Professional Documents

Culture Documents

Traphaco

Uploaded by

Quyen NguyenOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Traphaco

Uploaded by

Quyen NguyenCopyright:

Available Formats

RMIT

Classification: Trusted

Case study – TRAPHACO pharma

Traphaco Pharma (TRA) has grown and affirmed its position as a leading pharmaceutical manufacturer in

Vietnam. At present, Traphaco's flagship products such as Boganic and Cebraton (Hoat Huyet Duong Nao)

are taking the lion’s share in their respective market1. The distribution side is a major opportunity for the

vibrant pharmaceutical industry. Traphaco has worked hard to build a modern distribution system (DC) that

is now beginning to get contact with big names in pharmaceuticals and hand out their products in Traphaco's

system. Traphaco has also developed a network from more than 6,700 pharmacies in 2014 to over 27,000

pharmacies as today. The company awareness of the importance of fulfilment systems may lead to wastage or

blockade of financial resources, irrational utilization of drugs, shortage, or overage of essential medicines

among many others.

Traphaco operates in an extremely competitive environment. They face intense pressure to deliver Boganic

and Cebraton and new drugs and their profit margins are continually being squeezed. The retailers prefer

smaller and frequent shipments to a large number of DCs. Some competitors already looked at a drop-shipping

strategy, providing direct access to home and individual customers. It would be purpose-built around the needs

of the Vietnam pharmaceutical and healthcare customers. Proper storage conditions for pharmaceutical

products and paramedical supplies are crucial to maintaining their quality, safety, and efficacy. In addition,

order completion rate and customer services intensify pressures to provide premium service to a wide range

of delivery points, including hospitals, wholesalers, nursing homes, retailers and pharmacies, at a competitive

price. The SCM team has various options to consider, such as direct shipping, distributor storage and using

external 3PL services etc.

Option 1: Upgrading the existing DC to handle multiple order types and smaller delivery including individual

purchases. This ambitious plan is to create the most advanced warehouse ever built solely for healthcare

products in Vietnam. TRA started work on creating a 10,000 square-metre warehouse in Hung yen (extended

in 2025 to 25,000 square metres). Along with this strategy, TRA aims to upgrade the new warehouse

management software to enhance order visibility.

Option 2: Expanding Traphaco’s Warehouse Management to manage customers' multiple operating

procedures. The team expect the company's DC can handle 7,000 SKUs and 50,000 orders or 30 million units

per month for more than 65 major clients that distribute to around 30,000 delivery points. With the growing

e-com networks, the company is also considering investing in effective platforms to expand the sales of these

two flagships products.

Option 3: Outsourcing to a third-party fulfilment (3PL) company that can handle increasing and diverse needs

from customers. Several professional services with Warehouse Management solution (WMS) using the IBM

platform can provide automated processes and full visibility. All product movements are controlled by the

WMS solution, supported by radio-frequency (RFID) technology. These 3PL companies can accommodate

the multiple operating procedures, scalability of the growing list of clients using Advance Ship Notices

(ASNs) and importantly the WMS could manage batch control and track expiration dates—critical

functionality in the pharmaceutical industry.

You might also like

- Wal-Mart Stores, Inc., Global Retailer case study, the GUIDE editionFrom EverandWal-Mart Stores, Inc., Global Retailer case study, the GUIDE editionNo ratings yet

- Accenture Pharmaceutical DistributionDocument4 pagesAccenture Pharmaceutical DistributionMichael HendarmanNo ratings yet

- Attractive Long-Term Growth Potential: Sector Report Pharmaceutical IndustryDocument24 pagesAttractive Long-Term Growth Potential: Sector Report Pharmaceutical Industryhuong phamNo ratings yet

- Pharmacy2U ReportDocument15 pagesPharmacy2U Reportسنبل ملکNo ratings yet

- Serialization - Traceability and Big Data in The Pharmaceutical Industry PDFDocument19 pagesSerialization - Traceability and Big Data in The Pharmaceutical Industry PDFBúp CassieNo ratings yet

- DSCM - Shanghai Pharma - Group 8Document10 pagesDSCM - Shanghai Pharma - Group 8Chirag KocharNo ratings yet

- Pharma MarketingDocument55 pagesPharma MarketingArpan KoradiyaNo ratings yet

- Digital Channels in Pharma Fad or FutureDocument3 pagesDigital Channels in Pharma Fad or FutureManoj JosephNo ratings yet

- VII (1) - UpdatedDocument5 pagesVII (1) - UpdatedMDORRINo ratings yet

- Medco Express FINALDocument23 pagesMedco Express FINALSean MooreNo ratings yet

- Success in The Pharmacy Channel: by Pete Caldwell, Gareth Fitzgerald and Marco OcchettaDocument6 pagesSuccess in The Pharmacy Channel: by Pete Caldwell, Gareth Fitzgerald and Marco Occhettaaly_alsayedNo ratings yet

- Deloitte CH LSHC Digital Transformation Sandbox en 200715Document19 pagesDeloitte CH LSHC Digital Transformation Sandbox en 200715Marija BanjavčićNo ratings yet

- TotoDocument10 pagesTotoRon Mel VinNo ratings yet

- Marketing Plan Sample 1Document17 pagesMarketing Plan Sample 1Ryan ChikuniNo ratings yet

- Online PharmacyDocument19 pagesOnline PharmacyShshank87100% (1)

- CVS Web Strategy - Write UpDocument3 pagesCVS Web Strategy - Write UpAswin Prakash T0% (1)

- BCI Industry ReportDocument20 pagesBCI Industry ReportVivek Prakash100% (1)

- A Review of MarketingDocument9 pagesA Review of Marketingrahuly12No ratings yet

- Lifesciences Case - FinalDocument4 pagesLifesciences Case - FinalmohiniNo ratings yet

- Case Study On InnovaccerDocument3 pagesCase Study On InnovaccerAmarnath DixitNo ratings yet

- Why Supply Chain Management Is Important Management EssayDocument7 pagesWhy Supply Chain Management Is Important Management EssayHND Assignment Help100% (1)

- Logistics Final Take HomeDocument14 pagesLogistics Final Take HomeYdon026100% (2)

- E-Medicine Business:: Expected To Grow at An Exponential CAGR of 63.0% in The Next 2-3 Years and Has Currently 30,000Document9 pagesE-Medicine Business:: Expected To Grow at An Exponential CAGR of 63.0% in The Next 2-3 Years and Has Currently 30,000Deepali SehgalNo ratings yet

- How 1mg Is Changing Under Tata DigitalDocument10 pagesHow 1mg Is Changing Under Tata DigitalALLtyNo ratings yet

- The Pharma Sales GuidebookDocument13 pagesThe Pharma Sales GuidebookRoambiNo ratings yet

- Challenges PDFDocument4 pagesChallenges PDFRupal RawatNo ratings yet

- Truepill Report by Tanmay RajgadkarDocument6 pagesTruepill Report by Tanmay RajgadkarTanmay RajgadkarNo ratings yet

- Pharma Distribution in IndiaDocument5 pagesPharma Distribution in IndiaAjit KumarNo ratings yet

- Supply Chain Visibility in Healthcare - Beyond The DashboardDocument7 pagesSupply Chain Visibility in Healthcare - Beyond The DashboardKuber SethiNo ratings yet

- FowmeyerDocument10 pagesFowmeyerKashika MehtaNo ratings yet

- Retail PharmaciesDocument14 pagesRetail Pharmaciesrajan mishraNo ratings yet

- A Review of MarketingDocument5 pagesA Review of MarketingVikas KhannaNo ratings yet

- Modified Global Corporate StraegyDocument7 pagesModified Global Corporate StraegyKrishna Teja PanchakarlaNo ratings yet

- Issues and Challenges of Supply Chain Management in FMCG SectorDocument7 pagesIssues and Challenges of Supply Chain Management in FMCG SectorReeja RaviNo ratings yet

- Value Creating PurchasingDocument13 pagesValue Creating Purchasingmanish.cdmaNo ratings yet

- Assignment On Supply Chain Management in Healthcare: Done By, Hiren D AsraniDocument8 pagesAssignment On Supply Chain Management in Healthcare: Done By, Hiren D AsraniHiren AsraniNo ratings yet

- Aushadhi Pharma - Location Strategy For The National CapitalDocument12 pagesAushadhi Pharma - Location Strategy For The National CapitalSaurabh VermaNo ratings yet

- Metro Inc.: Resilient Business ModelDocument4 pagesMetro Inc.: Resilient Business ModelSudhir PowerNo ratings yet

- American WellDocument6 pagesAmerican WellPreetam Joga75% (4)

- Muller & Phipps ProjectDocument14 pagesMuller & Phipps Projectwaqasjaved8696730% (1)

- Africa: A Continent of Opportunity For Pharma and Patients - McKinsey & CompanyDocument6 pagesAfrica: A Continent of Opportunity For Pharma and Patients - McKinsey & CompanyMeenu KapoorNo ratings yet

- Practice Questions For CAF06 MFADocument59 pagesPractice Questions For CAF06 MFABabu raoNo ratings yet

- Supply Chain ProjectDocument5 pagesSupply Chain ProjectKHUSHAGAM PALIWAL 2020121No ratings yet

- Cepton Strategic Outsourcing Across The Pharmaceuticals Value ChainDocument9 pagesCepton Strategic Outsourcing Across The Pharmaceuticals Value ChainFrenzy FrenesisNo ratings yet

- Sales Casestudy Ans DataDocument4 pagesSales Casestudy Ans DataShreya KadamNo ratings yet

- The Pharmacy of The FutureDocument3 pagesThe Pharmacy of The Futureahmed alrbteNo ratings yet

- Business Plan: Pharmaceutical Repackaging Plant FounderDocument19 pagesBusiness Plan: Pharmaceutical Repackaging Plant FounderSheroze MasoodNo ratings yet

- Healthcare Supply ChainDocument351 pagesHealthcare Supply ChainLiêm LaNo ratings yet

- Business Concept: Pharmaceutical 3PL in The MENADocument10 pagesBusiness Concept: Pharmaceutical 3PL in The MENAMDORRINo ratings yet

- Test Answers: Patient Protection and Affordable Care Act)Document6 pagesTest Answers: Patient Protection and Affordable Care Act)deepanshuNo ratings yet

- Current Business Models of Pharmaceutical CompaniesDocument11 pagesCurrent Business Models of Pharmaceutical CompaniesMegha VyasNo ratings yet

- Pharmaniaga Berhad - SWOT AnalysisDocument4 pagesPharmaniaga Berhad - SWOT AnalysisSheryl Chow100% (1)

- EC136 Walmart - Jemmy PadillaDocument6 pagesEC136 Walmart - Jemmy PadillaaamirdalviNo ratings yet

- Getting The Dose Right: A Digital Prescription For The Pharma IndustryDocument8 pagesGetting The Dose Right: A Digital Prescription For The Pharma IndustryVinita VasanthNo ratings yet

- Transformation in The Pharmaceutical Industry - Developing Customer Orientation at Pharma CorpDocument17 pagesTransformation in The Pharmaceutical Industry - Developing Customer Orientation at Pharma CorpMegavarman GopalanNo ratings yet

- Designing and Managing Integrated Marketing Channels: PART V Delivering ValueDocument18 pagesDesigning and Managing Integrated Marketing Channels: PART V Delivering ValueUday SharmaNo ratings yet

- HHL Initiation Report PDFDocument27 pagesHHL Initiation Report PDFMohammed RihamNo ratings yet

- Pharma Supply Chain For Domestic DistributionDocument4 pagesPharma Supply Chain For Domestic DistributiondineshnutiNo ratings yet

- The Ultimate Guide To Starting A Successful Vending Machine BusinessFrom EverandThe Ultimate Guide To Starting A Successful Vending Machine BusinessNo ratings yet

- RMIT Harvard Referencing GuideDocument50 pagesRMIT Harvard Referencing GuideQuyen NguyenNo ratings yet

- rEADING TOPIC 2Document12 pagesrEADING TOPIC 2Quyen NguyenNo ratings yet

- RMIT Harvard Referencing GuideDocument56 pagesRMIT Harvard Referencing GuideQuyen NguyenNo ratings yet

- Mickeys Car PartsDocument14 pagesMickeys Car PartsQuyen NguyenNo ratings yet

- A Study On Online Payment Methods Among College Students With Special Reference To Christ CollegeDocument60 pagesA Study On Online Payment Methods Among College Students With Special Reference To Christ CollegeAnjaliNo ratings yet

- Chapter 1Document28 pagesChapter 1Audrey ConcepcionNo ratings yet

- Engineering Economy ProblemsDocument2 pagesEngineering Economy ProblemsBenj Paulo AndresNo ratings yet

- Welspun Corp Annual Report 2021 Interactive PDF 090821Document335 pagesWelspun Corp Annual Report 2021 Interactive PDF 090821Piyush Ashokchand ChopdaNo ratings yet

- ME76 Comprehensive Guidelines For The Graduating StudentsDocument8 pagesME76 Comprehensive Guidelines For The Graduating StudentsDanielle Angela TaccadNo ratings yet

- Joseph and The Law of ProcessDocument8 pagesJoseph and The Law of ProcessjohncalebandalNo ratings yet

- Gold Hofer BrochureDocument31 pagesGold Hofer BrochuresalaverriaNo ratings yet

- IOH Sales Pitch Data CenterDocument32 pagesIOH Sales Pitch Data CenterJati RoyatNo ratings yet

- Chapter Five: Risk, Return, and The Historical RecordDocument37 pagesChapter Five: Risk, Return, and The Historical RecordAreej AlGhamdi100% (1)

- Auditing Theories and Problems Quiz WEEK 1Document19 pagesAuditing Theories and Problems Quiz WEEK 1Sarah GNo ratings yet

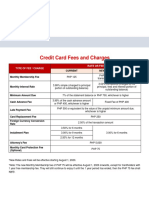

- Credit Card Fees and Charges: Type of Fee / Charge Rate or FeeDocument1 pageCredit Card Fees and Charges: Type of Fee / Charge Rate or FeeKram Yer EtentepmocNo ratings yet

- Loan LetterDocument1 pageLoan LetterMuhd HisyamuddinNo ratings yet

- CASE No. 51 Lanuza vs. de Leon Lanuza vs. de Leon, 20 SCRA 369Document2 pagesCASE No. 51 Lanuza vs. de Leon Lanuza vs. de Leon, 20 SCRA 369Al Jay MejosNo ratings yet

- Sfom Impl B2ceDocument28 pagesSfom Impl B2cesergio paredesNo ratings yet

- REFERENCESDocument10 pagesREFERENCESRona Faith TanduyanNo ratings yet

- What Is Cybersecurity Insurance and Why Is It ImportantDocument3 pagesWhat Is Cybersecurity Insurance and Why Is It ImportantJaveed A. KhanNo ratings yet

- 6 Advanced Wealth and Poverty VocabularyDocument3 pages6 Advanced Wealth and Poverty Vocabularylớp tiếng Anh cô DuyênNo ratings yet

- Imp Question Listing Inter Nov 23 ExamDocument3 pagesImp Question Listing Inter Nov 23 Examg6rb6nz0No ratings yet

- Fiverr 2020 Ebook Stys PDFDocument23 pagesFiverr 2020 Ebook Stys PDFcesarNo ratings yet

- Background of The Company (Khaadi)Document7 pagesBackground of The Company (Khaadi)Haider AliNo ratings yet

- DownloadDocument1 pageDownloadRasika JadhavNo ratings yet

- Gathering Information From SurveysDocument4 pagesGathering Information From SurveysQueenieCatubagDomingoNo ratings yet

- How PIM Adopters Are Outperforming Their CompetitionDocument37 pagesHow PIM Adopters Are Outperforming Their CompetitionAmirul Amin IV0% (1)

- Quantity Survey Estimation and Valuation NumericalsDocument122 pagesQuantity Survey Estimation and Valuation NumericalsAditya Mane33% (3)

- Macro EcomomicsDocument120 pagesMacro EcomomicsHATCATENo ratings yet

- Cia Candidate Assessment Test: Jakarta, 28 January 2012Document29 pagesCia Candidate Assessment Test: Jakarta, 28 January 2012Bobby IlyasNo ratings yet

- Intellectual Property Law-REPORTING SCHEDULE: Reportin G Date Topic Case NO. Case Title Reporter RemarksDocument2 pagesIntellectual Property Law-REPORTING SCHEDULE: Reportin G Date Topic Case NO. Case Title Reporter RemarksArrianne ObiasNo ratings yet

- Jaspersoft Studio User GuideDocument270 pagesJaspersoft Studio User GuideMohamad Amin100% (2)

- SR - No. Security - Name Isin Scrip - ID Intraday Stock ListDocument10 pagesSR - No. Security - Name Isin Scrip - ID Intraday Stock ListSashang S VNo ratings yet

- BIOMED Case StudyDocument3 pagesBIOMED Case StudyGanesh BirleNo ratings yet