Professional Documents

Culture Documents

949 User Manual-1410V04

Uploaded by

Denai01Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

949 User Manual-1410V04

Uploaded by

Denai01Copyright:

Available Formats

Warnings and cautions

Operate the pump in the rated pressure range of 40,000 psi (2,800 bar)

and do not exceed the safety pressure of 44,000 psi (3,080 bar).

When the system pressure is greater than 10,000 psi, you must close the

pre-pressurization shut off valve(#7)and then pressurize the system with

the high pressure handle.

Always tighten the gauges using two wrenches .

Close all valves and handles and tighten the ports when transporting the pump.

Always keep the reservoir cover vent valve(#4)open during operation.

Do not over tighten the valves, connectors and handles to avoid damage.

Change media immediately if it is contaminated.

Keep media level between 1/4 and 3/4 of the liquid reservoir filled.

Keep the threads clean and lubricious, and remove any dirt on threads.

Used by trained personnel only.

Additel is not liable for any safety problems or damages caused by misuse

or incorrect operation.

Specification

Pressure range: 12.5 psi ( 0.85 bar ) vacuum to

40,000 psi ( 2,800 bar ) positive pressure

949 Remark:If local atmosphere pressure is 1 bar, the vacuum can reach to 0.85 bar;

If local atmosphere pressure is P, the vacuum can reach to ( P 85% ) bar.

Hydraulic Ultra-High Pressure Test Pump User's Manual Temperature: (5 ~ 50)℃

[Version number:1410V04] Adjustment resolution: 0.015 psi ( 1 mbar )

Please download the latest version from www.additel.com Safety pressure: < 44,000 psi (3,080 bar)

Pressure media: Diethylhexyl Sebacate

Size: Height: 10.43'' ( 265 mm )

Base: 20.71'' ( 526 mm ) x 9.65'' ( 245 mm )

Weight: 35.5 lb ( 16 kg )

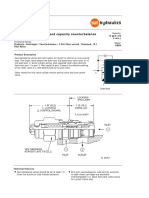

Views and Hydraulic Schematic

1- Vent valve

6 2- Over-flow reservoir Hydraulic Schematic

1 2 3 4 5 3- Positional Autoclave F-250-C,

9/16"-18UNF female

4- Reservoir cover vent valve 5

5- Reservoir

6- Liquid drain valve

7- Pre-pressure shut off valve

(Isolates the calibration volume from the

pre-pressure side of the pump) 1 7

9 7 9 8

8 8- High-pressure and fine adjustment

handle

9- Pre-pressure handle

Troubleshooting

Problem Cause Solution

Vent (#1) is not closed Close vent valve (#1)

Open pre-pressure shut off valve (#7). Caution: the pre-pressure side of the pump should not be exposed to

It is difficult to generate Pre-pressure shut off valve (#7) is closed

more than 10,000 psi (700 bar).

pressure with the

Not enough media is in the reservoir. Fill more media, and keep media level between 1/4 and 3/4 of the liquid reservoir filled

pre-pressure

handle (#9) Too much air is in the pump Purge the air from the system (see Preparation section of the manual)

Max pressure generation (could be as low as 5,000 psi, 350 bar) is

Close pre-pressure shut off valve and use high-pressure and handle (#8).

achieved with the pre-pressure handle (#9)

It is difficult to pressurize by The pre-pressure shut off valve (#7) is not closed completely Close pre-pressurization shut off valve (#7)

turning the high-pressure Reference gauge or devices under test (DUTs) are not connected tightly Check finger-tight connectors, re-tight if necessary

handle handle (#8) The connector of the DUT is not matched to connector Use proper adapter

It is difficult to generate Too much air is in the pump Purge the air from the system (see Preparation section of the manual)

high vacuum #4 valve is not open Open the #4 valve

Step 1: Turn pre-pressure handle (#9) all the way in clockwise, close pre-pressure shut off valve (#7),

open vent valve (#1).

Hard to pressurize Because of the large volume of the DUT, it will take additional steps to

Step 2: Turn pre-pressure handle (#9) all the way counterclockwise, close vent valve (#1).

large-volume DUT fill the volume to pressurize the DUT

Step 3: Open pre-pressure shut off valve (#7), pressurize the system.

Step 4: Repeat step 1 to 3.

Pressure gauges do not #4 valve is not open

reach to zero Open the #4 valve

Too much force was previously applied Do not over tighten

Hard to turn the This is normal. Close the pre-pressure shut off valve (#7) and use the high-pressure handle to adjust the

Hard to turn pre-pressure handle (#9) at high pressure

valves or handles pressure.

Lack of lubrication on threads Lubricate the threads

O-Rings for pressure connector

P/N Size Connector

1611300220 6.5X3 M20X1.5, 1/2BSP

Basic Operation

A ⑤ Vacuum displayed

Purge pocess

Connection B

Note: ① Gauge positions are exchangeable. If only one device under test (DUT) is connected, on the gauge

the third connector on pump should be closed with a plug.

② Connect the gauges on pump and tighten the connectors using two wrenches. Units

DIGITAL PRESSURE

CALIBRATOR

bar

A

0 25 50 75 100

DIGITAL PRESSURE

CALIBRATOR

Units

bar

A

0 25 50 75 100

①Always keep valve(#4)

SW V mA COM 24V

open during operation

SW V mA COM 24V

③close ④Turn all the way out

64 96

32

Pressure Gauge

Bar

128

②open

160

dial gauge pressure switch pressure transmitter flexible hose

Purge process (cont.)

Connection C Zeroing D Pressurizing process E

If air is still trapped in the pump, Note: Skip step ③ for dial gauge calibration

DIGITAL PRESSURE

CALIBRATOR

then repeat the purge process DIGITAL PRESSURE

CALIBRATOR DIGITAL PRESSURE

CALIBRATOR

in a narrow pressure range

Units

bar

A

2 or 3 more times until all the Units

bar

A

Units

bar

gas is removed from the system

A

0 25 0 25

50 75 50 75 0

100 100 25 50 75 100

64 96 64 96

Pressure Gauge Pressure Gauge

Bar

64 96

32

Bar 64 96 32 128

128 Pressure Gauge

Pressure Gauge Bar

④Wait for gauge to vent to zero 160

32

Bar

128

160

32 128

160

160

①Always keep valve(#4) ①Always keep valve(#4)

Bubbles open during operation open during operation

③open ⑤open

⑤Turn all the way in ③close ④a few turns ①close

②Pre-pressurizing ④high-pressure

②open ②open Pressurizing

③close

Depressurizing process F Vacuum process

G Vent H

If it is difficult to generate vacuum

DIGITAL PRESSURE

CALIBRATOR

pressure, then repeat the purging DIGITAL PRESSURE

CALIBRATOR

Units

bar

DIGITAL PRESSURE

CALIBRATOR

process to make sure all the gas Units

bar

is removed from the system

A 0 25 50

0 75 100

25 50 75 100

Units

64 96

bar

0.6 0.4

A

Pressure Gauge

Pressure Gauge

64 96

0 25 50 75 100 Bar

0.6 0.4

Bar 0.8 0.2

32 128 Pressure Gauge

Pressure Gauge

Bar

Bar 0.6 0.4 0.8 0.2

32 128

Pressure Gauge 0

0.6 0.4 -1

160 Bar

0.8 0.2 Pressure Gauge 0

-1

160 Bar

0.8 0.2

-1 0

-1 0

④open ①close

③Depressurizing ②Vacuum

④open

①Depressurizing ②close ③Fully turn

②open

①open

⑤Fully turn

Maintenance

Back to atmosphere I Fill media A Drain and Clean B

Note: Please degas after filling media liquid, ③ Open reservoir cover

Units

DIGITAL PRESSURE

CALIBRATOR

in case hard to generate pressure. vent valve (#4)

bar

A

0 25 50 75 100

0.6 0.4

Pressure Gauge

Bar

0.6 0.4

0.8 0.2 Pressure Gauge

-1 0

0.8

Bar

0.2 ④ Unscrew with hex wrench

-1 0

① Open reservoir

cover vent valve (#4) ②Fill media

②open ①back to atmosphere

⑤Remove the

reservoir(#5)

①Open drain valve (#6)

②Collect media using a container

Remark:

A: Additel has made a concerted effort to provide complete and current information for the proper use of the equipment. The product specifications and other information contained this manual are

subject to change without notice.

B: Above pictures are just for reference.

Additel Corporation, USA

www.additel.com

You might also like

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- EMEC MFKT Instruction Manual R2 10 09Document8 pagesEMEC MFKT Instruction Manual R2 10 09antonio vukeNo ratings yet

- VRR12LDocument16 pagesVRR12LNguyễn Tất ĐôngNo ratings yet

- Ruelco Self Contained Product Manual Rev 4Document11 pagesRuelco Self Contained Product Manual Rev 4DDani3214No ratings yet

- Manual Sail 2010Document23 pagesManual Sail 2010Juanxo Kerrigan Apaza FloresNo ratings yet

- Model 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24ADocument2 pagesModel 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24AАндрей9No ratings yet

- Installation Manual APSDocument14 pagesInstallation Manual APSTharaka MethsaraNo ratings yet

- Operating Manual: High-Pressure CleanersDocument44 pagesOperating Manual: High-Pressure CleanersPierre LangevinNo ratings yet

- 9E-A User Manuals and ServiceDocument10 pages9E-A User Manuals and Servicerponce161276No ratings yet

- Shuttle Series PDFDocument40 pagesShuttle Series PDFIvan IvanovicNo ratings yet

- D500 Manual EnglishDocument2 pagesD500 Manual EnglishEddie RedfearnNo ratings yet

- Pump Unload Pilot Valve SUN QPABDocument2 pagesPump Unload Pilot Valve SUN QPABankesh_ghoghariNo ratings yet

- Hydraulic Bolt Tensioner ManualDocument54 pagesHydraulic Bolt Tensioner ManualsabbahmabroukNo ratings yet

- Independence User Manual DNADocument64 pagesIndependence User Manual DNAJafar JilaniNo ratings yet

- Allied G 180 Suction Service ManualDocument12 pagesAllied G 180 Suction Service ManualRAVIMURUGANNo ratings yet

- T Ta Tac Eng UlDocument44 pagesT Ta Tac Eng UlDocu CenterNo ratings yet

- Heated Breathing Tube - BMCDocument15 pagesHeated Breathing Tube - BMCremeshlogoNo ratings yet

- 1150 Handbook v1641207997627Document44 pages1150 Handbook v1641207997627cerengolcurNo ratings yet

- 4-3 Directional Spool Valve 4WE-6-GDocument2 pages4-3 Directional Spool Valve 4WE-6-GRaphael SasdelliNo ratings yet

- 5 - Counter Balance Valve TSCA 70-10 - CBCHDocument4 pages5 - Counter Balance Valve TSCA 70-10 - CBCHIvan MaltsevNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity, Loadadaptive™ Counterbalance ValveDocument1 pageModel 3:1 Pilot Ratio, Standard Capacity, Loadadaptive™ Counterbalance ValveAlexis PeñaNo ratings yet

- Labnet Mini Microcentrifuge User Manual-0218Document8 pagesLabnet Mini Microcentrifuge User Manual-0218Gustavo MuñozNo ratings yet

- BYS 820 Infitsion PumpDocument22 pagesBYS 820 Infitsion PumpyuglerqnNo ratings yet

- Model 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- Comparison of FFP2, KN95, and N95 and Other Filtering Facepiece Respirator ClassesDocument3 pagesComparison of FFP2, KN95, and N95 and Other Filtering Facepiece Respirator ClassesfaithnicNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValvemateusT850No ratings yet

- Symphony Maintenance and Technical Guide 1907555 PDFDocument36 pagesSymphony Maintenance and Technical Guide 1907555 PDFRicha Potdar50% (4)

- Comparison of FFP2, KN95, and N95 and Other Filtering Facepiece Respirator ClassesDocument3 pagesComparison of FFP2, KN95, and N95 and Other Filtering Facepiece Respirator ClassesRavi S DwivedyNo ratings yet

- G77x - 77xK Valve - CatalogueDocument8 pagesG77x - 77xK Valve - CatalogueEzgi PelitNo ratings yet

- Powapak Air Ultra Operating ManualDocument45 pagesPowapak Air Ultra Operating ManualBenrub Flores75% (4)

- Chapt 6 AntijamDocument6 pagesChapt 6 AntijamManuelNo ratings yet

- CBCY Full en Us LetterDocument2 pagesCBCY Full en Us LetterVentas Control HidráulicoNo ratings yet

- Dwyer Series 490A DatasheetDocument4 pagesDwyer Series 490A Datasheetjose manuel quispe llerenaNo ratings yet

- 4-3 Directional Spool Valve 4WE 6 HDocument2 pages4-3 Directional Spool Valve 4WE 6 HRaphael SasdelliNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument1 pageModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveMuhtadin RizkiNo ratings yet

- Aspirador Quirurgico - Tomas PDFDocument6 pagesAspirador Quirurgico - Tomas PDFMario O.No ratings yet

- Installation & Maintenance Instructions: For The MIC Electronic Drain ValveDocument2 pagesInstallation & Maintenance Instructions: For The MIC Electronic Drain ValveLINo ratings yet

- Direct-Acting Relief Valve: DownloadDocument2 pagesDirect-Acting Relief Valve: Downloadaristi51No ratings yet

- Model 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveVignesh PandiyanNo ratings yet

- User - Manual 16 2080Document18 pagesUser - Manual 16 2080Daniel RiveraNo ratings yet

- VWR Vortex MixeDocument11 pagesVWR Vortex MixeaudiolimitNo ratings yet

- RDJA Full en Metric LetterDocument2 pagesRDJA Full en Metric LetteressamNo ratings yet

- Model Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveDocument2 pagesModel Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveRonildo - HydraparNo ratings yet

- Woman On TopDocument17 pagesWoman On ToplwinooNo ratings yet

- Data Sheet: Pressure RegulatorDocument4 pagesData Sheet: Pressure RegulatorFrank Jorge Hervas NinaNo ratings yet

- Nilfi SK E 130.2, E 140.2: User ManualDocument18 pagesNilfi SK E 130.2, E 140.2: User ManualDavid TynanNo ratings yet

- PSK SERIES MANUAL - Feb 2012 Rev K PDFDocument24 pagesPSK SERIES MANUAL - Feb 2012 Rev K PDFSamuel MuendaneNo ratings yet

- Introducing The: Ranger SystemDocument4 pagesIntroducing The: Ranger SystemSteven Ludeña GavinoNo ratings yet

- Cbcalin ValveDocument2 pagesCbcalin ValveArun51092No ratings yet

- 4-3 Directional Spool Valve 4WE6EDocument2 pages4-3 Directional Spool Valve 4WE6ERaphael SasdelliNo ratings yet

- MRT6 ManualDocument30 pagesMRT6 ManualMohamed AnisNo ratings yet

- Model 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveVignesh PandiyanNo ratings yet

- Banco de Valvulas (HY17-8822-M2 - UK - Handling - Storage)Document12 pagesBanco de Valvulas (HY17-8822-M2 - UK - Handling - Storage)Luis Cervantes BarradasNo ratings yet

- Piston Pumpa Za BačveDocument24 pagesPiston Pumpa Za Bačvesealion72No ratings yet

- BYPASSDocument2 pagesBYPASSSting DâuNo ratings yet

- Tec 6 Plus Vaporizer - v1.1 - 42318 PDFDocument2 pagesTec 6 Plus Vaporizer - v1.1 - 42318 PDFArik SaprolNo ratings yet

- Model Direct-Acting Relief Valve: Series 2 / Capacity: 50 GPM / Cavity: T-3ADocument2 pagesModel Direct-Acting Relief Valve: Series 2 / Capacity: 50 GPM / Cavity: T-3AJustinNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Baluns: What They Do and How They Do ItDocument8 pagesBaluns: What They Do and How They Do ItbudituxNo ratings yet

- Cable Sizing Selection Chart: DC Amps Circuit Type Cable Length Correct Cable SizeDocument1 pageCable Sizing Selection Chart: DC Amps Circuit Type Cable Length Correct Cable SizeRafid A. Jassem AlashorNo ratings yet

- Indonesia Crude Price 2010 - 1Document1 pageIndonesia Crude Price 2010 - 1Prasetyo BonchusNo ratings yet

- Guide ITS 90 Platinum Resistance ThermometryDocument56 pagesGuide ITS 90 Platinum Resistance ThermometryalonsoNo ratings yet

- Atmega128 I/O Ports: VersusDocument16 pagesAtmega128 I/O Ports: VersusZoranNo ratings yet

- P&IDDocument18 pagesP&IDhectornicolauNo ratings yet

- RelayDocument2 pagesRelayIván MartínezNo ratings yet

- ATMega TimerDocument22 pagesATMega TimerDenai01No ratings yet

- Refining Water Best PracticesDocument60 pagesRefining Water Best Practicesarini_aristia_sNo ratings yet

- Ergonomics Considerations of LCD Versus CRT DisplaysDocument3 pagesErgonomics Considerations of LCD Versus CRT Displayseyob1234No ratings yet

- 300+ TOP PIPING Engineering Interview Questions and Answers PDFDocument20 pages300+ TOP PIPING Engineering Interview Questions and Answers PDFjignesh chauhan100% (1)

- Pneumatically Operated Hydraulic Pump Type LP: 1. GeneralDocument13 pagesPneumatically Operated Hydraulic Pump Type LP: 1. GeneralGERALD SIMONNo ratings yet

- Edoc - Pub - Fire Hydrant Pump CalculationDocument3 pagesEdoc - Pub - Fire Hydrant Pump Calculationsushant_jhawerNo ratings yet

- Spare Parts List Series L90LS: Effective Date: December 28, 2011 Supersedes: March 15, 2011Document52 pagesSpare Parts List Series L90LS: Effective Date: December 28, 2011 Supersedes: March 15, 2011julio barrazaNo ratings yet

- Instrucalc PDFDocument1 pageInstrucalc PDFmarcosNo ratings yet

- Examination 4 - HydraulicsDocument3 pagesExamination 4 - HydraulicsjefreyNo ratings yet

- L-2 Housedrainage SystemDocument69 pagesL-2 Housedrainage SystemLumbini DuddeNo ratings yet

- WOLK 500 MonofasicaDocument10 pagesWOLK 500 MonofasicaClaudio Valencia MarínNo ratings yet

- Pump Definition Types Advantages Disadvantages Applications With PDFDocument8 pagesPump Definition Types Advantages Disadvantages Applications With PDFSatyam BNo ratings yet

- Implementos y ServiciosDocument12 pagesImplementos y ServiciosIMPLEMENTOS CAJAMARCANo ratings yet

- API 607 Fire Test Report - Copeland - 2 Inch Class 900 Ball Valve - June 9 2017.22172258Document16 pagesAPI 607 Fire Test Report - Copeland - 2 Inch Class 900 Ball Valve - June 9 2017.22172258Nilesh SargaraNo ratings yet

- The Hydraulic Pumping SystemDocument12 pagesThe Hydraulic Pumping SystemCarlos Lopez DominguezNo ratings yet

- Spob Musi Prosperity - Dock Repair List Owner Estimate: Scope of JobDocument3 pagesSpob Musi Prosperity - Dock Repair List Owner Estimate: Scope of Jobnugroho sulistiyadiNo ratings yet

- Check Cartridge Valves: Free Flow Nose To Side 60Document6 pagesCheck Cartridge Valves: Free Flow Nose To Side 60juanchis650No ratings yet

- Satr A 2010Document2 pagesSatr A 2010nadeem shaikhNo ratings yet

- MAST2776B Process Instrumentation TS Lesson 4 Rev.00Document60 pagesMAST2776B Process Instrumentation TS Lesson 4 Rev.00Hassan Al-HasanNo ratings yet

- Final Examination For Tech 1d and Btled Ia 20Document5 pagesFinal Examination For Tech 1d and Btled Ia 20cyrelle rose jumentoNo ratings yet

- Hyd System - Part 1 Single Lift Pump ( - A - Batt. Comp.) (25,1.0,35,1.6, RR) (02.0-14.0-005)Document6 pagesHyd System - Part 1 Single Lift Pump ( - A - Batt. Comp.) (25,1.0,35,1.6, RR) (02.0-14.0-005)rorroscNo ratings yet

- Bomba A10voDocument2 pagesBomba A10voSilas ThompsonNo ratings yet

- Suitability of Pelton, Francis and Kaplan TurbinesDocument2 pagesSuitability of Pelton, Francis and Kaplan TurbinesKamrul HasanNo ratings yet

- Pump Parts and EquipmentDocument18 pagesPump Parts and EquipmentCharles HuntNo ratings yet

- Well Control Daily Checklist Procedure VDocument13 pagesWell Control Daily Checklist Procedure VmuratNo ratings yet

- Renewable SeatDocument3 pagesRenewable SeatJakub GerardNo ratings yet

- Pump Function Test ProcedureDocument8 pagesPump Function Test ProcedureHazrin HasanNo ratings yet

- Hydraulic Winch Design Problem - Sizing of Hydraulic Pump and MotorDocument3 pagesHydraulic Winch Design Problem - Sizing of Hydraulic Pump and Motorgbm2246100% (2)

- Pipe Laying For Balayan Batangas MaterialsDocument1 pagePipe Laying For Balayan Batangas MaterialsFritz NatividadNo ratings yet

- Handpump-HHP-700 BarDocument2 pagesHandpump-HHP-700 BartruongNo ratings yet

- BROCHURE Metel Firepump 2017Document8 pagesBROCHURE Metel Firepump 2017Jakir AhmedNo ratings yet

- Pipe Design 4Document6 pagesPipe Design 4raghebomNo ratings yet

- MEC-A4-125B EnglishDocument2 pagesMEC-A4-125B Englishdragos manoleNo ratings yet