Professional Documents

Culture Documents

(No.43) PREDICTION OF PRESSURE DROP REQUIRED FOR SAFE UNDERBALANCED DRILLING

(No.43) PREDICTION OF PRESSURE DROP REQUIRED FOR SAFE UNDERBALANCED DRILLING

Uploaded by

Ganjar Hermadi0 ratings0% found this document useful (0 votes)

12 views8 pagesOriginal Title

[No.43] PREDICTION OF PRESSURE DROP REQUIRED FOR SAFE UNDERBALANCED DRILLING

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views8 pages(No.43) PREDICTION OF PRESSURE DROP REQUIRED FOR SAFE UNDERBALANCED DRILLING

(No.43) PREDICTION OF PRESSURE DROP REQUIRED FOR SAFE UNDERBALANCED DRILLING

Uploaded by

Ganjar HermadiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

Jour. of Engineering

Wol.10, No.3 (2000) 111-118

PREDICTION OF PRESSURE DROP REQUIRED

FOR SAFE UNDERBALANCED DRILLING

Musaed N. J. Al-Awad and Mohammed M. Amro

Petroleum Engineering Department, College of Engineering,

King Saud University, Riyadh 11421, Saudi Arabia

|LABSTRACT

Many benefits can be gained by te application of unerbalanced diling sich a maximizing hydrocarbon every and

rininiing diling problems,

1a tha work rock mechanics principals are wed to elaborate a mathematical mode to predic prs dup require for fe

‘ndetulanced drilng, Tismodel conbio nea porelatic re solton Mol- Coulomb failure crt androk mechani

propertien {compar th ndcedshear sree whe expermesal maximom allowable her rena fale formation

Fock under comiertion.Furhemare, te elaborated model can be sed for vertical, desional or hrizona well.

‘The model predicted thatthe allowable presse sop required for sae underbalanced dling is Function of ook suengh.

Figherundebalanced presse drop canbe achieved fer strong formation. On the other hand itis imposible to perform,

undebalanced ili for uncoated or very weak orhevily rare formations. Farheroe higher wnderbalanced

presure drop canbe performed for vertical wells i compared to horizontals. Horizontal wells dled parallel tothe

‘minimum horizontal insitapinial ses are the most sable when drilled sing underbalanced ring techiue.

"href, the mathematical rel presenta inthis paper provide power tol fo pediion of he undead perare

op margin required when dling Vera, ietioal or bozo oi orgs well.

2. Introduction

Underbatanced drilling is widely used nowadays to drill different types of reservoirs around the

‘world. Figure I shows the expected annual growth of underbalanced drilling within the next five

years [1], Underbalanced drilling is defined as drilling with the hydrostatic pressure ofthe drilling

‘uid intentionally designed to be lower than the pore fluid pressure of the formation being drilled

‘The hydrostatic mud pressure may be naturally less than the formation pore fluid pressure or it

can be induced. The induced state may be created by adding natural gas, nitrogen or air to the

drilling mud. Whether the underbalanced status is induced or natural, the result wll be an influx

‘of formation fluids, which must be circulated from the well and controlled at surface (2). The

lower hydrostatic pressure avoids the build up of mud cake on the formation as well as invasion of

‘the mud solids into the formation, which helps in improving the productivity of the reservoir.

‘Thus the objectives ofthe underbalanced drilling are {2-7}:

(Maximizing hydrocarbon recovery by reducing formation damage, reducing stimulation jobs

nd extending the life ofthe reservoir.

(Gi) Reducing rig and mud expenses by minimizing drilling problems such as reducing mud

losses, avoiding pipe differential sticking and improving penetration rate,

(ii) Obtaining additional reservoir information during drilling from the flowing reservoir fluids.

ry MUSAED NJ, AL-AWAD AND MOHAMMED M. AMRO

‘The objective of this work is to develop a mathematical technique to simplify the selection process

of pressure drop required for safe underbalanced drilling. The proposed technique accounts for

formation mechanical properties, well geometry and reservoir fluid pressure.

14000 7

12000-] No.of wells = 369,70 + 932.87 (Vear-1994) RA2=0,994

10000

1996 1995 1996 1997 1996 1999 2000 2001 2002 2003 2004 2005

‘Year

Fig. 1 Expected average annual growth of underbalanced drilling applications

around the world [1].

3. The Mathematical Model

Rock mechanics principles ae used to solve many problems facing the oil industry such as sand

production, wellbore instability, hydraulic fracturing, etc (8) n this work a mathematical model

based on rock mechanics principals is elaborated to predict the pressure drop required for safe

underbalanced drilling processes. This model combines in-situ principal tresses, well inclination,

‘well orientation, formation strength criteria and formation piysical properties. Formation rock

failure criteria are evaluated using Moht-Coulom failure criteria which is one ofthe most famous

and applied rock failure criterion, This criteria is defined as follows [9] =

qettotang ~@

‘Three mutual in-situ stresses are assumed namely, the vertical principal in-situ stress (0), the

‘maximum horizontal principal in-situ stess (,) and the minimum horizontal principal in-situ

stress (6). Wellbore instability can be preicted when these principal in-situ stresses are transformed

parallel to the wellbore axis (for inclined or horizontal wells) using the following matrices (see

Fig. 2)(9, 10}

PREDICTION OF PRESSURE DROP REQUIED FOR SAFE UNDERBALANCED PRILLING 113

Fig. 2 Distribution of stresses acting on a deviated well.

o,|=| sin’B cos? 0 Io

oz} [oos*Bsin?a sin? Bsinta costar}. Oy

'0,] eos*Beosta sin*Boosta sin’a fo,

] 2

@)

re)

ble

sin2fsing -sin2fsna 0 Yo,

sin2acosA sin fsin2a -sin2a| oy

cos Bint -sin2poosa 0 |%

‘Three induced stresses are acting on the wall ofa borehole. These are, the vertical induced stress

(c_), the radial induced stress (c,) and the tangentiak induced stress (0,) which can be computed

as follows:

o,

09 = (0, +0, ~ Pre) ~ 2(0, - 0) 00820 ~ 4, sin20

0, = Oy ~ 20(0, ~ 0,) 00820 - Avr, sin 20

ete a)

afory sind + cose

Ter

ue MUSAED N. J. AL-AWAD AND MOHAMMED M. AMRO

By knowing the magnitude of the wellbore (mud) pressure, the induced principal stresses acting

‘on the wall ofa borehole can be computed 2s follows

)=$ lee = oF + 425.

+b leo — 0.7 +4te,

Finally, borehole instability using underbalanced drilling can be predicted by comparing the

‘computed and the experimentally measured shear stresses (see Fig. 3) as follows (11, 12] :

0) = Oy = Pac

1

a, = Hoy +0.

(3)

1

a= Hoo +

eer [2 $2] an 6)

Ts * [54] a

‘Therefore, borehole instability will ake place if the model predicted shear stress is equal or

greater than the laboratory measured shear sires. Data shown in Table I are used to predict the

safe pressure drop required for safe underbalanced drilling

Vertical principal in-situ stress (0,) = 1.0 psi.

Horizontal Maximum principal in-situ stress (0,) = 0.85 psi/f

orizontal Minimum principal in-situ stress (,) = 0.75 psi.

Poisson's ratio (v) = 0.22.

‘Angle of internal fiction (9) = 24 degrees,

‘Apparent cohesion (¢,) = ranging from 160 psi to 1900 psi

Uniaxial compressive strength (o,) = ranging from493 psi to $850 psi.

Pore fluid pressure (D) = 4000 psi.

Wall true vertical depth = 7200 ft

Inclination angle (ct) 0° for vertical well and 90° for horizontal well.

Orientation angle (B) = 0° for well parallel too, and 90° for well parallel to,

Rotation angle around the wellbore 0 = 90°.

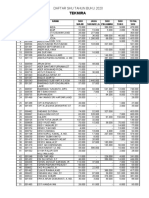

‘Table 1 Formation properties used as model input data,

PREDICTION OF PRESSURE DROP REQUIRED FOR SAFEUNDERBALANCED DRILLING 115

‘maximura principal in-situ stress (04)

Well configuration ‘Acting stresses as

‘Vertical weil parallel to the vertical in- -

situ principal stress (6) oi and oy 085-075 0.10

Horizontal well parallel tothe o

‘minimum principal in-situ stress (0))). ©, and oy 1.00-0.85 =0.15

Horizontal well parallel tothe comin son 075-028

Table 2 Acting in-situ differential tess for various well configurations.

Shear stress

Fig. 3 Representation of shear stresses acting on the vicinity of a borehole

4. Results and

‘Successful application of the underbalanced drilling depends mainly on the monitoring and

‘manipulating the hydrostatic pressure of the drilling fluid. By using the mathematical model

described in this work, the range of the allowable pressure drop in underbalanced drilling was

redicted to ensure hole stability while drilling. Figure 4 shows the range of allowable pressure

6 \MUSAED NJ, ALAWAD AND MOHAMMED M. AMRO

drop for safe underbalanced drilling of three wel configurations. In this figure, different compressive

strength values were taken to calculate the allowable pressure drop. It shows that horizontal wells

Grilled parallel to the minimum in-situ principal stress (6,) have the widest range of allowable

pressure drop that can be applied while borehole stability is maintained. In this case the two

sinu stresses that have an influence on borehole stability are the maximum horizontal principal

situ (0,) and the vertical principal in-situ (o,) as shown in Table 2. Therefore, under the assumed

{in-situ stress state, safe underbalanced drilling operations can be performed onty for formation

having a compressive strength greater than 6000 psi. The other case of horizontal wells that

Grilled parallel to the maximum principal horizontal in-situ stress (0), the minimum horizontal

principal in-situ (6,) and the vertical principal in-situ (0,) are the acting stresses. Thus, the

range of pressure drop required that for safe underbalanced drilling can be performed caly if the

target formation compressive strength exceeds 7600 psi approximately otherwise borehole instability

(collapse) occurs.

In case of vertical well, the in-situ principal stress that influence the stability of the well are the

:inimum principal horizontal in-situ stress (0,), the maximum horizontal principal in-situ (0)

‘Therefore an underbalanced drilling can performed safely only for formations having a compressive

strength greater than 4500 psi under the same in-situ stress state shown in Table 1. However,

borehole instability occurs ifn underbalanced drilling operation would be performed in formations

‘with a compressive strength below 4500 psi regardless the diection or the typeof the drilled hole.

“Therefore the mathematical model presented in this paper can be applied for any type of reservoir

to predict the underbalanced or overbalanced limit in order to maintain borehole stability while

drilling.

Overbalued dling 2

P= (PoP). psi

‘Underbalaned deiling zone

Fe Bothole ded panel w 6,

a Borholedeiled pall w oy,

[Ae Bothote aied parallel 1 oF

vo 2000 oo om soon eioo O80

‘Uniaxial compressive strength, pi

Fig. 4 Predicted allowable pressure drop required for safe underbalanced

‘riling operations.

PREDICTION OF PRESSURE DROP REQUIRED FOR SAFE UNDERBALANCED DRILLING 117

'. Conclusions

‘Based on the output data gained from the application of the elaborated model presented in this

paper, the following conclusions are obtained:

~ Pressure drop required for safe underbalanced drilling is function of rock strength.

= In horizontal wells, the margin for underbalanced pressure drop was found less compared to

‘vertical wells,

= Horizontal wells drilled parallel to the minimum horizontal in-sim principal stress are the

‘most stable when drilled using underbalanced drilling technique.

~ Borehole instability occurs if underbalanced drilling is performed for unconsolidated, weak 0:

heavily fractured formations.

REFERENCES

1. Duda, J, Medley, G. and Deskins, G.: “Strong Growth Projected For Underbalanced Dring”,

Oil And Gas Journal, (Sept. 1996).

2. “Underbalanced Drilling Technology”, By Deutag Northland Underbalanced Drilling Services,

Presented At The Proceedings Of The 1999 SPE Technical Symposium, Dhahran, Saudi

Arabia, (25-27 October, 1999).

3, Butles,S, D. and Teichrob, R, R.: “Monitoring Downhole Pressures And Flow Rates Critical

For Underbalanced Drilling.”, Oil and Gas Journal, (Sept. 16 1996) 31-39.

4, Beanoin, D. B., Thomas, F.B., Biet, R. F. and Bennoin, D. W, :“Underbalanced Drilling

Praises and Perils”, SPE Drilling & Completion, (December, 1998).

‘5, Koji Kusaka, Dinesh Patel, Sam Gomersall, John Mason and Phit Doughty: “Underbalance

Perforation In Long Horizontal Wells In He Andrew Field”, SPE Drilling & Completion,

(December, 1998).

6. Adam, T. and Bourgoynr, Jr. : “Well Control Considerations For Underbalanced Drilling”,

‘SPE Paper No. 38584 Presented At The 1997 SPE Annual Technical Conference, San Antonio,

‘Texas, (5-8 October, 1997).

7. Bennion, D. B., Thomas, F.. Jamaluddin, A. K, M. and Ma, T : “Using Underbalanced

Drilling To Reduce Invasive Formation Damage And Improve Well Productvity.”, Journal

(Of Canadian Petroleum Technology, Vol. 39, No. 7, (2000) 52-60,

8. MusaedN. J. Al-Awad : “Rock Mechanics Applications In Petoleum Engineering Practices”,

Oil And Gas European Magazine, Germany, (December 1998) 18-20.

9, Bjaer E,, Holt RM., Hofsrud P, Ragen AR. and Risnes R.: “Petroleum Related Rock

Mechanics.”, Eisevier Science Publishers B.V., Amsterdam, The Netherlands, 1st edition,

(0992) 338.

us MUSAED N.J. AL-AWAD AND MOHAMMED M. AMRO

10. Musaed N. J, Al-Awad : “Investigation Of Factors Affecting The Stability Of Horizontal Oil

‘And Gas Wells, 1997 SPE Technical Symposium, Saudi Aramco, Dhahran, (June 8-10,

1997) 79-90.

11. Musaed N. J. Al-Awad : “The Investigation Of The Source Of Sand Produced Ftom Competent

Sandstone Reservoirs.”, The Second Jordanian Mining Conference, Jordanian Universi

‘Amman, Jordan, (April 26-29, 1997) 393-405,

12, Musaed N. J, Al-Awad, and Saad El-Din M. Desouky : “Prediction Of Sand Production From

AA Saudi Sandstone Reservoir.", Revue De L’ Institute Francias Du Petrole, Vol. 52, No. 4,

luly-August, 1997) 1-8.

You might also like

- Modul Valve and Fitting Petronas DepanDocument2 pagesModul Valve and Fitting Petronas DepanGanjar HermadiNo ratings yet

- Teori EkonomiDocument58 pagesTeori EkonomiGanjar HermadiNo ratings yet

- ELECTRICAL Post TESTDocument4 pagesELECTRICAL Post TESTGanjar HermadiNo ratings yet

- 4Xlfn 6wduw: Kwwsvwruhvhed/FrpdsdfprghpvDocument29 pages4Xlfn 6wduw: Kwwsvwruhvhed/FrpdsdfprghpvGanjar HermadiNo ratings yet

- TG Global TrendsDocument9 pagesTG Global TrendsGanjar HermadiNo ratings yet

- Shu GabunganDocument23 pagesShu GabunganGanjar HermadiNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)