Professional Documents

Culture Documents

Mti035390 - Rev C

Uploaded by

cadav16951Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mti035390 - Rev C

Uploaded by

cadav16951Copyright:

Available Formats

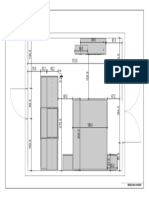

150.0 5.

91

120.0 4.72

15.0 .59 110.0 4.33

R136.0 5.35

16.0 .63 R415.0 16.34

60.0 2.36 60.0 2.36 80.0 3.15 2 PLACES

2 PLACES

12.0 .47

160.0 6.30 5 5

22.5 .89

107.5 4.23

20.0 .79

90.0 3.54

R5.0 .20

45.0 1.77

272.0 10.71

215.0 8.46

75.0 2.95

90.0 3.54 180.0 7.09 CL

107.5 4.23

135.0 5.31

35.0 1.38

3.2

3.2

10.0 .39

8X 13.5 0.53 THRU. B

105.0 4.13 REF 9.5 .37

4X M12X1.75

133.0 5.24 55.0 2.17

CL THRU

75.0 2.95 65.0 2.56 C

169.0 6.65

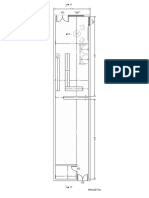

ALL WELDS TO BE FULL, AND CONTINUOUS WHERE C ADDED 65mm HOLE 14 OCT 2019 JDD

POSSIBLE. B 52mm HOLE ADDED & DIMENSION CHANGED FROM 90mm TO 105mm 13/09/2017 LB

160x80x5 S2355JRH A INITIAL RELEASE 31/05/2016 SG

THERMAL STRESS RELIEVE AND REMOVE SCALE AFTER REV. DESCRIPTION DATE APPROVED

WELDING.

MTI WELDING TECHNOLOGIES LTD

WWW.MTIWELDING.COM 80 BAY 1, FIRST AVE, PENSNETT ESTATE, KINGSWINFORD, DY6 7FQ, UK

VENDOR SHALL ALLOW FOR WELD JOINT FIT UP, This drawing and all information hereon constitute confidential BREAK SHARP EDGES

SHRINKAGE AND WARPING. MACHINING and proprietary property of MTI. Any disclosure, transmission,

UOS PERMISSIBLE VARIATION

0 UPTO 10 = 0.15 .5MM MAX UNLESS NOTED

ALLOWANCES ARE FOR REFERENCE ONLY, ACTUAL copying, altering, or modifying of this drawing or any

information hereon without written permission of MTI is

10 UPTO 50 = 0.25

50 UPTO 100 = 0.50

CLEAN & REMOVE CHIPS.

MACHINING ALLOWANCES ARE AT THE VENDOR'S expressly prohibited. This paragraph shall apply regardless of

any agreement, purchase order or other writing or

100 UPTO 500 =

OVER 500 = 1.00

0.75

THIRD ANGLE

DISCRETION. documentation to the contrary. ANGLE 2 PROJECTION

ENGINEERED BY DRAWN BY CHECKED BY APPROVAL DATE SCALE WEIGHT (KG)

MASK ALL MACHINED SURFACES. PAINT TO SDG SDG AS 31-05-2016 1:2 7.5

SPECIFICATION SUPPLIED WITH PURCHASE ORDER.

MATERIAL TREATMENT

EN 10025-S275 (BS 4360-GR43A) POWDER COATED

FABRICATION TOLERANCES - DIN EN ISO 13920 Class B RAL9001 (CREME WHITE)

UNLESS OTHERWISE SPECIFIED

TITLE REFERENCE P/N SHEET SIZE SHEET NUMBER

Over Over Over Over Over Over Over Over

2 30 400 1000 2000 4000 8000 12000 16000 Over

HMI ARM STANDOFF A3 1 OF 2

to up to up to up to up to up to up to up to up to 20000

BRACKET

PART NUMBER REVISION

30 400 1000 2000 4000 8000 12000 16000 20000

1 2 3 4 6 8 10 12 14 16 1. MTI035390 C

40. FWT 100 040 MENON PISTON MACHINE\00.Previous Data\Machine\ 21-10-2021 18:34:29

52.5 2.07

80.0 3.15

52.0 2.05

MTI WELDING TECHNOLOGIES LTD

WWW.MTIWELDING.COM 80 BAY 1, FIRST AVE, PENSNETT ESTATE, KINGSWINFORD, DY6 7FQ, UK

This drawing and all information hereon constitute confidential UNLESS OTHERWISE SPECIFIED BREAK SHARP EDGES

and proprietary property of MTI. Any disclosure, transmission, PERMISSIBLE VARIATION .5MM MAX UNLESS NOTED

copying, altering, or modifying of this drawing or any CLEAN & REMOVE CHIPS.

information hereon without written permission of MTI is ANGLE 2.0

expressly prohibited. This paragraph shall apply regardless of X 1.5 mm FINISH

X.X 0.5 mm Ra μm THIRD ANGLE

any agreement, purchase order or other writing or PROJECTION

documentation to the contrary. X.XX 0.13 mm

ENGINEERED BY DRAWN BY CHECKED BY APPROVAL DATE SCALE WEIGHT (KG)

SDG SDG AS 31-05-2016 1:2 7.5

MATERIAL TREATMENT

EN 10025-S275 (BS 4360-GR43A) POWDER COATED

RAL9001 (CREME WHITE)

TITLE REFERENCE P/N SHEET SIZE SHEET NUMBER

HMI ARM STANDOFF A3 2 OF 2

BRACKET

PART NUMBER REVISION

1. MTI035390 C

P:\40. FWT 100 040 MENON PISTON MACHINE\00.Previous Data\Machine\ 21-10-2021 18:34:29

You might also like

- 300398035a Final Receiving-ModelDocument1 page300398035a Final Receiving-Modelrohit_parashar1992No ratings yet

- Bioseed Fire Hydrant Hydraulic Analysis Schematic DiagramDocument1 pageBioseed Fire Hydrant Hydraulic Analysis Schematic DiagramzaccNo ratings yet

- TerasaDocument1 pageTerasaAndreea DanNo ratings yet

- Pg068 - T11 Conductor ResistanceDocument1 pagePg068 - T11 Conductor ResistanceDolyNo ratings yet

- Chemical Injection Flow RateDocument5 pagesChemical Injection Flow RateMark Dominic FedericoNo ratings yet

- Laboratorio 01 EL NUMERO PIDocument4 pagesLaboratorio 01 EL NUMERO PIAnonymous spq6Rc9HCNo ratings yet

- HDM 128GS24: Dimensional DrawingDocument2 pagesHDM 128GS24: Dimensional DrawingMitchell DanielsNo ratings yet

- SP Wearing GradationDocument1 pageSP Wearing GradationUsman RafiqNo ratings yet

- Print PlotDocument1 pagePrint PlotPriyabrata RoyNo ratings yet

- Option 3Document1 pageOption 3stephanNo ratings yet

- Denah Lt.2Document1 pageDenah Lt.2Tiga PagiNo ratings yet

- Ejercicio en ClaseDocument11 pagesEjercicio en Clase77475690No ratings yet

- Ejercicio en Borrador MicroDocument2 pagesEjercicio en Borrador MicroMelissa HawkinsNo ratings yet

- Tamplarie GalgauDocument1 pageTamplarie GalgauOana VaidaNo ratings yet

- Eb Ssep 1.1 13Document1 pageEb Ssep 1.1 13vandana sathishNo ratings yet

- 5to. NIVEL CanchaDocument1 page5to. NIVEL CanchaJorge ManuelNo ratings yet

- Design 001Document3 pagesDesign 001Carlos Alvarez L.No ratings yet

- Red CerradaDocument2 pagesRed CerradaNiler Nehemías Trinidad InocencioNo ratings yet

- Planta 2 Puerto MexicoDocument1 pagePlanta 2 Puerto MexicoPedro BernalNo ratings yet

- 3 Tecnicas AcotadaDocument1 page3 Tecnicas AcotadaDanny MaczNo ratings yet

- Data GC WillDocument30 pagesData GC Willrausyan fikriNo ratings yet

- Plan-Converted Merged OrganizedDocument20 pagesPlan-Converted Merged OrganizedDarel John CagapeNo ratings yet

- Sieve AnalysisDocument9 pagesSieve AnalysisAsif Abbas KhushalNo ratings yet

- A D E H F B: Planta Alta ESC. 1: 100Document1 pageA D E H F B: Planta Alta ESC. 1: 100Dani HernándezNo ratings yet

- CBR Results For Collected Soil Sample From Filling Area (Base Course) at NRO of IOCL at Munavalli Village of Shiggaon, Haveri DistDocument5 pagesCBR Results For Collected Soil Sample From Filling Area (Base Course) at NRO of IOCL at Munavalli Village of Shiggaon, Haveri DistDevaraj H.ANo ratings yet

- The Tolerance Unless Classified 0.3mm: Outline Dimension & Block DiagramDocument1 pageThe Tolerance Unless Classified 0.3mm: Outline Dimension & Block DiagramadilNo ratings yet

- Crane GirderDocument3 pagesCrane GirderMohamed Alaa ElsheriefNo ratings yet

- Pipe DonghwaDocument1 pagePipe DonghwaNguyễn Văn TâyNo ratings yet

- Bioseed Fire Hydrant Schematic DiagDocument1 pageBioseed Fire Hydrant Schematic DiagzaccNo ratings yet

- Combistop 38: Instruction and Mounting Manual Type 38 / GBDocument2 pagesCombistop 38: Instruction and Mounting Manual Type 38 / GBGENTA NUSA ATLANTISNo ratings yet

- Supply Lead ResistanceDocument2 pagesSupply Lead ResistanceCharlie Dela RosaNo ratings yet

- Papel de Weibull Ing Rosado Pacheco, ReneDocument1 pagePapel de Weibull Ing Rosado Pacheco, Renejos luis rodriguez floresNo ratings yet

- 1 HW1 FinishedDocument5 pages1 HW1 Finishedheckwithit9No ratings yet

- Data Hujan HarianDocument34 pagesData Hujan HarianAgung RubianNo ratings yet

- Tablas CeneguelDocument1 pageTablas CeneguelMargarito Robles KingNo ratings yet

- VODRV DN65-DN300 Flow Measurement Brochure CraneFS PDFDocument8 pagesVODRV DN65-DN300 Flow Measurement Brochure CraneFS PDFvineeth8624No ratings yet

- VODRV DN65-DN300 Flow Measurement Brochure CraneFS PDFDocument8 pagesVODRV DN65-DN300 Flow Measurement Brochure CraneFS PDFvineeth8624No ratings yet

- Roofdeck Plan: Proposed Two (2) - Storey Commercial Building With RoofdeckDocument1 pageRoofdeck Plan: Proposed Two (2) - Storey Commercial Building With Roofdeckdante mortelNo ratings yet

- Pianta Progetto V2Document1 pagePianta Progetto V2Daniel BunayNo ratings yet

- H Seal ProfileDocument5 pagesH Seal ProfileChrisNo ratings yet

- DENAH-Layout1 (4) 2Document1 pageDENAH-Layout1 (4) 2ILHAM FAISALNo ratings yet

- ENGG1811 Spreadsheet LabDocument18 pagesENGG1811 Spreadsheet Labsri.nellaiappanextraNo ratings yet

- Postcovid Inflation2Document1 pagePostcovid Inflation2ayusha chandrikapureNo ratings yet

- 100m2 PDFDocument1 page100m2 PDFHv ScNo ratings yet

- 4 STOREY SCHMTC Hydrant-ModelDocument1 page4 STOREY SCHMTC Hydrant-ModelzaccNo ratings yet

- Time (Minutes) Time (Minutes)Document3 pagesTime (Minutes) Time (Minutes)Karl HelbiroNo ratings yet

- Ing. Hospital-Layout2Document1 pageIng. Hospital-Layout2santodelacruzNo ratings yet

- BiofeedbackDocument1 pageBiofeedbackJuan Manuel JorqueraNo ratings yet

- Asia Speed Reading Progress ChartDocument1 pageAsia Speed Reading Progress ChartfrogsruletheworldNo ratings yet

- Tarea 2.informe de La Primera Inspección Ocular de La EdificaciónDocument3 pagesTarea 2.informe de La Primera Inspección Ocular de La EdificaciónDaniel OrtegaNo ratings yet

- Plano Casa Planta6x6 Terreno7x15 2p 3d 1.5b Verplanos - Com 0029Document1 pagePlano Casa Planta6x6 Terreno7x15 2p 3d 1.5b Verplanos - Com 0029ARENAS VERGARA GUSTAVO ANGEL ARQUITECTURANo ratings yet

- Final Receiving-Mode2Document1 pageFinal Receiving-Mode2rohit_parashar1992No ratings yet

- Manufacturers Pump Curve Data Pump Curves For New ConditionsDocument1 pageManufacturers Pump Curve Data Pump Curves For New Conditionsanto3harrish3fdoNo ratings yet

- Anggraini Lenry Rahman (1910247973) - TUGAS 1 - Sistem Pengambilan KeputusanDocument8 pagesAnggraini Lenry Rahman (1910247973) - TUGAS 1 - Sistem Pengambilan Keputusananggraini.lenryrahmaNo ratings yet

- Dhoma Gjumit GjermaniDocument1 pageDhoma Gjumit GjermaniVanesa KrasniqiNo ratings yet

- Plano para LAR-ModelDocument1 pagePlano para LAR-Modelrosita urbinaNo ratings yet

- A 1 Linear Terminal Ground and Second Floor Plan: Open AreaDocument1 pageA 1 Linear Terminal Ground and Second Floor Plan: Open AreaJOHN KEAN NIEMONo ratings yet

- Data Untuk Routing Waduk: Hasil PerhitunganDocument2 pagesData Untuk Routing Waduk: Hasil PerhitunganSiti RauhunNo ratings yet

- 1 ModelDocument1 page1 ModelMohammad MehrabiNo ratings yet

- The Challenge To Live According To The Gospel: 21 February 2021 1st Sunday of Lent Year BDocument4 pagesThe Challenge To Live According To The Gospel: 21 February 2021 1st Sunday of Lent Year BSam MaestroNo ratings yet

- Reading Comprehension Pre TestDocument7 pagesReading Comprehension Pre TestMimimiyuhNo ratings yet

- IIRDocument2 pagesIIRJagan FaithNo ratings yet

- Pasir Ex UD - Am Tes 2024Document8 pagesPasir Ex UD - Am Tes 2024Achmad MaulanaNo ratings yet

- Lesson Plan Entre P Dec 7Document12 pagesLesson Plan Entre P Dec 7yannie isananNo ratings yet

- Mum LatecityDocument14 pagesMum LatecityGkiniNo ratings yet

- Classification by Depth Distribution of Phytoplankton and ZooplanktonDocument31 pagesClassification by Depth Distribution of Phytoplankton and ZooplanktonKeanu Denzel BolitoNo ratings yet

- If Else ExercisesDocument5 pagesIf Else ExercisesHoney Jean PerezNo ratings yet

- Answerkey Precise ListeningDocument26 pagesAnswerkey Precise ListeningAn LeNo ratings yet

- 2.HVT Terminacion InstrDocument18 pages2.HVT Terminacion Instrelectrica3No ratings yet

- Annual Implementation Plan FinalDocument3 pagesAnnual Implementation Plan FinalMichelle Ann Narvino100% (2)

- Dunhill The Old WindmillDocument2 pagesDunhill The Old WindmillMaría Hernández MiraveteNo ratings yet

- Fire Master Mirine PlusDocument3 pagesFire Master Mirine PlusCarlos BarriosNo ratings yet

- Neonatal HypothermiaDocument8 pagesNeonatal Hypothermiamia liaNo ratings yet

- Securing Your Organization From Modern Ransomware: Ransomware Attacks Are Now A Team EffortDocument11 pagesSecuring Your Organization From Modern Ransomware: Ransomware Attacks Are Now A Team EfforttiagouebemoraisNo ratings yet

- Kyt KtiDocument13 pagesKyt KtiIbunnaya100% (1)

- ESET TechnologyDocument21 pagesESET TechnologyValentin SalcianuNo ratings yet

- Advantage Dis OqpskDocument5 pagesAdvantage Dis OqpskHarun AminurasyidNo ratings yet

- Lesson Plan - Manner, Matter, and MethodDocument3 pagesLesson Plan - Manner, Matter, and MethodRIVALDO MALAWATNo ratings yet

- Pengaruh PH Ekstraksi Terhadap Rendemen, Sifat Fisiko-Kimia Dan Fungsional Konsentrat Protein KACANG GUDE (Cajanus Cajan (L.) Millsp.)Document11 pagesPengaruh PH Ekstraksi Terhadap Rendemen, Sifat Fisiko-Kimia Dan Fungsional Konsentrat Protein KACANG GUDE (Cajanus Cajan (L.) Millsp.)Rezaa RezNo ratings yet

- New Criticism Hills Like White Elephants FinalDocument4 pagesNew Criticism Hills Like White Elephants Finalapi-313631761No ratings yet

- Proceso Gmaw (RMD)Document8 pagesProceso Gmaw (RMD)Wilfredo RamirezNo ratings yet

- Polyethylene PolyamineDocument6 pagesPolyethylene PolyamineAV kayanNo ratings yet

- BS en 13369-2018 - TC - (2020-11-30 - 09-45-34 Am)Document164 pagesBS en 13369-2018 - TC - (2020-11-30 - 09-45-34 Am)Mustafa Uzyardoğan100% (1)

- Transfer Request 2022 - CBOA CHENNAIDocument5 pagesTransfer Request 2022 - CBOA CHENNAIVignesh NarayananNo ratings yet

- Kuka Interbus InterfaceDocument11 pagesKuka Interbus InterfaceAnonymous Zh6p3ENo ratings yet

- 18TE72 - Wireless Communication Experiential Learning ReportDocument10 pages18TE72 - Wireless Communication Experiential Learning ReportRitika BakshiNo ratings yet

- 5.1 CompleteDocument11 pages5.1 Completenyanmoemyat2010No ratings yet

- RLA-Grade 6 2023Document4 pagesRLA-Grade 6 2023Catherine Mabini BeatoNo ratings yet

- Structural Analysis of English SyntaxDocument26 pagesStructural Analysis of English SyntaxremovableNo ratings yet