Professional Documents

Culture Documents

Giant Unloader 22760A

Uploaded by

razaq athab0 ratings0% found this document useful (0 votes)

8 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views2 pagesGiant Unloader 22760A

Uploaded by

razaq athabCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

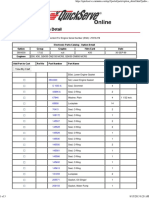

Models

22760A / 22760L / 22760APM

Unloader / Regulator

22760A-SS / 22760-01 (Viton) / 22760-03 (EPDM) = Unloaders

22760AR / 22760LR / 22760ARPM = Regulators

ITEM#PART# DESCRIPTION QTY.

1 12301 Valve Body 1

2 12302 Guide Plug (Except 22760APM, 22760ARPM) 1

2A 12336 Guide Plug (22760APM, 22760ARPM Only) 1

3 06015 O-Ring (Except 22760-01, 22760-03) 1

3 06015-0001 O-Ring, Viton (22760-01Only) 1

3 06015-0003 O-Ring, EPDM (22760-03 Only) 1

4 12303 Piston Rod (Except 22760APM, 22760ARPM) 1

4A 12337 Piston Rod (22760APM, 22760ARPM Only) 1

5 22764 Serrated Pin 1

6 12305 Guide Ring 1

7 12018 Guide Ring 2

8 11507 O-Ring (Except 22760-01, 22760-03) 2

8 11507-0001 O-Ring, Viton (22760-01 Only) 2

8 11507-0003 O-Ring, EPDM (22760-03 Only) 2

10 12307 O-Ring, Piston (Except 22760-01, 22760-03) 1

10 12307-0001 O-Ring, Piston, Viton (22760-01 Only) 1

10 12307-0003 O-Ring, EPDM (22760-03 Only) 1

11 12308 Backup Ring, Piston (Except 22760-01, 22760-03) 1

11 12308-0001 Backup Ring, Viton (22760-01, 22760-03 Only) 1

12 12309 Valve Seat 1

12A 12324 Kick Back Valve Seat 1

13 12014 Valve Ball 1

13A+ 12325 Kick Back Valve Cone 1

13B+ 12326 O-Ring (Except 22760-01, 22760-03) 1

13B+ 12326-0001 O-Ring, Viton (22760-01, 22760-03 Only) 1

14 12321 Bypass Valve Spring 1

15 12007 O-Ring (Except 22760-01, 22760-03) 2

15 12007-0001 O-Ring, Viton (22760-01 Only) 2

15 12007-0003 O-Ring, EPDM (22760-03 Only) 1

16 12311 Plug 1

17A+ 12328 Kick Back Valve Spring 1

18 12313 Spring Retainer (Except 22760A-SS) 1

18 12350-4000 Spring Retainer S.S. (22760A-SS Only) 2

19 12280 Plug 2

20 12332 Copper Seal 2

21 12350-4000 Kick Back Valve, Spring Retainer 1

21A 12351 O-Ring (Except 22760A-SS) 1

21A 12351 O-Ring (22760A-SS Only) 2

21A 07770-0001 O-Ring, Viton (22760-01, 22760-03 Only) 1

22 12317 Lock Nut 1

+Items 13A, 13B, & 17A are not present 23 12318 Spring Tension Disc 1

in 22760AR, 22760LR or 22760ARPM 24 12319 Spring (except 22760L & 22760LR) 1

24 12106 Spring (22760L & 22760LR Only) 1

Repair Kit # 09108 25 13263 Hand Wheel, Brown 1

Includes Items #: 3, 6, 7, 8, 10, 11, 13B, 15, 21A 26 12323 Bearings 1

27 12320 Limiting Nut 2

Repair Kit # 09108-01 - Viton

28 12335 Nut (22760APM, 22760ARPM Only) 1

Includes Items #: 3, 6, 7, 8, 10, 11, 13B, 15, 21A 29 12333 Retainer (22760APM, 22760ARPM Only) 1

Repair Kit # 09108-03 - EPDM 30 12334 Lock Washer (22760APM, 22760ARPM Only) 1

Includes Items #: 3, 6, 7, 8, 10, 11, 13B, 15, 21A

OPERATING CONDITIONS

U.S (Metric)

Flow (22760A, 22760AR, 22760ARPM, 22760APM, 22760A-SS, 22760-01): ....... 1.3 - 8 GPM ........ (5-30 L/min)

Flow (22760L ,22760LR & 22760-03): ..................................................................... 0.03 - 8 GPM ...... (0.1 - 30 L/min)

Pressure (22760A, 22760AR, 22760ARPM, 22760APM, 22760A-SS, 22760-01): . 145 - 3045 PSI ... (10 - 210 Bar)

Pressure (22760L, 22760LR & 22760-03): .............................................................. 600 PSI .............. (40 bar)

Max Temp.: ................................................................................................................ 1600 F ................. 700 C

Inlet Port: ................................................................................................................................................. 3/8" FNPT

Outlet Port: .............................................................................................................................................. 3/8" FNPT

Bypass: ................................................................................................................................................... 1/4" FNPT

INSTALLATION & OPERATING INSTRUCTIONS

Construction Characteristics

• Ball Kick-Back Valve, Tapered Kick-Back Valve or Plate Kick-Back Valve

• Interchangeable Stainless Steel Valve Seats.

• Connections for Pressure Gauge, Pressure Switch and Flow Switch.

Operation

The whole discharge must be guided through the valve. Should the actual operating pressure

exceed the adjusted operating pressure, the valve then acts as a pressure regulator. When the

spray gun shuts off, the valve switches to pressure-free bypass operation, and the spray pressure

between gun and valve remains idle. The valve can be operated together with several spray guns.

It is also possible to connect several pumps to one common discharge line.

Service and Adjustment

Service and adjustment of the unloader should only be performed by a skilled tradesmen.

Safety Instructions

Observe direction of flow. Under no circumstances, should the bypass be closed or

fitted with any shut-off device.

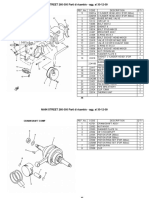

Replacement of Piston Seals

1. Remove the guide plug (2) out of valve body (1). Remove the serrated pin (5) and take the

piston rod (4/4A) out of plug.

2. Cut out the worn seals.

3. Grease all parts lightly with Silicone before reinstalling.

4. Put guide ring (6), O-ring (8) and guide ring (7) carefully over the threads onto the piston rod.

Note order of installation.

5. Clip the O-ring (10) and backup rings (11) onto the piston body. Check inner surfaces of casing

and guide plug (dirt or damage will quickly wear out seals).

To Check Valves

1. Remove the plugs (16, 18, 21) and examine balls (13) and cones (13A), as well as valve seats

(12 /12A) for wear.

2. Valve seats can be removed with an inner-hexagon-wrench (6mm). If the valve seat (12) (in the

kick-back ball version) is worn, the ball (13) must be “coined” carefully against the sealing

edges of the valve seat.

3. Glue in new valve seats with Loctite 572. Before putting into operation, allow the glue to dry for

60 minutes.

Adjusting Pressure

1. The Valve should be tension-free, i.e., loosen nut (22) and hand wheel (25) so that the piston

rod (4/4A) can be moved manually.

2. Spring tension is performed with the pressure spring (24) and nut (22) via the spring tension

disc (23). Adjustments are to be made with an open gun [if multiple guns are used, all need to be

open] and while the pump is running. When the required operating pressure has been reached,

no more water should run out on the bypass side. On the hand-wheel-version, the maximum

operating pressure can be set by tightening and locking the limiting nut (27) to the spring tension

disc (23). Various operating pressures (up to the maximum operating pressure) can be set by

turning the hand wheel. If the nozzle hole is properly suited to the output and pressure of the

pump, no more water should flow through the bypass after the required operating pressure has

been reached. If the required operating pressure has been reached and the nozzle hole is too

small to allow all the fluid to run through the hole, do not adjust account the valve higher than

the maximum operating pressure of the pump. In this case, the bypass is to be left partially

open. Nevertheless, it is recommended to use properly sized nozzles.

Troubleshooting Guide

Problem Cause Remedy

Leaky gun Repair gun

Valve switches Leaky pressure pipe Seal pressure pipe

repeatedly when gun is Leaky O-rings (8,10) Replace O-rings.

closed Worn out kick-back valve Replace kick-back valve body or o-ring

body (12A) or o-ring (13B) or examine valve seat. Giant Industries, Inc.

900 N. Westwood Ave.

Defective O-Ring (8) / Replace piston rod seals and examine Toledo, Ohio 43607

Leaky piston rod

support Ring (7) surfaces in guide plug

419-531-4600

Nozzle too small, too

Install larger nozzle

419-531-6836 Fax

Leaky bypass at much water

www.giantpumps.com

nominal pressure Examine ball (13) and bypass valve

Worn out bypass valve

body (12) and renew as necessary

© Copyright 2010

Pressure Gauge shows Giant Industries, Inc.

Valve set too high above Turn back hexagon nut (22) or hand

high pressure peaks

operating pressure wheel (25) or readjust locking nuts (27)

when shutting off gun 02/10 22760A.PMD

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Fuel System 15-00 (Hino Engine Type J08etm-Ksda)Document5 pagesFuel System 15-00 (Hino Engine Type J08etm-Ksda)ABELARDO PINA0% (1)

- SQ100Document3 pagesSQ100Solrac Nauj Ogaitnas100% (1)

- OIL TANK - CRAWLER EXCAVATOR Doosan SOLAR 340LC-7 - BODY PARTS - 777partsDocument2 pagesOIL TANK - CRAWLER EXCAVATOR Doosan SOLAR 340LC-7 - BODY PARTS - 777partsSRINIVASA RAO MARTURINo ratings yet

- Breaker (Internal Parts) (HB980) - (S - N A00Y00101 - A00Y19999) - BreakerDocument3 pagesBreaker (Internal Parts) (HB980) - (S - N A00Y00101 - A00Y19999) - Breakeryoga_jpbmbm0% (1)

- MAIN PIPING (3) - WHEEL EXCAVATOR Doosan DX55W - BODY PARTS - 777partsDocument2 pagesMAIN PIPING (3) - WHEEL EXCAVATOR Doosan DX55W - BODY PARTS - 777partsJUAN CARDONANo ratings yet

- Fig.2. Gear Housing: (E) (D) (C) (B) (A) 4TNE106T-TBLDocument1 pageFig.2. Gear Housing: (E) (D) (C) (B) (A) 4TNE106T-TBLComercial AlfaOmega LimitadaNo ratings yet

- Dt200r Parts BookDocument44 pagesDt200r Parts BookGeeNo ratings yet

- Yanmar 4tne106tDocument23 pagesYanmar 4tne106tMarielis Contreras100% (2)

- Despiece GN125Document51 pagesDespiece GN125elreyleon1100% (1)

- 3tnv82a SybDocument27 pages3tnv82a SybKerim SpiljakNo ratings yet

- Mangueras y BombaDocument3 pagesMangueras y BombaRamón ManglesNo ratings yet

- Yanmar 4tnv98t Gge Engine Parts CatalogDocument3 pagesYanmar 4tnv98t Gge Engine Parts Cataloglawrence100% (45)

- Suzuki AX100-115 - DespieceDocument51 pagesSuzuki AX100-115 - DespieceLeandro BelleraNo ratings yet

- 4tnv106t GgehcDocument22 pages4tnv106t GgehcDzmitryNo ratings yet

- 3 Ym 20Document39 pages3 Ym 20sergeateliermarineNo ratings yet

- Hydrostatic Circuitry (W - Cooling Fan Motor) (W - Cooling Upgrade) - (S - N 531115051 - 531139999, 531211661 - 531239999) - S300Document3 pagesHydrostatic Circuitry (W - Cooling Fan Motor) (W - Cooling Upgrade) - (S - N 531115051 - 531139999, 531211661 - 531239999) - S300yonathan nelsonNo ratings yet

- 4 DL MicroficheDocument56 pages4 DL MicroficheMelvin ScorfnaNo ratings yet

- 250cc (RMX250S SJ13A 1989-1996)Document86 pages250cc (RMX250S SJ13A 1989-1996)CarolinaMuñozAvalos100% (1)

- Illustrated Part Breakdown: MODEL: T30-P Engine Air StarterDocument4 pagesIllustrated Part Breakdown: MODEL: T30-P Engine Air StarterTAYFUNNo ratings yet

- 4tn100te-Gb1 4tn100teDocument100 pages4tn100te-Gb1 4tn100teXavier Solias Ribalta100% (1)

- Hydraulic Piping (1 - 2) (Front Attachment Line) - Wheel Loader Komatsu Wa20-1 - Work Equipment Control System 777partsDocument2 pagesHydraulic Piping (1 - 2) (Front Attachment Line) - Wheel Loader Komatsu Wa20-1 - Work Equipment Control System 777partsashraf elsayedNo ratings yet

- 590 - Turbo Loader Backhoe (01/88 - 12/91) 06 - Power Train 6-10 - Torque Converter Housing, Pump and Output ShaftDocument4 pages590 - Turbo Loader Backhoe (01/88 - 12/91) 06 - Power Train 6-10 - Torque Converter Housing, Pump and Output ShaftJESUS100% (1)

- 4JH2 Yanmar Parts Catalog Y00R3512 000Y00R3512 PDFDocument110 pages4JH2 Yanmar Parts Catalog Y00R3512 000Y00R3512 PDFMAJID SADEGHIANNo ratings yet

- Magnapunch Parts PunchDocument18 pagesMagnapunch Parts PunchAlex GonzalezNo ratings yet

- 580M Siii Carcasa de La Transmision 4WDDocument3 pages580M Siii Carcasa de La Transmision 4WDALEX DIEGONo ratings yet

- 750cc (GSX750 AE111 1998-2001)Document61 pages750cc (GSX750 AE111 1998-2001)eternalrider2No ratings yet

- BRAKE PIPING (2) - WHEEL EXCAVATOR Doosan DX55W - BODY PARTS - 777partsDocument2 pagesBRAKE PIPING (2) - WHEEL EXCAVATOR Doosan DX55W - BODY PARTS - 777partsJUAN CARDONANo ratings yet

- 01 6CHL-N PDFDocument403 pages01 6CHL-N PDFGladson GladsonNo ratings yet

- Kioti PX1103PSC-JP, PX9030PSC-JP Tractor Parts ManualDocument10 pagesKioti PX1103PSC-JP, PX9030PSC-JP Tractor Parts ManualLisakolyNo ratings yet

- 2 Ym 15Document38 pages2 Ym 15sergeateliermarineNo ratings yet

- Parts Catalog - Option DetailDocument3 pagesParts Catalog - Option DetailRudiansyah RudiNo ratings yet

- Rotary Hammer - 0 611 228 703 - GBH 2-24 DSRDocument5 pagesRotary Hammer - 0 611 228 703 - GBH 2-24 DSRFrancois VaaltynNo ratings yet

- Hydraulic Circuitry (Cooler, Filter, Tank) - MT55Document4 pagesHydraulic Circuitry (Cooler, Filter, Tank) - MT55Iliyan VasilevNo ratings yet

- ) ) CT20 Parts - Pedido Stock Crítico 15-04-11 - Rudyñ-Ñ-ÑDocument23 pages) ) CT20 Parts - Pedido Stock Crítico 15-04-11 - Rudyñ-Ñ-Ñjhon ramosNo ratings yet

- Cylinder Head & BonnetDocument7 pagesCylinder Head & BonnetYamahauki SusukiNo ratings yet

- 2 MainstreetDocument25 pages2 MainstreetyoNo ratings yet

- 250cc (GN250 NJ41A 1996-2001)Document74 pages250cc (GN250 NJ41A 1996-2001)Balazs Bruzsenyak100% (1)

- Tlglf4b 09 09 MarkedDocument2 pagesTlglf4b 09 09 MarkedyuanNo ratings yet

- 344-2149 Cylinder Head GPDocument2 pages344-2149 Cylinder Head GPmuhammad rusdiansyahNo ratings yet

- RX-K Rx-King Crankshaft & PistonDocument1 pageRX-K Rx-King Crankshaft & PistonDevii AryaNo ratings yet

- TDI T30-P Air Starter Illustrated Parts Breakdown T30-P-716 - 6701234 - 01Document4 pagesTDI T30-P Air Starter Illustrated Parts Breakdown T30-P-716 - 6701234 - 01Rogelio PerezNo ratings yet

- CHN 25Document14 pagesCHN 25bapsi01100% (1)

- Lift Cylinder - Wheel Loader Komatsu Wa20-1 - Work Equipment Control System 777partsDocument2 pagesLift Cylinder - Wheel Loader Komatsu Wa20-1 - Work Equipment Control System 777partsashraf elsayedNo ratings yet

- Flywheel YanmarDocument1 pageFlywheel YanmarĐặng MinhNo ratings yet

- Part Book of Transmission JS200TDocument15 pagesPart Book of Transmission JS200TJohny Mazer IchsanNo ratings yet

- 20 & 29 Usgpm Variable Thru Shaft, Side Ported, Inline Piston PumpsDocument4 pages20 & 29 Usgpm Variable Thru Shaft, Side Ported, Inline Piston PumpsMahmoud Abo-hashemNo ratings yet

- Parts List Price KohlerDocument715 pagesParts List Price KohlerMuh SabriNo ratings yet

- KHE37 Parts Manual - SCCA 2014Document41 pagesKHE37 Parts Manual - SCCA 2014Rogelio MirelesNo ratings yet

- UntitledDocument37 pagesUntitledDiesel RuizNo ratings yet

- TORQUE CONVERTER - Wheel Loader Komatsu WA120-1 - TORQUE CONVERTER AND TRANSMISSION 777partsDocument2 pagesTORQUE CONVERTER - Wheel Loader Komatsu WA120-1 - TORQUE CONVERTER AND TRANSMISSION 777partsashraf elsayedNo ratings yet

- T115le Vega-Zr TransmissionDocument1 pageT115le Vega-Zr TransmissionPuji RiatnoNo ratings yet

- Tor23 Parts BookDocument20 pagesTor23 Parts BookDavid MusanNo ratings yet

- SoftCare2 Pro ManualDocument233 pagesSoftCare2 Pro Manualrazaq athabNo ratings yet

- HydroMinder 511Document2 pagesHydroMinder 511razaq athabNo ratings yet

- Software Test Rig Development and TestinDocument67 pagesSoftware Test Rig Development and Testinrazaq athabNo ratings yet

- HydroMinder 506Document2 pagesHydroMinder 506razaq athabNo ratings yet

- Buderus 600 - 11S - 19S - 24S - 24C - MAR - 10 Service ManualDocument68 pagesBuderus 600 - 11S - 19S - 24S - 24C - MAR - 10 Service Manualrazaq athabNo ratings yet

- 3 Floor, UB Centre, Bakhtyari, Erbil: Gulf Keystone Petroleum International LTD Kurdistan Region of IraqDocument1 page3 Floor, UB Centre, Bakhtyari, Erbil: Gulf Keystone Petroleum International LTD Kurdistan Region of Iraqrazaq athabNo ratings yet

- ARO Pump ManualDocument8 pagesARO Pump Manualrazaq athabNo ratings yet

- Cummins Insite 8.5.2 With Keygen Free Download, Setup, Activation - OBDII365.com Official BlogDocument6 pagesCummins Insite 8.5.2 With Keygen Free Download, Setup, Activation - OBDII365.com Official Blograzaq athabNo ratings yet

- Unit-3 Automotive Accessories & Lighting SystemsDocument19 pagesUnit-3 Automotive Accessories & Lighting Systemsrazaq athabNo ratings yet

- Computers and On-Board Diagnostics: ObjectivesDocument15 pagesComputers and On-Board Diagnostics: Objectivesrazaq athabNo ratings yet

- How To Test A Manifold's Absolute Pressure Map SensorDocument5 pagesHow To Test A Manifold's Absolute Pressure Map Sensorrazaq athabNo ratings yet

- Part 1 - How To Test The Manifold Absolute Pressure (MAP) Sensor (GM 2.2L)Document7 pagesPart 1 - How To Test The Manifold Absolute Pressure (MAP) Sensor (GM 2.2L)razaq athabNo ratings yet

- Scan Tool Test ProceduresDocument42 pagesScan Tool Test Proceduresrazaq athabNo ratings yet

- All Vehicle Systems - جميع منظومات السيارة الحديثهDocument1 pageAll Vehicle Systems - جميع منظومات السيارة الحديثهrazaq athabNo ratings yet

- Stylus cx3700 SeriesDocument40 pagesStylus cx3700 Seriesrazaq athabNo ratings yet

- 300kW User ManualDocument76 pages300kW User Manualrazaq athabNo ratings yet

- Auto Start & Auto Mains Failure Control Modules: GensetDocument3 pagesAuto Start & Auto Mains Failure Control Modules: Gensetrazaq athabNo ratings yet

- Automatic Washing MachineDocument36 pagesAutomatic Washing Machinerazaq athabNo ratings yet

- How To Install Perkins EST 2018A & 2016C On Win7 & Win10 - Auto Repair Technician Home PDFDocument1 pageHow To Install Perkins EST 2018A & 2016C On Win7 & Win10 - Auto Repair Technician Home PDFrazaq athabNo ratings yet