Professional Documents

Culture Documents

Af 201 Forum 2

Uploaded by

Chand DivneshCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Af 201 Forum 2

Uploaded by

Chand DivneshCopyright:

Available Formats

Traditional Costing Relevance

Traditional Costing, otherwise known as Volume-Based costing allocated factory overhead costs based

on the volume of production resources used. This is usually applied to cost drivers such as labour hours

or machine hours. Today, where accuracy of data holds the key to the success and development of many

Companies, the relevance of traditional costing method is often question. According to me, traditional

costing is quite relevant but in different aspects of the business. For instance, if a business is looking to

produce external reports, traditional costing would be appropriate as it is easier to implement and

allows users to easily understand the report. Furthermore, traditional costing is useful for companies

with a lower overhead cost compared to its direct cost of production. It is best used for manufacturers

that produce a few products. The implementation of traditional costing is inexpensive and therefore

would be appropriate for these types of businesses. However, there is a different type of costing that

provides more accurate cost information than traditional costing which is known to be Activity-Based

Costing (ABC). But this does not completely void the relevance of traditional costing today. Thus the

decision of which costing method to use is solely based on the information needs of the users. Managers

will need accurate information to make profitable decisions therefore ABC would be used. External

reporting would need traditional costing as implementing an expensive costing system would be

impractical.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Mid-Semester Exam: Af 302 - Information SystemsDocument14 pagesMid-Semester Exam: Af 302 - Information SystemsChand DivneshNo ratings yet

- Week 2 Tutorial SolutionDocument3 pagesWeek 2 Tutorial SolutionChand DivneshNo ratings yet

- Week 4 Tutorial Question Refer To Deegan Chapter 3 Part A Questions: 3.2, 3.10, 3.19, 3.24 (From Deegan Textbook) Part BDocument1 pageWeek 4 Tutorial Question Refer To Deegan Chapter 3 Part A Questions: 3.2, 3.10, 3.19, 3.24 (From Deegan Textbook) Part BChand DivneshNo ratings yet

- Af201 Mid-Test-S2 2019 - FINALDocument10 pagesAf201 Mid-Test-S2 2019 - FINALChand DivneshNo ratings yet

- Week 3 Tutorial Question Refer To Godfrey Chapter 2 Part A Questions: 5, 8,13, 14 (From Godfrey Textbook) Part BDocument1 pageWeek 3 Tutorial Question Refer To Godfrey Chapter 2 Part A Questions: 5, 8,13, 14 (From Godfrey Textbook) Part BChand DivneshNo ratings yet

- Week 2 Tutorial QuestionsDocument2 pagesWeek 2 Tutorial QuestionsChand DivneshNo ratings yet

- Week 2 Tutorial SolutionDocument3 pagesWeek 2 Tutorial SolutionChand DivneshNo ratings yet

- Week 2 Tutorial SolutionDocument3 pagesWeek 2 Tutorial SolutionChand DivneshNo ratings yet

- Week 4 Tutorial SolutionDocument1 pageWeek 4 Tutorial SolutionChand DivneshNo ratings yet

- AF201 REVISION PACKAGE s1, 2021Document4 pagesAF201 REVISION PACKAGE s1, 2021Chand DivneshNo ratings yet

- Tutorial 07: Project ManagementDocument1 pageTutorial 07: Project ManagementChand DivneshNo ratings yet

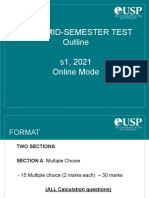

- Af201 Mid-Semester Test Outline s1, 2021 Online ModeDocument4 pagesAf201 Mid-Semester Test Outline s1, 2021 Online ModeChand DivneshNo ratings yet

- Af201 Final Exam Revision Package - S2, 2020 Face-to-Face & Blended Modes Suggested Partial SolutionsDocument9 pagesAf201 Final Exam Revision Package - S2, 2020 Face-to-Face & Blended Modes Suggested Partial SolutionsChand DivneshNo ratings yet

- Week 9: Tutorial 08 Questions With Possible Solutions: IS333: Project Management - Semester I 2021Document3 pagesWeek 9: Tutorial 08 Questions With Possible Solutions: IS333: Project Management - Semester I 2021Chand DivneshNo ratings yet

- AF201Final Exam - Suggested Solution - s1, 2019 - Final Qs 2, 3, 4Document3 pagesAF201Final Exam - Suggested Solution - s1, 2019 - Final Qs 2, 3, 4Chand DivneshNo ratings yet

- AF201 Final Exam s2, 2019 - Suggested Solution Q3 Q4Document2 pagesAF201 Final Exam s2, 2019 - Suggested Solution Q3 Q4Chand DivneshNo ratings yet

- AF201 Final Exam - Suggested Solution - s1, 2018 - Final Qs 1, 2, 3Document2 pagesAF201 Final Exam - Suggested Solution - s1, 2018 - Final Qs 1, 2, 3Chand DivneshNo ratings yet

- Tutorial 07: Project ManagementDocument1 pageTutorial 07: Project ManagementChand DivneshNo ratings yet

- AF210 Unit 4 Tutorial SolutionsDocument5 pagesAF210 Unit 4 Tutorial SolutionsChand DivneshNo ratings yet

- Tutorial 04 Questions With Possible Solutions: IS333: Project Management - Semester I 2021Document2 pagesTutorial 04 Questions With Possible Solutions: IS333: Project Management - Semester I 2021Chand DivneshNo ratings yet

- Tutorial 09: Questions With Possible SolutionsDocument4 pagesTutorial 09: Questions With Possible SolutionsChand DivneshNo ratings yet

- Af201 Final Exam Revision PackageDocument12 pagesAf201 Final Exam Revision PackageChand DivneshNo ratings yet

- Week 9: Tutorial 08 Questions With Possible Solutions: IS333: Project Management - Semester I 2021Document3 pagesWeek 9: Tutorial 08 Questions With Possible Solutions: IS333: Project Management - Semester I 2021Chand DivneshNo ratings yet

- Af302 Semester 1 - 2017 Mid-Test Solutions: Question 1 Multiple Choice SolutionsDocument9 pagesAf302 Semester 1 - 2017 Mid-Test Solutions: Question 1 Multiple Choice SolutionsChand DivneshNo ratings yet

- Tutorial 03: Questions With Partial SolutionsDocument4 pagesTutorial 03: Questions With Partial SolutionsChand DivneshNo ratings yet

- Unit 4 - Reviewed - Recorded PDFDocument11 pagesUnit 4 - Reviewed - Recorded PDFRajneetChandNo ratings yet

- Tutorial 02 Questions With Possible SolutionsDocument3 pagesTutorial 02 Questions With Possible SolutionsShretha RamNo ratings yet

- Tutorial 05 Questions With Possible Solutions: IS333: Project Management - Semester I 2021Document3 pagesTutorial 05 Questions With Possible Solutions: IS333: Project Management - Semester I 2021Chand DivneshNo ratings yet

- Tutorial 01 Questions With Possible SolutionsDocument3 pagesTutorial 01 Questions With Possible SolutionsChand DivneshNo ratings yet