Professional Documents

Culture Documents

Case Study 9

Uploaded by

aulia_affani0 ratings0% found this document useful (0 votes)

109 views5 pagesWestover electrical, Inc., is a medium-size manuIacturer oI wire windings used in making electric motors. Reiects in the Winding Department have been killing us the past two months, says Joe Wilson. He has brought in a consultant to take a look at the situation and make recommendations.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWestover electrical, Inc., is a medium-size manuIacturer oI wire windings used in making electric motors. Reiects in the Winding Department have been killing us the past two months, says Joe Wilson. He has brought in a consultant to take a look at the situation and make recommendations.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

109 views5 pagesCase Study 9

Uploaded by

aulia_affaniWestover electrical, Inc., is a medium-size manuIacturer oI wire windings used in making electric motors. Reiects in the Winding Department have been killing us the past two months, says Joe Wilson. He has brought in a consultant to take a look at the situation and make recommendations.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 5

Case Study 9: Managing Quality

Westover Electrical, Inc.

Westover Electrical, Inc., is a medium-size Houston manuIacturer oI wire windings used in

making electric motors. Joe Wilson, VP operations, has experienced an increasing problem with

reiected product Iound during the manuIacturing operation. "I`m not sure where to begin,"

admitted Joe at the weekly meeting with his boss. "Reiects in the Winding Department have been

killing us the past two months. Nobody in operations has any idea why. I have iust brought in a

consultant, Roger Gagnon, to take a look at the situation and make recommendations about how

we can Iind out what is going on. I don`t expect Roger to make technical recommendationsiust

see iI he can point us in the right direction."

Gagnon`s Iirst stop later that day was the production Iloor. His discussions with the production

supervisors in the Winding Department indicated that they had no real grasp oI what the problem

was or what to do to correct it. A tour oI the winding operation indicated that there were three

machines that wound wire onto plastic cores to produce the primary and secondary electric motor

windings. AIter inspection by quality control (QC), these windings then went to the Packaging

Department. Packaging personnel, Gagnon Iound, inspect their own work and make corrections

on the spot. The problem is that too many windings are Iound to be deIective and require

reworking beIore they can be packaged.

Gagnon`s next stop was the Quality Control Department, where he obtained the records Ior the

past month`s Winding Department reiects.

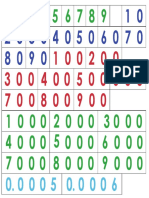

TABLE 1. 1anuary Transformer Reject Log: Winding Process

Date

No. oI Reiect Units by Cause

No.

Inspected Winder

Bad

Wind

Twisted

Wire

Broken

Leads

Abraded

Wire

Wrong

Core

Wrong

Wire

Failed

Electrical

Test

1 100 1 1 0 4 1 0 0 1

100 2 2 1 0 0 1 5 0

100 3 0 0 0 5 0 0 3

2 100 1 0 1 3 0 0 0 0

100 2 3 1 0 0 2 3 0

100 3 0 0 1 6 0 0 0

3 100 1 1 0 0 2 0 0 0

100 2 0 0 0 0 0 3 0

100 3 0 0 1 4 0 0 3

4 100 1 0 0 3 0 0 0 0

100 2 0 0 0 0 0 2 0

100 3 0 0 0 3 1 0 3

5 100 1 0 1 5 0 0 0 0

100 2 0 0 0 0 0 2 1

100 3 0 0 0 3 0 0 2

8 100 1 0 0 2 0 0 0 0

100 2 0 0 0 0 0 1 0

100 3 0 0 0 3 0 0 3

9 100 1 0 1 2 0 0 0 0

100 2 0 0 0 0 0 1 0

100 3 0 0 0 3 0 0 4

10 100 1 0 0 5 0 0 0 0

100 2 1 0 0 0 1 0 0

100 3 0 0 0 5 0 0 4

11 100 1 0 0 4 0 0 0 0

100 2 0 0 0 0 0 0 0

100 3 0 0 0 4 0 0 4

12 100 1 0 0 3 0 1 0 0

100 2 1 0 1 0 0 0 0

100 3 0 0 0 5 0 0 4

15 100 1 0 0 2 0 0 1 0

100 2 0 0 0 0 0 1 0

100 3 0 0 0 3 0 0 3

16 100 1 0 0 6 0 0 0 0

100 2 0 0 0 0 0 0 0

100 3 0 0 0 3 0 0 3

17 100 1 0 1 1 0 0 0 0

100 2 0 0 0 0 0 0 1

100 3 0 0 0 3 0 0 3

18 100 1 1 0 2 0 0 0 0

100 2 0 0 0 0 0 1 0

100 3 0 0 0 4 0 0 1

19 100 1 0 0 2 0 0 0 0

100 2 0 0 0 0 0 0 0

100 3 0 0 0 3 0 0 1

22 100 1 0 1 4 0 0 0 0

100 2 0 0 0 0 0 0 0

100 3 0 0 0 3 0 1 2

23 100 1 0 0 4 0 0 0 0

100 2 0 0 0 0 0 0 1

100 3 0 0 0 4 0 0 3

24 100 1 0 0 2 0 0 1 0

100 2 0 1 0 0 0 0 0

100 3 0 0 0 4 0 0 3

25 100 1 0 0 3 0 0 0 0

100 2 0 0 0 1 0 0 0

100 3 0 0 0 2 0 0 4

26 100 1 0 0 1 0 0 0 0

100 2 0 1 0 1 0 0 0

100 3 0 0 0 2 0 0 3

29 100 1 0 0 2 0 0 0 0

100 2 0 0 1 0 0 0 0

100 3 0 0 0 2 0 0 3

30 100 1 0 0 2 0 0 0 0

100 2 0 0 0 0 1 0 0

100 3 0 0 0 2 0 0 3

Note. Assume that each deIective unit was reiected because oI one single deIect.

DISCUSSION QUESTIONS

1. Prepare an outline Ior Roger Gagnon`s report.

2. What charts, graphs, computer printouts, and so Iorth might be included in the report?

3. Prepare Gagnon`s recommendation, with iustiIication, on one page.

4. Prepare the detail necessary to supplement Gagnon`s recommendation and iustiIication so

that Joe Wilson will understand how Gagnon arrived at his recommendations.

$ource. ProIessor Victor E. Sower, Ph.D., C.Q.E., Sam Houston State University.

You might also like

- Cost Estimating Manual for Pipelines and Marine Structures: New Printing 1999From EverandCost Estimating Manual for Pipelines and Marine Structures: New Printing 1999Rating: 5 out of 5 stars5/5 (2)

- Case StudyDocument7 pagesCase StudySimantoPreeomNo ratings yet

- Libro 1Document1,363 pagesLibro 1Edgar CespedesNo ratings yet

- Estados It Uac I On Financier ADocument7 pagesEstados It Uac I On Financier Aaide calvaNo ratings yet

- Joinr Reactions REKPONDDocument81 pagesJoinr Reactions REKPONDRaima HashunahNo ratings yet

- Sistema Decimal MontessoriDocument10 pagesSistema Decimal MontessoriRebeca Beatriz RodasNo ratings yet

- Estado Situacion FinancieraDocument7 pagesEstado Situacion FinancieraByron SincheNo ratings yet

- Estado Situacion FinancieraDocument7 pagesEstado Situacion FinancieraByron SincheNo ratings yet

- Balanzas Jun-18Document383 pagesBalanzas Jun-18JOSE LUISNo ratings yet

- Bảng 1. Giá Trị Hàm Mật Độ Phân Phối Chuẩn Hóa Φ (U) =Document11 pagesBảng 1. Giá Trị Hàm Mật Độ Phân Phối Chuẩn Hóa Φ (U) =chuchuNo ratings yet

- bảng số XSTKDocument12 pagesbảng số XSTKThảo VânNo ratings yet

- Increments & Corrections TableDocument21 pagesIncrements & Corrections Tablemateo100% (1)

- Kombinasi @380 KWDocument4 pagesKombinasi @380 KWPetrus GunturNo ratings yet

- Mis Assignment (2019-2020) : Group: 4 Section: ADocument10 pagesMis Assignment (2019-2020) : Group: 4 Section: AAditi singhNo ratings yet

- 3.2 ULS CyclicDocument5 pages3.2 ULS CyclicLaura RossNo ratings yet

- BNG S Xac Sut THNG KeDocument12 pagesBNG S Xac Sut THNG KeLại Phương ThảoNo ratings yet

- Phụ lục: Bảng 1. Giá Trị Hàm Mật Độ Phân Phối Chuẩn HóaDocument10 pagesPhụ lục: Bảng 1. Giá Trị Hàm Mật Độ Phân Phối Chuẩn HóaLoi Nguyen DaiNo ratings yet

- Annual Risk Assessment WorksheetDocument64 pagesAnnual Risk Assessment WorksheetJohan HunterNo ratings yet

- Competition Balls 0623Document9 pagesCompetition Balls 0623blue skyNo ratings yet

- BWG CalculatorDocument10 pagesBWG CalculatorELIECER SANCHEZNo ratings yet

- Tube Gauge Calculator: Measurement Section British - Inches Metric - MilimetersDocument17 pagesTube Gauge Calculator: Measurement Section British - Inches Metric - MilimetersELIECER SANCHEZNo ratings yet

- Competition BallsDocument9 pagesCompetition Ballsblue skyNo ratings yet

- Competition Balls 0425Document9 pagesCompetition Balls 0425blue skyNo ratings yet

- Supercias Estado Situacion FinancieraDocument7 pagesSupercias Estado Situacion FinancieraByron SincheNo ratings yet

- Bảng 1. Giá Trị Phân Phối Poisson P (: PX x e xDocument12 pagesBảng 1. Giá Trị Phân Phối Poisson P (: PX x e xBui Phuoc ThanhNo ratings yet

- Bang Phan Phoi FisherDocument12 pagesBang Phan Phoi FisherMy DươngNo ratings yet

- Ảnh Màn Hình 2023-08-08 Lúc 09.17.38Document12 pagesẢnh Màn Hình 2023-08-08 Lúc 09.17.38HIEU MINHNo ratings yet

- Duct Size Selector ProgramDocument2 pagesDuct Size Selector ProgramNiaYuniantiAndiniNo ratings yet

- TestDocument3 pagesTestbart bartowskiNo ratings yet

- Estado Situacion FinancieraDocument7 pagesEstado Situacion Financierapaguaymiguel91No ratings yet

- Bang So TT XSTKDocument8 pagesBang So TT XSTKNgọc NguyễnNo ratings yet

- Cinamtannin B1Document5 pagesCinamtannin B1SurahmatNo ratings yet

- REE1012ps MeDocument2 pagesREE1012ps Memaurp_spaceNo ratings yet

- Duct SizingDocument6 pagesDuct SizingDan DalameNo ratings yet

- Cash Flow: The Table Below Shows The Forecasted Cash-Flow of The ProjectDocument14 pagesCash Flow: The Table Below Shows The Forecasted Cash-Flow of The Projectlengyianchua206No ratings yet

- Format Analisa ManualDocument7 pagesFormat Analisa ManualFarah HanifatulNo ratings yet

- Bangtra MD ChuẩnDocument1 pageBangtra MD ChuẩnPhạm Chi MaiNo ratings yet

- LisDocument74 pagesLisFernando L. EscobarNo ratings yet

- Standard Normal Tail AreaDocument1 pageStandard Normal Tail AreajohnNo ratings yet

- Competition Balls 1Document9 pagesCompetition Balls 1blue skyNo ratings yet

- Supercias Estado Situacion FinancieraDocument7 pagesSupercias Estado Situacion FinancieraByron SincheNo ratings yet

- Abaco de Fadum CargasDocument5 pagesAbaco de Fadum CargaslocopexNo ratings yet

- Abaco de Fadum CargasDocument5 pagesAbaco de Fadum CargaslocopexNo ratings yet

- Ruaumoko 5 Pisos Ejecutable PDFDocument95 pagesRuaumoko 5 Pisos Ejecutable PDFPablo SeitzNo ratings yet

- ENVI0613 PsDocument2 pagesENVI0613 PsArlyss MarquezNo ratings yet

- Cuadernillo 1° Grado San José. Sil y MalviDocument302 pagesCuadernillo 1° Grado San José. Sil y MalvilibrerialgpilarNo ratings yet

- Date de Intrare (Caracteristici Geometrice Si de Material)Document8 pagesDate de Intrare (Caracteristici Geometrice Si de Material)Arianna SchulerNo ratings yet

- A Bang So Xac Xuat Thong KeDocument16 pagesA Bang So Xac Xuat Thong KeTrần Thị ThơmNo ratings yet

- Determinacion de AddressDocument67 pagesDeterminacion de AddressJoel CurielNo ratings yet

- Competence Level of Production: TrainerDocument4 pagesCompetence Level of Production: TrainerDayanand SharmaNo ratings yet

- Corrección CurvasDocument4,351 pagesCorrección CurvasGiovanny AldásNo ratings yet

- In NNNNNNNNN NNDocument22 pagesIn NNNNNNNNN NNChâu Lưu HoàngNo ratings yet

- Contador 80Document37 pagesContador 80claudiaNo ratings yet

- XT1212 PsDocument2 pagesXT1212 PsTheSummitExpressNo ratings yet

- Bang PP Xac Suat ABCDocument4 pagesBang PP Xac Suat ABCĐạt ĐạtNo ratings yet

- Cultivio SayonaraDocument12 pagesCultivio SayonaraFredy Lubin Olivar CharryNo ratings yet

- Microsoft Word - Sim-2probability and Probability DistributionpdfDocument1 pageMicrosoft Word - Sim-2probability and Probability DistributionpdfEngr EmCanNo ratings yet

- HDF YLS6000 Durma 1.05Document762 pagesHDF YLS6000 Durma 1.05ChrisNo ratings yet

- Identificacion de Parametros: Ejercicio N°1Document24 pagesIdentificacion de Parametros: Ejercicio N°1hectorNo ratings yet