Professional Documents

Culture Documents

Site Prepration and Earth Works

Site Prepration and Earth Works

Uploaded by

shoaib akhtar0 ratings0% found this document useful (0 votes)

17 views32 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views32 pagesSite Prepration and Earth Works

Site Prepration and Earth Works

Uploaded by

shoaib akhtarCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 32

‘STANDARD SPECIFICATION

cei

‘SITE PREPARATION AND EARTHWORKS

RAS AZ ZAWR ALUMINIUM SMELTER PROJECT

onations

[DOO] 2S.tone ZOO [este tor Conamuston [SC —| We

me

}

ae el zal call led

|

eae ra

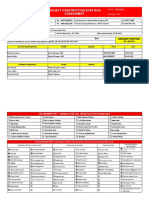

[Rev [Date eoason for Revision —| By | CHECK, ‘CUENT

Project Document | 25457-1000-SPS-CGO0D002 Rev. 001

Gilet Document N

ae as

[RAS AZ ZAWR ALUMINIUM SMELTER PROJECT

| Ste Preparation and Earthworks Doe Na, 25457-1000-8PS-0600.0002 Rar, 001

TABLE OF CONTENTS

1.0 GENERAL.

1.1 Work included

1.2 Work not included...

2.0 CODES AND STANDARDS.

2.1 Intemational codes and standards.

22 Other regulating requirements.

3,0 TECHNICAL REQUIREMENTS.

3.1 Material,

3.1.1. Use of materials

3.1.2 Water.

3.13 Testing.

32. Details of Construction

32.1 Clearing - ~

322. Removai of topsoil I

3.23 Contaminated soil oF materia. ~

8.24 Materials from borrow pits .ucucrunsnnnnsnn

325 Overburden -

3.26 Excavation of rock

BISSo0emwaviiioovve

32.7 Common excavation, = 12

32.8 Treatment of Sud g7@d08 nnn vont

329 Cuts 13

3.2.10 Treatment of GUIS sssnnnnsnnnnnersnsnsnen 14

3.2.11 Blasting, cas.

32.12 Fil 18

32.13 Materials . oo ary

3.2.14 Drainage and dewatering 21

8.2.18 Stockpiling of materials... = wan

3.2.16 Construction of drains 22.

32.17 Compaction 22

8.2.18 Soil and! or rock testing. 25,

32:18 Stne and concrete sop proacton ar

3.2.20 Sprayed concrete. 29.

3.2.21 Surface finish and tolerances 29

RAS AZ ZAWR ALUMINIUM SMELTER PROJECT

| Ste Preparation and Earthworks ec Na, 25467-1000-9PS-C00-0002

1.0 GENERAL

This specification applies to the general and technical raquirements for site preparation

and earthworks at the site of the Ras Az Zawr Smelter Project, Kingdom of Saudi

‘Arabia,

‘This specification and its supploments should be read in conjunction with other

‘specifications, data sheets and drawings.

Unless otherwise specie, all work covered by this specification shall be in accordance

with the applicable sections of the referenced documents in Section 2., Codes and

‘Standards, and with al relevant local government statulery requirements

1.1 Work Included

This specication applies to all operations associated with, but nat limited to, the

following:

Site clearing:

Removal and placing of topsoil

Cut and fil operations;

Preparation of in-situ materials;

Development of borrow pits;

‘Stockpiling of materials;

Disposal of surplus excavated materials;

Moisture conditioning and compaction;

‘Siope protection;

In-situ and laboratory testing of soll andor rock materials;

Tolerances and surface finish,

1.2 Work notincluded

Construction of pavement layers:

‘Trenching for pipe lines and underground services;

Excavation in confined areas for foundations and ground slabs;

Speciaity earthworks associated with construction of landscaped areas.

2.0 CODES AND STANDARDS.

“The following documents give support to or are referradto inthis specification.

80 1000 St unite and recommendatione forthe uee oftheir multiplee

‘and of certain other units

1803-0 ‘Quanttes and units - Part 0 General principles

RAS AZ ZAWR ALUMINUM SMELTER PROJECT

| Ste Preparation and Eartworis

180 8601

EN 206-1

EN 12620

ENV 13670-1

EN 939-2

180 33104

10 a3102

180 565,

EN ISO 14688-1

EN ISO 14689+1

EFNARC

ASTMC 127

ASTMC 136

ASTM C 150

ASTM D 420

ASTM D 422

ASTM D 659,

ASTM D 854

ASTM D 1140

‘Doe No. 25457:1000.3°S-C600.0002 Rev. 001,

Data_elements and interchange formats — Information

interchange ~ Representation of dates and times

Concrete - Specification, performance, production and

conformity

Aggregates for concrete

Execution of concrete stuctures - Part 1: Common

Tests for geometrical properties of aggregates — Part 2:

Determination of particle size distibution ~ Test sieves,

nominal size of apertures:

Tests sieves - Technical requirements and testing - Part 1

Test sieves of metal wire cloth

Tests sieves ~ Technical requirements and testing - Pat 2:

Test sieves of perforated metal plate

‘Test sieves - Metal wire cloth, perforated metal plate and

clectroformed sheet - Nominal sizes of openings

Geotechnical investigation and testing — Identification and

classification of soll~ Part 1: Identification and description

Geotechnical investigation and testing ~ Identification and

clasefication of rock ~ Part 1: Identication and description

European specification for sprayed concrete

‘Standard Test Method for Density, Relative Density (Spectic

Gravity), and Absorption of Coarse Aggregate

‘Standard Method for Sieve Analysis of Fine and Coarse

Aggregates of Solis

‘Standard Specifications for Portland Cement

Practice for Investigating and Sampling Soil and Rock for

Engineering Purposes.

Partcle-Size Analysis of Soils

‘Standard Terminology Relating to Soil, Rock, and Contained

Fluids

Spectic Gravity of Sols

‘Amount of Material in Solls Finer Than the No. 200 (75

microns) Sieve

RAS AZ ZAWR ALUMINIUM SMELTER PROJECT

| Ste Preperation and Eaton ‘oe No, 25457-1000-9°S-C090-0000 Fev. 001,

ASTM D 1556 ‘Standard Test Method for Density and Unit Weight of Sol in

Place by Sand Cone Method

ASTM 1557 ‘Standard Test Method for Laboratory Compaction

Characteristics of Soil using Modified Etfort (2700kN-mv®)

ASTM 1586 Method for Penetration Test and Splt-Barrel Sampling of

Sols

ASTM D 1587 Practice for Thin-Walled Tube Sampling of Soils

ASTM 01883 ‘Standard Test Method for CBR (Calfornia Bearing Ratio) of

Laboratory Compacied Solis

ASTMD 2113 Practice for Diamond Core Driling for Site Investigation

ASTM D 2116 Laboratory Determination of Water (Moisture) Content of

Sol and Rock

ASTM 2166 LUnconfined Compressive Strength of Cohesive Soils

ASTM D 2494 Test Method for Permeability of Granular Soils (Constant

Head)

ASTM D 2495 (One Dimensional Consolidation Properties of Soils using

Incremental Loading

ASTM D 2487 ‘Standard Practice for Classification of Sols for Engineering

Purposes (Unified Soil Classification System)

ASTM D 2488, Description and Identification of Soils (Visual Manual

Procedure)

ASTM D 2573, Standard Test Method for Feld Vane Shear Test in

Cohesive Soils

ASTM D 2850 Unconsolidated-Undrained Triaxial Compression Test on

Cohesive Soils

ASTM D 2937 Standard Test Method for Density of Sol in Place by the

Drive-Cylinder Method

ASTM D 2938 Unconfined Compressive Strength of Intact Rock Core

Specimens,

ASTM D 2080 Direct Shear Test of Sols Under Consolidated Drained

Conditions

RAS AZZAWR ALUMINIUM SMELTER PROJECT

| Ste Preperation and Eatwoia

ASTM D 3148

ASTM D 3441

ASTM 04186

ASTM D 4220

ASTM D 4318

ASTM. 4973

ASTM D 4643

ASTM D 4648

ASTM D 4750

ASTM 04767

ASTM 04914

ASTM D 5030

ASTM D 5078

ASTM D 5434

ASTM D 5608

ASTM 5731

ASTM 05778

ASTM 05784

(ce No. 26467.1000-2S-C600:0002 Rev. 00%,

Elastic Modul of Intact rock Gore Specimens in Uniani

Compression.

‘Standard Test Method for Deep Quasi-Static Cone and

Friction Cone Penetration Tests of Sols,

‘One Dimensional Consolidation Properties of Saturated

Cohesive Soils using Controlled Strain Loading

Practice for Presorving and Transporting Samples

Liquid Limit, Plastic Limit, and Plasticity Index of Soils,

‘Standard Test Method for Rapid Determination of Carbonate

Content of Soils

‘Standard Test Method for Determination of Water (Moisture)

Content for Soil by the Microwave Oven Method

Laboratory Miniature Vane Shear Test for Saturated Fine-

Grained Clayey Sol

Determining Subsurface Liquid Levels in a Borehole or

‘Monitoring Well (Observation Well)

‘Standard Test Method For Consolidated Undrained Triaxia

Test on Sol Samples

‘Standard Test Methods for Density and Unit Weight of Sol

‘and Rock in Place by the Sand Replacement Method in a

Test Pit

‘Standard Test Method for Density of Soll and Rock in Place

by the Water Replacement Mathod in a Test Pit

Preserving and Transporting Soll Samples

Field Logging of Subsurface Explorations of Soil and Rlock

‘Standard Practice for Decontamination of Field Equipment

Used at Low Level Radioactive Waste Sites.

Determination ofthe Point Load Strength Index of lock

‘Standard Test Method for Performing Electronic Friction

Cone and Piezocone Penetration Soundings

‘Standard Guide for Use of Hollow-Stem Augers for Geo-

BRAS AZ ZAWR ALUMINIUM SMELTER PROJECT

| Ste Prepaation and Earthworks

jeralon and Eartworks Doe No. 25487-1000:9°S.CG00.0002 Fe. 001

ASTM 06151

ASTM D6169

ASTM 06286

ASTM 06519

ASTM D698

ASTMG 51

‘AASHTO T-280

AASHTO T-291

environmental Exploration and the Installation of Subsurface

Water-Quality Monitoring Devices

‘Standard Practice for Using Hollow-Stem Augers for

Geotechnical Exploration and Soil Sampling

Standard Guide for Selection of Soll and Rock Sampling

Devioes Used With Dril Rigs for Environmental

Investigations

Standard Guide for Selection of Driling Methods for

Environmental Site Characterization

Standard Practice for Sampling of Soil Using the

Hycraulcally Operated Stationary Piston Sampler

Standard Test Methods for In-Place Density and Water

Content of Soil and Soil Aggregate by Nuclear Methods

(Ghallow Depth)

‘Standard Test Method for Measuring Ph of Soll for Use in

Corrosion Testing

Standard Methad of Test for Determining Water-Soluble

Sulfate lon Content in Soil

Standard Methad of Test for Determining Water-Soluble

Chloride lon Content in Soil

2.2. Other regulating requirements,

Kingdom of Saudi Arabia: General Specifications for Road and bridge Construction

3.0 TECHNICAL REQUIREMENTS.

3.4 Materials

3.11 Use of materials

Materials for use in the earthworks shall be won from approved borrow areas.

excavated in cuts, taken from stockpiles or from other sources as approved. The

‘operation of earthworks shall achieve the optimum use of excavated material

‘The earthworks activites shall be planned such that the better quality materials are not

wasted through use in the lower layers of fils but retained for use in the upper layers as

[RAS AZ ZAV/R ALUMINIUM SMELTER PROJECT

| Ste Preparaion and Earthworks be No. 25487-1000-9°-0400-0000 ev. 001

detailed on the drawings. If competent material is wasted through poor planning, then

no compensation shall be made for costs associated wth opening up and reinstating

‘additional borrow pis for replacement materials.

may be directed where particular available materials are to be used in the Works. This

shal apply to both the location where the material is to be used and the level at which

the matenal isto be placed.

3.4.2 Waler

Al water used in compaction and mixing activities shal be clean fresh water. Fresh

water shall be tested for pH, Sulphate, Chloride, and Total Dissolved Solids. The resuts

shal bo submitied to the PROJECT MANAGER for review and approval prior to

construction

Brackish water can be used upon approval by the PROJECT MANAGER. Brackish

\atar shal be tested for pH, sulphate, chloride and Total Dissolved Solids, The results

shall be submitted to the PROJECT MANAGER for review and approval prior to

‘construction. Note that if brackish water is used, then concrete and any underground

features shail be protected against any chemical attack from the brackish water.

3.13 Testing

Laboratory and in-situ testing of soil and or rock materials wil be caried out by a

Cortracorappointed testing frm, on samples. taken fom the completed layers,

stockpiles or borow pits as required, in accordance with Section 32.18, Sol and! or

Tock tests. No layer Isto be covered by a succeeding layer unl it has been approved

‘Areas affected by the testing or sampling of materials shall be repaired and shall be

| equa in strength to the resto the layer

3.2. Details of Construction

32.1 Clearing

32.1.1 General

‘The area to be cleared shall be clearly marked on the ground atleast 48 hours prior to

the intention to commence site clearing. Any items wthin the area to be cleared which

are requited to remain intact for the duration of the Works shall be nominated and

cleary identified

Notwithstanding these limitations, clearing shall be carried out over the areas

‘comprising the fll extent of the Works, including borrow areas, stockpile sites, access

roads, drain alignments, fence lines, fire breaks and the areas set aside for tho

‘establishment on the site. All such areas shall be as shown on the drawings or as

directed,

{EOA NOTE hea Pap a Dame abet Pn ee

H Pages

RAS AZ ZAWR ALUMINIUM SMELTER PROJECT

|_Ste Preperation and Eoahworks ‘oe No. 25457-1000.P5-C600 0002 Rev. oot

‘The area to 20 cleared shall be that contained within the limits of top of cut batters or

toe of fil embankments, including any drains, plus 3.0 m.

All cleared areas shall be kept clear of re-growth for the duration of the Works

32.12 Clearing

Clearing shal include the removal from the area of the Weiks of all vegetation, roots,

surface boulters, debris and rubbish. The demolition and removal of structures, rot

‘separately scheduled for payment, is deomed to comprise part of the clearing operation

Clearing of any borrow or stockpile area shall not commence until ithas been confined

in writing that such area must be cleared and the extent of the area to be cleared

approved.

If so required by the Contractor, any large depressions occurring as a result of clearing

‘operations shall be filed with ‘material approved and thoroughly compacted 10 the

| finaly end elt contons speci in Seeon 32.10, Tenment of cut, (8 o

©).

82.1.3 Disposal ol refuse

| sit vegtaton and, brshucod, shal be prelerety used in re

vogetationlendscaping or cepoced of off ste

Debris, bouleers, rubble, supeticial obstructions and roots shall be disposed of off sta,

BBuming of vegetation wll not be permited,

2.2.2. Removal of topsoil

‘After completion of al clearing operations, the areas to receive fil, and other areas as

may be indicated on the drawings, shall be stripped of topsoil, and! or organic soils or

| ‘other deleterious material likely to inhibit proper compaction.

Care shall be taken to ensure that the stripped topsol is not contaminated with la'ge

amounts of materials other than topsoil, including large roots, large stones and ober

| ‘similar large tems of refuse.

‘Topsoil shall be placed in stockpiles at approved locations, and positioned well clear of

‘other stockpled materials and natural drainage lines. Designated soll types shall be

stockpiled separately and the maximum height of stockpiles shall not exceed 3 m.

‘Stockpiles shail be formed and leveled such that water does not pond on the surace,

Drainage furrows or berms shall be constructed to divert surface water away from the

I to0 ofthe stockpile embankments and thus prevent erosion,

‘Stockpiles that will remain for an extended period shall be adequately protected from

surface erosion,

RAS AZ ZAWR ALUMINIUM SMELTER PROJECT

| Ste Preperation and Eartworks Dee No. 25457:1090.2S-6600.0002 Fev. 005,

3.2.3 Contaminated soll or material

Inthe event that contaminated material or soil is discovered atthe site

‘The suspected contaminated material or soll shall be isolated and necessary

| precautions exercised in dealing with the material

|The existence of contaminated material or oll shall be promptly advised

‘The levels of soll or material contamination existing atthe site shal be established.

{All contaminated material or sol shall be removed from site and disposed of as required

by Kingdom regulations.

3.24 Materials from borrow pits

3.24.1 Work tobe included

“The work at borrow pits shall include everything required in obtaining borrow materials,

for use in the Works, including excavating trial holes, clearing the borrow pit site,

removing and stockpling topsoll, stripping and stockpliing any excess or unsuitable

‘overburden, excavating selected material and final trimming of the abandoned borrow

allin accordance with the specification or as directed

3242 Borrow pits

“The winning of material from borrow pits shall be subject to any specified environmental

limitations and restrictions. Soll andlor rack tests may be required to ensure that the

materials obtained from borrow pits to be used in the Works comply with the

requirements of the specification and to confirm that the supply is adequate.

‘The stripping of topsoil, peat and organic soll within borrow pits shall be undertaken in

accordance with Section 3.2.2, Removal of topsoil, except that stockpiles shall be

located around the perimeter ofthe working pit for ease of subsequent replacement.

Vegetation to be used for re-vegetation shall also be stockpiled around the perimeter of

the working pi.

Earth banks and interceptor drains shall be constructed prior to the construction of

borrow pits to divert drainage lines and flows away from borrow areas.

Where possible, borrow areas are to be left ree draining

3.243 Fencing of borrow pits

‘Where borrow pit areas are required to be fenced, the fence shall be of an approved,

temporary stock-proof type.

3244 Water

borrow pits

{501 NOTE. T aad op an a nna ees renee he

RAS AZ ZAWR ALUMINIUM SMELTER PROJECT

|_Ste Preparation and Earhworke ec No 26457-1000. 3PS-€600-0002 Rev. 001

All necessary arrangements forthe supply and delivery in respect of any water that may

be required at borrow pits shall be made.

9.24.5 Quality of materials,

Only approved materials shall be taken from borrow pits to be used in the construction

of the Works, Material undertying the approved material in any part of the borrow pit

‘may be unsuitable, and care shall be exercised to exclude such unsuitable material

324.6 Taking and testing of samples

From time to time, selected samples shall be taken and tested from approved sources

at the Engineers request to ensure that the qualily of material from such sources

complies with the specification. This may be in addition to material quality testing as

required in other sections of this specification.

324.7 Treatment of abandoned borrow pits

(On completion ofall operations atthe borrow pit, the borrow atea shall be rehabiltated

| ‘as soon as practicable.

ifthe borrow pts to remain exposed ter tho completion of the Contact, the sides of

the bortow pt shall e sloped to an adequate incinain to ensure stably ofthe slopes

inorder to rehabiltate the borrow pt, ary Unsuitable overburden trom the pt sha be

spread evenly over the borrow pt area, and the remaining topsoil (nckiding peat and

ergaric sols, ppicabe), shall then be spread ever the borow pit areas and stopes

0/26 fo leave a neat, aven surface. The surface shal be scared onthe contour to @

depth of 300 mm Where necessary, topsoil shal be obtained from another source and

Spread over the borrow pit area. Fotowing replacement of everburden, stockpiled

| egetation avaitabia) shal be evenly spread over ho surface ofthe borrow area

“The ‘tow of water into the borow pit shall be prevented by the construction of earth

banks and interception drains as may be rected, together wth any associated erosion

| protection works, Where possible, borrow pis shal beet roe draining.

‘Temporarily installed fencing and gates shall be dismantled when the area has been

determined to be sate.

3.25 Overburden

Aer stripping sol from a borrow area,

removed and stockpiled as cirected.

ny remaining unsuitable overburden shall be

[At the beginning of each fortnight, the extent of the area of overburden proposed to be

removed shall be determined petiodically. No removal of overburden or other borrow

‘operation shall be commenced until the area has been surveyed to allow quantities to

be determined

[RAS AZ ZAWR ALUMINIUM SMELTER PROJECT

| Ste Preparation and Eartworks Doe No, 25457-1000-9PS. 0600-0002

32.6 Excavation of rock

Flock in open excavation is defined as material which cannot be ripped at arate greater

than 75 bank cubic meters per hour using a single shank No. 9 Series D ripper or

‘equivalent, subject to a 45,000 kg pul of the drawbar of a crawler tractor fited with 610

‘mm wide tracks, traveling at an average speed, including slippage and stalls, of not

less than 1.6 km per hour (Caterpillar D10 dozer or equivalent in fist gear). The dozer

shall bo engaged in full ime ripping and shall not be engaged in pushing, dozing or

other dozing assignments. Boulders exceeding 1.5 cubic meters and with @ minimum

dimension greater than one meter shall be defined as rock.

Fock in trench or confined foundation excavation is defined as material wich cannot be

‘excavated at a rate greater than 20 bank cuble meters per hour using an hydraulic

‘excavator of not less than 90 KW flywheel power and fited with an approved bucket

having a breakout force of not less than 100 KN (Caterpllar 225 or equivalent)

Boulders with a minimum dimension greater than one meter and boulders that are

‘across the full trench width shall be defined as rack.

32.7. Common excavation

‘Common excavation shall comprise all material other than that defined as rock

5.28 Treatment of Sub grades

32.8.1 General Treatment of Sub grades ator Stripping

Aer sipping, ground surfaces shall be prepared fr fil placement, cut operation or as

a finished sub-grae surface. In areas of paved road consiructon, sol testing wil be

Undertaken fo detomnine the insitycry dena, meistue content and GBR valves from

which a subsequent pavement type can be contimed (Refer to specication 25457-

| 4000:345-C600:0003," section "45.1," for_ minimum. crtera). Once. confimed

preparation of the surface can be undertaken. This shal include scartying o! the

fxposed sub-grade, adjustment of the moisture content and compaction to achieve the

| specie requirements.

Proof-roling utiizing loaded rubber tired heavy machinary such as scrapers or other

‘approved equipment, shall be undertaken to confirm sub-grade intogriy, Costs

associated with proot-roling shall be deemed to be included in the sub-grade

preparation rate. Proof-oling shall consist of a minimum of three complete passes of

the proot-roling equipment applied to the prepared sub-grade.

‘Any soft or loose material that cannot be satisfactorily compacted shall be removed and

replaced with approved fil, placed and compacted in accordance with Section 3.2.10,

Treatment of cus, (e) or ()

3.28.2 Sub grade treatment in cut areas (other than rock).

RAS AZ ZAWR ALUVINIUM SMELTER PROJECT

| Ste Preparation end Eanhwoks ‘ec No, 25467-1000-3PS-000.0002 fev. 001

When the required sub-grade surface is exposed and is fee of rock or rock bars, it shall

be ripped, conditioned and re-compacted to the compaction specified in Section 3.2.10,

Treatment of cuts.

If saturated material is encountered at the level of sub-grade, the saturated material

shall be dried out and the sub-grade shall be opened up to faciitale drying out

‘Adequate time shall be allowed for the drying out to occur. The instalation of miter or

‘subsoil drains may also form part of the remedial works

{ter proot-raling of the sub-grade, the surface shall be immed to the required levels,

‘shape and falls as shown on the drawings.

9.2.8.3 Sub grade treatment in rock

Rock sub-grade to receive fl shall be cleaned of all lose material

Rock sub-grade to receive structure and! or equipment foundations / needs to comply

with project concrete specication slabs shall be an exposed, clean rock surface with

‘no fil (other than C15 “dental” concrete fil, f necessary, and as per Section 3.2.10("),

below) or disturbed material. That is, in these particular areas, where rock sub-grades

hhave depressions which exceed the specified tolerance on grade, dental concrete shall

bbe used to achieve the specified tolerance on grade.

3.29 Cuts

‘All excavation necessary for the completion of the Works, regardless of the

| classification of the material encountered, shall be performed,

Cuts shall be made true tothe slopes, widths and levels shown on the drawings, or as

directed, Cuts shall generally be excavated to sub-grade level, prepared building pad

level, or such other level as may be defined on the drawings. However, due regard to

the nature of the material being excavated may require that an unsuitable in-situ

‘material exposed at the defined level, be required to be excavated over the areas and to

| the depths directed,

Where cut slopes are to be topsolled, they shall be left sufficiently rough to ensure that,

| both during and after placing, the topsoil will ramain on the slope.

Where rock material is removed by blasting, the method of dling and blasting, e.g.

line driling, pre-spliting, cushion blasting, etc, shall be selected according to the

‘material encountered, so as to achieve the most stable side slope and the minimum of

over-break.

Where materal in the slope of the cut is unstable, the slope of the cut shall be flattened

to.a stable slope, or reinforced by rock boling, wire meshing, sprayed concreting oF

‘other means, as directed.

RAS AZ ZAWR ALUMINIUM SMELTER PROUECT

| Ste Preperation and Eartworks ‘oe No. 25457-1000.9PS-C600-0002 Fv. 001,

‘Suitable material from cuts shall be stockpiled, as directed, for use in fils, re-contouring

fof areas such as depressions, anti-erosion works, earth banks and levees and other

| works.

‘Where material is placed to spol, shall not be dumped at random, but shall be leveled

‘and shaped to a minimum slope of one vertical to two hundred horizontal (0.5 %) at the

completion ofall spoil operations.

No suitable materials chall be spoiled to waste without writen authority.

Finished surfaces from cuts shall be compacted to a minimum of 95% relative

‘compaction with respect to the maximum dry density as determined in accordance with

the modified proctor test.

3.2.10 Treatment of cuts

When the excavation has been completed to the required level and cross-section, the

‘exposed formation shall be trimmed of all loose material, shall be within specified

tolerances and, where not exposed rock, shall be compacted as specified in Section

3.2.12, Fil These operations are deemed to comprise part of the works necessary to

achieve the specified surface finish

It itis found thatthe in-situ material below the defined level does not provide a stable

Working platform, further excavation shall be performed and this additional excavation

shall be replaced by suitable approved material, placed and compacted according to

clause 3.2.10 (4) or (e)

Wherever exposed in-situ material is suitable for use as a pavement layer, but requires

‘additonal preparation to comply with the specification requirements, then one of the

folowing procedures shall be adopted:

‘a, Whore only one layer requires treatment it shall be scarified to the depth required

and re-compacted over the required width and depth to the specitied compaction.

This shall be classified as preparation of in-situ material for that particular layer.

b. Where more than one layer of the material requires addtional compaction, the

‘upper layer shall be removed to permit the compaction ofthe then exposed lower

layer, as described in (a) above, The removal of the upper layer shall normally be

done’ by blading of the material to windrows for subsequent replacing and

‘compaction. The lower layer, and the subsequently prepared upper layer, shall

be classified separately of in-situ material for each of the paricular layers. Other

methods of removing the upper layer, such as to stockpile for subsequent

replacement and compaction may apply, in which case the provisions of Section

1 3.2.15, Stockpiling of materials, shall apply.

© Where additional material has to be imported to obtain the required layer

thickness, then the in-situ material in that layer shall be scarifed, the necessary

"ae Pony pan a ral acetate nen ee ee

RAS AZ ZAWR ALUMINIUM SMELTER PROJECT

|_Ste Prepantion and Earthwork ‘Doe No. £5467-1000-9PS CG00-0002 Fev. 001

imported material placed and mixed, and this combined material compacted to

the required levels,

Where excavation in rock has been achieved by blasting and the surface of the

‘excavation upon which pavement is to be placed is iregular, e.g., areas to rocoive

roads or other vehicular pavements, the depressions shall be filed with selected

‘material and compacted as spectted in clause 3.2.10(4) or (e). After completion of the

filing, the surface shall be trimmed tothe spectied tolerance,

Where the in-situ material satisfies the requirements cf the specification and in artving

fat the required lines, cross-sections and levels, this material is loosened to an

Unacceptable degree, and then the disturbed material shall be re-compacted to meet

| the specttication.

Over-excavation shall be made good as follows, or by such other method as may suit

| the particular circumstance:

4, Backlil over-excavated areas with approved il (select sub-grade material)

‘compacted in layers to achieve compaction as specified in Section 3.2.12, Fil.

@. Over-excavation under structure and! or equipment foundations! slabs shall be

backfilled to the proper line and level with C12/15 “dental” concroto,

3.2.11 Blasting

| Where excavation in rock by blasting is permitied, care shall be exercised not to

‘overshoot. Any material outside the authorized cross-section, which may be shattered

oF loosened by such blasting, shall be removed. All actvtios in regard to the use of

explosives shall be strictly in accordance with the KSA regulations, the project

environmental management plan, industy-recognizec safe working practices and the

| requirements contained herein.

‘Supplemental detailed blast design requirements for particular excavation conditions

| may be issued by the PROJECT MANAGER, i required,

3.2.12 Fi

3212.1 General

All fils shall be constructed with relevant tolerances to the slopes, widths and levels

| ‘shown on the drawings, or as directed.

Fills shall be constructed with suitable approved material, in accordance with the

clauses contained herein. Unless otherwise authorized, all suitable materials obtained

‘rom cuts shall be placed before any material is borrowed or imported,

| eencores ie tnathae a acids hun issuance tee re ae

1 po sae

RAS AZ ZAWR ALUMNIUM SMELTER PROJECT

|_Ste Preparation and Earthworks (oe No, 2547-1000:9°S.6600.0002 Rew. 003,

32.122 Fil Placement

Al fils shall be compacted to @ minimum of 95 % with respect to the maximum dry

density as determined in accordance with the modified Proctor test. For fil materials.

classified as SP, SP-SM, and SW-SM, water shall be added only for workabilty and

{dust contro. For these materials, the construction methodology for fil placement shall

be as follows:

‘Spread a loose lit of il material witha thickness of 800 mm

Grade the fil material wth a grader

‘Add one pass of water using a water truck

Grade and trim with a grader

‘Compact the material with 6 to 10 passes using a minimum 10-ton vibratory smooth

drum roll.

Test the material for compaction

After successful compaction testing, add another lit and repeat steps 2, 9, 4,5, and 6.

8. Ifthe material dries out due to inactivity atthe ste or high weather temperature, a ight

pass of water shall be applied if necessary for constructabilty and workability.

9. Material classtied as SM with percent fines greater than 15% may require additional

water for compaction. For this material, the Contractor is responsible to determine the

range of moisture content in order to achieve a minimum of 95 % with respect to the

‘maximum dry density as determined in accordance withthe modified Procior test.

10. The Contractor shal verty the above construction methodology prior to execution

Note that the above construction methodology will not be applicable for subbase and

‘base course materials. The Contractor shal determine the construction methodology for

these materials through tial pads prior to execution.

In general, the fils shall bo constructod

a Inuniform horizontal layers, with loose layer thickness not exceeding 300 mm for

{il materials compacted with approved large compection equipment (as

determined by Contractor) including smooth vibratory steel drum rollers, e.g.

typically 200 kN static weight,

b. —Inareas not accessible with large compaction equipment, not exceeding 150 mm

{or fil materials compacted with approved small compaction equipment (as

determined by Contractor), including various "walk-behind" and riding smooth

vibratory stee! drum rolers, ¢.., typically 20 to 80 KN static weight, various

“walk-behind” vibratory steel plate compactors, anc “jumping; jack’ impactor

In all cases, tne maximum particle size of il materials shall be:

1. Not exceeding two-thirds of loose lit thickness. (ie. 200 mm maximum particle

size for 300 mm loose layer thickness; 100 mm maximum particle size for 150

1mm loose layer thickness)

Pan ea

[RAS AZ ZAWR ALUMINIUM SMELTER PROJECT

| Stee ‘ec No, £5457-1000-3PS-000-0002 ev. Ot

. Not exceeding 100 m for fil materials placed wihin 300 mm of any underground

structure,

©. Not exceeding 75 mm for fil materials placed within 300 mm of the sub-grade for

paving or structure/ equipment padsifoundations

4. In all instances, “nesting’ of large particles will not be permitted. Cemented

aggregations of particles wil similarly not be permitted

‘Should the full dopth of the compacted layer not acheve the specified density andior

‘moisture coneition, it will be required that additional compaction effort be supplied,

‘additional moisture conditioning be supplied, or that the thickness of fil layers be

1 reduced.

Where blasted rock is used as fil material, whatever methods are necessary shall be

used, including secondary blasting, crushing andlor screening, to produce rock not

‘exceeding the maximum particle sizes noted above, and meeting the gradation criteria

1 given herein,

Fil materials shail be placed and spread to form a horizontal layer. The top iit of fil

shall have sufficient crown and cross-fall to provide adequate drainage for water at all

imes during the construction period. All cut and fil sutaces shall be sealed to prevent

infitrtion of water and softening of sub-grade. Sealing shall consist of compacting tho

surface to @ smooth consistency with a smooth vibratory steel drum roller, 9. typically

100 to 200 KN static weight.

Where material was obtained for filing with a maximum dimension greater than noted

above, either the size of the material shall be reduced so that it can be placed in the fil,

fr the non-conforming material shall be transported and disposed of at an approved

disposal area andior used in other site development applications, such as rip rap.

Where embankment fil Is 1o be constructed on strpped surface with a side slope

steeper than 1 vertical to 6 horizontal (17 %), a bench of adequate width (minimum of 8

'm Wide) shall be cut at the toe of the embankment Io permit the intial embankment

‘construction to commence with horizontal layers of unitorm cross-sectional depth,

In addition, where the side slope of the stripped surface is 1 vertical to 3 horizontal

(83 %) or steeper, or where the construction abuts existing embankment fil, the stripped

surface under the embankment fil shall be excavated to provide a contiguous series of

horizontal stops at least 300 mm deep forming a key fer the embankment,

Where directed, the benches shall be drained by means of subsurface drains

32.12.38 Fil Placement on Sabkha Material

Fill placement on the Sabkha shall be in accordance with the following construction

methodology:

2. Spread the first loose it of fil material with a t

‘ness of 700 mm

LEGAL NOTE Tema Pepnyaecd anee nad ee a m

AS AZ ZAWR ALUMINIUM SNELTER PROJECT

| Ste Preparation and Earthworts Doc No. 25487-1000-9PS: 6600-0002

Grade the fil material with a grader

‘Add one pass of water using a water truck, necessary

Grade and trim with a grader itnecessary

Compact the material with 6 to 10 passes using a minimum 10-ton vibratory

smooth drum role.

“Test the material for compaction

ler successful compaction testing, add another lit witha thickness of 800 mm,

and repeat steps b,c, d, , and t

The Contractor shall verity the above construction methodology prior to execution.

‘The fil material placed on Sabkha material shall be compacted to & minimum of 90 %

with respect to the maximum dry density as determined in accordance with the modified

Proctor test. For fil materials classified as SP, SP-SM, and SW-SM, water may be

‘added only for workability and dust control. The testing frequency is shown in Table 3.

‘Any material under structures for temporary construction camp and lay down areas like,

cranes, concrete foundations, grade slabs, roads and paved areas shall be compacted

to.a minimum of 95%colave compaction with respect to the mocifiod Proctor test for a

minimum depth of 900 mm. No permanent strictures shall be built on the fil placed on

‘Sabkha material

3.2.13Materals

Common or general fi

‘Sound, hard, durable, inert mbxture of graval and sand mineral earth free from any

possible effect by water or the elements, well graded with maximum fragment size not

{0 exceed the maximum particle size(s) noted above.

‘This material shall be predominantly taken from onsite excavation, and shall additionally

‘have: liquid limit not exceeding 25 %, plasticity index not exceeding 10 %, total sulphate

Ccontent measured as S03 not exceeding 0.20 %; and chioride content not exceeding

0.02 %,

Hf the fil exceeds the above limits for sulphates and chlorides, concrete and any

Underground features shall be protected against attack due to sulphates and chlorides.

‘The type of protection shall be approved by the PROJECT MANAGER.

b. Unacceptable fi

Fine-grained mineral earth (clay or si), organic matter, construction and/ or demolition

debris, cinders, ashes, refuse, large stones, large rock fragments, imbers, vegetation,

fil contaminated with chemical impurties and other unsuitable matter.

©. Concrete fil

| Inaczordance with concrete specication of minimum compressive strength cass C1.

BRAS AZ ZAWR ALUVINIUM SMELTER PROJECT

| Ste Preparation nd Earthworks Doc No, 25487-1000-9°S-0600-0002 Rev. 001

4. Select and Structural fil

‘The fil material intended to be used for embankments and to support the structural

{foundations of floors must comprise only the “select materials” which has been

described in the project geotechnical report as follows:

Selector Structural fil material shall consist only of inorganic material and shall have

(0-20% passing the No. 200 sieve. Fil material should pass 100% the 50 mm sieve.

Besides, that portion of material passing sieve No. 40 should not have liquid limit more

than 35 and plasticity index of not more than 12. Atterberg limits are not required fr

select fil material with les than 15% passing sieve No. 200. Select fil material sha

have a total sulphate content measured as SOG not exceeding 0.20 %, chloride content

Not exceeding 0.02 % and carbonate content of less than 25% by weight,

1 the fil material available from onsite excavation does not meet the above

requizements, then the material shall be borrowed from offsite borrow arcas or

procured from off site material manufacturers.

fe. Riprap

‘Sound, hard, durable inet rock fragments or field stone with maximum dimension of

ach fragment or stone not to exceed 1.5 times its minimum dimension. Gradation

requicements for riprap shall be as indicated in Table 3.

1. Geotexiefiter material

‘The fiter fabric shall normally satisfy the following requirements,

Mass > 825 9m?

Tensile strength

uniform load eae

Prolongation at

rupture be)

Hydraulic

‘conductivity 103mis

Mesh (a

maximum opening d.<300ym

‘minimum opening d>2ym

For more rigorous conditions, additional requirements will be provided on drawings or

direct.

8.2.18.1 Placing of fil around structures

This clause covers the requirements for the placement and compaction of fil adjacent to

or preparatory to the construction of structures such as retaining walls, wing walls and

RAS AZ ZAWR ALUMINIUM SMELTER PROJECT

| Ste Preparation and Earthworks Dos No, 25487-1000:9PS-C600-0002 Rev. 001

large culverts that are not othenvise provided for in any other special provision in the

Contract. Such il shal be placed at locations as specified or shown on the drawings.

‘No fil shall be placed against concrete within 14 days cf casting. Unless a geotoxtile.

‘materal is specified as a drainage medium or uniess otherwise specified, materia to be

placed within 300mm of bridge abutments, retaining walls, wing walls of large culverts

‘hall consist of structural fi, The bottom of the structural fil or any geotextle material

shall be connected to suitable drainage outfall, as stown on the drawings, or as

otherwise spectied

Compaction equipment shall not be operated within the minimum distances from

Structures shown in Table 2. These minimum distances apply until the fil reaches the

level above the top of the structure corresponding to the relevant spectied minimum

cover. Compaction of fil closer-in to structures than these minimum distances shall be

bby hand methods: compaction of fil at the haunches of round or curved-sided culverts

‘shall similarly be by hand methods. The diference in level of any fill being placed on

‘opposite sides of a structure or structural component shell not exceed Hi or 600 mm,

whichever ie lees, where His the height of the structure,

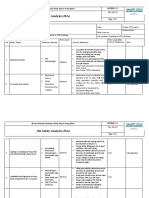

TABLE 2

COMPACTION EQUIPMENT CLEARANCE FROM STRUCTURES

alers Tit anes | — Wana

[ Minum distance | "romabuimerts, | cova ovr

GEESE) | TEE, |‘tomasesol | relanngwateand | pot caver

atc weight | Totalapsiedtorce | ‘Cehens im) | whgwalle ‘)

conr ‘a | et ,

<2 <2, a a5 oe,

2-80 2-0 033 oS

B= 100 S1=100 12 12 ot

ors 200 [Tar = 200 Za 12 aa

201950 201-380 | Greaerolaer | Geaerottzar | a7

neigitotsivctve | neigh sure

Te rag Taran ven mds

Total apt forces he sm of sai oad and verte component of centuga ce

32.132 Saturated excavated material

Saturated materials are not expected to be encountered within cut operations. They

may be deemed as unsuitable if it is demonstrated that the material cannot be

teasonably dried out within the constraints of the appreved construction program. It

deemed suitable, saturated materials may be spread in uniform thin layers and allowed

to dry oul to a moisture content at which the material can 2e compacted.

| EASAzzawn ALosweLTER PROsECT

Ste Preparation and Earthworks Doe No. 25457-1000:2°S.6600.0002 Rew. 001

Where saturated materials are encountered, the instalation of sub-soil drainage andior

cout off drains to divert ground or surface water from fe site of excavations may be

required,

8.2.14 Drainage and dewatering

‘Altnecessary catch drains and diversions to ensure proper drainage of the Works shall

bbe constructed. All necassary labor, materials, plant and equipment to keap the Works

[protected in such a manner as to prevent water ponding on the work site shall be

provided.

‘Should ponding of water occur on the work site thrcugh negligence or inadequate

quencing oF proteaion of tho Werk. and if ouch pording anclor water saturation of

the strata may have caused softening, loss of bearng sttength, heave, setlement or

any other eect ofa detrimental nature, then the suspect strata shall be excavated and

removed and immediately replaced, compacted and timmed to level by using such

| material as dkected

{All work required for draining and control of the surface and sub-surface waters in the

‘work site to allow excavation work and placement of backill to be performed in water-

fee areas shall be performed.

‘The dry condition shall be maintained continuously under all conditions and at all times

Until backfling and compaction has been completed, or until the work components

placed in the excavation are able to withstand the approved effects of water, as

! ‘determined by PROJECT MANAGER,

! Dewatering shall not be stopped without prior approval,

For the purpose of this clause the term “dry” shall not be deemed to preclude the

presence of dampness contained in the earth as distin from free water belng present,

provided that any damp earth or "muck" cannot enter or contaminate the various

‘components of the Works.

‘Tho dewatering method and disposal arrangements shall not cause any damage to or

have any detrimental effect on adjacent structures, services or adjoining land, nor

contravene any stalutory environmental regulation or requirement. All damage caused

| by the disposal of water shall be made good.

i ‘Water shall not be discharged or conveyed onto the land or into any Storm water drain

without pror approval

3.2.18 Stockpiling of materials,

Where practicable, excavated material shall be transported and placed in its final

I position in the Works in the same operation

RAS AZ ZAWR ALUMINIUM SMELTER PROJECT

|_Ste Preparation and Earthworks (oc No, 25457-1000-9PS 600-0002 Rev. 001

When specifically directed in writing, or in accordance with the provisions of the

| Contract, excavated material shal be stockpiled at one or more designated locations

‘Thereafter, the material in stockpile shall be loaded, transported, processed (where

applicable) and used as required.

3.2.16 Construction of drains

‘This work shall consist of the construction of drains epecfially elated to bulk earthwork

‘operations, such as interception drains, side drains and open channe's.

3.2.16:1 Interception drains

Interception drains shall be constructed beyond the limits of excavated slopes in order

to prevent surface run-off from eroding the slopes andior entering the area of the

Works, They shall be constructed such thatthe water contained inthe drain shall not be

I ‘closer than 5 m from the top of the excavation slope.

Interception drains shall be constructed to the gradients required to prevent ponding of

water. To prevent accumulation of water in tha drains, they shall, at intervals, be

directed away from the excavation slope so as to discharge onto the natural ground,

Where construction occurs on erodibie solls or on steep gradients, suitable erosion

protection such as stone paving, dissipaters and stepped cut-off berms shall be

‘constructed, so as to prevent erosion of the drain.

Interception drains shall be constructed by excavating on the lowest side of the drain

area and forming and compacting a bank on the highest side so that run-of flows on the

Natural ground above the earth bank. Measures shall be taken to ensure that the

discharge of water onto natural ground does not cause erosion of the ground.

‘The dimensions and details of interception drains shall be as shown on the drawings of

as directed

3.2162 Side érains and open channels

Side drains and open channels shall be excavated and shaped to conform to the

dimensions shown in the drawings. Side drains shall be maintained and kept tree of

| obstructions throughout ihe performance of the Works.

Side drains and open channels shall be protected against erosion, all as specified in

| Section 3.2161, Interception drains, above.

‘The dimensions and details of side drains and open channels shall be as shown on the

drawings or as directed.

3.2.17 Compaction

3.2.17.1 Methods and procedures

EASAzzAWe suum seLTeRPROWECT

Ste Preperation and Earhworts ‘oc Na. £5457-1000-9PS-C00-0002 fev. 001

‘The necessary plant and equipment shall be provided and approved methods employed

to obtain the required compaction levels. All compaction shall be undertaken by

| purpose-built compaction equipment.

Before commencing production earthworks in any ofthe specified areas of the site, the

proposed methods and procedures to be used shall be demonstrated over atrial area at

the site. The proposed methods and procedures must be agreed upon before

proceeding with general compaction over the site. Where changes to the agreed

procedures for compaction are required, the proposed changes shall be approved

before proceeding withthe revised procedures.

‘The tral shall determine the type and number of equipment, the pattem of passes to be

used, the thickness of the loose layer fo be compacted, any processing requirements for

site-blended materials and the maximum dry density and optimum moisture content of

the layer for compaction.

‘The trial: (1) shall have a minimum plan area of 1500 square meters; (2) shall be

constructed of atleast ree sucpessively-compacted bose layers; and (3) shal have a

minimum of one laboratory test se, and five in-situ densily and moisture content tests

‘equally spaced across the tral plan area, for each successively-compacted loose layer

‘All ial results shall be reported to, and accepted by PROJECT MANAGER prior 9

‘commencement of production earthworks.

Each layer of material requiring compaction shall be compacted in suitable continuous

‘Sections over the full with of the layer concemed, such that the speciied degree of

| ‘compaction is achieved throughout the full depth of the layer.

‘An overlap of not less than the depth of the layer being compacted shall be maintained.

between the surfaces traversed by adjacent passes ol the compaction equipment, and

this overlap shall also apply to each unit of towed mutizie arrangement rollers.

‘Adequate precautions shall be taken not to stratify fils with planes of cleavage.

Compaction shall, wnere practicable, be carried out by routing equipment parallel to the

I longitudinal axs of the embankment

Every precaution shall be taken when operating compaction equipment over or adjacent

to structures, so as not to damage structures or disturb the foundations. Any such

| damage or disturbance shall be repaired.

‘The loose, uncompacted thickness of material placed prior to compaction shall be

‘compatible with the compactive ffciency of the equipment used. Should the

‘compacted layer fail to achieve the specified density andior other specified criteria, the

material shall be placed in layers of reduced thickness, or the compactive effort

increased.

Compaction to the specified density andlor other specified citeria shall be carried out

by means of the approved methods and procedures bu, in all cases, final compaction of

RAS AZ ZAWR ALUMNIUM SMELTER PROJECT

| Ste Preparation and Earthworks ‘No. 25457-1000-9PS.6600.0000 Rew. 00

the layer shall be carriod out by roling with smooth whee! or pneumatic tired rollers, and

| final shaping to correct level and camber by blading wity sof propelled gradere,

During compaction, the surface of each layer shall be graded so as to prevent the

formation of rus end to preserve a unfom surface tre to grade and cross-section

‘Any weak spots that become apparent during compacion shall be cut out and repaired

| with sound materi

Where vibrating rollers are used, the vibrator shall nol be activated until a minimum of

two "static" passes have been completed. In addition, the vibrator shall be deactivated

during any tum or change in direction of the rol

Where tamper spreader machines are used for material placement, spreading and

‘compaction, the material shall comply in all respects with the grading and moisture

‘content requirements for the particular layer prior to the material being placed in the

machine. The tamper spreader machine shall be operated and maintained by

experienced personnel.

‘Small, mechanical compactors shall be used to achieve the specified compaction in

areas that are inaccessible to normal compaction equipment, or where heavy

equipment may disturb footings and light structures.

32.17.2 Addition of water

COnly clean, fresh water shall be used forall site Works including compaction and dust

Control, The use of brackish water or sat water can be permitted upon approval by the

PROJECT MANAGER,

Water may be added and uniformly mixed with the material at the source, such as

borrow pit or stockple, by an approved method, or may be added and mixed in-place on

the Works.

Bolore water is added, the material shall, i necessary, be thoroughly broken up by

means of disc harrowe or other suitable equipment, to ensure that there are no clods or

lumps which might prevent the uniform distribution of water, and the material shall be

| thoroughly mixed to ensure that tis homogeneous.

Where water is added and mixed in-place, the required amount of water shall be added

by repeated tips of water transporters with sprinkler bars, The use of high-pressure

| nozzles will not be permitted.

“The thorough mixing of water withthe materia to be compacted shall be caried outwith

disc havrows, ploughs, sel-propelled graders or other suitable equipment. Mixing shall

be continued until a uniform and homogeneous mixture is obtained. It may be

necessary for moisture contrl tests to be cariod out on tho material prior to

1 compaction,

AS AZ ZAWR ALUMINIUM SMELTER PROJECT

| Ste Preparation and Eaworks oe No, 25457.1000.80S-6600 0000 ev. cO8

‘Should the material be too wet due to rain or any other cause, it shall be harrowed and

allowed to dry out to the correct moisture content before compaction proceeds.

3.2.18 Soll and! or rock testing

‘The quality of the work, including all materials used, shall be confirmed by testing

Al fil placements will be observed fulltime by the PROJECT MANAGER'S field

‘geotechnical engineer,

‘Sampling and testing to determine density, moisture, gradation and related properties of

the soll and! or rock material, and to evaluate its suitability or otherwise for use as filing

‘material, shall be performed,

‘Such sampling and testing shall be undertaken to demonstrate that the specified degree

‘of compaction has been achieved and that all materials provided and used conform to

the spectication requirements,

NNo layer shall be covered by a succeeding layer until it has been approved. Areas

affected by tho testing or sampling of materials shall be made good, and the repairs

shall be equal in strength tothe rest ofthe layer.

Testing shall be carried out in accordance with the standard test methods of test as

listed in Section 2.1. The approximate location, including nothing, easting and

‘elevation, in the case of in-situ tests, shal be provided.

Where the in-sity density of a compacted sub-grade, or fil layer is less than the

spectied percentage compaction (or outside the bounds of acceptable placement

‘moisture content), the layer shall be re-worked and retested until the specified

‘compaction is achieved.

Al testing shall be cartiod out by a cortfied testing company, appointed by the

Contractor, accepted by PROJECT MANAGER and which complies with government

rogulations,

In-situ density and moisture content test results shall be provided within 24 hours from

performance of the tests onsite,

Laboratory test set results shall be provided at least five days prior to the use on site of

proposed fil materials in the Works. Alltest results shall be provided in duplicate.

In-situ donsity tests shall be by the sand replacement and! or by the nuclear device

method, however, it the nuclear device is employed it shall be calibrated using the

standard reference block at least once a daytwice per day, and also calibrated by

comparison with immediately adjacent sand replacement tests atleast twice per week.

RAS AZ ZAWR ALUMINIUM SMELTER PROJECT

| Ste Preperation sed Earhwoets ‘Dos No 25457-1000-3PS.6600.0002 Rov. 001

Insitu moisture content tests shall be by the oven-drying method or by the nuclear

‘method , however, i he nuclear device is employed it chall be calibrated against oven

dying as a standard.

A single moctied Proctor test shall be performed at a rate of 1 per day per work area,

The results from the single modified Proctor test wil b used to determine the maximum

dry density based on family of modified Proctor curves. When performing the single

‘modified Proctor tes, itis appropriate to add water to tho soll sample close to the

‘optimum moisture content in order to easily identity the maximum dry density from the

family curves,

This single point (dey donsity/ moisture content) shal be used to select the

representative laboratory compaction curve (rom a famiy of cUves provided initaly by

| PROJECT MANAGER) fr evaluating complance wih the compaction requiroment. The

‘ale a testing shal be as shown in Table 3, below.

tc Pep nd hh ane

RAS AZ ZAWR ALUMINIUM SMELTER PROJECT

| Ste Preparation and Earthworks Do No. 25167.1000.29S-0600:0000 Rev. 001,

Table3

‘Winimum froquoney

Location Type of test of fed compaction

teats per mork area

For each matoral, the

following tests (laboratory

test eet) shal be performed:

‘Ore (1 insta donsity|

‘and moisture content,

tea per 1000 me of fit

Modified Proctor tast ee

Maximum dry density

Earthworks it) | Optimum moisture content | 8) er 100 m3 of

ma inasceeeblet ge

“igual iplastc ‘compaction equipment.

imtplastioty index ve (t) sl point

Serer | oniassenes,

fords content

‘Carbonate corto Be day pet work area.

or each materal tha] Ore (atu cenaty

following tests laboratory | ané moisture content

test sel) shall be pertormed: | tee per 2000 m2 oti

suface area.

| artworks (tat | Modiied Procior test ‘One (1) per 100 m3 ot

placement on | -Gradatonigran ee {il vlume for areas

Sapkha) distribution inaccessible to large

“Liquid enipastic compaction equip

limivpiasesy index

Sulphate content (ne (1) single point

“Chiorde content ‘mediisg Proctor tot,

Carbonate content pe: day per work area

‘Ore (1) in-situ density

‘and moisture content

{eat pls single point

laboratory compaction

| test per 2000 m2 of

| sub grade surface area

‘Sw grade

Sit grade. | As for earthworks ti)

3.2.19 Stone and conerete slope protection

3219.4 General

Slope protection shall be as shown on the drawings, cr as directed by the PROJECT

MANAGER.

“The slope surfaces to be protected shall be trmmed back, removing loose material to

‘expose compacted filing or undisturbed natural ground. Any soft spots shall be dug out

and all deficiencies made good with common fil material, which shall be watered,

compacted and tested.

RAS AZ ZAWR ALUMINIUM SVELTER PROJECT

| Ste Preparation and Earthworks ‘ec Ni, 25457-1000-9PS. 600-0002

oor

Where protection is required at locations other than the slopes of embankments, the

‘matefial shall be dug out until sound, undisturbed material is exposed, and the

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Daily JSA - Excavation and Soil CollectionDocument4 pagesDaily JSA - Excavation and Soil Collectionshoaib akhtarNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Daily JSA - Diesel FillingDocument3 pagesDaily JSA - Diesel Fillingshoaib akhtarNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Daily JSA - Back Filling, Levelling and ComapactionDocument3 pagesDaily JSA - Back Filling, Levelling and Comapactionshoaib akhtarNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- MSHEM-09.00-Contractors EHSS ManagementDocument54 pagesMSHEM-09.00-Contractors EHSS Managementshoaib akhtarNo ratings yet

- Productivity Norms For Civil WorksDocument189 pagesProductivity Norms For Civil Worksshoaib akhtarNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Asphalt RestorationDocument24 pagesAsphalt Restorationshoaib akhtar100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- WBS Activity List Partial1 1Document6 pagesWBS Activity List Partial1 1shoaib akhtarNo ratings yet

- Project Construction EHSS RISK Assessment-1Document11 pagesProject Construction EHSS RISK Assessment-1shoaib akhtarNo ratings yet

- Daily JSA - Fence Post InstallationDocument5 pagesDaily JSA - Fence Post Installationshoaib akhtarNo ratings yet