Professional Documents

Culture Documents

AC - System - Diagnostics - Poster - Loop Components Temperature

Uploaded by

Kello jamesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AC - System - Diagnostics - Poster - Loop Components Temperature

Uploaded by

Kello jamesCopyright:

Available Formats

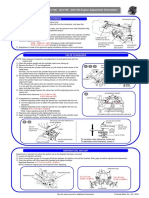

AC System Diagnostics - Loop Components Temperature HOW TO PROCEED

FOR PROPER DIAGNOSTICS,

FOLLOW THE STEPS BELOW

RECOMMENDED TOOLS

PROFESSIONAL DEVICES

DESIGNED FOR AC SERVICE

DUAL PROBE

EXPANSION VALVE EVAPORATOR THERMOMETER

DIRECTLY ON THE UNIT

2-5 °C

35-41 °F

DIRECTLY ON THE SURFACE

0-5 °C

32-41 °F

ABOVE 10 °C

2 Start the AC system, set it to

produce the lowest temperature

and maximum air blow

INFRARED

THERMOMETER

/ 50 °F

3

POTENTIAL CAUSES Start the

ABOVE 10 °C BELOW 0 °C engine

1

• Lack of improper compressor lubrication

/ 50 °F / 32 °F • Lack of condenser fins / fins deteriorated

• Restricted flow inside the condenser Measure the

POTENTIAL CAUSES FREEZING, • Restricted flow inside the receiver dryer temperature

• Fan not running and compare

• Lack of or improper compressor lubrication POTENTIAL CAUSES received values

• Fan too slow with cases

• Lack of condenser fins / fins deteriorated • Improper refrigerant

• Improper / contaminated refrigerant presented

• Restricted flow inside the condenser • contaminated refrigerant in the poster.

• Too high / low refrigerant level

4

• Restricted flow inside the receiver dryer • Air in the AC loop Wait, until the engine

• Fan not running • Moisture in the AC loop gets to its proper

working temperature

• Fan too slow • Compressor constantly running

• Improper / contaminated refrigerant (improper compressor control)

• Too high / low refrigerant level

Assess temperature ranges

PROPER IMPROPER SPECIAL

TEMPERATURES TEMPERATURES ATTENTION

RANGE RANGE REQUIRED

COMPRESSOR SUCTION LINE

EVAPORATOR - COMPRESSOR

The temperature diagnostics is one of the basic methods to troubleshoot the

air-conditioning system cost-effectively and quickly. Temperature ranges

5-15 °C presented in the material are only for guidance, and are applicable for

41-59 °F AC loop equipped with an expansion valve and where measurements

are taken under an ambient temperature of 20 °C/68 °F

BELOW 5 °C

/ 41 °F

POTENTIAL CAUSES

• Faulty expansion device

• Freezing low pressure hose

• Low refrigerant level TEMPERATURES DIFFERENCE METHOD - CONDENSER’S INLET TEMP. MINUS OUTLET TEMP.

• Leakage in the loop

• Contamination

• Compressor overload (speed)

THE DIFFERENCE MEASURED

IS EQUAL TO / BETWEEN RANGE OF:

CONDENSER CONDENSER

INLET TEMP. OUTLET TEMP.

5-14 °C / 41-58 °F

POOR SYSTEM PERFORMANCE,

HIGH PRESSURE

RECEIVER DRYER

POTENTIAL CAUSES

DIRECTLY ON THE UNIT

• Restricted airflow through

the condenser’s surface – soiled

CONDENSER - RECEIVER DRYER • Bent tubes / fins, corroded / missing fins

• Malfunctioning AC fan / fan clutch

CONDENSER TO RECEIVER DRYER LINE • System overcharge

30-50 °C CONDENSER OUTLET CONDENSER INLET

86-122 °F TO RECEIVER DRYER FROM COMPRESSOR

COMPRESSOR

40-60 °C 60-90 °C 14-19 °C / 58-66 °F

ABOVE 50 °C DIRECTLY ON THE UNIT

104-140 °F 140-194 °F SERPENTINE CONDENSER

/ 122 °F

60-90 °C

POTENTIAL CAUSES 140-194 °F ABOVE 60 °C ABOVE 90 °C 19-28 °C / 66-82 °F

• Lack of lubrication / 140 °F / 194 °F PARALLEL FLOW CONDENSER

• Too much UV dye removing the oil film

• Fans not running ABOVE 90 °C

• Fans not running at all speeds / 194 °F POTENTIAL CAUSES

• Blockage of the condenser inside • Lack of lubrication

• Fins corroded by salt & water

POTENTIAL CAUSES • Too much UV dye removing the oil film 30 - 45 °C / 86-113 °F

• Too much refrigerant in the AC system Fans not running / not running at all speeds

• Contaminated refrigerant • Lack of improper compressor lubrication

• POOR SYSTEM PERFORMANCE,

• Condenser inner Blockage HIGH PRESSURE

• Nitrogen/ Air in the AC system • Lack of condenser fins / fins deteriorated

• Fins corroded by salt & water

• Blocked filter dryer • Restricted flow inside the condenser

• Too much refrigerant in the AC system POTENTIAL CAUSES

• Blocked expansion valve • Restricted flow inside the receiver dryer

• Contaminated refrigerant • Internal clogs or restrictions

• Compressor running all the time • Fan not running

• Nitrogen/ Air in the AC system inside the condenser

• Fan too slow

• Blocked filter dryer • malfunctioning condenser

• Improper / contaminated refrigerant

• Blocked expansion valve

• Too high / low refrigerant level

• Compressor running all the time

Want You can rely on our AC system expertise backed by more than 95 years of experience in the cooling business. We match any learning need. Our concept is worldwide. All rights are reserved. Nissens® is a registered trademarks owned by Nissens A/S. Neither

this complete poster nor any parts of it may be copied, reproduced or published in any way

Depending on the required knowledge, We teach in many languagesand can without written permission from Nissens A/S. Copyrights Nissens A/S, Ormhøjgårdvej 9,

to learn Learn more about technical trainings available from Nissens worldwide and get access to Nissens’ technical materials NTC offers various learning levels. offer training in Europe, Asia and North America. DK-8700 Horsens, Denmark. www.nissens.com

Every possible effort and endeavor have been made in order to ensure that the information

more? related to service and diagnostics of the automotive climate systems at www.nissens.com/training We explain matters simply. We listen to the aftermarket. contained in this poster is correct at the date of issue. Nissens A/S, however, disclaims any liability

for printing errors or inaccuracies, and for any damage or caused by use of the poster data.

We tell stories, show examples, and present We base our knowledge on reliable expert sources

very illustrative pictures and videos. across Europe and America.

Printed in the EU. January 2017

You might also like

- 2007 Nissan Xterra 16Document18 pages2007 Nissan Xterra 16Roma Roma100% (1)

- Sony str-dn1030 Ver1.0 PDFDocument122 pagesSony str-dn1030 Ver1.0 PDFciineNo ratings yet

- Tools OBDIIpinjumpDocument1 pageTools OBDIIpinjumpbob loblawNo ratings yet

- Jthomas 2010Document408 pagesJthomas 2010Frankie MurdockNo ratings yet

- Starting & Charging System: SectionDocument36 pagesStarting & Charging System: Sectionmuki461100% (1)

- Temco Fireplace ManualDocument17 pagesTemco Fireplace ManualSullymar DiazNo ratings yet

- Onan Electronic Ignition UpgradeDocument4 pagesOnan Electronic Ignition UpgradeGeorgia SchurmeierNo ratings yet

- Honda HRA214 Quick AdjustDocument1 pageHonda HRA214 Quick AdjusthicksdpNo ratings yet

- Passat W8 Engine Management, Motronic ME 7.1.1: Self-Study Program Course Number 843103Document56 pagesPassat W8 Engine Management, Motronic ME 7.1.1: Self-Study Program Course Number 843103António FernandesNo ratings yet

- Kd900 ManualDocument60 pagesKd900 ManualDeusdete RamNo ratings yet

- 02 - EMF Parking BrakeDocument72 pages02 - EMF Parking Brakejoker63000No ratings yet

- Test Nav Install Troubleshoot Rev6Document34 pagesTest Nav Install Troubleshoot Rev6Maria Elena Beltran PuricaNo ratings yet

- Important Information: SpecificationsDocument5 pagesImportant Information: SpecificationsCassandra HuttoNo ratings yet

- 2011 LD ElectricalPickupsChassisCabs 100813 PDFDocument240 pages2011 LD ElectricalPickupsChassisCabs 100813 PDFZak CarriganNo ratings yet

- Despiece Enduro 2t 125 2015 v09r1Document102 pagesDespiece Enduro 2t 125 2015 v09r1Claudiu MorarNo ratings yet

- Rebuilding Nippon Denso Alternator 00-01 A - JeepForumDocument14 pagesRebuilding Nippon Denso Alternator 00-01 A - JeepForumejen_glNo ratings yet

- Important Information: Section 1D - Mercury Jet InstallationDocument39 pagesImportant Information: Section 1D - Mercury Jet InstallationigorNo ratings yet

- K-Pipe 50 - 01-20130710Document23 pagesK-Pipe 50 - 01-20130710MateuszNo ratings yet

- John Deere Z225 EZTrak Mower (North American Version) Service Repair Manual (Tm1477)Document15 pagesJohn Deere Z225 EZTrak Mower (North American Version) Service Repair Manual (Tm1477)zhuangfuqian31No ratings yet

- Speeduino Miata / MX5 Manual: This Manual Is Compiled From The Speeduino Documentation Wiki: Thu Sep 20 2018Document44 pagesSpeeduino Miata / MX5 Manual: This Manual Is Compiled From The Speeduino Documentation Wiki: Thu Sep 20 2018Manny MoralesNo ratings yet

- 95-99 Nissan Maxima Wire Harness BreakageDocument14 pages95-99 Nissan Maxima Wire Harness Breakageohromeo100% (2)

- 2013 Nissan Xterra Service Repair Manual PDFDocument12 pages2013 Nissan Xterra Service Repair Manual PDFfjjsjekdmmeNo ratings yet

- Lawn Tractors: Customer Care Hot LineDocument14 pagesLawn Tractors: Customer Care Hot LineTenny SupNo ratings yet

- EGES240 BDocument54 pagesEGES240 BEdwin GilNo ratings yet

- Dynacorn Catalog CamaroDocument70 pagesDynacorn Catalog Camarormoshier666No ratings yet

- THE IDIOT’S GUIDE TO TUNING SU CARBSDocument7 pagesTHE IDIOT’S GUIDE TO TUNING SU CARBSHimanshu SinghNo ratings yet

- Electric Controller Ebike KT 6 9 12 18 Mosfet 36V 48V 250W 1500W 2000W Bluetooth - EBayDocument9 pagesElectric Controller Ebike KT 6 9 12 18 Mosfet 36V 48V 250W 1500W 2000W Bluetooth - EBayTom HarkinsNo ratings yet

- MC-10086369-5448 Gear Learning Procedure UpdateDocument3 pagesMC-10086369-5448 Gear Learning Procedure Updatedemoracingedu0% (1)

- Service ManualDocument28 pagesService ManualJose Manuel Barradas100% (1)

- EGES240 CDocument50 pagesEGES240 CEdwin GilNo ratings yet

- Ls Installation InstructionsDocument14 pagesLs Installation Instructionsdalekilgore84No ratings yet

- Pwe23 Mini ManualDocument4 pagesPwe23 Mini Manualdan theman100% (1)

- Sioux 7192 PDFDocument22 pagesSioux 7192 PDFJeff LetcherNo ratings yet

- Onan Electronic Ignition UpgradeDocument4 pagesOnan Electronic Ignition Upgradesurpluselect100% (1)

- Chev 1990 CK Truck Electrical Manua PDFDocument154 pagesChev 1990 CK Truck Electrical Manua PDFFELIPE OCHOANo ratings yet

- User'S Manual: Split Type Room Air ConditionerDocument24 pagesUser'S Manual: Split Type Room Air Conditionerkhr saabNo ratings yet

- Front Drive AxleDocument19 pagesFront Drive AxleGeraldo Pozos VazquezNo ratings yet

- Reverse Camera Installation Guide: Tools and Supplies NeededDocument9 pagesReverse Camera Installation Guide: Tools and Supplies Neededaxell AxelzonNo ratings yet

- 2004 Acura TSX Power Steering Troubleshooting GuideDocument144 pages2004 Acura TSX Power Steering Troubleshooting Guidejorge antonio guillenNo ratings yet

- Regina BookDocument38 pagesRegina Bookporkface100% (1)

- Trailer 2015 - Owners - ManualDocument90 pagesTrailer 2015 - Owners - ManualJean Peltier100% (1)

- BMW ETK User ManualDocument59 pagesBMW ETK User ManualricarsenioNo ratings yet

- Body Electrical System: GeneralDocument24 pagesBody Electrical System: GeneralMile MartinovNo ratings yet

- Charging System Troubleshooting Guide: Kawasaki Ninja 650R (ER-6F) & ER-6N ResourceDocument16 pagesCharging System Troubleshooting Guide: Kawasaki Ninja 650R (ER-6F) & ER-6N Resourcemarcelo ustarezNo ratings yet

- Snap-on Scanner Personality Key Update GuideDocument2 pagesSnap-on Scanner Personality Key Update GuideKidd0% (1)

- Transfer Case Control System (TCCS) Schematic DiagramsDocument270 pagesTransfer Case Control System (TCCS) Schematic DiagramsTÚI BA GANG100% (1)

- Tuning and Log View Software User ManualDocument66 pagesTuning and Log View Software User ManualIanNo ratings yet

- Grizzly 350Document130 pagesGrizzly 350Danyel LeonNo ratings yet

- Restraints: Air Bag ModuleDocument135 pagesRestraints: Air Bag ModuleFabianNo ratings yet

- 2017 JEP MPS Catalog FIN LR SPR PDFDocument28 pages2017 JEP MPS Catalog FIN LR SPR PDFEdwinNo ratings yet

- Avalon Astoria Service ManualDocument106 pagesAvalon Astoria Service ManualGeorge GeorgeNo ratings yet

- mm38 PDFDocument32 pagesmm38 PDFDieselkNo ratings yet

- In-House Practical Training: Fabrication of Disc BrakesDocument22 pagesIn-House Practical Training: Fabrication of Disc BrakesBharat100% (1)

- ZIMO Go Kart K3 K5Document5 pagesZIMO Go Kart K3 K5Haydeen PerezNo ratings yet

- Technical Data: Rotax Kart Type R1, Model 2002Document2 pagesTechnical Data: Rotax Kart Type R1, Model 2002Gallego VilaNo ratings yet

- Ramal Honda ZCDocument6 pagesRamal Honda ZCGonzalo Muñoz ValdesNo ratings yet

- EX2600-6 Specs PDFDocument16 pagesEX2600-6 Specs PDFbasNo ratings yet

- Mpez-6 Installation Manual - Inline 201007Document8 pagesMpez-6 Installation Manual - Inline 201007api-244989438No ratings yet

- How To Reset and ReLearn The AdaptationsDocument4 pagesHow To Reset and ReLearn The AdaptationsasdfNo ratings yet

- Isolasi Dan Karakterisasi Selulosa ReviewDocument7 pagesIsolasi Dan Karakterisasi Selulosa Reviewsayang jiminNo ratings yet

- Kami Export - Investigating The PH ScaleDocument8 pagesKami Export - Investigating The PH ScaleAlberto RiveraNo ratings yet

- Final Final Year Project ReportDocument53 pagesFinal Final Year Project Reportsehaj02843% (7)

- Atomic Structure and Interatomic Bonding WorksheetDocument10 pagesAtomic Structure and Interatomic Bonding WorksheetعبداللهأحمدNo ratings yet

- Change of State (3) BSEEDocument5 pagesChange of State (3) BSEEJoan BalendrezNo ratings yet

- General Discussion of Lanthenides and ActinidesDocument53 pagesGeneral Discussion of Lanthenides and ActinidesFaraz SiddiquiNo ratings yet

- Electrochemical Cells ExplainedDocument27 pagesElectrochemical Cells ExplainedKazim RazaNo ratings yet

- PEEK PropertiesDocument56 pagesPEEK Propertiesa100acom50% (2)

- 2008 Tadross2Document98 pages2008 Tadross2potpuraaaNo ratings yet

- Activity 4Document4 pagesActivity 4Mark Galerio100% (1)

- Sustainable Innovations in Waterless Dyeing Using SCF TechniquesDocument14 pagesSustainable Innovations in Waterless Dyeing Using SCF TechniquesDeep SinojiyaNo ratings yet

- Destilación Solar JOULEDocument16 pagesDestilación Solar JOULEClemen AlarconNo ratings yet

- Chapter-Ii Literature Survey 2.1 Review of LiteratureDocument7 pagesChapter-Ii Literature Survey 2.1 Review of LiteratureramNo ratings yet

- Instruction Manual for Boy's Gas CalorimeterDocument6 pagesInstruction Manual for Boy's Gas Calorimeterramniwas123No ratings yet

- Hydrocarbons MarathonDocument353 pagesHydrocarbons MarathonGully GamingNo ratings yet

- Chemistry Unit 1 Revision 1Document23 pagesChemistry Unit 1 Revision 1cuchikapoorNo ratings yet

- Chapter 3 - Reacting Mixtures and CombustionDocument54 pagesChapter 3 - Reacting Mixtures and CombustionrrhoshackNo ratings yet

- Thermodynamics IDocument7 pagesThermodynamics IJustinnNo ratings yet

- Characterizing: DissolvedDocument9 pagesCharacterizing: DissolvedskljoleNo ratings yet

- Temperature Rise of Electrical MachinesDocument11 pagesTemperature Rise of Electrical MachinesSBNSSenanayake60% (5)

- Astm C351-92BDocument5 pagesAstm C351-92BPaulo Fernando Costa OliveiraNo ratings yet

- Ws Eastman Com ProductCatalogApps PageControllers ProdDatashDocument2 pagesWs Eastman Com ProductCatalogApps PageControllers ProdDatashJuan Victor Sulvaran ArellanoNo ratings yet

- LAS Week 2 GenChem2-Q2Document6 pagesLAS Week 2 GenChem2-Q2Drech LanadoNo ratings yet

- 4 1 - Atomic Theory BondingDocument38 pages4 1 - Atomic Theory Bondingapi-309810985No ratings yet

- ABLATION 0471615250.excerpt PDFDocument101 pagesABLATION 0471615250.excerpt PDFAsit RayNo ratings yet

- Packing Material For Absorption Tower in Sodium Nitrite Plant, RCF ExperienceDocument5 pagesPacking Material For Absorption Tower in Sodium Nitrite Plant, RCF ExperienceS Bharadwaj ReddyNo ratings yet

- DocScanner 16 Apr 2024 10 32 AmDocument1 pageDocScanner 16 Apr 2024 10 32 Amjeenikalnahai07No ratings yet

- NEET - FormulaHandbook - ChemDocument81 pagesNEET - FormulaHandbook - ChemArnavNo ratings yet

- CM TB Solutions C01Document3 pagesCM TB Solutions C01MahamIsmail86% (7)

- HT-Assisgnment-1-Questions-2019-20 Even SemDocument1 pageHT-Assisgnment-1-Questions-2019-20 Even SemGagan gowdaNo ratings yet