaruba anwarNo ratings yet

- Pranjal Jain ResumeDocument1 pagePranjal Jain ResumeSanskarNo ratings yet

- WJ-Series WJ-Series: Turbine Meter Instructions Turbine Meter InstructionsDocument8 pagesWJ-Series WJ-Series: Turbine Meter Instructions Turbine Meter InstructionsIndra SUdirmanNo ratings yet

- F 8 BCDCDocument33 pagesF 8 BCDCyenNo ratings yet

- Quiz On CVP AnalysisDocument9 pagesQuiz On CVP AnalysisRodolfo ManalacNo ratings yet

- Challenges On Successful Completion and Delivery oDocument11 pagesChallenges On Successful Completion and Delivery oketema tasewNo ratings yet

- Ebook PDF Understanding Social Welfare A Search For Social Justice 9th Edition PDFDocument42 pagesEbook PDF Understanding Social Welfare A Search For Social Justice 9th Edition PDFquintin.lane537100% (34)

- Mimosa BackhaulDocument240 pagesMimosa BackhaulThanh Kieu TienNo ratings yet

- Septi Febriyanti S.SosDocument2 pagesSepti Febriyanti S.SosAJI PANGESTUNo ratings yet

- Iso-14001 Certificate Environment Management SystemDocument2 pagesIso-14001 Certificate Environment Management SystemwavchanakyaNo ratings yet

- Mercado vs. Espiritu (Digest)Document1 pageMercado vs. Espiritu (Digest)Tini GuanioNo ratings yet

- State and Non-State InstitutionDocument29 pagesState and Non-State InstitutionLawrence DumpNo ratings yet

- VAT Code and Percent Using BRF+Document8 pagesVAT Code and Percent Using BRF+Yazeed_GhNo ratings yet

- Theoretical Framework Quality Development TheoryDocument2 pagesTheoretical Framework Quality Development TheoryMiguel VienesNo ratings yet

- How The CIA Made Google (Google Did Not Start in Susan Wojcicki's Garage)Document9 pagesHow The CIA Made Google (Google Did Not Start in Susan Wojcicki's Garage)karen hudesNo ratings yet

- JICA-2014 - Pakistan Top Exporters & ProductsDocument76 pagesJICA-2014 - Pakistan Top Exporters & ProductsAdnan AzharNo ratings yet

- Big Data PresentationDocument24 pagesBig Data PresentationsfsgNo ratings yet

- TBChap 010Document112 pagesTBChap 010alaamabood6No ratings yet

- Tcs Employment Application FormDocument6 pagesTcs Employment Application FormRaveenaNo ratings yet

- PMP Chapter-12 P. Procurement ManagementDocument30 pagesPMP Chapter-12 P. Procurement Managementashkar299No ratings yet

- Unit 6 SeDocument54 pagesUnit 6 Se7killers4uNo ratings yet

- Managerial Theories, Approaches, Functions and ReferencesDocument4 pagesManagerial Theories, Approaches, Functions and Referencesdheeksha puvvadaNo ratings yet

- Astm C955-09Document4 pagesAstm C955-09rodrigoNo ratings yet

- Retrieve PDFDocument1 pageRetrieve PDFSilat Millenium24No ratings yet

- LP3-Product Costing MethodsDocument12 pagesLP3-Product Costing MethodsCarla GarciaNo ratings yet

- Sun Pharmaceuticals LTD.: Company Name: By: Rahna Vijayan (PGP/23/350)Document2 pagesSun Pharmaceuticals LTD.: Company Name: By: Rahna Vijayan (PGP/23/350)Sharon RodriguesNo ratings yet