Professional Documents

Culture Documents

High-capacity drainage geocomposite

Uploaded by

Thameem SharaafOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High-capacity drainage geocomposite

Uploaded by

Thameem SharaafCopyright:

Available Formats

TECHDRAIN GTG 834 (33.

10)

Drainage geocomposite

PRODUCT DESCRIPTION :

TECHDRAIN GTG 834 (33.10) is a high-density polyethylene (HDPE)

TRIPLANAR geonet with two Polypropylene (PP) geotextiles heat

laminated. The geonet is made with 3 strands, whose geometry create

channels with a high flow capacity, also under pressure and at very low

gradients. Techdrain has an excellent behavior when it works at higher

pressures.

FUNCTION: DRAINAGE, FILTRATION, SEPARATION and PROTECTION in

only one product.

MAIN USES: Landfill cappings, new landfills, water reservoirs, horizontal

drainage in embankments and platforms of roads, railways, trams and

other trafficked areas, retaining structures, bridges, foundations,

basements, canals, cut-and-cover tunnels, tunnels and other

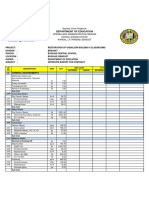

Characteristics Value Unit Qualifier Standard

(1)

Tri-planar geonet

Polymer High-density polyethylene ( HDPE )

Carbon black 2-3 % Range ASTM D 4218

3

Density 0.94 g / cm Min ASTM D1505

Thickness 330 (8.4) mil (mm) MAV ASTM D 5199

Transmissivity(2) MD 9.0 x 10-3 m² / sec(3) MARV ASTM D 4716

Tensile Strength MD 91.4 (16.0) lb / in (kN / m) MARV ASTM D 5035

(1)

Geotextile

Polymer Polypropylene ( PP )

Mass per unit area 10 (340) oz / yd² (g / m²) MARV ASTM D 5261

Grab strength 270 (1200) lbs (N) MARV ASTM D 4632

Grab elongation 50 % MARV ASTM D 4632

Tear strength 100 (450) lbs (N) MARV ASTM D 4533

CBR Puncture 735 (3.3) lbs (kN) MARV ASTM D 6241

Water flow rate 75 (3055) gpm / ft² (l / m²·min) MARV ASTM D 4491

-1

Permittivity 1,0 sec MARV ASTM D 4491

AOS 100 (150) US Sieve (µm) MaxARV ASTM D 4751

UV resistance after 500 hours 70 %retained -- ASTM D 4355

Drainage geocomposite

Ply adhesion MD 1 (178) lb / in (g/ cm) MAX ASTM D 7005

(2) -3 (3)

Transmissivity MD 3.0 x 10 m² / sec MARV ASTM D 4716

TECHDRAIN:

- Standard roll format is 11.18ft wide (3.6 m).

- Has to be covered within 14 days after installation.

(1) Geonet and geotextile properties listed are prior to lamination.

(2) Transmissivity measured using water at 21 ± 2º with a gradient of 0.1 and a confining pressure of 10,000 psf (480 kPa) between stainless

steel plates after 15 minutes. Values may vary between individual labs.

(3) 10-3 m2 / s = l / m·s

Qualifiers:

- MARV = Minimun Average Roll Value

January 2019

- MAV = Minimum Average Value

- MAX = Maximum Value

- Min = Minimum Value

- MaxARV = Maximum Average Roll Value

- MD = Machine direction (longitudinal)

These specifications are average values based on our present state of knowledge.

INTERMAS declines any responsibility due to their use in projects or civil works and hands them for informative purposes only

You might also like

- TECHDRAIN GTG27.6 Drainage Geocomposite Properties & UsesDocument1 pageTECHDRAIN GTG27.6 Drainage Geocomposite Properties & UsesJORGE LUIS GAMARRA MIRANDANo ratings yet

- High-density polyethylene geonet drainage geocompositeDocument1 pageHigh-density polyethylene geonet drainage geocompositeThameem SharaafNo ratings yet

- Ds - INTERDRAIN GM & GMG 27.6 - enDocument1 pageDs - INTERDRAIN GM & GMG 27.6 - enThameem SharaafNo ratings yet

- Ds - TECHDRAIN GTG 30.6 - enDocument1 pageDs - TECHDRAIN GTG 30.6 - enThameem SharaafNo ratings yet

- Geocomposite Tn300 English 170220171841Document1 pageGeocomposite Tn300 English 170220171841AminulIslamNo ratings yet

- TDS 140N - TipicosDocument2 pagesTDS 140N - TipicosCris AranzNo ratings yet

- Woven polypropylene geotextile TG-706 specificationsDocument1 pageWoven polypropylene geotextile TG-706 specificationsMarvin WilliamsNo ratings yet

- Miratech GT500: Technical Data SheetDocument3 pagesMiratech GT500: Technical Data SheetNicolás CanoNo ratings yet

- Product Datasheet PP-200 MARV - TYPE - 2 - BHIMJI - RAMESH HADIYADocument1 pageProduct Datasheet PP-200 MARV - TYPE - 2 - BHIMJI - RAMESH HADIYARamesh HadiyaNo ratings yet

- DRISCOPLEX 6500 Tubería y AccesoriosDocument7 pagesDRISCOPLEX 6500 Tubería y AccesoriosBrayan CJNo ratings yet

- Styroflex 2G66: Styrene Butadiene Copolymer (SBC)Document3 pagesStyroflex 2G66: Styrene Butadiene Copolymer (SBC)Ronaldo CamargoNo ratings yet

- MacMat Technical Data SheetDocument1 pageMacMat Technical Data SheetinfoNo ratings yet

- Geotex 4X4HF PDSDocument1 pageGeotex 4X4HF PDStranoNo ratings yet

- GP100ORXP enUS ASTMDocument1 pageGP100ORXP enUS ASTMRaul ArmendarizNo ratings yet

- Technical Data Sheet: Property Test Method Unit FrequencyDocument1 pageTechnical Data Sheet: Property Test Method Unit FrequencyJuli JulekNo ratings yet

- Especificacion - Textured - LLDPEDocument1 pageEspecificacion - Textured - LLDPERainer TerronesNo ratings yet

- Especificación LLDPEDocument1 pageEspecificación LLDPERainer TerronesNo ratings yet

- Specs Woven 2002 - Updated 102018Document1 pageSpecs Woven 2002 - Updated 102018tranoNo ratings yet

- Polygomma EPDM Roofing Membrane CatalogueDocument4 pagesPolygomma EPDM Roofing Membrane Cataloguepolygomma Industries Pvt. LtdNo ratings yet

- GT Geotextile: Non Woven Polyester GeotextileDocument1 pageGT Geotextile: Non Woven Polyester Geotextilemohamad imam ukhrowiNo ratings yet

- US 160NW: Property Test Method English MetricDocument1 pageUS 160NW: Property Test Method English MetricChrislet VaelNo ratings yet

- Deckorators WPC Properties: Property Test Method ResultDocument1 pageDeckorators WPC Properties: Property Test Method ResultCarlos CardenasNo ratings yet

- Pultruded Composites Material Property ComparisonDocument5 pagesPultruded Composites Material Property ComparisonJohn WycliffeNo ratings yet

- Global Synthetics Proliner HDPE Smooth DatasheetDocument1 pageGlobal Synthetics Proliner HDPE Smooth DatasheetMatt GhanaviNo ratings yet

- SKAPS M330 SpecDocument1 pageSKAPS M330 SpectranoNo ratings yet

- PAVCO Perú - Geotextil NT - NW011 - Marv - Abril - 13 Eng PDFDocument1 pagePAVCO Perú - Geotextil NT - NW011 - Marv - Abril - 13 Eng PDFArmandoNo ratings yet

- Solmax - HDPE REFLECTIVE IMPERIALDocument6 pagesSolmax - HDPE REFLECTIVE IMPERIALchipnowNo ratings yet

- Comparison GBX11 TriAxDocument1 pageComparison GBX11 TriAxjordiNo ratings yet

- Tensar - BX161060 MPDSDocument1 pageTensar - BX161060 MPDSkapoor234No ratings yet

- Titan Wickdrain - Sept2022 FICHA TECNICA MECHAS DRENANTESDocument1 pageTitan Wickdrain - Sept2022 FICHA TECNICA MECHAS DRENANTESJean CausilNo ratings yet

- Product Specification: Interax™ Foundation NXF-FG GeogridDocument1 pageProduct Specification: Interax™ Foundation NXF-FG GeogridRobert Gomez FlorNo ratings yet

- Mirafi S800: Gai-LapDocument1 pageMirafi S800: Gai-LapRamiro ChambiNo ratings yet

- BinanizincspecsDocument6 pagesBinanizincspecsJimmy ThomasNo ratings yet

- Durolon HFR 1910Document2 pagesDurolon HFR 1910elrolo3000No ratings yet

- Polygomma EPDM Pond Liner BrochureDocument4 pagesPolygomma EPDM Pond Liner Brochurepolygomma Industries Pvt. LtdNo ratings yet

- Mirafi-500X PDSDocument1 pageMirafi-500X PDSLarry Wayne Sumpter, JrNo ratings yet

- Data Sheet - Polyfelt® Alidrain AD530 (300 604-td-10-18) PDFDocument1 pageData Sheet - Polyfelt® Alidrain AD530 (300 604-td-10-18) PDFErnie ErnieNo ratings yet

- HDPE Espec. Tec. FM SeriesDocument1 pageHDPE Espec. Tec. FM SeriesYhonny ValenzuelaNo ratings yet

- Geotex 250st PdsDocument1 pageGeotex 250st PdssoumyarajNo ratings yet

- Ficha Tecnica Abs Tairilac Ag12a0Document1 pageFicha Tecnica Abs Tairilac Ag12a0Rula SiuNo ratings yet

- Property Test Method English Metric: US Fabrics, Inc. - 3904 Virginia Avenue - Cincinnati, OH 45227Document1 pageProperty Test Method English Metric: US Fabrics, Inc. - 3904 Virginia Avenue - Cincinnati, OH 45227Chrislet VaelNo ratings yet

- MIRATAKDocument1 pageMIRATAKmiroslava mondragonNo ratings yet

- Product Data Sheet PP 200Document1 pageProduct Data Sheet PP 200AlonsoNo ratings yet

- Geotex 3X3HF PDSDocument1 pageGeotex 3X3HF PDStranoNo ratings yet

- Textured HDPE Geomembrane Technical Data SheetDocument1 pageTextured HDPE Geomembrane Technical Data SheetAndrew Zapanta Jr.No ratings yet

- PP PP9074MED DatasheetDocument1 pagePP PP9074MED DatasheetDiogo SouzaNo ratings yet

- TDS-GEOPROTEC-GS3000S-22-01 Rev.01Document1 pageTDS-GEOPROTEC-GS3000S-22-01 Rev.01AMINNo ratings yet

- Non Woven, Needle Punched, Staple FiberDocument2 pagesNon Woven, Needle Punched, Staple FiberAnonymous MAQrYFQDzVNo ratings yet

- T700S R4 - 04132018 ActualDocument2 pagesT700S R4 - 04132018 ActualVaibhav AnuseNo ratings yet

- Nilex Woven 2006 Product SpecificationsDocument1 pageNilex Woven 2006 Product SpecificationstranoNo ratings yet

- Ccis 200Document1 pageCcis 200bbomersbackNo ratings yet

- Mirafi 600X: Minimum Average Roll Value Mechanical Properties Test Method Unit MD CDDocument1 pageMirafi 600X: Minimum Average Roll Value Mechanical Properties Test Method Unit MD CDGautam RaiNo ratings yet

- NTPEP Approved Geotextile US 4800Document1 pageNTPEP Approved Geotextile US 4800Chrislet VaelNo ratings yet

- 01.03.02.106 Spesifikasi-SOLMAX THA HDPE 2.00mm Black Smooth - 1084285 (HDS-200LM)Document1 page01.03.02.106 Spesifikasi-SOLMAX THA HDPE 2.00mm Black Smooth - 1084285 (HDS-200LM)Aswin MustaminNo ratings yet

- PQAGT250 Signed-1Document1 pagePQAGT250 Signed-1Roger Vila RojasNo ratings yet

- JUNE2020 Transparent Noise Barrier Technical Datasheet Final ReducedDocument2 pagesJUNE2020 Transparent Noise Barrier Technical Datasheet Final Reducedionut cerneaNo ratings yet

- Non-Woven Geotextile As Per MORTH (PPGT - 150 GSM - Type-3) - TDSDocument1 pageNon-Woven Geotextile As Per MORTH (PPGT - 150 GSM - Type-3) - TDSSumit Gupta100% (1)

- T700S Technical Data Sheet 1 PDFDocument2 pagesT700S Technical Data Sheet 1 PDFgk9No ratings yet

- Acoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsFrom EverandAcoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsNo ratings yet

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceFrom EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNo ratings yet

- BS en 15836-1-2010Document22 pagesBS en 15836-1-2010Thameem SharaafNo ratings yet

- Qdrain C15 65 10F Eng 1Document1 pageQdrain C15 65 10F Eng 1Thameem SharaafNo ratings yet

- Qdrain C15 65 12P Eng 1Document1 pageQdrain C15 65 12P Eng 1Thameem SharaafNo ratings yet

- Qdrain C20 65 10F EngDocument1 pageQdrain C20 65 10F EngThameem SharaafNo ratings yet

- Qdrain C15 65 14F Eng 1Document1 pageQdrain C15 65 14F Eng 1Thameem SharaafNo ratings yet

- BaseLok GeoCell Installation GuideDocument4 pagesBaseLok GeoCell Installation GuideThameem SharaafNo ratings yet

- NGF TEC BrochureDocument5 pagesNGF TEC BrochureThameem SharaafNo ratings yet

- Qdrain ZW8 100 10F Eng Rev0 20Document1 pageQdrain ZW8 100 10F Eng Rev0 20Thameem SharaafNo ratings yet

- BS en 15836-2-2010Document24 pagesBS en 15836-2-2010Thameem Sharaaf100% (1)

- Particular Spec For Geocell - Industrial Plots - East RailwayDocument4 pagesParticular Spec For Geocell - Industrial Plots - East RailwayThameem SharaafNo ratings yet

- PRS-NEOWEB® Cellular Confinement System (PDFDrive)Document17 pagesPRS-NEOWEB® Cellular Confinement System (PDFDrive)Thameem SharaafNo ratings yet

- Geoinfra Geocells FinalDocument6 pagesGeoinfra Geocells FinalAzzam IdrisNo ratings yet

- Bearing Capacity 1Document10 pagesBearing Capacity 1Thameem SharaafNo ratings yet

- Specification of SUDAS For TRMDocument1 pageSpecification of SUDAS For TRMThameem SharaafNo ratings yet

- Experimental Studies On Geocells and Mat Systems For Stabilization of Unpaved Shoulders and Temporary RoadsDocument139 pagesExperimental Studies On Geocells and Mat Systems For Stabilization of Unpaved Shoulders and Temporary RoadsThameem SharaafNo ratings yet

- SUDAS Design Manual For Turf Reinforcement Mats (TRM)Document5 pagesSUDAS Design Manual For Turf Reinforcement Mats (TRM)Thameem SharaafNo ratings yet

- Geosynthetic Design Guidance For Landfill Cells - NSCEPDocument211 pagesGeosynthetic Design Guidance For Landfill Cells - NSCEPThameem SharaafNo ratings yet

- Ds - TECHDRAIN GTG 720 - enDocument1 pageDs - TECHDRAIN GTG 720 - enThameem SharaafNo ratings yet

- Ds - INTERDRAIN GMG 620 - enDocument1 pageDs - INTERDRAIN GMG 620 - enThameem SharaafNo ratings yet

- Ds - INTERDRAIN GMG 620 - enDocument1 pageDs - INTERDRAIN GMG 620 - enThameem SharaafNo ratings yet

- PDS033 Standard GeotextilesDocument2 pagesPDS033 Standard GeotextilesThameem SharaafNo ratings yet

- Steel Mesh System For Reinforced FillDocument25 pagesSteel Mesh System For Reinforced FillThameem SharaafNo ratings yet

- NourEddine-EJECE-2017-Performance of Nonwoven Geotextiles On Soil Drainage and FiltrationDocument20 pagesNourEddine-EJECE-2017-Performance of Nonwoven Geotextiles On Soil Drainage and FiltrationRadhika KpNo ratings yet

- Edmonton - Calgary - San Diego - Seattle - Toronto - VancouverDocument7 pagesEdmonton - Calgary - San Diego - Seattle - Toronto - VancouverThameem SharaafNo ratings yet

- Geotextiles 2 Intro To Geotextiles in Erosion Control PDFDocument26 pagesGeotextiles 2 Intro To Geotextiles in Erosion Control PDFPhilip T LopezNo ratings yet

- Salt Barrier: The Problem of SaltDocument5 pagesSalt Barrier: The Problem of SaltThameem SharaafNo ratings yet

- Industrial Visit.: Mechanical EngineeringDocument9 pagesIndustrial Visit.: Mechanical EngineeringShivraj KolambekarNo ratings yet

- Elcb & RCDDocument18 pagesElcb & RCDKhay SaadNo ratings yet

- Cadb He 21 Pro H - D 4930Document8 pagesCadb He 21 Pro H - D 4930IgorVutucNo ratings yet

- Discussion - The Behavior and Load-Carrying Capacity of Unstiffened Seated Beam ConnectionsDocument6 pagesDiscussion - The Behavior and Load-Carrying Capacity of Unstiffened Seated Beam Connectionsyyanan1118No ratings yet

- Multicycle Circulating Valve With Lock Module: Applications DescriptionDocument1 pageMulticycle Circulating Valve With Lock Module: Applications DescriptionYves-donald MakoumbouNo ratings yet

- Nova Scotia Standards For Construction and Installation For Petroleum Storage Tank SystemsDocument84 pagesNova Scotia Standards For Construction and Installation For Petroleum Storage Tank SystemsMJ MagdyNo ratings yet

- Generation of Residual Stresses in Rotary Swaging ProcessDocument9 pagesGeneration of Residual Stresses in Rotary Swaging ProcessHyune Boom SheenNo ratings yet

- CFD analysis of automobile radiator with helical tubesDocument12 pagesCFD analysis of automobile radiator with helical tubesAleksandar PasicNo ratings yet

- Cbse Design Basis ReportDocument20 pagesCbse Design Basis ReportSheikh_MutaharNo ratings yet

- Flexible Cement Waterproof CoatingDocument2 pagesFlexible Cement Waterproof CoatingDharryl Dharryl DharrylNo ratings yet

- BILL No 8 - AtriumDocument86 pagesBILL No 8 - AtriumTigistuNo ratings yet

- Polymer Nanocomposites - Electrical and Thermal Properties - H0 (Springer) PDFDocument354 pagesPolymer Nanocomposites - Electrical and Thermal Properties - H0 (Springer) PDFDaniel LiconaNo ratings yet

- Betopom Arastirma 2Document31 pagesBetopom Arastirma 2KvncGmz DzrNo ratings yet

- Data Sheet Filter Drier With Interchangeable Solid Core Type DCRDocument8 pagesData Sheet Filter Drier With Interchangeable Solid Core Type DCRDima ArfNo ratings yet

- 1-21 Fire Resistance of Building AssembliesDocument37 pages1-21 Fire Resistance of Building Assembliesthongtn2007No ratings yet

- Company ProfileDocument24 pagesCompany ProfileMohamed RusfanNo ratings yet

- BUGUIAS CS Gabaldon, BENGUET PDFDocument6 pagesBUGUIAS CS Gabaldon, BENGUET PDFDenver Esyaben Sin-otNo ratings yet

- ADVANCEDBeam ManualCompositeDocument28 pagesADVANCEDBeam ManualCompositeAmir ShaikNo ratings yet

- Structure Design Report of ConveyorDocument46 pagesStructure Design Report of ConveyorNeeraj KumarNo ratings yet

- Service & Maintenance ManualDocument44 pagesService & Maintenance ManualAnonymous 2iQ1B59No ratings yet

- Design of crash barrier with reinforced concreteDocument1 pageDesign of crash barrier with reinforced concreteAnkush SharmaNo ratings yet

- CP 52 PresentationDocument27 pagesCP 52 Presentationshankar_04No ratings yet

- Cold Rooms - Notes From Danfoss CoursepptxDocument74 pagesCold Rooms - Notes From Danfoss CoursepptxFrancisco SeijasNo ratings yet

- CIVIL AGGREGATES: PROPERTIES AND USESDocument32 pagesCIVIL AGGREGATES: PROPERTIES AND USESgexNo ratings yet

- Project Cost Estimates and Bill of MaterialsDocument9 pagesProject Cost Estimates and Bill of MaterialsDean ArigNo ratings yet

- The Effects of Contaminants On The Gas Nitriding of Nitralloy-135Document61 pagesThe Effects of Contaminants On The Gas Nitriding of Nitralloy-135saltbathNo ratings yet

- Grade Beam Design CalculationDocument4 pagesGrade Beam Design CalculationArnold VercelesNo ratings yet

- Trial Mix Design G25N Sual ProjectDocument1 pageTrial Mix Design G25N Sual ProjectZulaika LainiNo ratings yet

- Boiler EmergencyDocument41 pagesBoiler Emergencysubrata guhaNo ratings yet

- Labor Manhours Cost Amp Rates PDF FreeDocument51 pagesLabor Manhours Cost Amp Rates PDF FreeBenjamin AsuncionNo ratings yet