Professional Documents

Culture Documents

Nickel Alloys Resist Catastrophic Corrosion

Uploaded by

Ronak shahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nickel Alloys Resist Catastrophic Corrosion

Uploaded by

Ronak shahCopyright:

Available Formats

Selection of Nickel-Base Alloys for

Metal Dusting Resistance

The causes of "metal dusting", a potentially severe corrosion problem resulting from the steam

reforming process, are examined. Long-term laboratory data is presented which shows how the

consideration of alloy content can be effective in resisting metal dusting attack. A newly-developed

alloy offers promising potential for metal dusting limited applications.

Brian A. Baker and Gaylord D. Smith

Special Metals Corporation

Stephen A. McCoy

Special Metals Wiggin, Limited

Introduction to examine the causes of, and potential solutions to,

this often-disastrous problem. Special Metals corpora-

T

he production of synthesized gas (syngas) tion has been actively involved in characterizing and

from methane or natural gas via steam reform- developing new materials to cope with the increasing

ing is a common step to begin production of demand on equipment in harsh metal dusting environ-

hydrogen and ammonia, as well as methanol and other ments. Research has been conducted on a number of

liquid hydrocarbons. The syngas stream consists of a alloys, apart from the traditionally used primary and

mixture of CO, H2 and H2O, with lower levels of CO2 secondary reformer material ENCOLOY alloy 800H, to

and some CH4. When such gas mixtures are present in better understand the role of alloying in resisting

attack. This article presents long-term laboratory data

the process stream in the critical temperature range of

and shows how the consideration of alloy content can

about 400° to 800°C, the phenomenon labeled "metal

be effective in resisting metal dusting attack. In addi-

dusting" can potentially be a severe corrosion problem.

tion, mechanical properties are shown for the newly-

Metal dusting can be described as a catastrophic car-

developed INCONEL alloy 693 in comparison with

burization phenomenon which occurs under conditions

other nickel-base alloys which exhibit enhanced resist-

where the carbon activity of the gaseous atmosphere is

ance to metal dusting.

greater than one. Metal dusting is manifested by the

disintegration of the affected metal into a powdery

Causes of Metal Dusting

mixture of graphite and metal particles. Oxides and

carbides are also often present in the powdery mixture,

The amount of steam used for the reforming process

or "dust".

has been driven lower by the need for greater efficien-

Past and present failures resulting from metal dusting

cy, resulting in lower steam-to-hydrogen ratios. Higher

have prompted end users and material producers alike

front-end pressures have also increased the CO content

AMMONIA TECHNICAL MANUAL 257 2002

of the syngas. Lower H2O/H2 ratios in combination posed for nickel-base alloys, which does not involve

with higher CO/CO2 ratios result in lower oxygen par- the formation of an intermediate metastable carbide.

tial pressures and higher carbon activities, respectively, Such a mechanism begins in the same way as for iron-

and serve to increase the severity of metal dusting base alloys, with saturation of the alloy matrix with

attack. Metal dusting is often avoided in industry by carbon/carbides. However, in the case of nickel-base

designing around the critical metal dusting temperature alloys, the saturated matrix directly decomposes into

range. Syngas is produced at temperatures above the metal particles and graphite (Grabke, 1998; Lai, 1990)

critical range (>800°C) and transferred to a boiler via a Figure 1 illustrates the equidistant diffusion (assuming

short transfer line where it is rapidly quenched to tem- a material which exhibits isotropic diffusion behavior)

peratures below the critical metal dusting range of carbon from a point defect hi the protective oxide

(<400°C). Alloy ferrules that are used in the transfer scale which results in saturation of a hemispherical

line do often experience metal dusting and are periodi- region with carbon. Subsequent decomposition of this

cally replaced. The need to maximize the efficiency of saturated area results hi disintegration of the alloy

steam reforming technology has led to the development matrix and not simply grain fallout, producing a pit

of equipment which must be capable of operating with- having the same hemispherical shape as the carbon-sat-

in the range of temperature and carbon activity which urated region.

can promote metal dusting. This necessitates the use of The presence of an adherent, protective, oxide sur-

materials which exhibit excellent resistance to metal face layer that can heal is required for protection of an

dusting attack. alloy against metal dusting attack. While oxide forma-

The mechanism of metal dusting for iron-base alloys tion may be stable, the oxide layer may still be suscep-

begins with saturation of the alloy matrix with car- tible to disruption. Higher levels of the scale forming

bon/carbides, usually hi a localized manner, and subse- element will then make the scale healing process more

quent formation of metastable Fe3C, or cementite. rapid and complete. Ultimate resistance to metal dust-

ing may involve complex interactions of scale charac-

Decomposition of the cementite as the carbon activity

teristics, diffusivity of scale-forming elements and car-

approaches unity produces kon particles and powdery bon through the alloy matrix and carbon saturation lim-

carbon. The metal particles then strongly catalyze fur- its.

ther carbon deposition. A different mechanism is pro-

Defect, fe Oxide

Figure 1. The equidistant diffusion of carbon from a localized defect in the protective oxide scale

that results in the saturation of a hemispherical region with carbon.

AMMONIA TECHNICAL MANUAL 258 2002

Figure 2. Cross section of metal dusting pit in alloy 600 reformer pig-

tail pipe which was in service for approximately 5 years.

Etchant: 5% HNO3 in methanol, electrolytic.

Figure 3. Cross section of metal dusting pit in alloy 800 reformer

pigtail connecting ring which was in service for approximately 5

years.

Etchant: 5% HNOß methanol, electrolytic.

AMMONIA TECHNICAL MANUAL 259 2002

Alloy Performance in Metal Dusting Laboratory Testing

Environments

Table 1 shows the chemical composition for each

The tendency of synthetic gas streams to promote alloy tested, as well as for other alloys mentioned in

metal dusting has been heightened by changing pro- this article. Test specimens were prepared from com-

cessing conditions and the use of advanced catalysts. mercially available material; sample dimensions were

Techniques such as injection of additional steam and approximately 2.5 cm X 2.5 cm X thickness. Samples

sulfur-containing species into the gas stream, which are were ground to a 120-grit finish for standardization

known to minimize the effects of metal dusting, are no purposes.

longer viable in many processes due to the increased Exposures were performed in a horizontal tube fur-

use of catalysts which are sensitive to sulfur content. nace at 621°C in an atmosphere generated from an inlet

Higher gas pressures and temperatures, in conjunction gas mixture of CO-20% H2. Samples were cycled,

with lower H2O/H2 ratios and higher CO/CO2 ratios, lightly brushed, and ultrasonically cleaned and mass

are becoming the norm for modern reforming opera- change was measured at approximately two-week

tions. This combination of conditions may necessitate intervals. In addition to mass change, pitting depth was

the use of materials which offer resistance to metal also determined for each sample using an optical

dusting that is superior to that of previously commonly microscope having a calibrated fine focus knob.

used alloys such as the Cr-Mo stainless steels and Fe- Figure 4 shows mass loss rates vs. time for the alloys

Ni-Cr alloys. tested. The rate was calculated by dividing the mass

Two commonly used alloys that typically offer good change (only shown if negative) per unit area by the

overall corrosion resistance as well as high temperature total test time. The maximum pit depth as a function of

strength under a wide range of conditions are time is plotted in Figure 5. Figure 6 shows the result of

INCONEL alloy 600 and INCOLOY alloy 800H. multiple regression analysis of the log of the pit pro-

Metal dusting failures of alloy 800 are well document- gression rate, calculated by averaging the pit depth

ed (Esaklul, 1992; Special Metals, 1997). and problems over the total testing duration, vs. a summation of the

with alloy 600 have been encountered as well. Figures wt. % of various alloying additions. Only the austentic

2 and 3 show metal dusting attack of both the alloy 600 nickel-base alloys and Fe-Ni-Cr alloys were included

piping and the alloy 800 connecting ring, respectively, in this calculation; the ferritic alloy, MA956, and also

from a reformer pigtail (Strauss and Grabke, 1998). alloy 400 were excluded. The ferritic materials exhibit

The reformer had been in service for about 5 years. a different mechanism due to the high diffusion rates of

Harsher conditions have necessitated the use of alloys the scale formers through the matrix. The best fit was

having high nickel contents in addition to higher levels produced using the following summation:

of scale-forming elements, such as chromium. Alloy

601 has been used for waste heat boiler shells and tub- (%Ni+%Co)+5*%Mo+20*%Ti+33*%Al+15*%Si+

ing in ammonia plants, as well as for reformer compo- 2*%Cr-2*%Fe.

nents which has resulted in greater production due to

decreases in downtime and repair costs. For even This same regression technique was used to charac-

greater protection against metal dusting under the terize the variation in mass loss rate with the percent-

harshest conditions, alloys such as INCOTHERM alloy age of certain alloying additions (Figure 7). Again,

TD, INCOLOY alloy MA956, INCOCLAD only the austenitic nickel-base and Fe-Ni-Cr alloys

671/800HT and INCONEL alloy 617, INCONEL alloy were included in the calculation. The best fit was

690, and INCONEL alloy 693, offer promising poten- obtained using the following summation:

tial as upgrades from the commonly used alloy 601.

2*(%Ni+%Co)+6*%Mo+31 *%Ti+34*%Al+80*%

Si+9*%Cr-%Fe.

AMMONIA TECHNICAL MANUAL 260 2002

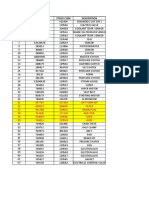

Table 1. Nominal Composition of Commercial Alloys

Alloy Ni Cr Fe Mn Si Al Ti C Other

INCONEL alloy MA754 78 20 - - - 0.3 0.5 0.05 0.5 Y2O3

INCOTHERM alloy TD 73 22 - - 1.4 - - 0.01 3.0 Mo

INCONEL alloy 600 72 15.5 8 0.3 0.3 0.3 0.3 0.08 -

INCONEL alloy MA758 67 30 - - - 0.4 0.5 0.05 0.5Y203

MONEL alloy 400 64 0.1 1.6 0.7 0.1 0.02 0.4 0.15 32.2 Cu

INCONEL alloy 693 62 30 4 - - 3 - - Nb,Zr

INCONEL alloy 625LCF 61 21.5 2.5 - 0.1 0.2 0.2 0.02 9 Mo, 3.6 Nb

INCONEL alloy 601 60.5 L 23 13 0.2 0.2 1.4 0.4 0.05 -

INCONEL alloy 690 59 29 9 0.2 0.1 0.3 0.3 0.02 -

INCONEL alloy 671 53 46 - - - 0.3 0.3 0.03 -

INCONEL alloy 6 17 55 22 1 - 0.1 1.2 0.4 0.08 12.5 Co, 9 Mo

NMONIC alloy 263 51 20 39 0.3 0.1 0.5 2.2 0.06 20 Co, 5.9 Mo

INCOLOY alloy 825 42 21.5 28 0.4 0.1 0.1 1 0.02 3 Mo, 2Cu

INCOLOY alloy DS 37 16 41 1.0 2.3 - - 0.08 -

INCOLOY alloy 330 35 19 44 1.0 1.3 - - 0.07 -

INCOLOY alloy 803 34 27 36 1.0 0.8 0.4 0.4 0.08 -

INCOLOY alloy 864 34 21 39 0.4 0.8 0.3 0.6 0.03 4.2 Mo

INCOLOY alloy 32 21 45 0.9 0.1 0.4 0.4 0.07 -

800/800HT

INCOLOY alloy MA956 - 20 75 - - 4.5 0.5 0.05 0.5Y203

T 1 1—<—'—>—i 1 1 r

O 2000 4000 6000 8000 10000 12000 14000 16000 18000

Exposure Time, hrs

Figure 4. Mass loss rate vs. exposure time for alloy samples exposed to CO-20% H2 at 621° C.

AMMONIA TECHNICAL MANUAL 261 2002

1000 2000 3000 «X» 5000 6000 7000 1000 900Q 10000 11000 12000 13000 14000 15000 16000 17000 18000

Exposure Time, Hours

Figure 5. Maximum pit depth measurements for alloy samples exposed to CO-20% H2

at 621°C.

CO-20%H2at621°C

1 3

^«X)

4i -^ ** - *33Q

*DS 4803

c .4 . * * 825

_£ *

864 " .tȤP1

2

g - -*KQ

45- finn * 263MA754m

Coo '^* * ^625LCF

690 ^ 4671

1 -5-

1 MA758 ^61?

«

Q.

_R S .

* 693

a .6 .

3 0 50 100 150 200 250

0

(%NI+%Co)+5^oMo+20«%TI+33* /oAI+15*%Sl+2*(%Cf-%Fe)

Figure 6. Results of multiple linear regression for pit progression rate vs.

composition.

AMMONIA TECHNICAL MANUAL 262 2002

CO-20%H2at621°C

I

1-1- 80

°*

• 330

825 «f600

8 c

-4- MA754 625LCF

« -5

R71

671

693

100 200 300 400 500 600

Figure 7. Results of multiple linear regression for mass loss rate vs.

composition.

As a general trend, nickel-base alloys exhibited minum, may also gain the same benefit from its molyb-

lower mass loss rates and pitting progression rates than denum addition. Alloy 625LCF, a refined version of

iron-base alloys. Exceptions include alloys 600 and alloy 625, has performed reasonably well and contains

MA754, which contain only 15% and 20% chromium, 21.5% chromium, 9% molybdenum, and 3.6% niobium

respectively, have no other significant additions of and probably benefits from its fine grain structure. The

scale-forming or carbide-forming elements, and had a high silicon content of alloy TD may have afforded

fairly high mass loss rate resulting from numerous, some enhancement in performance, in addition to its

albeit fairly shallow, pits. Alloy 690 (Ni-29Cr-9Fe), 3% molybdenum content.

commonly used as heat-exchanger tubing in the The alloys 671 and 693 exhibit, overall, the most

nuclear industry, exhibits much lower mass loss and pit promising performance trends in both resisting pitting

progression rates than alloy 601, which is increasingly attack and resisting mass loss, and contain the highest

used as an upgrade from iron-base materials such as combinations of nickel, chromium, and aluminum. The

Cr-Mo steels, austenitic stainless steels, and Fe-Ni-Cr protection of the material is enhanced by the very high

heat-resistant alloys such as alloy 800. The mechani- level of scale-forming elements which form a dense,

cally alloyed corollary to alloy 690, alloy MA758, also adherent and self healing protective oxide surface

exhibits good performance. Alloy MA956, a ferritic layer. Alloy 671, with its substantial chromium content,

alumina former, also exhibited good performance. could be utilized in the form of a bimetallic clad tube,

Alloy 263 performed well despite its modest chromium being mechanically very poor as a monolithic material

level of 20% and 39% iron content, and appears to pos- within the metal dusting temperature range. INCO-

sibly gain protection from its substantial titanium addi- CLAD tubes having an alloy 671 layer on the OD and

tion and possibly its molybdenum addition, which may alloy 800HT at the ID have been successfully used in

promote early carbide formation and provide diffusion- coal-fired boilers with service times exceeding 20

aï blocking of the carbon flux (Fahrmann and Smith, years. The best performer overall in the laboratory test

2000). Alloy 617, having 22% chromium and 1.2% alu- was alloy 693, which possesses very high chromium

AMMONIA TECHNICAL MANUAL 263 2002

Table 2. Room-Temperature Tensile Properties for Annealed differences in properties between the

Material oxide scale and the substrate. The fol-

lowing data are intended to highlight

Alloy 0.2% Yield Ultimate Tensile Elongation, % the properties of the newly-intro-

Strength, MPa (ksi) Strength, MPa (ksi) duced alloy 693. Typical room-tem-

perature tensile properties for alloys

601 276 (40) 621 (90) 55 601, 617, 690, and 693 are shown in

617 379 (55) 827 (120) 53 Table 2. The properties for alloy 693

690 414 (60) 758 (110) 47 are similar to those for alloy 690.

693 414 (60) 827 (120) 43 Figure 7 compares the stress rupture

properties of alloys 601, 617, 690,

and 693 via a Larson-Miller plot.

and aluminum contents. ln-situ field exposures in syn-

Figure 8 shows stress vs. rupture life for alloys 601 and

gas environments have confirmed this alloy's superior

693. Low-cycle fatigue results for alloys 693 and

performance.

625LCF are shown in Figure 9. Alloy 693 possesses

fatigue properties at 593°C and 704°C which are supe-

Alloy Properties

rior to those of alloy 625LCF at 538°C. Alloy 625LCF

While corrosion resistance is of the utmost impor- is used as a benchmark and has been specifically

tance in applications which may cause metal dusting, developed and applied for the purpose of resisting

mechanical properties are also an important considera- fatigue in high temperature bellows applications.

tion when selecting a material. Materials with high Tables 3 and 4 show room-temperature and elevated

creep strength in the metal dusting temperature range temperature tensile results for alloy 693 after interme-

can be more resistant to scale disruption caused by the diate-temperature exposure. Respectable elongation

1000

100

20 30 40 50 60 70

LMP = (1.8T+490X20+log{Tr)yiOOO, T in °C, Tr in

Hours

Figure 8. Larson-Miller plot representing stress rupture data for alloys 617, 693, 601, and

690.

AMMONIA TECHNICAL MANUAL 264 2002

1000

|693-704°C

601-704°CF

I•t

(A

ö>

10 100 1000 10000 100000

Rupture Life, Hours

Figure 9. Stress rupture data comparing alloys 601 and 693 at 649°C, 704°C, and 982°C.

Strain Control Low Cycle

Fatigue - Alloy 693

niA -,

O .Ul^

A U<U1

n 019 -

o>

£

Rj

\_,

^

n ni -

V/.UI • 693-593°C

dc_ n (V\Q .

C u.uvo • 693-704°C

1 0.006- X^

-. Ü0 UÜ4

^ ^^^^-

004. -

B ^

625LCF-538°C

— 625LCF-649°C

s - '" ••» • «

o n 002 -

0. T" " i ' 1 1

1000 10000 100000 1000000 1E+07

Cycles, Nf

Figure 10. Low-cycle fatigue data for alloys 625LCF and 693.

AMMONIA TECHNICAL MANUAL 265 2002

Table 3. Room-Temperature Tensile Results for Alloy 693

Exposure 0.2% Yield Ultimate Tensile Elongation, % Exposure Time, h

Temperature, °C (°F) Strength, MPa (ksi) Strength, MPa (ksi)

As-Produced 410 (59.5) 834 (121.0) 43.0 As-Produced*

649 (1,200) 672 (97.5) 1,065 (154.5) 32.5 100

649 (1,200) 814(118.0) 1,179 (171.0) 28.8 500

704 (1,300) 645 (93.5) 1,045 (151.5) 48.9 100

704 (1,300) 816(118.3) 1,181 (171.3) 28.8 500

760 (1,400) 631 (91.5) 1,048 (152.0) 47.2 100

816(1,500) 634 (92.0) 1,048 (152.0) 55.2 100

* Hot-Rolled and Annealed Rod

Table 4. Elevated-Temperature Tensile Results for Alloy 693 (Tested at Exposure Temperature)

Exposure 0.2% Yield Ultimate Tensile Elongation, % Exposure Time, h

Temperature, °C (°F) Strength, MPa (ksi) Strength, MPa (ksi)

649 (1,200) 411 (59.6) 643 (93.2) 28.9 As-Produced*

649 (1,200) 534 (77.5) 776(112.5) 21.8 100

704 (1,300) 457 (66.3) 634 (91.9) 16.3 As-Produced

704 (1,300) 569 (82.5) 769(111.5) 14.6 100

704 (1,300) 561 (81.3) 776(112.5) 18.9 500

704 (1,300) 556 (80.7) 769(111.6) 20.3 1,000

760 (1,400) 461 (66.9) 607 (88.1) 9.9 As-Produced

760 (1,400) 524 (76.0) 658 (95.5) 17.2 100

760 (1,400) 338 (49.0) 549 (79.6) 29.1 500

760 (1,400) 322 (46.7) 542 (78.6) 32.0 1,000

816 (1,500) 431 (62.5) 558 (81.0) 15.3 As-Produced

816(1,500) 314 (45.5) 434 (63.0) 23.4 100

values are maintained after exposure times of up to metal dusting. Field and laboratory data confirm the

1,000 h hi the critical temperature range of 704°C to desirability of addition of certain scale-forming and

760°C. carbide-forming elements hi conjunction with a nickel-

base alloy matrix to limit pit progression rates. The

Conclusion newly-developed alloy 693 offers promising potential

for metal-dusting limited applications.

Due to development of advanced catalysts and efforts

to increase the efficiency of processes involving the Acknowledgments

production of syngas, metal dusting corrosion has

become more prevalent. Failures of iron-base alloys, as The authors would like to thank Chad Clary for his

well as nickel-base alloys which contain insufficient assistance with laboratory testing and sample evalua-

scale-forming elements, have prompted equipment tion.

designers to seek materials that are more resistant to

AMMONIA TECHNICAL MANUAL 266 2002

Literature Cited Lai, G. Y., "High Temperature Corrosion of

Engineering Alloys," ASM, pp. 69-72 (1990).

Esakiul, K. A., ed., Handbook of Case Histories in Pippel, E., J. Woltersdorf, and R. Schneider, Materials

Failure Analysis, ASM, pp. 351-353 (1992). and Corrosion, 49, 309 (1998).

Fährmann, M. G., and G. D. Smith, "Corrosion/2000," Special Metals, Private Communication (Dec. 1997).

NACE International Paper No. 232 (2000). Strauss, S. and H. J. Grabke, Materials and Corrosion,

Grabke, H. J., Materials and Corrosion, 49, 303 49, 321 (1998).

(1998).

QUESTIONS AND ANSWERS

Rob Gommans, Gommons Metallurgical Services: one would not expect gross Al loss from the liquid

How does alloy 602CA compare to the alloys tested? weld pool; the expected decrease in Al level would be

Brian Baker, Special Metals Corporation: We have about 10%. Right now, we're recommending welding

actually tested the alloy 602CA material in our labora- with INCONEL filler metal 52 and capping the sur-

tory metal dusting test. The results from our test envi- faces with INCONEL filler metal 72 for metal dusting

ronment show that the pitting rate of alloy 602CA is resistance.

intermediate between that of alloys 601 and 690, and Carl E. Jaske, CC Technologies: What is the relative

significantly higher than that of alloy 693. cost of alloy 693 vs. similar nickel-base alloys?

Gommans: Alloy 693 contains 3% Al. How are the Baker: The cost of alloy 693 will be higher than that

welding properties? And loss of Al from the liquid of alloy 601. The specific cost factor will depend upon

weld pool? the product form.

Baker: We have performed numerous welding trials, Jaske: What type and amount of field testing has been

using various filler metals and joining to various other done to evaluate real service performance vs. laborato-

base metals. The weldability of alloy 693 has been ry testing?

shown to be quite favorable. We are still working Baker: Several field exposures in syngas environ-

toward commercialization of a matching filler materi- ments have shown that the real service performance of

al. If welding is performed with inert gas shrouding, alloy 693 correlates quite well with laboratory results.

AMMONIA TECHNICAL MANUAL 267 2002

You might also like

- The Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelRating: 5 out of 5 stars5/5 (4)

- Alloy Solutions To Metal Dusting Problems in The Chemical Processing IndustryDocument8 pagesAlloy Solutions To Metal Dusting Problems in The Chemical Processing IndustryGiuseppe Di RuoccoNo ratings yet

- Alloy Solutions To Metal Dusting Problems in The Petrochemical Industry PDFDocument8 pagesAlloy Solutions To Metal Dusting Problems in The Petrochemical Industry PDFZeeshan SajidNo ratings yet

- Metal Dusting in A Laboratory Environment - Alloying Addition EffectsDocument15 pagesMetal Dusting in A Laboratory Environment - Alloying Addition EffectsClaudia MmsNo ratings yet

- Correlation of Oxidation Carburization and Metal Dusting Controlling Corrosion by Corrosion (51300-01374-Sg)Document38 pagesCorrelation of Oxidation Carburization and Metal Dusting Controlling Corrosion by Corrosion (51300-01374-Sg)coolguy12345No ratings yet

- Synth and Prop of Novel Structural BinderDocument10 pagesSynth and Prop of Novel Structural BinderMaximiliano ZarateNo ratings yet

- Resisting Metal Dusting CorrosionDocument2 pagesResisting Metal Dusting CorrosionRonald MesinaNo ratings yet

- Adham Adnan 2018 IOP Conf. Ser. Mater. Sci. Eng. 370 012039Document9 pagesAdham Adnan 2018 IOP Conf. Ser. Mater. Sci. Eng. 370 012039Diego MatillaNo ratings yet

- Selection of Stirring and Shrouding Gases For Steelmaking Applications PDFDocument20 pagesSelection of Stirring and Shrouding Gases For Steelmaking Applications PDFRasul BzNo ratings yet

- Micropore Carbon Furnace Lining: Janusz Tomala and Stefan BasistaDocument6 pagesMicropore Carbon Furnace Lining: Janusz Tomala and Stefan BasistaKalai SelvanNo ratings yet

- 1 s2.0 S2214785322074181 MainDocument4 pages1 s2.0 S2214785322074181 Mainhuac5828No ratings yet

- Iwcc Cu-Vortrag AldDocument16 pagesIwcc Cu-Vortrag Aldhadjlarbi-h100% (1)

- Electrochemical and Molecular Modelling Studies of CO2 Corrosion Inhibition Characteristics of Alkanolamine Molecules For The Protection of 1Cr SteelDocument15 pagesElectrochemical and Molecular Modelling Studies of CO2 Corrosion Inhibition Characteristics of Alkanolamine Molecules For The Protection of 1Cr SteelRonald Lucas Silva Lefundes OliveiraNo ratings yet

- Low-Carbon Carbon-Bonded Alumina Refractories For Functional Components in Steel TechnologyDocument10 pagesLow-Carbon Carbon-Bonded Alumina Refractories For Functional Components in Steel TechnologyRyanto SitanggangNo ratings yet

- Seminar On Oxidation Resistant CoatingDocument18 pagesSeminar On Oxidation Resistant CoatingManoj IyengarNo ratings yet

- Failure Analysis of Heat Resistant Alloy in Process GasDocument16 pagesFailure Analysis of Heat Resistant Alloy in Process GasBubai111No ratings yet

- Materials Chemistry and Physics: 4 Hassan Gheisari Dehsheikh, Salman Ghasemi-KahrizsangiDocument8 pagesMaterials Chemistry and Physics: 4 Hassan Gheisari Dehsheikh, Salman Ghasemi-KahrizsangiPamungkas AzmiNo ratings yet

- Metals 12 01170Document15 pagesMetals 12 01170John TorrezNo ratings yet

- Recovery of Iron From Mill Scale by Reduction WithDocument12 pagesRecovery of Iron From Mill Scale by Reduction WithSaghar FarajzadehNo ratings yet

- 3 Chemical Reactions in WeldingDocument13 pages3 Chemical Reactions in WeldingPrafulla Subhash SarodeNo ratings yet

- Metallurgy Copper Wire PDFDocument8 pagesMetallurgy Copper Wire PDFstolen mechieducNo ratings yet

- A New Approach To Ductile Iron InoculationDocument12 pagesA New Approach To Ductile Iron InoculationZody YtuNo ratings yet

- Recycling of The Steelmaking By-Products Into TheDocument11 pagesRecycling of The Steelmaking By-Products Into Theyin xing gaoNo ratings yet

- Kho Swinbourne10 mpm188 EAFDocument9 pagesKho Swinbourne10 mpm188 EAFRICCO LauwisNo ratings yet

- Ceramics International: Min Chen, Song Gao, Lei Xu, Nan WangDocument6 pagesCeramics International: Min Chen, Song Gao, Lei Xu, Nan WanghardiantisNo ratings yet

- Formation of Chromium Oxide On 316L Austenitic Stainless SteelDocument7 pagesFormation of Chromium Oxide On 316L Austenitic Stainless SteelfarzanefrhNo ratings yet

- Thermally Stable IrCe0.9La0.1O2 Catalyst For High - Wang2016Document17 pagesThermally Stable IrCe0.9La0.1O2 Catalyst For High - Wang2016Darya DaryaNo ratings yet

- Effect of Shielding Gases On Austenitic Stainless Steel Overlay by FCAW Process On Low Alloy SteelDocument7 pagesEffect of Shielding Gases On Austenitic Stainless Steel Overlay by FCAW Process On Low Alloy SteelAdam Al AufaNo ratings yet

- Jounel Paper CompleteDocument6 pagesJounel Paper CompleteBABLU YADAVNo ratings yet

- SlagCarbonationReview AuthorreprintsDocument27 pagesSlagCarbonationReview AuthorreprintsK Suresh AkkihebbalNo ratings yet

- Marina A. Ermakova, Dmitry Yu. Ermakov, Andrey L. Chuvilin, and Gennady G. KuvshinovDocument15 pagesMarina A. Ermakova, Dmitry Yu. Ermakov, Andrey L. Chuvilin, and Gennady G. Kuvshinovjocy1989No ratings yet

- Crystals 11 01091 v2Document12 pagesCrystals 11 01091 v2Gian Luca Riva RiquelmeNo ratings yet

- Corrosion Science 50 (2008) 2620–2634Document15 pagesCorrosion Science 50 (2008) 2620–2634pepe martinezNo ratings yet

- Kho Swinbourne10 Mpm188 EAFDocument9 pagesKho Swinbourne10 Mpm188 EAFalilounahdisteNo ratings yet

- Low-Density Nanoporous Iron Foams Synthesized by Sol-Gel AutocombustionDocument7 pagesLow-Density Nanoporous Iron Foams Synthesized by Sol-Gel AutocombustionJahidul IslamNo ratings yet

- Project Carburizing Lupu Stefan EnglezaDocument5 pagesProject Carburizing Lupu Stefan EnglezaStefan LupuNo ratings yet

- Evaluation of The Use of Steel Slag in ConcreteDocument9 pagesEvaluation of The Use of Steel Slag in ConcreteГригорий ЛевашовNo ratings yet

- Reducing Boiler Failure with Superior Iron Transport TechnologyDocument37 pagesReducing Boiler Failure with Superior Iron Transport TechnologyMaulizarNo ratings yet

- Hjhy 6dcvb GGDocument10 pagesHjhy 6dcvb GGAngel FajmNo ratings yet

- OsidationDocument49 pagesOsidationSadhasivam VeluNo ratings yet

- InTech-Chemical and Physical Properties of Fluxes For Saw of Low Carbon SteelsDocument19 pagesInTech-Chemical and Physical Properties of Fluxes For Saw of Low Carbon SteelsSiap SiapNo ratings yet

- Journal Review 5Document15 pagesJournal Review 5Venus Abigail GutierrezNo ratings yet

- The Influence of HH Type Steel Microstructure On The Distortion Behavior of Grate Bar Part in The Indurating Machine of Pelletizing PlantDocument6 pagesThe Influence of HH Type Steel Microstructure On The Distortion Behavior of Grate Bar Part in The Indurating Machine of Pelletizing PlantkiddNo ratings yet

- Hydrogen Attack: Piping FundamentalsDocument1 pageHydrogen Attack: Piping FundamentalsWArya RaWigunanNo ratings yet

- Drmpfile 1Document10 pagesDrmpfile 1ramadoss_alwar7307No ratings yet

- Materials and Design: N. Yasavol, F. MahboubiDocument5 pagesMaterials and Design: N. Yasavol, F. MahboubiKalpNo ratings yet

- Porous ElectrodeDocument34 pagesPorous ElectrodeMirghani MohamedNo ratings yet

- Evalution of Properties and Feasibility of Non Metallic Geopolymer Coating For Corrosion Protection of RebaarsDocument10 pagesEvalution of Properties and Feasibility of Non Metallic Geopolymer Coating For Corrosion Protection of RebaarsEditor IJTSRDNo ratings yet

- Thermo-Chemistry of Non-Metallic Inclusions in Ductile Iron: ArticleDocument15 pagesThermo-Chemistry of Non-Metallic Inclusions in Ductile Iron: ArticleMonish KumarNo ratings yet

- Dry Regenerable Cuo/ - Al O Catalyst For Simultaneous Removal of Sox and Nox From Ue GasDocument7 pagesDry Regenerable Cuo/ - Al O Catalyst For Simultaneous Removal of Sox and Nox From Ue GasCatur Budi KusumoNo ratings yet

- 196 203 JMTR Jul16Document8 pages196 203 JMTR Jul16Liviu BadeaNo ratings yet

- Metals 11 01108Document12 pagesMetals 11 01108John TorrezNo ratings yet

- Alloy Recovery and Control in Steel MeltingDocument14 pagesAlloy Recovery and Control in Steel MeltingArjun KoduriNo ratings yet

- Chemical Reactions and Metal Flow in WeldingDocument40 pagesChemical Reactions and Metal Flow in WeldingJim GrayNo ratings yet

- Gas-phase flame synthesis of magnetic iron oxide nanoparticlesDocument9 pagesGas-phase flame synthesis of magnetic iron oxide nanoparticlesPpa Gpat AmitNo ratings yet

- Corrosion Brass, Steel and Brass Coated WiresDocument13 pagesCorrosion Brass, Steel and Brass Coated WiresMichaela JoanidisovaNo ratings yet

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Vocabulary Important WordsDocument7 pagesVocabulary Important WordsRonak shahNo ratings yet

- US3768541Document5 pagesUS3768541Ronak shahNo ratings yet

- Nabl 400Document674 pagesNabl 400Ronak shahNo ratings yet

- Wire Drawing FormulasDocument17 pagesWire Drawing Formulasdofan thrimavithanaNo ratings yet

- Inconel 17Document73 pagesInconel 17Ronak shahNo ratings yet

- Inconel 62Document15 pagesInconel 62Ronak shahNo ratings yet

- Inconel 690Document8 pagesInconel 690Ronak shahNo ratings yet

- Nickel Alloy Bar SpecificationDocument11 pagesNickel Alloy Bar SpecificationRonak shahNo ratings yet

- Bil Jax 2622T - ManualDocument60 pagesBil Jax 2622T - ManualDuynamndk100% (1)

- 36 Insp Pad Plate A OriDocument2 pages36 Insp Pad Plate A OriHastagnya Jangan LupaNo ratings yet

- Easyscan2 Short ManualDocument8 pagesEasyscan2 Short ManualRamon RelosaNo ratings yet

- OP100 D & OC 100 D - Spare Parts Manual 12 - 2002 - ENGDocument76 pagesOP100 D & OC 100 D - Spare Parts Manual 12 - 2002 - ENGRafael CastroNo ratings yet

- Directional Drilling Short Answer Questions 2016Document7 pagesDirectional Drilling Short Answer Questions 2016AKSHAY SHEKHAWAT0% (2)

- Engg Drawing QuestionsDocument30 pagesEngg Drawing QuestionsVarun Shastry50% (2)

- Chapter 09 Flow Measurement Applications Aps Compatibility ModeDocument12 pagesChapter 09 Flow Measurement Applications Aps Compatibility ModeBig BangNo ratings yet

- LinkDocument2 pagesLinkFresh aliveNo ratings yet

- Structural Geology CompiledDocument381 pagesStructural Geology CompiledLen-Len Cobsilen100% (2)

- A Practical Study For New Design of Essential OilsDocument17 pagesA Practical Study For New Design of Essential OilsEmmanuel PlazaNo ratings yet

- EcgDocument29 pagesEcgSouvikDattaNo ratings yet

- 1.2. Modular Programming - En-UsDocument12 pages1.2. Modular Programming - En-UsChandrasekhar K100% (1)

- OJT Lob LODocument29 pagesOJT Lob LOEsa Ghanim0% (1)

- Laser CommunicationsDocument19 pagesLaser CommunicationsRakeshNo ratings yet

- Kleppner (Introduction To Mechanics) (Errata)Document3 pagesKleppner (Introduction To Mechanics) (Errata)almarpa0% (1)

- Critical Spare For Manitou MT X1840 New ManitouDocument3 pagesCritical Spare For Manitou MT X1840 New ManitouamonNo ratings yet

- Linksys SRW-2048 User GuideDocument96 pagesLinksys SRW-2048 User GuideshiuksliadezesNo ratings yet

- Estimating Power Demand Using Diversity FactorDocument31 pagesEstimating Power Demand Using Diversity FactorRamesh Ananthanarayanan0% (1)

- Ball Drop ActivityDocument4 pagesBall Drop ActivityKogilan ChitranNo ratings yet

- Aseptic Process TechnologyDocument19 pagesAseptic Process TechnologyHimanshu ShahuNo ratings yet

- Alpha Lubricator Manual MC-2.5Document283 pagesAlpha Lubricator Manual MC-2.5diansulaeman100% (2)

- User Manual For AzAmerica - S1005 - 20131023Document35 pagesUser Manual For AzAmerica - S1005 - 20131023Alonso IbacetaNo ratings yet

- Building DesignDocument68 pagesBuilding DesignRafael Lemos100% (1)

- 1 2 10 P Gliderdesign1Document6 pages1 2 10 P Gliderdesign1api-325609547No ratings yet

- Quartz Analogue Watches User Manual: Display and FunctionsDocument3 pagesQuartz Analogue Watches User Manual: Display and FunctionsFlorin MihaiNo ratings yet

- Msds Innuprep Dna Rna Mini KitDocument21 pagesMsds Innuprep Dna Rna Mini KitsyaranfbNo ratings yet

- Byv10ed 600pDocument10 pagesByv10ed 600pdavid.gjeorgevskiNo ratings yet

- Welding ReportDocument15 pagesWelding ReportSamNo ratings yet

- TP ConductionDocument25 pagesTP Conductionizham shukeriNo ratings yet