Professional Documents

Culture Documents

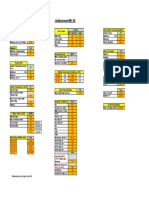

Check Sistemas King Air E90-1

Uploaded by

sergio leivaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Check Sistemas King Air E90-1

Uploaded by

sergio leivaCopyright:

Available Formats

Chequeos en tierra de los sistemas King Air E90

FUEL SYSTEM

1. FUEL FIRE VALVE SWITCHES-àCLOSED

2. FUEL SYSTEM CIRCUIT BRAKERSàCHECK

3. STANDBY PUMPSà(Escuchar para la operación)

4. BATTERY SWITCH-->ON ( Fuel Pressure Light – ON)

5. FUEL FIREWALL VALVE SWITCHESàOPEN ( Fuel Pressure Lights – OFF)

6. LEFT STANDBY PUMPàOFF (Left Fuel Pressure Light – ON)

7. CROSSFEED SWITCHàOPEN (Crossfeed light – ON ;Left Fuel Pressure Light OFF)

8. CROSSFEED SWITCHàCLOSE

9. RIGHT STANDBY PUMPàOFF (Right Fuel Pressure Light – ON)

10. FUEL QUANTITYàCHECK (Main and Auxiliary)

11. FIRE DETECTION-----à TEST

FIRE DETECTION

1. MOVER EL TEST SWITCH DE OFF POR CADA POSICION ( OFF – 1 – 2 Y 3 )

2. SE ILUMINARÁ EL PANEL ANUNCIADOR POR CADA POSICIONE QUE PASE LA

SELECTORA.

3. SI POR ALGUNA RAZON, AL PASAR POR UNA DE LAS POSICIONES DEL SWITCH , NO

SE ILUMINA EL PANEL ANUNCIADOR , SIGNIFICA QUE HAY UN PROBLEMA EN EL

CIRCUITO DE DETECTOR.

ELECTRIC TRIM

AUTOPILOT SYSTEM………..

*******************

OVERSPEED GOVERNORS

1. PROPELLER LEVERSàHIGH RPM

2. POWER LEVERSàBELOW 1900 RPM

3. PROPELLER PROP TEST SWITCHàHOLD TO PROP GOV TEST

4. POWER LEVERSàINCREASE TO STABILIZED (1900-2000 RPM) Observe ITT and

Torque Limits

5. POWER LEVERSàREDUCE TO 1900 RPM

6. PROPELLER TEST SWITCHà RELEASE

PRIMARY GOVERNORS

àEXERCISE AT 1900 RPM

AUTOFEATHER

1. POWER LEVERSàIDLE

2. AUTOFEATHER ARM SWITCHàTEST

3. POWER LEVERSà500 FT TORQUE (AUTOFEATHER ARM Light Iluminate)

4. LEFT ENGINE POWER LEVERàRETARD , AUTOFEATHER ARM Light extinguish at +-

400 ft torque , CONTINUE RETARD UNTIL IDLE AND PROPELLER LEFT START

FEATHER AT +- 200 FT TORQUE .

5. REPEAT PROCEDURE WITH RIGHT ENGINE .

6. TEST COMPLETEDàAUTOFEATHER ARM SWITCHàARM

SECONDARY LOW PITCH STOPS

1. CONDITION LEVERSàHIGH IDLLE

2. POWER LEVERSàIDLE (Read propeller rpm)

3. PROPELLER TEST SWITCHESàHOLD TO SECONDARY IDLE STOP TEST

4. POWER LEVERSàALING AFT EDGE WITH TOP OF REVERSE RANGE MARKS

5. SECONDARY LOW PITCH STOP LIGHTàCHECK ON

6. PROPELLER RPMàCHECK STABILIZED AT 210+-40 ABOVE RPM IN STEP Nro2.

7. PROPELLER TEST SWITCHESàRELEASE

8. PROPELLER RPMàCHECK (Must increase above step Nro6)

9. POWER LEVERSàIDLE

10. PROPELLER TEST SWITCHESàMOMENTARILY TO SEC IDLE STOP TEST (To

extinguish lights)

GYRO SUCTION AND PNEUMATIC SYSTEM

1. GYRO SUCTION AND PNEUMATIC PRESSUREàCHECK ( HIGH IDLE)

2. CONDITION LEVERSàLOW IDLE

PRESSURIZATION SYSTEM

1. BLEED AIR VALVESàOPEN

2. CABIN PRESSURE CONTROLLERàSET 500ft BELOW FIELD ELEVATION

3. PRESSURIZATION SWITCHàTEST

4. CABIN RATE INDICATORàCHECK AND RELEASE

5. FOR TO SET PRESSURIZATION BEFORE TAKE OFF

• CHECK ENVIROMENTAL CONTROL SETTINGS (HEAT OR COOL , MANUAL OR

AUTO, AS DESIRED)

• OPEN BLEED AIR VALVES.

• PRESSURIZATION SWITCHàPRESS

• SELECT CRUISE ALTITUDE FOR TRIP

• AFTER TAKE OFF , ADJUST THE RATE CONTROLLER ( 10 A CLOCK )

DEFLECTORES ANTI ICE:

• SET 1000 lbs TORQUE OR ABOVE

• EXTEND ( PULL ) --> CHECK FOR TORQUE DROP , INDICATING VANE EXTENSION.

• RETRACT (PUSH )--> CHECK FOT TORQUE INCREASE TO PREVIOUS READING ,

INDICATING VANE RETRACTION.

SURFACE DEICE

• DE ICE SWITCHES--> CHECK BOTH POSITION ( SINGLE - MANUAL )

• CHECK DE ICE PRESSURE GAGE

• CHECK BOOTS VISUALLY FOR INFALTION AND HOLD DOWN

ENGINE AUTO IGNITION

• POWER LEVERS-->IDLE

• AUTO IGNITION SWITCHES--> ARM

• ANNUNCIATOR PANEL-->IGNITION ON

• POWER LEVERS-->ADVANCE TO ABOVE 425 LBS TORQUE

• AUTO IGNITION-->CHECK ON

• POWER LEVERS-->RETARD TO IDLE (ANNUNCIATOR LIGHTS ON , GREEN ARM

LIGHTS – OFF)

PROPELLER DE ICE

• PROPELLER DEICE SWITCH (MAIN)-->ON

• PROPELLER DEICE AMMETER-->CHECK 14 TO 18 AMP

• CHECK THE AUTOMATIC TIMER , 2 MINUTNES MINIMUN , PICK DOWN EVERY 30

SEG.

You might also like

- PDF DocumentDocument10 pagesPDF DocumentNIKHIL DASARINo ratings yet

- IFRQuick Review SheetsDocument10 pagesIFRQuick Review SheetsDharavGosalia100% (3)

- Weight and BalanceDocument2 pagesWeight and BalancePedro PalzaNo ratings yet

- POH King Air 100 PDFDocument377 pagesPOH King Air 100 PDFsergio leiva100% (2)

- Classic Airliners 76 Older Types, Worldwide, Describen and IllustratedDocument162 pagesClassic Airliners 76 Older Types, Worldwide, Describen and Illustratedsergio leivaNo ratings yet

- Atlantic Crossing Checklist: On Ground PredepartureDocument1 pageAtlantic Crossing Checklist: On Ground PredepartureCaroline LemelinNo ratings yet

- T-44C FMS GuideDocument143 pagesT-44C FMS GuideTrung Dung100% (1)

- Hawker-Siddeley HS.748 V1 ManualDocument18 pagesHawker-Siddeley HS.748 V1 Manualdani20100% (1)

- LJ 55 - Pilot Training Manual - (Vol 1)Document84 pagesLJ 55 - Pilot Training Manual - (Vol 1)Cassiano Capellassi100% (3)

- Engl10 Q4 M1 DistinguishTechnicalTermsUsedinResearch Pagulongan V0-Module-1Document32 pagesEngl10 Q4 M1 DistinguishTechnicalTermsUsedinResearch Pagulongan V0-Module-1Kath Nees67% (3)

- FAA FSB Report for Learjet 60XR Pilot TrainingDocument30 pagesFAA FSB Report for Learjet 60XR Pilot Trainingfierrohalcon100% (1)

- LR-31A PTM V1R01 (1) - OrganizedDocument388 pagesLR-31A PTM V1R01 (1) - OrganizedAQS Centro capacitacion aerea100% (1)

- ICCEY CHECK (Pre StallsDocument3 pagesICCEY CHECK (Pre Stallsyoselin rodriguezNo ratings yet

- Embraer Phenom 100Document4 pagesEmbraer Phenom 100AtharNo ratings yet

- Falcon 2000LX SpecDocument18 pagesFalcon 2000LX SpecHeinz KrauseNo ratings yet

- 208B (867SHP-G1000) POH Supplement 18Document48 pages208B (867SHP-G1000) POH Supplement 18Jose Francisco ColinaNo ratings yet

- 8168 ApproachDocument18 pages8168 ApproachHaytham ZakiNo ratings yet

- Falcon 2000 FAA TC A50NM Rev 8 PDFDocument19 pagesFalcon 2000 FAA TC A50NM Rev 8 PDFAndrei IЗNo ratings yet

- Balanced Scorecard ThesisDocument59 pagesBalanced Scorecard Thesisapi-3825626100% (5)

- MJC Dh8d ManualDocument134 pagesMJC Dh8d ManualDarek Czarnecki100% (1)

- Lear Jet 31Document359 pagesLear Jet 31GUTBERMAR100% (1)

- King Air Brochure PDFDocument40 pagesKing Air Brochure PDFJonathon DukeNo ratings yet

- King 90Document35 pagesKing 90Carlos Francisco Cedillo Bruzual100% (3)

- 208B - Diferencias - Con - 208B EXDocument123 pages208B - Diferencias - Con - 208B EXLu SaNo ratings yet

- Brfo193 Radiotherapy Dose Fractionation Third-Edition PDFDocument137 pagesBrfo193 Radiotherapy Dose Fractionation Third-Edition PDFMed MedNo ratings yet

- Embraer ERJ 190-200 LR Embraer 195 G-FBEH 06-10 PDFDocument13 pagesEmbraer ERJ 190-200 LR Embraer 195 G-FBEH 06-10 PDFMusab PorscheNo ratings yet

- CL 604 Normal Checklist REV 108Document3 pagesCL 604 Normal Checklist REV 108CLDriverNo ratings yet

- Business Model Canvas TemplateDocument5 pagesBusiness Model Canvas TemplateAsraihan Raihan100% (1)

- Strength and Serviceability of Hanger ConnectionsDocument12 pagesStrength and Serviceability of Hanger ConnectionsVitor OlivettiNo ratings yet

- H900XP Study Guide R1.1Document28 pagesH900XP Study Guide R1.1Leandro Aquino Dos Santos100% (1)

- Tecnam P92 ChecklistDocument2 pagesTecnam P92 Checklistmark1032No ratings yet

- Flight Operations: Operational Information Supplement For G150 and G200 AirplanesDocument6 pagesFlight Operations: Operational Information Supplement For G150 and G200 AirplanesAlisa KirjanovaNo ratings yet

- C-208B Gran Caravan: Perfiles de VueloDocument6 pagesC-208B Gran Caravan: Perfiles de VueloJose Francisco ColinaNo ratings yet

- Pc-6 Msfs User GuideDocument45 pagesPc-6 Msfs User GuideXing OuyangNo ratings yet

- Cessna 152 ManualDocument135 pagesCessna 152 ManualRezwan Ahmed Khan100% (1)

- King Air Type Certificate A24CE - Rev - 105Document43 pagesKing Air Type Certificate A24CE - Rev - 105tomay77767% (3)

- Downloaded From Manuals Search EngineDocument57 pagesDownloaded From Manuals Search Engineviola beckNo ratings yet

- Certificado Tipo Bell 204Document10 pagesCertificado Tipo Bell 204maocartoNo ratings yet

- BE20 CAE Operating HandbookDocument174 pagesBE20 CAE Operating HandbookGabedi MoNo ratings yet

- Ica 19001 05 Opt 1 Rev A PDFDocument12 pagesIca 19001 05 Opt 1 Rev A PDFtayo_bNo ratings yet

- Cessna 208B Operating Limitations and MarkingsDocument62 pagesCessna 208B Operating Limitations and MarkingstumbNo ratings yet

- Learjet 85 enDocument2 pagesLearjet 85 enkokiskoNo ratings yet

- 2018 CQ KV Answer Guide 1Document18 pages2018 CQ KV Answer Guide 1Anonymous 8qSMEmdKNo ratings yet

- AIREPDocument1 pageAIREPTim RolandNo ratings yet

- Falcon 2000 FAA TC A50NM Rev 8 PDFDocument19 pagesFalcon 2000 FAA TC A50NM Rev 8 PDFAndrei IЗNo ratings yet

- Ata 22 I-Aea1Document9 pagesAta 22 I-Aea1Antonio CorteNo ratings yet

- g3 FlashcardsDocument263 pagesg3 FlashcardsSantiago Hidalgo100% (1)

- Rotate-MD-80 - Tutorial FlightDocument47 pagesRotate-MD-80 - Tutorial FlightgochilindaNo ratings yet

- Ad - 2 Mmlo VacDocument3 pagesAd - 2 Mmlo VacAxl Ps YoNo ratings yet

- Boeing 757 ChecklistsDocument1 pageBoeing 757 ChecklistsMehedi HasanNo ratings yet

- Beechcraft G36 Bonanza Performance and SpecsDocument2 pagesBeechcraft G36 Bonanza Performance and SpecsPranav IweNo ratings yet

- FPG 750Document34 pagesFPG 750Olegas LesinasNo ratings yet

- EMB505 Performance Tables PDFDocument13 pagesEMB505 Performance Tables PDFGuilherme Kazuo OgawaNo ratings yet

- Airport Information: Details For TOCUMEN INTLDocument35 pagesAirport Information: Details For TOCUMEN INTLREGINO MARCANONo ratings yet

- Procedimientos Ifr MMMXDocument24 pagesProcedimientos Ifr MMMXFabian TorresNo ratings yet

- Q400 Connector LocationsDocument922 pagesQ400 Connector LocationsDaniel Juratovich100% (2)

- Lehc All ChartsDocument4 pagesLehc All ChartsJaucafoNo ratings yet

- CE500 Note Taking Guide v1.12Document16 pagesCE500 Note Taking Guide v1.12MiguelNo ratings yet

- NASA Information Summaries Introduction To Flight TestingDocument6 pagesNASA Information Summaries Introduction To Flight TestingBob AndrepontNo ratings yet

- 1986 Embraer 120ER (245 - ZS-SRW) SpecsDocument8 pages1986 Embraer 120ER (245 - ZS-SRW) SpecsFrancesco V CasseseNo ratings yet

- Congratulations in It Is Will It, For: To of Find Flying Pilot's Gria. Airplane. To To To ofDocument201 pagesCongratulations in It Is Will It, For: To of Find Flying Pilot's Gria. Airplane. To To To ofLuís Eduardo MansuetoNo ratings yet

- Chapter 14: Navigation and Communication: GeneralDocument32 pagesChapter 14: Navigation and Communication: GeneralMax powersNo ratings yet

- SF50 Vision Jet CheckListDocument6 pagesSF50 Vision Jet CheckListfederico armellaNo ratings yet

- C172R ChecklistDocument40 pagesC172R ChecklistlunanxlNo ratings yet

- ETP Premium Installation Instructions: MY P&WC POWER Offline Technical Publications (Single and Multi-User Modes)Document15 pagesETP Premium Installation Instructions: MY P&WC POWER Offline Technical Publications (Single and Multi-User Modes)Samirnov IcNo ratings yet

- Examen de Limitaciones MU-2NDocument1 pageExamen de Limitaciones MU-2Nsergio leivaNo ratings yet

- Flight Dynamics in MSFS V1.0 PDFDocument60 pagesFlight Dynamics in MSFS V1.0 PDFGraham WaterfieldNo ratings yet

- 208comp 08 00Document134 pages208comp 08 00kevin mwanzaNo ratings yet

- Obtaining A Good Weather Briefing PDFDocument13 pagesObtaining A Good Weather Briefing PDFsergio leivaNo ratings yet

- Checklits PavDocument2 pagesChecklits Pavsergio leivaNo ratings yet

- Avoid Thunderstorms - Radar Helps But Has LimitsDocument5 pagesAvoid Thunderstorms - Radar Helps But Has LimitsLohrasp SuraliwalaNo ratings yet

- MountainFyingTruemper PDFDocument7 pagesMountainFyingTruemper PDFsergio leivaNo ratings yet

- Accident Prevention Program: Part I-Engine Operation For PilotsDocument7 pagesAccident Prevention Program: Part I-Engine Operation For Pilotssergio leivaNo ratings yet

- Problem29 40Document1 pageProblem29 40IENCSNo ratings yet

- Of Our TimesDocument84 pagesOf Our TimesThe Journal of Music100% (1)

- 1Document5 pages1qweqweNo ratings yet

- Template PharmaconDocument4 pagesTemplate PharmaconDanang RaharjoNo ratings yet

- How To Make Lampblack - AllDocument6 pagesHow To Make Lampblack - AllclaudjiuNo ratings yet

- Studi Kasus Pada PT Damar Bandha Jaya Corp. BogorDocument10 pagesStudi Kasus Pada PT Damar Bandha Jaya Corp. BogorMayHan13No ratings yet

- Power Over Ethernet - Wikipedia, The Free EncyclopediaDocument7 pagesPower Over Ethernet - Wikipedia, The Free EncyclopediaManitNo ratings yet

- Otr Product CatalogDocument116 pagesOtr Product CatalogIwan KurniawanNo ratings yet

- Practice Reading GraphsDocument4 pagesPractice Reading GraphsSharon TaylorNo ratings yet

- Practical File ON Programming For Problem Solving Lab (: 21BTCS181)Document15 pagesPractical File ON Programming For Problem Solving Lab (: 21BTCS181)Vaibhavi SinghNo ratings yet

- 7 Principles Video Content CreationDocument2 pages7 Principles Video Content CreationJackiee Fiorela PalaciosNo ratings yet

- Khwaja Moinuddin Chishti Language UniversityDocument30 pagesKhwaja Moinuddin Chishti Language UniversityShivam ShuklaNo ratings yet

- Doctor's Office Call About Infected Foot InjuryDocument5 pagesDoctor's Office Call About Infected Foot InjuryNur annisa HarahapNo ratings yet

- Institute of Graduate Studies (Igs)Document46 pagesInstitute of Graduate Studies (Igs)Syara Shazanna ZulkifliNo ratings yet

- Materials that absorb and decayDocument2 pagesMaterials that absorb and decayDominic NoblezaNo ratings yet

- Service Training: Vorsprung Durch Technik WWW - Audi.deDocument15 pagesService Training: Vorsprung Durch Technik WWW - Audi.depuncimanNo ratings yet

- Solar Pump Inverter PV100 PV200 User Manuel Rev1Document49 pagesSolar Pump Inverter PV100 PV200 User Manuel Rev1faitgpsNo ratings yet

- International Standard Iso/Iec Software Cycle Processes: Standards SectionDocument16 pagesInternational Standard Iso/Iec Software Cycle Processes: Standards SectionDavid SalgadoNo ratings yet

- Oakham Surgery New Patient FormDocument7 pagesOakham Surgery New Patient FormTrần Thanh ThảoNo ratings yet

- Marketing Strategies Audit On Hewlett Packard (HP)Document19 pagesMarketing Strategies Audit On Hewlett Packard (HP)auraNo ratings yet

- Nature of MarketingDocument15 pagesNature of MarketingMohamaad SihatthNo ratings yet

- Central Bank Digital Currency:: The Future of Payments For CorporatesDocument29 pagesCentral Bank Digital Currency:: The Future of Payments For CorporatesknwongabNo ratings yet

- Cement and Concrete Research: Amin Abrishambaf, Mário Pimentel, Sandra NunesDocument13 pagesCement and Concrete Research: Amin Abrishambaf, Mário Pimentel, Sandra NunesJoseluis Dejesus AnguloNo ratings yet

- Timbering Week 5Document22 pagesTimbering Week 5FikaduKitessa0% (1)