Professional Documents

Culture Documents

Nickel Metal - GHS - EN - vEU 1.3

Uploaded by

Hang NguyenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nickel Metal - GHS - EN - vEU 1.3

Uploaded by

Hang NguyenCopyright:

Available Formats

Nickel Metal

(In accordance to Regulation (EC) No. 1907/2006, Annex II, as amended by Regulation (EU) 2015/830)

Section 1. Identification of the Substance and Company

1.1 Product Identification:

Product Name: Nickel

Synonyms:

Pellets P-Pellets S-Pellets

Discs Chips Plating Rounds

Melt Rounds Premium Melt Rounds Assorted Melt Rounds

EC No: 231-111-4

CAS No: 7440-02-0

REACH Registration number: see Section 15

1.2 Relevant Identified Uses of the Substance or mixture and Uses Advised Against

Identified Uses:

Formulation or re-packing; Use of nickel metal in the production of stainless, special steels and special alloys

Formulation or re-packing; Use of nickel metal in the production of integrated steel and iron

Formulation or re-packing; Use of nickel metal in electric arc furnace carbon steel manufacturing

Formulation or re-packing; Use of nickel metal in the production of brazing alloys

Formulation or re-packing; Use of nickel metal for the production of silver-nickel contact materials

Formulation or re-packing; Use of nickel metal and nickel containing alloys for the production of steel and other alloy

powders by atomisation

Use at industrial sites; Use of nickel metal containing powders in additive manufacturing (3D-printing)

Use at industrial sites; Use of nickel-containing stainless, special steels and special alloys

Use at industrial sites; Use of nickel-containing integrated steel and iron

Use at industrial sites; Use of nickel-containing carbon steel

Use at industrial sites; Use of nickel powder or nickel alloy powder in powder metallurgy

Use at industrial sites; Use of nickel-containing brazing alloys in industrial settings

Widespread use by professional workers; Use of nickel-containing consumables for welding/brazing by professionals

Use at industrial sites; Use of silver-nickel contact materials

Use at industrial sites; Use of nickel-containing steel and other alloy powders

Use at industrial sites; Use of nickel-containing alloys for sand blasting in industrial settings

Formulation or re-packing; Use of nickel metal in formulating and repackaging of surface treatment products

Use at industrial sites; Use of nickel metal in metal surface treatment (nickel electroplating and nickel electroforming

technologies)

Use at industrial sites; Use of nickel metal in sputter deposition techniques

Use at industrial sites; Use of nickel metal in thin film deposition by evaporation technique

Use at industrial sites; Use of nickel metal for thermal spraying

Updated: 21-April-2020 Nickel metal Page1 of 17

V1.3 (EU)

Formulation or re-packing; Use of nickel metal powder in the formulation of micronutrient additives for biogas production

Use at industrial sites; Use of nickel metal-derived micronutrient powder in biogas production

Widespread use by professional workers; Use of nickel metal-derived micronutrient in compostable bags in biogas

production

Use at industrial sites; Use of pre-reduced nickel-containing catalyst

Use at industrial sites; Intermediate use of nickel metal for the manufacture of other substances in catalyst or catalyst

precursor manufacture

Use at industrial sites; Use of nickel metal in the production of abrasive tools

Use at industrial sites; Production of batteries using nickel electrodes

Use at industrial sites; Use of nickel metal in the production of nickel-containing electronics

Use at industrial sites; Intermediate use of nickel metal for the manufacture of nickel-containing inorganic pigments

Use at industrial sites; Use of nickel metal powder in the production of magnets

Use at industrial sites; Intermediate use of nickel metal for the manufacture of nickel salts

Use at industrial sites; Use of nickel containing anti-seize lubricant

Service life (worker at industrial site); Service life of nickel alloys and nickel-coated metal objects (machining and

handling) in industrial settings

Service life (professional worker); Service life of nickel alloys and nickel-coated metal objects (machining and handling) in

professional settings

Service life (worker at industrial site); Service life of nickel-containing electronic parts and batteries in industrial settings

Service life (professional worker); Service life of nickel-containing electronic parts and batteries in professional settings

Service life (worker at industrial site); Service life of abrasive tools containing nickel in industrial settings

Service life (professional worker); Service life of abrasive tools containing nickel in professional settings

Consumer use: Use of nickel-containing alloys for welding/brazing by consumers

Uses Advised Against:

Use of nickel-containing High Sulphur stainless steel for surgical implants (AISI grade 303 or ISO 7153-1

reference grade N)

Use of nickel and nickel compounds in tattoo inks or permanent makeup products.

Use of nickel containing food contact materials for which release into foodstuff would exceed more than

0.14mg/kg food of nickel

1.3 Details of the Supplier of the Safety Data Sheet

Manufactured by:

In Canada: Vale Newfoundland and Labrador

Vale Canada Limited Long Harbour Processing Plant

Ontario Operations Long Harbour, NL

Sudbury, ON Canada A0B 2J0

Canada P0M 1N0

In the UK:

Vale Europe Limited

Clydach Refinery

Clydach, Swansea

Updated: 21-April-2020 Nickel metal Page 2 of 17

V1.3 (EU)

UK, SA6 5QR

Telephone number: +44 (0) 1792 8412501

Email: Europe.Regulation@vale.com

Distributed by: REACH Only Representative for Vale Canada

Vale Canada Limited H2 Compliance

200 Bay St., Royal Bank Plaza Rubicon Building, CIT Campus

Suite 1600, South Tower, PO Box 70 T12Y275, Bishopstown

Toronto, ON Cork, Republic of Ireland

Canada, M5J 2K2 Chris Terrett, OR Manage

Email: msds@vale.com Telephone number: +353-21-486-8121

Chris.Terrett@h2compliance.com

Imported by:

In North & South America: In Asia (Except India, & Pakistan)

Vale Americas Inc. Vale Base Metals Pacific PTE. Ltd

140 E. Ridgewood Avenue One Temasek Avenue #39-01

Suite 415, South Tower Millenia Tower

Paramus, NJ 07652 Singapore, 039192

U.S.A.

In Europe, Middle East, Africa, India & Pakistan

Vale International SA

Route de Pallatex 29

1162 Saint-Prex

Switzerland

1.4 Emergency Telephone Number

For Fire, Spill, or chemical emergency call CHEMTREC: +1 703 527-3887

for Europe call CHEMTREC: +(44) 870 8200418

Section 2. Hazards Identification

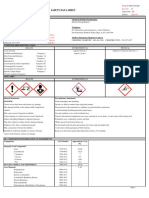

2.1 Classification of the Substance:

Classification according Regulation (EC) No. 1272/2008

Skin Sensitization – Category 1

Carcinogenicity – Category 2

Specific Target Organ Toxicity, Repeated exposure – Category 1

Hazard Pictograms: GHS07 - Exclamation mark, GHS08 - Health Hazard

Updated: 21-April-2020 Nickel metal Page 3 of 17

V1.3 (EU)

Signal Word: Danger

Hazard Statements: H317 - May cause an allergic skin reaction.

H351 - Suspected of causing cancer

H372 - Causes damage to lungs through prolonged or repeated inhalation

exposure

Precautionary Statements: P201, P202, P260, P261, P272, P280, P264, P270, P302+P352, P308+P313,

P333+P313, P314, P321, P362+P364, P405, P501

2.2: Label elements

Product identifier: Nickel

CAS #: 7440-02-0

Symbols:

GHS07 - Exclamation mark GHS08 - Health Hazard

Signal Word: Danger

Hazard Statements: H317 - May cause an allergic skin reaction.

H351 - Suspected of causing cancer

H372 - Causes damage to lungs through prolonged or repeated inhalation

exposure

Precautionary Statements: P202 - Do not handle until all safety precautions have been read and

understood

P261 - Avoid breathing dust or fume. Wear respiratory protective

equipment if fine dusts are generated.

P280 - Wear protective gloves and protective clothing

P302+352 - If on skin: Wash with plenty of soap and water.

P501 - Dispose of contents/container in accordance to local; regional;

national and international regulations

Updated: 21-April-2020 Nickel metal Page 4 of 17

V1.3 (EU)

2.3: Other hazards

The PBT and vPvB criteria of Annex XIII of the REACH regulation does not apply to inorganic substances, such as nickel

metal.

2.4: Additional Information

For full text of Precautionary Statements see section 16.

Section 3. Composition

3.1 Substances

Substance Mixture

Hazardous Typical C.A.S. EINECS/EC Label

Ingredients Composition Number No.

Nickel Metal (Ni) >99% 7440-02-0 231-111-4

3.2 Mixtures

Not applicable

Section 4. First Aid Measures

4.1 Description of first aid measures

Inhalation No specific first aid required. Get medical advice/attention if you feel unwell.

Skin Contact Remove contaminated clothing, and wash affected areas thoroughly

With soap and water. If skin irritation or rash occurs: Get medical

advice/attention. Show label if possible.

Eye Contact Irrigate eyeball thoroughly with water for at least 10 minutes. If

discomfort persists, seek medical attention.

Ingestion No specific first aid required. Get medical advice/attention if you feel unwell.

4.2 Most important symptoms and effects, both acute and delayed

Skin contact: rash; Eye contact: redness

4.3 Indication of any immediate attention and special treatment needed

If exposed or concerned: Get medical advice attention

Updated: 21-April-2020 Nickel metal Page 5 of 17

V1.3 (EU)

Section 5. Fire Fighting Measures

5.1 Extinguishing media

Suitable extinguishing media Any, type to be selected according to materials stored in the immediate

neighbourhood.

Unsuitable extinguishing media None

5.2 Special hazards arising from the substance or mixture

Non-flammable. May oxidize to nickel oxide if exposed to high temperatures within a fire. Keep containers cool with

water spray.

5.3 Advice for firefighters

Wear protective equipment if required for other materials within the immediate vicinity.

Section 6. Accidental Release Measures

6.1 Personal precautions, protective equipment and emergency procedures

Avoid generation of dusty atmospheres. Do not inhale dusts. Contaminated work clothing should not be allowed out of

the workplace. Use personal protective equipment as required. Wash hands, and face thoroughly after handling.

6.2 Environmental precautions

No specific measures needed.

6.3 Methods and material for containment and cleaning up

Pick up and replace in original container. Nickel-containing material is normally collected to recover nickel values.

6.4 Reference to other sections

See also section 7 and 8.

Section 7. Handling and Storage

7.1 Precautions for safe handling

Prevent the generation of inhalable dusts e.g. by the use of suitable ventilation. Do not inhale dust. Wear appropriate

nationally approved respirators if handling is likely to cause the concentration limits of airborne nickel to exceed the

locally prescribed exposure limits. Wear suitable protective clothing and gloves. Contaminated work clothing should not

be allowed out of the workplace.

Updated: 21-April-2020 Nickel metal Page 6 of 17

V1.3 (EU)

7.2 Conditions for safe storage, including any incompatibilities

Keep in the container supplied, and keep container closed when not use. Local regulations should be followed regarding

the storage of this product.

7.3 Specific end uses

See section 1.2.

Section 8. Exposure Controls / Personal Protection

8.1 Control parameters

8.1.1 Exposure Limits:

Nickel Metal (Ni) – CAS 7440-02-0

Exposure Limit Year

3

ACGIH TLV-TWA 1 (mg/m

1.5 * ) 2008

UK WEL 2 0.5 2006

Japan 1 1968

Korea 1 2006

China 1 2007

* - as Ni in inhalable fraction

8.1.2 Biological limit value

Not established

8.1.3 PNECs and DNELs

Unit DNEL

Dermal

Long-term local mgNi/cm2/day 0.035

Inhalation

Acute local mgNi/m3 11.9

Long-term systemic mgNi/m3 0.05

Long-term local mgNi/m3 0.05

Compartment Unit PNEC

Freshwater μg Ni/L 7.1

Sediment (bioavailable)

mg Ni/kg 109

(freshwater)

Marine water μg Ni/L 8.6

Updated: 21-April-2020 Nickel metal Page 7 of 17

V1.3 (EU)

Sediment (marine mg Ni/kg 109

water)

Agricultural soil mg Ni/kg 29.9

8.2 Exposure Controls

8.2.1 Appropriate Engineering Controls

Mechanical extraction ventilation may be required if user operations change it to other physical or chemical forms,

whether as end products, intermediates or fugitive emissions, which are inhalable. Maintain airborne nickel levels as low

as possible. Avoid repeated skin contact.

8.2.2 Individual protection

measures, such as personal

protective equipment

Eye/face protection None specific, but recommended to wear eye protection.

Skin protection (Hand protection/ Wear suitable protective clothing and gloves, which should be selected

other) specifically for the working place, depending on concentration and quantity of the

hazardous material (overalls and leather/rubber gloves). Wash skin thoroughly

after handling and before eating, drinking or smoking. Change contaminated

clothing frequently. Launder clothing and gloves as needed. Use of skin-

protective barrier cream advised.

Respiratory protection If required, use an approved respirator with particulate filters.

Thermal hazards Not applicable.

8.2.3 Environmental exposure controls

No specific measures needed.

Section 9. Physical and Chemical Properties

9.1 Information on basic physical and chemical properties

Silver-grey, odourless metal powder.

Physical state at 20°C and 101.3 kPa solid

Melting / freezing point 1455°C

Boiling point 2730°C

Decomposition temperature Not applicable

Relative density 8.9 g/cm3 at 25°C

Vapour pressure 1 mm Hg at 1810°C.

Updated: 21-April-2020 Nickel metal Page 8 of 17

V1.3 (EU)

Vapour density Not applicable

Surface tension Not applicable

Water solubility Not applicable

pH Not applicable

Evaporation rate Not applicable

Partition coefficient n-octanol/water (log value) Not applicable

Flash point Not applicable

Flammability Non-flammable

Explosive properties Non-explosive

Self-ignition temperature Autoflammability is not applicable to massive

nickel metal.

Oxidising properties Non-oxidising

Granulometry

Particle size distribution: <100 um, <99%

Stability in organic solvents and identity of relevant

Not applicable

degradation products

Dissociation constant Not applicable

Viscosity Not applicable

Magnetic properties Ferromagnetic

9.2 Other information

None

Section 10. Stability and Reactivity

10.1 Reactivity

Stable under normal conditions.

10.2 Chemical stability

Stable under normal conditions.

10.3 Possibility of hazardous reactions

Stable under normal conditions

10.4 Conditions to avoid

This product can react vigorously with acids to liberate hydrogen, which can form explosive mixtures with air. Under

special conditions nickel can react with carbon monoxide in reducing atmospheres to form nickel carbonyl, Ni(CO)4, a

toxic gas. Metal powders when heated in reducing atmospheres may become pyrophoric.

Updated: 21-April-2020 Nickel metal Page 9 of 17

V1.3 (EU)

10.5 Incompatible materials

Acids, strong oxidizing agents

10.6 Hazardous decomposition products

Nickel carbonyl gas.

Section 11. Toxicological Information 3

11.1 Information on toxicological effects

Acute toxicity

Ingestion Non-toxic- LD50 Oral Rat>9000 mg/kg

Inhalation Not classified

Skin contact Not classified

Eye contact No information available

Skin corrosion/irritation

Not classified

Serious eye damage/irritation

Not classified

Respiratory or skin sensitization

Skin Sens. Category 1. Nickel metal is a well-known skin sensitizer. Direct and prolonged skin contact with metallic nickel

may induce nickel allergy and elicit nickel allergic skin reactions in those people already sensitized to nickel, so called

nickel allergic contact dermatitis. Individuals known to be allergic to nickel should avoid contact with nickel whenever

possible to reduce the likelihood of nickel allergic contact dermatitis reactions (skin rashes). Nickel metal induced asthma

is very rare. The data is not sufficient to conclude that nickel metal is classified as a respiratory sensitizer.

Germ cell mutagenicity

Not classified

Carcinogenicity

Carcinogenicity – Category 2. To date, there is no evidence that nickel metal causes cancer in humans based on

epidemiology data from workers in the nickel producing and nickel consuming industries. A recent animal (rat) inhalation

study showed no increased respiratory cancer risk for nickel metal powder indicating that no carcinogen classification is

warranted for nickel metal The U.S. National Toxicology Program has listed metallic nickel as reasonably anticipated to be

a human carcinogen. The International Agency for Research on Cancer (IARC)(Vol 49) found there was inadequate

evidence that metallic nickel is carcinogenic to humans but since there was sufficient evidence that it is carcinogenic to

Updated: 21-April-2020 Nickel metal Page 10 of 17

V1.3 (EU)

animals, IARC concluded that metallic nickel is possibly carcinogenic to humans (Group 2B). In 1997, the ACGIH

categorized elemental nickel as: A5 "Not Suspected as a Human Carcinogen". Epidemiological studies of workers

exposed to nickel powder and to dust and fume generated in the production of nickel alloys and of stainless steel have not

indicated the presence of a significant respiratory cancer hazard.

Reproductive toxicity

Not classified

STOT – single exposure

Not classified

STOT repeated exposure

STOT repeated Category 1. Causes damage to lungs through prolonged or repeated exposure. Animal studies (rats) show

that repeated dose inhalation of micron-sized metallic nickel powder damages the lung. Chronic inflammation, lung

fibrosis and accumulation of nickel particles were observed.

Aspiration hazard

None anticipated

11.2 Other information

None

Section 12. Ecological Information

12.1 Toxicity

Not classified as hazardous to the aquatic environment.

12.2 Persistence and degradability

The PBT and vPvB criteria of Annex XIII to the Regulation do not apply to inorganic substances, such as nickel metal. The

methods for determining the biological degradability are not applicable to inorganic substances

12.3 Bioaccumulative potential

Nickel does not tend to bioaccumulate or biomagnify in aquatic or terrestrial systems.

12.4 Mobility in soil

The substance is essentially insoluble in water and therefore poorly mobile in soil.

12.5 Results of PBT and vPvB Assessment

Not applicable

12.6 Other adverse effects

None anticipated

Updated: 21-April-2020 Nickel metal Page 11 of 17

V1.3 (EU)

Section 13. Disposal Considerations

13.1 Waste treatment methods

Product

Methods of Disposal The generation of waste should be avoided or minimized wherever possible.

Disposal of this product, solutions and any by-products should at all times comply

with the requirements of environmental protection and waste disposal legislation

and any regional local authority requirements. Dispose of surplus and non-

recyclable products via a licensed waste disposal contractor. Waste should not be

disposed of untreated to the sewer unless fully compliant with the requirements of

all authorities with jurisdiction.

Hazardous Waste The classification of the product may meet the criteria for a hazardous waste.

Packaging

Methods of disposal Generation of waste should be avoided or minimized wherever possible. Waste

packaging should be recycled. Incineration or landfill should only be considered

when recycling is not feasible.

Special precautions Container must be disposed of in a safe way. Care should be taken when handling

emptied containers that have not been cleaned or rinsed out. Empty containers or

liners may retain some product residues. Avoid dispersal of spilled material and

runoff and contact with soil, waterways, drains and sewers.

13.2 Additional information

None

Section 14. Transport Information

ADR/RID ADN IMDG IATA

14.1 UN Number None None None None

14.2 UN proper Not applicable Not applicable Not applicable Not applicable

shipping name

14.3 Transport Not classified as Not classified as Not classified as Not classified as

classes dangerous for dangerous for dangerous for dangerous for

transport transport transport transport

14. Packing group Not applicable Not applicable Not applicable Not applicable

14.5 Not applicable Not applicable Not applicable Not applicable

Environmental

hazards

Updated: 21-April-2020 Nickel metal Page 12 of 17

V1.3 (EU)

14.6 Special precautions for user

Transport within user’s premises: always transport in closed containers that are upright and secure. Ensure that persons

transporting the product know what to do in the event of an accident or spillage.

14.7 Transport in bulk according to Annex II of Marpol and the IBC Code

Not harmful to the marine environment (non HME).

Section 15. Regulatory Information

15.1 Safety, health and environmental regulations/legislation specific for the substance

EU Regulation (EC) No. 1907/2006 (REACH)

Candidate List of SVHC for Not listed

Authorisation

Annex XIV List of substances Not listed

subject to Authorisation

Annex XVII List of substances Entry 27; Restriction on the use of nickel in jewelry and articles

subject to Restriction coming into direct/prolonged contact with skin.

Community Rolling Action Plan Not listed

REACH Registration #’s:

01-2119438727-29-XXXX – Vale Europe Limited

01-2119438727-29-XXXX – Vale Canada Limited (H2 Compliance acting as Only Representative)

15.2 Chemical Safety Assessment

Available. See Annex 1 for Exposure Scenarios.

Section 16. Other Information

Indications of Change:

1.0 − Original document

1.1 – Updated Only Representative for Vale Canada.

1.2 – Update of identified uses and Appendix 1-Exposure Scenarios. Removal of reference to Manitoba products.

1.3 – Update of identified uses and Appendix 1 – Exposure Scenarios.

Full text of Precautionary Statements

Prevention:

P201 - Obtain special instructions before use

P202 - Do not handle until all safety precautions have been read and understood

Updated: 21-April-2020 Nickel metal Page 13 of 17

V1.3 (EU)

P260 - Do not breathe dust or fume

P261 - Avoid breathing dust or fume. Wear respiratory protective equipment if fine dusts are generated.

P272 - Contaminated work clothing should not be allowed out of the workplace.

P280 - Wear protective gloves and protective clothing

P264 - Wash hands, and face thoroughly after handling.

P270 - Do not eat, drink or smoke when using this product.

Response:

P302+P352 - If on skin: Wash with plenty of soap and water.

P308+P313 - If exposed or concerned: Get medical advice/attention

P333+P313 - If skin irritation or rash occurs: Get medical advice/attention.

P314 - Get medical advice/attention if you feel unwell.

P321 - See Safety Data Sheet for specific treatment

P362+P364 – Take off contaminated clothing and wash it before reuse

Storage:

P405 - store locked up

Disposal:

P501 - Dispose of contents/container in accordance to local, regional, national, and international regulations

Legend

The following acronyms may be found in this document:

ACGIH American Conference of Governmental Industrial Hygienists

DNEL Derived No Effect Level

LTEL Long Term Exposure Limit

LR Lead Registrant

MMAD Mass Median Aerodynamic Diameter

NIOSH National Institute of Occupational Safety and Health

OEL Occupational Exposure Limits

OR Only Representative

OSHA Occupational Safety and Health Administration

PBT PBT: Persistent, Bioaccumulative and Toxic

PNEC Predicted No Effect Concentration

STEL Short Term Exposure Limit

STOT Specific Target Organ Toxicity

TLV-TWA Threshold Limit Value – Time Weighted Average

vPvB very Persistent and very Bioaccumulative

WEL Workplace Exposure Limit (UK HSE EH40)

Updated: 21-April-2020 Nickel metal Page 14 of 17

V1.3 (EU)

Safety Data Sheet prepared by:

Vale Canada Limited

200 Bay St., Royal Bank Plaza

Suite 1600, South Tower, PO Box 70

Toronto, ON, Canada,

M5J 2K2

msds@vale.com

SDS available online at http://www.vale.com/canada/en/business/mining/nickel/pages/default.aspx

Note:

Vale Canada Limited believes that the information in this Material Safety Data Sheet is accurate. However, Vale

Canada Limited makes no express or implied warranty as to the accuracy of such information and expressly disclaims

any liability resulting from reliance on such information.

1. Threshold Limit Values of the American Conference of Governmental Industrial Hygienists. 2016

2. Maximum Exposure Limit of the Health and Safety Executive in the U.K. in EH40/00.

3. Describes possible health hazards of the product supplied. If user operations change it to other chemical forms,

whether as end products, intermediates or fugitive emissions, the possible health hazards of such forms must be

determined by the user.

Updated: 21-April-2020 Nickel metal Page 15 of 17

V1.3 (EU)

ANNEX 1 – Exposure Scenarios

Exposure Scenarios can be obtained by clicking on the following link:

http://www.vale.com/canada/EN/business/mining/product-safety-information/reach-scenarios-metals-

powder/Pages/default.aspx

If you are unable to retrieve the document or have difficulties, please use the following email address for assistance:

msds@vale.com

ES1 - Formulation or re-packing; Use of nickel metal in the production of stainless, special steels and special alloys

ES2 - Formulation or re-packing; Use of nickel metal in the production of integrated steel and iron

ES3 - Formulation or re-packing; Use of nickel metal in electric arc furnace carbon steel manufacturing

ES4 - Formulation or re-packing; Use of nickel metal in the production of brazing alloys

ES5 - Formulation or re-packing; Use of nickel metal for the production of silver-nickel contact materials

ES6 - Formulation or re-packing; Use of nickel metal and nickel containing alloys for the production of steel and other

alloy powders by atomisation

ES7 - Use at industrial sites; Use of nickel metal containing powders in additive manufacturing (3D-printing)

ES8 - Use at industrial sites; Use of nickel-containing stainless, special steels and special alloys

ES9 - Use at industrial sites; Use of nickel-containing integrated steel and iron

ES10 - Use at industrial sites; Use of nickel-containing carbon steel

ES11 - Use at industrial sites; Use of nickel powder or nickel alloy powder in powder metallurgy

ES12 - Use at industrial sites; Use of nickel-containing brazing alloys in industrial settings

ES13 - Widespread use by professional workers; Use of nickel-containing consumables for welding/brazing by

professionals

ES14 - Use at industrial sites; Use of silver-nickel contact materials

ES15 - Use at industrial sites; Use of nickel-containing steel and other alloy powders

ES16 - Use at industrial sites; Use of nickel-containing alloys for sand blasting in industrial settings

ES17 - Formulation or re-packing; Use of nickel metal in formulating and repackaging of surface treatment products

ES18 - Use at industrial sites; Use of nickel metal in metal surface treatment (nickel electroplating and nickel

electroforming technologies)

ES19 - Use at industrial sites; Use of nickel metal in sputter deposition techniques

ES20 - Use at industrial sites; Use of nickel metal in thin film deposition by evaporation technique

ES21 - Use at industrial sites; Use of nickel metal for thermal spraying

ES22 - Formulation or re-packing; Use of nickel metal powder in the formulation of micronutrient additives for biogas

production

ES23 - Use at industrial sites; Use of nickel metal-derived micronutrient powder in biogas production

ES24 - Widespread use by professional workers; Use of nickel metal-derived micronutrient in compostable bags in

biogas production

ES25 - Use at industrial sites; Use of pre-reduced nickel-containing catalyst

Updated: 21-April-2020 Nickel metal Page 16 of 17

V1.3 (EU)

ES26 - Use at industrial sites; Intermediate use of nickel metal for the manufacture of other substances in catalyst or

catalyst precursor manufacture

ES27 - Use at industrial sites; Use of nickel metal in the production of abrasive tools

ES28 - Use at industrial sites; Production of batteries using nickel electrodes

ES29 - Use at industrial sites; Use of nickel metal in the production of nickel-containing electronics

ES30 - Use at industrial sites; Intermediate use of nickel metal for the manufacture of nickel-containing inorganic

pigments

ES31 - Use at industrial sites; Use of nickel metal powder in the production of magnets

ES32 - Use at industrial sites; Intermediate use of nickel metal for the manufacture of nickel salts

ES 33- Use at industrial sites; Use of nickel containing anti-seize lubricant

ES34 - Service life (worker at industrial site); Service life of nickel alloys and nickel-coated metal objects (machining

and handling) in industrial settings

ES35 - Service life (professional worker); Service life of nickel alloys and nickel-coated metal objects (machining and

handling) in professional settings

ES36 - Service life (worker at industrial site); Service life of nickel-containing electronic parts and batteries in

industrial settings

ES37 - Service life (professional worker); Service life of nickel-containing electronic parts and batteries in professional

settings

ES38 - Service life (worker at industrial site); Service life of abrasive tools containing nickel in industrial settings

ES39 - Service life (professional worker); Service life of abrasive tools containing nickel in professional settings

ES40 – Consumer use: Use of nickel-containing alloys for welding/brazing by consumers

Updated: 21-April-2020 Nickel metal Page 17 of 17

V1.3 (EU)

You might also like

- Nickel Metal - GHS - EN - v2.6Document16 pagesNickel Metal - GHS - EN - v2.6Hang NguyenNo ratings yet

- Solder Paste SAC305 and SAC 387Document8 pagesSolder Paste SAC305 and SAC 387QuýNguyễnNo ratings yet

- Welding Wire SG2Document4 pagesWelding Wire SG2Ferry PrasetiaNo ratings yet

- Butyl Acrylate MSDSDocument12 pagesButyl Acrylate MSDSMohamed HalemNo ratings yet

- 54L EutectrodeDocument9 pages54L EutectrodeJuan LondonoNo ratings yet

- code-W&N ARTISTS' WHITE SPIRIT SDS (ENGLISH) .Document11 pagescode-W&N ARTISTS' WHITE SPIRIT SDS (ENGLISH) .ecanalle01No ratings yet

- 308L-16 EutectrodeDocument10 pages308L-16 EutectrodeJuan LondonoNo ratings yet

- MATERIAL SAFETY DATA SHEET FOR DRY CHARGE BATTERYDocument6 pagesMATERIAL SAFETY DATA SHEET FOR DRY CHARGE BATTERYBatanNo ratings yet

- Direct To Tile Coating 276998Document18 pagesDirect To Tile Coating 276998Bose CatNo ratings yet

- 4 EUTECTRODE#US En#99006#1,0Document11 pages4 EUTECTRODE#US En#99006#1,0mohamed AdelNo ratings yet

- SDS 791471000 Inconel 718 English EUDocument9 pagesSDS 791471000 Inconel 718 English EUConstantin Romica StoicaNo ratings yet

- Battery Information Sheet: Industrial Nickel-Cadmium Cells, Modules and Battery SystemsDocument6 pagesBattery Information Sheet: Industrial Nickel-Cadmium Cells, Modules and Battery SystemsLuis Angel SantiagoNo ratings yet

- Safety Data SheetDocument7 pagesSafety Data SheetGermanYPNo ratings yet

- MSDS Copper CathodeDocument8 pagesMSDS Copper CathodeREIG Ingatlan KftNo ratings yet

- Oxygen (Refrigerated) : Safety Data SheetDocument10 pagesOxygen (Refrigerated) : Safety Data SheetDavid GoNo ratings yet

- MSDS - Yuasa Battery WetDocument9 pagesMSDS - Yuasa Battery WetBatanNo ratings yet

- 141R GY1D175 MsdsDocument9 pages141R GY1D175 Msdskasturi sarawanaNo ratings yet

- MSDS Saft NiCd Cells 2012Document6 pagesMSDS Saft NiCd Cells 2012Christina GrayNo ratings yet

- Caustic Soda Pels (Axiall) SDSDocument4 pagesCaustic Soda Pels (Axiall) SDSDeo FactuarNo ratings yet

- SOS Soap PadsDocument13 pagesSOS Soap PadsDevie PebrianaNo ratings yet

- Certus Cleaner and Degreaser MsdsDocument9 pagesCertus Cleaner and Degreaser MsdsCHIHEBNo ratings yet

- Yuasa Lead-Acid BatteryDocument13 pagesYuasa Lead-Acid BatteryNur Cholis HadiNo ratings yet

- MSDS MD 60Document9 pagesMSDS MD 60heru fahrudhiNo ratings yet

- SDS 791351002 TiAl6V4 Gd23 Type 2 EnglishDocument9 pagesSDS 791351002 TiAl6V4 Gd23 Type 2 EnglishAkshay DolasNo ratings yet

- MD-TempMSDS R120160722Document7 pagesMD-TempMSDS R120160722Sruthi SomanNo ratings yet

- Dimethyldisulfide SDSDocument12 pagesDimethyldisulfide SDSCHRISTOPHER WEALTHNo ratings yet

- Safety Data Sheet: Revised: AEDocument7 pagesSafety Data Sheet: Revised: AERoberto VargasNo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument10 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingJake VergaraNo ratings yet

- 4 TUFTRAK#US En#99008#1,0Document9 pages4 TUFTRAK#US En#99008#1,0mohamed AdelNo ratings yet

- HiTEC9325G MSDSDocument6 pagesHiTEC9325G MSDSSameh RadwanNo ratings yet

- ECO Leak Finder Aerosol BDS001308 3 20130621Document10 pagesECO Leak Finder Aerosol BDS001308 3 20130621Nair R RakeshNo ratings yet

- MSDS - Stadis 450Document20 pagesMSDS - Stadis 450aegean227No ratings yet

- MSDS Stadis 450 EngDocument19 pagesMSDS Stadis 450 EngAlejandro RojasNo ratings yet

- Material Safety Data Sheet: Page 1 of 9Document9 pagesMaterial Safety Data Sheet: Page 1 of 9Har HurNo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument11 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingRaja Mohd Amirul AfiqNo ratings yet

- Aggregates - Limestone Dolomite Safety Data SheetDocument8 pagesAggregates - Limestone Dolomite Safety Data SheetJEAN KATHLEEN SORIANONo ratings yet

- Fly Ash and Bottom Ash Safety Data Sheet Provides Cancer WarningDocument8 pagesFly Ash and Bottom Ash Safety Data Sheet Provides Cancer WarningomercomsatNo ratings yet

- Hydrate Msds enDocument15 pagesHydrate Msds enMrutunjay PatraNo ratings yet

- MSDS Magnet Copper WireDocument3 pagesMSDS Magnet Copper Wireบุญมาชัย มิ่งขวัญNo ratings yet

- Hoja de Seguridad de Electrodo de Cobre Sulfato de CobreDocument6 pagesHoja de Seguridad de Electrodo de Cobre Sulfato de Cobrehenry307No ratings yet

- MSDS - Carbothane 134 Part ADocument10 pagesMSDS - Carbothane 134 Part AChantelleNo ratings yet

- SDS Safety Data Sheet for Welding MaterialsDocument12 pagesSDS Safety Data Sheet for Welding MaterialsJose Antonio AlarconNo ratings yet

- Tin Coated Copper Wire SDS - V2Document6 pagesTin Coated Copper Wire SDS - V2quycoctuNo ratings yet

- 339 Epoxy Primer Base-SDS - NZDocument9 pages339 Epoxy Primer Base-SDS - NZjoshNo ratings yet

- 0014 5g4gc5kubDocument7 pages0014 5g4gc5kubNandar Min HtetNo ratings yet

- BT25 MSDS PDFDocument21 pagesBT25 MSDS PDFMithil SawantNo ratings yet

- Dynapack HC500W Battery MSDS - 2022-A00095683enwDocument6 pagesDynapack HC500W Battery MSDS - 2022-A00095683enwNikolayNo ratings yet

- Battery Information Sheet: Saft Compact Nickel-Cadmium Cells and BatteriesDocument7 pagesBattery Information Sheet: Saft Compact Nickel-Cadmium Cells and BatteriesCTQMNo ratings yet

- Battery Information Sheet: Saft Compact Nickel-Cadmium Cells and BatteriesDocument7 pagesBattery Information Sheet: Saft Compact Nickel-Cadmium Cells and BatteriesMohamed DhifallahNo ratings yet

- Asn96a3c05-0.63 enDocument5 pagesAsn96a3c05-0.63 enZoran ConstantinescuNo ratings yet

- MSDS - TC API MODIFIED Thread CompoundDocument10 pagesMSDS - TC API MODIFIED Thread Compoundv2nssysy6fNo ratings yet

- MATERIAL SAFETY DATA SHEET for IKA-40 Oilfield ChemicalDocument9 pagesMATERIAL SAFETY DATA SHEET for IKA-40 Oilfield Chemicaldaniel abiaNo ratings yet

- Ambersil Cold GalvaniseDocument12 pagesAmbersil Cold GalvaniseMatt HadleyNo ratings yet

- Safety Data Sheet: Nickel-Cadmium Aircraft Cells and BatteriesDocument7 pagesSafety Data Sheet: Nickel-Cadmium Aircraft Cells and BatteriesYun JungNo ratings yet

- Product Data Sheet Safety Data Sheet Dynalub 520Document4 pagesProduct Data Sheet Safety Data Sheet Dynalub 520Dima LovetskyNo ratings yet

- Jotamastic 80 Comp A Safety Data SheetDocument20 pagesJotamastic 80 Comp A Safety Data SheetE.Caglar BugraNo ratings yet

- Msds Stainless SteelDocument11 pagesMsds Stainless Steelrakesh marwahNo ratings yet

- Occupational Radiation Protection in the Uranium Mining and Processing IndustryFrom EverandOccupational Radiation Protection in the Uranium Mining and Processing IndustryNo ratings yet

- Corrosion: Corrosion ControlFrom EverandCorrosion: Corrosion ControlL L ShreirRating: 5 out of 5 stars5/5 (1)

- ASTP5004Document13 pagesASTP5004Hang NguyenNo ratings yet

- ASTM G102 Standard Practice For Calculation of Corrosion Rates and Related Information From Electrochemical MeasurementsDocument7 pagesASTM G102 Standard Practice For Calculation of Corrosion Rates and Related Information From Electrochemical MeasurementsHang NguyenNo ratings yet

- Evaporation Rates of Volatile Liquids by Shell Thin-Film EvaporometerDocument8 pagesEvaporation Rates of Volatile Liquids by Shell Thin-Film EvaporometerHang NguyenNo ratings yet

- Evaporation Rates of Volatile Liquids by Shell Thin-Film EvaporometerDocument8 pagesEvaporation Rates of Volatile Liquids by Shell Thin-Film EvaporometerHang NguyenNo ratings yet

- Experiment 3 FinalDocument13 pagesExperiment 3 FinalRvin OngNo ratings yet

- REFRIGERANTSDocument15 pagesREFRIGERANTSedwin barutNo ratings yet

- PIE_REV_WS_CHEMISTRY_Bonding Types and PropertiesDocument9 pagesPIE_REV_WS_CHEMISTRY_Bonding Types and PropertiesJes AnthonyNo ratings yet

- Word DocumentDocument7 pagesWord DocumentHlumelo SompondoNo ratings yet

- Industrial Training Performed at Piramal Pharma Solutions, Mahad, Dist-RaigadDocument32 pagesIndustrial Training Performed at Piramal Pharma Solutions, Mahad, Dist-RaigadChandan A. Wagh100% (1)

- General Organic Chemistry - Sheet - 10 - 11 & 12) (Hyperconjugation & Aromaticity) Level - 1 1Document10 pagesGeneral Organic Chemistry - Sheet - 10 - 11 & 12) (Hyperconjugation & Aromaticity) Level - 1 1IznnxxkozsksnndNo ratings yet

- Alora Night Glowing Cream DHM 2033Document4 pagesAlora Night Glowing Cream DHM 2033Muhammad ImranNo ratings yet

- Xii-Chemistry-Qb-Ans-Anil-12. Aldehydes, Ketones & Carboxylic AcidsDocument14 pagesXii-Chemistry-Qb-Ans-Anil-12. Aldehydes, Ketones & Carboxylic Acidscsd4995No ratings yet

- Performance - Task - Lab - Report (With Answer) Coffee PowderedDocument2 pagesPerformance - Task - Lab - Report (With Answer) Coffee PowderedGrechelle Audrey T. CasmoNo ratings yet

- Astm D332Document3 pagesAstm D332NizarHamrouniNo ratings yet

- Limited: Polyethylene Terephthalate (PET) JADE CZ-302 Jiangyin Xingyu New Material, Chine Properties DescriptionDocument1 pageLimited: Polyethylene Terephthalate (PET) JADE CZ-302 Jiangyin Xingyu New Material, Chine Properties DescriptionTiare Vásquez PérezNo ratings yet

- Step Growth Polymerization: Understanding Factors that Drive EquilibriumDocument55 pagesStep Growth Polymerization: Understanding Factors that Drive EquilibriumGoopNo ratings yet

- Nano Material EsDocument156 pagesNano Material EsAreitos DelgadoNo ratings yet

- 20 eDocument57 pages20 eakanksha vermaNo ratings yet

- Tryptose Sulphite Neomycin Agar-TD-TM 609Document3 pagesTryptose Sulphite Neomycin Agar-TD-TM 609Ventas LabsupplyNo ratings yet

- Distillation of Creosote and Creosote-Coal Tar Solutions: Standard Test Method ForDocument5 pagesDistillation of Creosote and Creosote-Coal Tar Solutions: Standard Test Method ForCasey RybackNo ratings yet

- Method Statement - FStructural Steel Fabrication - VR MallDocument18 pagesMethod Statement - FStructural Steel Fabrication - VR MallAkash YadavNo ratings yet

- SCH4U1 CH 7 ReviewDocument1 pageSCH4U1 CH 7 ReviewRashmi PrabhakarNo ratings yet

- Algae - InformationDocument13 pagesAlgae - InformationPreNo ratings yet

- Catalysis Letters 10.1007s10562-012-0829-xDocument8 pagesCatalysis Letters 10.1007s10562-012-0829-xyokeshNo ratings yet

- Gas Turbine Packaging Options and Features Klaus Brun, Ph.D. Marybeth G. NoredDocument25 pagesGas Turbine Packaging Options and Features Klaus Brun, Ph.D. Marybeth G. Noredvaratharajan g rNo ratings yet

- 1 ACapstoneeeeersDocument30 pages1 ACapstoneeeeersSamantha Jeka Bianca Asna100% (2)

- Fertilizer and Lime Regulations in SCDocument9 pagesFertilizer and Lime Regulations in SCAnas El Kadiri100% (2)

- Strahman Hoses and Hose AssembliesDocument1 pageStrahman Hoses and Hose AssembliesrheriNo ratings yet

- TDS - Bronco Cemgrout SP75Document4 pagesTDS - Bronco Cemgrout SP75Jignessh JoshiNo ratings yet

- Benzoin Essential Oil COA GC AnalysisDocument2 pagesBenzoin Essential Oil COA GC AnalysisAgung RianaNo ratings yet

- Biochem Reviewer Module 1 2Document9 pagesBiochem Reviewer Module 1 2cam broquelNo ratings yet

- IsomerismDocument49 pagesIsomerismkarmanyaraina4No ratings yet

- 80005302enDocument134 pages80005302enUlfahanny RachsetyaNo ratings yet

- Harga Satuan Obat Generik TerbaruDocument8 pagesHarga Satuan Obat Generik TerbaruBunga LadipaNo ratings yet