Professional Documents

Culture Documents

Critical Speed Calculator - Shared - Critical Speed Mini in Balancing Stand

Uploaded by

Thành Nhân0 ratings0% found this document useful (0 votes)

5 views2 pagesOriginal Title

Critical Speed Calculator - shared - Critical speed mini in balancing stand

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views2 pagesCritical Speed Calculator - Shared - Critical Speed Mini in Balancing Stand

Uploaded by

Thành NhânCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

>>> Click File > Make a Copy to start using this spreadsheet!!

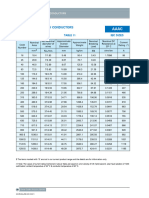

Rotor weight (m) 12.02 grams

Shaft diameter (d) 3.175 mm

Length of shaft (L) 46.4 [1] mm Distance between centre of bearings

Shaft Young's Modulus (E) 200 Gpa https://en.wikipedia.org/wiki/Young%27s_modulus

200000000000 N/m2

Moment of Inertia (I) 0.0000 m4 https://testbook.com/question-answer/critical-speed-of-the-shaft-is-affected-by--60226511008eb5e8474a945f#:~:text=Whirling%20speed%20or%20Critical%20speed,speed%20at%20which%20resonance%20occurs.

Critical Speed (Nc) 1005.076114 rps https://www.roymech.co.uk/Useful_Tables/Drive/Shaft_Critical_Speed.html#cent_short

1st harmonic 60,305 rpm 1,005.08 Hz

2nd harmonic 241,218 rpm 4,020.30 Hz

3rd harmonic 542,741 rpm 9,045.69 Hz

Sub-multiples [2] RPM Hz

2 30,152 502.54

3 20,102 335.03

4 15,076 251.27

5 12,061 201.02

6 10,051 167.51

7 8,615 143.58

8 7,538 125.63

9 6,701 111.68

10 6,030 100.51

11 5,482 91.37

12 5,025 83.76

13 4,639 77.31

14 4,307 71.79

15 4,020 67.01

16 3,769 62.82

17 3,547 59.12

18 3,350 55.84

19 3,174 52.90

20 3,015 50.25

[1] 34 space between pillars

5 mm up to bearing edge

1.2mm up to bearing centre

So 34 + 5 + 5 + 1.2 + 1.2 = 46.4

Rotor is 10mm wide, so spacers should be:

(34 + 5 + 5 - 10) / 2 = 17mm

[2] "It is furthermore of great importance, in order to avoid vibrations which would interfere with the proper application of the process, that the

speed at which the grinding is effected should bear a definite relation to the critical, corresponding to the fundamental natural vibration, and the

following rule should be observed: If the system is run in two bearings the grinding speed should be an odd multiple or submultiple of the critical.

If, on the other hand, the system is supported on one side only, the speed should be an even multiple or submultiple of the critical." ~ Nikola

Tesla

You might also like

- Book - Steel TableDocument120 pagesBook - Steel Tablevisarut100% (1)

- Steel Profiles South AfricaDocument9 pagesSteel Profiles South Africadaniel pNo ratings yet

- BS Iso 21940-1-2019Document40 pagesBS Iso 21940-1-2019airul6100% (2)

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Sections: Universal Columns (UC) EurocodeDocument2 pagesSections: Universal Columns (UC) EurocodeRajesh RNo ratings yet

- Stainless Steel Pipe Dimension As Per Astm & Weight-Kg. Per Mtr. (Ansi B36.19)Document2 pagesStainless Steel Pipe Dimension As Per Astm & Weight-Kg. Per Mtr. (Ansi B36.19)Mohammad SaleemNo ratings yet

- 7,3 020ROUGS4 Chapter7 PavementDesign Part3Document27 pages7,3 020ROUGS4 Chapter7 PavementDesign Part3fadi eidNo ratings yet

- UT Book ArticlesDocument135 pagesUT Book ArticlesAnonymous uXdS9Y7100% (1)

- M9 Experiment Lab ReportDocument5 pagesM9 Experiment Lab ReportShageenth Hashmeesh Sandrakumar100% (2)

- Pump CurveDocument3 pagesPump CurveLINIEL DE JESUSNo ratings yet

- Wide Beam DesignDocument6 pagesWide Beam DesignNaveen RevannaNo ratings yet

- Heavy Hex Bolt DimensionsDocument6 pagesHeavy Hex Bolt DimensionsSUJIT PATEL100% (1)

- I SectionsDocument2 pagesI SectionsThanawatNo ratings yet

- Standard Sectional Reference Dimension (MM.) Geometrical Moment Sectional Area (CM) of Inertia (CM) L LDocument2 pagesStandard Sectional Reference Dimension (MM.) Geometrical Moment Sectional Area (CM) of Inertia (CM) L LnoppadolNo ratings yet

- MaryDocument9 pagesMarymhtofighiNo ratings yet

- GC Turpentine Lot 69Document2 pagesGC Turpentine Lot 69sidharthsud28No ratings yet

- 3Document81 pages3Suraj DasNo ratings yet

- Instruction Sheet: S-Series Hydraulic Torque WrenchesDocument7 pagesInstruction Sheet: S-Series Hydraulic Torque WrenchesJacinto PujotaNo ratings yet

- 0-AAAC-Oman-01 PageDocument1 page0-AAAC-Oman-01 Pagenarinder kumarNo ratings yet

- QNS DataDocument5 pagesQNS DataAryamaan SinghNo ratings yet

- Pressure Drop Calculation R3Document24 pagesPressure Drop Calculation R3rupawer56No ratings yet

- Dasar Karakteristik MaterialDocument13 pagesDasar Karakteristik Materialkhusnul nurhidayatiNo ratings yet

- Tabla de Equivalencias de Valores DCP Vrs CBRDocument1 pageTabla de Equivalencias de Valores DCP Vrs CBRJulesNo ratings yet

- RPM RWHP RWTQ FWHP FWTQ FW Ve Green Field Yellow Runner CFM Intake CFM Piston SpeedDocument31 pagesRPM RWHP RWTQ FWHP FWTQ FW Ve Green Field Yellow Runner CFM Intake CFM Piston SpeedSmoking Wheels100% (7)

- Jis g3466-3Document1 pageJis g3466-3Nhuận PhạmNo ratings yet

- Table Sched 40 & 80Document1 pageTable Sched 40 & 80Clinton HarmanNo ratings yet

- Pipe Schedule PDFDocument1 pagePipe Schedule PDFbayu270589100% (1)

- Vacuum Flow Through OrificeDocument1 pageVacuum Flow Through Orificeمحمد عبدالدايمNo ratings yet

- Resistencia Tension Pernos ASTM F1554Document4 pagesResistencia Tension Pernos ASTM F1554mrnicusNo ratings yet

- DuroFlow Series PSDocument2 pagesDuroFlow Series PSPepito PerezNo ratings yet

- Catalog Current Rating & Voltage Drop Iec Al X Xlpe Armour and Non Armou...Document1 pageCatalog Current Rating & Voltage Drop Iec Al X Xlpe Armour and Non Armou...muhammad ridwanNo ratings yet

- Prevailing Torque Guide: Inch SizesDocument1 pagePrevailing Torque Guide: Inch Sizeskarthi.indya9274No ratings yet

- Analysis of Large Diameter Cyclone Plant Performance. Proc. 9th Aust. Coal Prep. Conf., Yeppoon, Oct. 2002 (Aust. Coal Prep - Soc.), 68-89Document22 pagesAnalysis of Large Diameter Cyclone Plant Performance. Proc. 9th Aust. Coal Prep. Conf., Yeppoon, Oct. 2002 (Aust. Coal Prep - Soc.), 68-89JD FCNo ratings yet

- Speed - Calc - Rebar - Repeater Mill - 27 02 2020Document3 pagesSpeed - Calc - Rebar - Repeater Mill - 27 02 2020DARA SINGHNo ratings yet

- Case Study 1Document22 pagesCase Study 1JD FCNo ratings yet

- 3005 Tabla Sigmas - PPMDocument10 pages3005 Tabla Sigmas - PPMDiana ArreolaNo ratings yet

- Nozzle Load For Flange Rating Class 150#: Nozzle Size Fa (KN) FL (KN) FC (KN) MT (KNM) ML (KNM) MC (KNM)Document6 pagesNozzle Load For Flange Rating Class 150#: Nozzle Size Fa (KN) FL (KN) FC (KN) MT (KNM) ML (KNM) MC (KNM)olekNo ratings yet

- Datasheet 6x19 Fibre Core GalvanisedDocument1 pageDatasheet 6x19 Fibre Core GalvanisedKurnia Adi WibowoNo ratings yet

- Mohammed Hama Honia Ali Aya SaadDocument5 pagesMohammed Hama Honia Ali Aya SaadHonya Hemn AliNo ratings yet

- Appendix C Overhead Line ImpedancesDocument12 pagesAppendix C Overhead Line ImpedancesHermis Escandell MedinaNo ratings yet

- Parallel Flanges Channels - Steel DimensionsDocument1 pageParallel Flanges Channels - Steel DimensionsAxiv The GreatNo ratings yet

- JIS G3466 - Thailand - CONTENT1011579693989745Document1 pageJIS G3466 - Thailand - CONTENT1011579693989745Nguyễn Tiến TùngNo ratings yet

- Betz Limit CalculationDocument2 pagesBetz Limit CalculationShyam SundarNo ratings yet

- Aw2.9bk6 12ax1 ManualDocument63 pagesAw2.9bk6 12ax1 ManualjassimNo ratings yet

- Formula GeomekanikaDocument9 pagesFormula GeomekanikaFsocietyNo ratings yet

- Aaac - Tabela CabosDocument4 pagesAaac - Tabela CabosKarin SpringerNo ratings yet

- Sieve Analysis and Slope CalcsDocument3 pagesSieve Analysis and Slope CalcsMostafizur RahmanNo ratings yet

- Optimal ValueDocument2 pagesOptimal ValueChristian M. MortelNo ratings yet

- (26-28) SGP Pipe SteelDocument3 pages(26-28) SGP Pipe SteelSugi ZhuangNo ratings yet

- F4001 Vortex Flowmeter ManualDocument24 pagesF4001 Vortex Flowmeter ManualHafidGaneshaSecretrdreamholicNo ratings yet

- Sections: Universal Beams (UB)Document18 pagesSections: Universal Beams (UB)rezetane mohamed amineNo ratings yet

- Deeplay-Eks-2018-015 - IrregularWave-HsHmaxRelationDocument9 pagesDeeplay-Eks-2018-015 - IrregularWave-HsHmaxRelationGunawan SuwarnoNo ratings yet

- Drainase Dezty OkDocument49 pagesDrainase Dezty OkFaridNo ratings yet

- Calculo de Erosion UsleDocument10 pagesCalculo de Erosion UsleJose Luis EstupiñanNo ratings yet

- Pump CurveDocument3 pagesPump CurveAnton PaneNo ratings yet

- GSM Fabric Thickness Fabric Cover Factor Bending LengthDocument4 pagesGSM Fabric Thickness Fabric Cover Factor Bending LengthPalashNo ratings yet

- Inch - MM Conversions: Revised Feb 2011Document1 pageInch - MM Conversions: Revised Feb 2011kamaldhar007No ratings yet

- Pelton TurbineDocument6 pagesPelton TurbineOsim AbesNo ratings yet

- White Fork Lift MSB Series Lift Trucks Parts CatalogDocument10 pagesWhite Fork Lift MSB Series Lift Trucks Parts Catalogdonald100% (51)

- Hitungan Mekanika Fluida Rev01Document19 pagesHitungan Mekanika Fluida Rev01misfat nawalNo ratings yet

- APR2C2Document2 pagesAPR2C2AnushkaNo ratings yet

- Constant Head Permeability Test in Sand: University of Texas at ArlingtonDocument8 pagesConstant Head Permeability Test in Sand: University of Texas at ArlingtonSalihin MasriNo ratings yet

- Simple Stress StrainDocument8 pagesSimple Stress StrainJames Ortega33% (3)

- Tzempelikos D. Et Al - Airflow Patterns in A Laboratory Batch-Type, Tray Air Dryer - Ic-Scce2012 - ProceedingsDocument10 pagesTzempelikos D. Et Al - Airflow Patterns in A Laboratory Batch-Type, Tray Air Dryer - Ic-Scce2012 - ProceedingsAndronikos FiliosNo ratings yet

- Zeilinger, Interpretation and Philosophical Foundation of Quantum MechanicsDocument12 pagesZeilinger, Interpretation and Philosophical Foundation of Quantum MechanicsManuel SepúlvedaNo ratings yet

- Faustus Teacher GuideDocument14 pagesFaustus Teacher GuideZACHARY DENGNo ratings yet

- Brilliant: Physics Olympiad Model ExaminationDocument9 pagesBrilliant: Physics Olympiad Model ExaminationKalyani BaijuNo ratings yet

- MT Lab ManualDocument62 pagesMT Lab ManualArun Chandra BabuNo ratings yet

- Simulationandmodelingofahydraulicsystem Fluidsim Oronjak PDFDocument5 pagesSimulationandmodelingofahydraulicsystem Fluidsim Oronjak PDFHadi NurhidayatNo ratings yet

- 5 Propeller Theory - ExamplesDocument4 pages5 Propeller Theory - ExamplesVăn NguyễnNo ratings yet

- Structural Analysis and Design Group: National Aerospace Laboratories, BangaloreDocument1 pageStructural Analysis and Design Group: National Aerospace Laboratories, Bangalorealagarg137691No ratings yet

- Thermodynamics of Phase Transitions: 3.A. 3.B. 3.C. 3.D. 3.E. 3.F. 3.G. 3.HDocument49 pagesThermodynamics of Phase Transitions: 3.A. 3.B. 3.C. 3.D. 3.E. 3.F. 3.G. 3.HAnonymous 4nyKDmNo ratings yet

- 12SEAGC1996 The Response of Vertical Piles To Ground Movements From Adjacent Braced ExcavationsDocument7 pages12SEAGC1996 The Response of Vertical Piles To Ground Movements From Adjacent Braced ExcavationsfreezefreezeNo ratings yet

- Design For Static LoadingDocument5 pagesDesign For Static LoadingPrince SinghNo ratings yet

- Lead CreepDocument11 pagesLead CreepEamonnSlatteryNo ratings yet

- Chap17 SDocument90 pagesChap17 STest GgNo ratings yet

- Huzayyin Ahmed A 201111 PHD ThesisDocument113 pagesHuzayyin Ahmed A 201111 PHD ThesisHafiziAhmadNo ratings yet

- 2005 09 MSCRDocument5 pages2005 09 MSCRSri RamyaNo ratings yet

- Chapter 3 Statically Determinate and Indeterminate Systems: 3.1 Principles of Solid MechanicsDocument17 pagesChapter 3 Statically Determinate and Indeterminate Systems: 3.1 Principles of Solid MechanicsHamza MahmoodNo ratings yet

- 2105ENG FE ProjectDocument18 pages2105ENG FE ProjectDylan Perera0% (1)

- Rectangular Hollow Plate-Fine Analysis-1Document14 pagesRectangular Hollow Plate-Fine Analysis-1Francisco UribeNo ratings yet

- Notes in Che 324 Prepared: Engr. Brenda T. Domingo Coloma, CheDocument8 pagesNotes in Che 324 Prepared: Engr. Brenda T. Domingo Coloma, ChePaul Philip LabitoriaNo ratings yet

- Engineering Properties of Biological Materials and Food Quality 3 (2+1)Document8 pagesEngineering Properties of Biological Materials and Food Quality 3 (2+1)Melanie Saldivar CapalunganNo ratings yet

- Unit-4-Computer Aided DesignDocument15 pagesUnit-4-Computer Aided DesignMuthuvel M100% (2)

- Stabilization of Aircraft StructureDocument10 pagesStabilization of Aircraft StructureJanuva K JNo ratings yet