Professional Documents

Culture Documents

Tyrell Train To Train

Tyrell Train To Train

Uploaded by

Florencia Sabrina EnriquezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tyrell Train To Train

Tyrell Train To Train

Uploaded by

Florencia Sabrina EnriquezCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/267588287

Train-to-Train Impact Test of Crash Energy Management Passenger Rail

Equipment: Structural Results

Conference Paper · January 2006

DOI: 10.1115/IMECE2006-13597

CITATIONS READS

39 1,618

4 authors, including:

David Tyrell

U.S. Department of Transportation, retired

89 PUBLICATIONS 817 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Passenger rail equipment crashworthiness research View project

Rail tank car integrity research View project

All content following this page was uploaded by David Tyrell on 14 April 2015.

The user has requested enhancement of the downloaded file.

Proceedings of IMECE2006

2006 ASME International Mechanical Engineering

ProceedingsCongress

of 2006 and

ASME Exposition

International

November 5-10, 2006, Chicago, Illinois, USA

Mechanical Engineering Congress & Exposition

November 5-10, Chicago, Illinois

IMECE2006-13597

IMECE2006-13597

A Train-to-Train Impact Test of Crash Energy Management

Passenger Rail Equipment: Structural Results

David Tyrell

Karina Jacobsen

Eloy Martinez

Volpe National Transportation Systems Center

US Department of Transportation

Cambridge, MA 02142 USA

A. Benjamin Perlman

Tufts University

Medford, MA 02155 USA

ABSTRACT transferred through the integrated end frame, and progressive

On March 23, 2006, a full-scale test was conducted on a controlled collapsed was contained to the energy absorbers at

passenger rail train retrofitted with newly developed cab end the roof and floor level. The results of this full-scale test have

and non-cab end crush zone designs. This test was conducted clearly demonstrated the significant enhancement in safety for

as part of a larger testing program to establish the degree of passengers and crew members involved in a push mode

enhanced performance of alternative design strategies for collision with a standing locomotive train.

passenger rail crashworthiness. The alternative design strategy

INTRODUCTION

is referred to as crash energy management (CEM), where the

The Federal Railroad Administration (FRA), with assistance

collision energy is absorbed in defined unoccupied locations

from the Volpe Center, has been conducting research on

throughout the train in a controlled progressive manner. By

passenger rail equipment crashworthiness to develop technical

controlling the deformations at critical locations the CEM train

information needed by FRA to promulgate passenger rail

is able to protect against two dangerous modes of deformation:

equipment safety regulations [1, 2, 3]. The principal focus of

override and large-scale lateral buckling.

the passenger rail equipment crashworthiness research has been

The CEM train impacted a standing locomotive-led train of

the development of structural crashworthiness and interior

equal mass at 31 mph on tangent track. The interactions at the

occupant protection strategies. The results of the research have

colliding interface and between coupled interfaces performed

also been used in the development of railroad procurement

as expected. Crush was pushed back to subsequent crush zones

specifications [4, 5] and industry standards [6, 7].

and the moving passenger train remained in-line and upright on

the tracks with minimal vertical and lateral motions. Background

The added complexity associated with this test over Cab car- and multiple unit (MU) locomotive-led trains

previous full-scale tests of the CEM design was the need to present a challenging situation in collisions. The presence of

control the interactions at the colliding interface between the passengers in lead vehicles of lighter weight and lower

two very different engaging geometries. The cab end crush strength, in comparison with conventional locomotives,

zone performed as intended because the locomotive coupler presents a potential hazard in the event of a collision. In order

pushed underneath the cab car buffer beam, and the deformable to address this exposure, FRA has conducted research on

anti-climber engaged the uneven geometry of the locomotive strategies intended to improve the crashworthiness of cab cars

anti-climber and short hood. Space was preserved for the and MU locomotives [8, 9, 10, 11, 12, 13].

operator as the cab end crush zone collapsed. Cab cars, MU locomotives, and conventional coach cars

The coupled interfaces performed as predicted by the must support an 800,000-pound longitudinal static load applied

analysis and previous testing. The conventional interlocking at the buff stops without permanent deformation. (See 49

anti-climbers engaged after the pushback couplers triggered C.F.R. 238.203 [3].) This requirement assures a minimum

and absorbed the prescribed amount of energy. Load was strength of the vehicle’s occupied volume. The buff stops are

11 Copyright © 2006 by ASME

located approximately 6 feet from the end of the vehicle and to take place in a controlled manner. Sacrificial crush zones can

support the compressive longitudinal loads from the coupler, as be designed into unoccupied locations in the rail vehicles, such

seen schematically in Figure 1. Meeting this requirement using as brake and electrical service closets and bicycle storage areas,

conventional design practices has resulted in structures that are as well lightly occupied areas, such as vestibules and stairwells.

nearly uniform in their axial strength. These structures are as These crush zones are designed to crush gracefully, with a

strong at the ends as at the mid-length. lower initial force and increased average force. Idealized coach

and cab-end force/crush characteristics are shown in Figure 2.

With such crush zones, multiple vehicles share energy

absorption during the collision, consequently preserving the

integrity of the occupied areas by managing the collision

energy.

In cab cars and MU locomotives, measures are required to

provide protection for the train operator, who is located closest

to the impact in a train-to-train collision. One alternative is to

move the operator back from the end of the cab car/MU

locomotive, inboard of the crush zone. Interior measures

similar to those used for the passengers can be employed to

protect the operator. Another alternative is to keep the operator

at the end of the cab car/MU locomotive, ahead of the crush

Figure 1. Schematic Illustration of Conventional Passenger zone. In this alternative, the operator’s cab is surrounded by a

Car structure that can slide back as the energy dissipation elements

are crushed. The area behind the operator is unoccupied but

When a cab car, MU locomotive, or conventional coach car could be used as a utility closet for brake or electrical

is loaded longitudinally, the structure of the vehicle’s body is equipment. This arrangement allows for preservation of the

initially very stiff. As the load is increased, deflections of the operator’s volume in the event of a collision but exposes the

vehicle body remain relatively small until a critical load is operator to higher deceleration than the passengers. To protect

reached, and the body begins to cripple. Once crippled, its the operator in this arrangement, additional measures, such as

ability to further support a longitudinal load is compromised. seatbelts, airbags, or other inflatable structures, may be

As a result, a much lower load is required to deform the vehicle necessary.

body longitudinally, and the deflections of the vehicle body The approach of including crush zones is termed crash

increase significantly. This behavior is shown schematically as energy management (CEM). It extends from current

the conventional force/crush characteristic in Figure 2. conventional crashworthiness design practice; the 800,000-

Because the longitudinal force develops in the impacting cars pound buff strength requirement prescribes the strength of the

first, once the peak force is attained and the vehicle body structure that supports the crush zone. By doing so, current

cripples, the colliding vehicle of a train will lose the ability to practice controls the force required for crushing the crush zone,

transmit significant longitudinal forces rearward to the trailing which in turn influences the amount of energy absorbed.

cars. In a collision, a colliding vehicle that performs in this Greater buff strength allows greater crushing forces to be

manner will singularly absorb much of the collision energy as supported, and, in turn, greater energy can be absorbed for a

the occupied volume crushes. If the collision is extreme, this given crush distance.

situation can result in the colliding vehicle being destroyed.

3000000 In-Line Impact Tests

CEM Coach Car

FRA and Volpe have conducted six tests to measure the

CEM Cab Car

2500000 crashworthiness performance of existing equipment and to

Conventional

measure the performance of equipment incorporating CEM

2000000 features. The collision scenario addressed by these tests is a

cab car-led passenger train colliding with a conventional

Force (lbf)

1500000 locomotive-led passenger train. The tests conducted for each

equipment type include:

1000000 1. Single-car impact into a fixed barrier

2. Two coupled car impact into a fixed barrier

500000 3. Cab car-led train collision with standing conventional

locomotive-led train

0 The overall objectives of these tests are to demonstrate the

0 1 2 3 4 5

effectiveness of:

Crush (ft)

− Improved crashworthiness cab car and MU locomotive

Figure 2. Idealized CEM Force/Crush Characteristics structural designs

Passenger rail equipment crashworthiness can be − Improved crashworthiness coach car structural designs

significantly increased if the force/crush behavior is engineered − A variety of interior occupant protection strategies

22 Copyright © 2006 by ASME

This arrangement of the tests allows comparison of the In the train-to-train test of existing equipment [18], at a

existing equipment’s performance with the performance of closing speed of 30 mph, the colliding cab car crushed by

improved crashworthiness equipment. The sequence of impact approximately 22 feet. No crush was imparted to any of the

tests allows an in-line train-to-train collision to be studied in trailing equipment. Due to the crippling of the cab car

incremental levels of complexity. These tests are intended to structure, the cab car overrode the conventional locomotive.

measure the crashworthiness of a single passenger car, then the The space for the operator’s seat and for approximately 47

interactions of two such cars when coupled, and finally the passenger seats was lost. During the train-to-train test of CEM

behavior of complete trains, including the interactions of the equipment, at a closing speed of 31 mph, the front of the cab

colliding cars. Table 1 summarizes the results of the car crushed by approximately 3 feet. The controlled

conventional and CEM equipment in-line tests. deformation of the cab car prevented override. All of the crew

Table 1. Summary of In-line Test Results and passenger space was preserved.

While computer simulation models are not necessary to

Test

Results describe the results of the full-scale tests, they are critical to

Critical Measurement

Description Conventional CEM Equipment their conduct. Such models were used to determine the impact

Equipment

Occupant volume Loss Preserved speed and measurements to be made, as well as to predict the

Single-car Force-crush characteristic Decreasing Increasing behavior of the equipment during the test. In turn, these

Test

Mode of deformation Ramp Controlled models have been refined using the test measurements. The

results of the first three tests were especially useful in refining

Occupant volume Loss Preserved

the models. For the fourth and subsequent tests, the pre-test

Two-car Interaction of coupled cars Sawtooth buckled Remained in-line

Test predictions have been within the repeatability of the test. These

Distribution of crush Focused on Distributed

impact car models can then be used to predict the results of similar

Occupant volume Loss Preserved collision scenarios with varying initial conditions.

Train-to- Colliding equipment interaction Override Engagement

train Test

TRAIN-TO-TRAIN TEST DESCRIPTION

Distribution of crush Focused on

impact car Distributed Figure 3 shows a schematic of the train-to-train impact test.

In this test, a moving cab car-led train impacted a standing

The results from these tests show that the CEM design has locomotive-led train. The locomotive-led train included two

superior crashworthiness performance over existing equipment. hopper cars, ballasted such that both trains weighed nearly the

In the single-car test of existing equipment [14] at a closing same. The impact locomotive was an EMD F40 compliant with

speed of 35 mph, the car was reduced in length by the Association of American Railroads (AAR) S580 standard

approximately 6 feet, with intrusion into the occupied area. [7]. The cab car-led train included four passenger cars and a

The draft sill was crippled during the impact, with plastic trailing locomotive. The passenger car consist is typical of a

deformation extending past the buff stops. Under the single-car commuter push-pull consist with a locomotive at one end,

test conditions at a closing speed of 34 mph, the CEM car leading away from a city, and a cab car at the other to lead into

crushed about 3 feet, preserving the occupied area. As a result the city. The impact occurred on tangent track, with the cab

of the controlled crush of the carbody structure, its wheels car-led train initially traveling at 30.8 mph.

remained on the rails [15]. CEM end structures were installed at each end of each

In the two-car test of existing equipment [16] at a closing passenger car. The interfaces contacting a locomotive (front

speed of 26 mph, the impact car again crushed by end of the lead cab car and the rear end of the car adjacent to

approximately 6 feet. No crush of the trailing car occurred. the rear of the locomotive) had cab end crush zones that

The conventional couplers caused the cars to buckle laterally included such features as a deformable anti-climber, pushback

and derail. As a result of this misalignment of the coupled cars, operator’s compartment, and crushable components.

the trucks immediately adjacent to the coupled connection Simulations of the test were conducted in order to verify

derailed. In the two-car test of CEM equipment, at a closing that the CEM design would function as intended and to

speed of 29 mph, the cars preserved the occupant areas. The determine the size and placement requirements for the

impact car crushed at the front and rear, and the trailing car structural instrumentation. These simulations assured that the

crushed at the front. The pushback couplers allowed the cars to final crush zone designs limited the potential for override of the

remain in-line with all of the wheels on the rails [17].

Cab End Crush Zone Non-cab End Crush Zones Cab End Crush Zone Consist 2: Locomotive and

Two Ballasted Freight Cars

Consist 1: Cab Car, Four Passenger Standing

V

Cars, and Trailing Locomotive

Figure 3. Schematic of Train-to-Train Test

33 Copyright © 2006 by ASME

colliding equipment, and would be able to propagate the crush impacting equipment to the extent necessary for the anti-

among all the train’s cars. Instrumentation included climber and integrated end frame to engage the impacting

accelerometers on all the cars, displacement transducers on the equipment appropriately.

car suspensions and on the crush zones, strain gages at As the anti-climber begins to deform, it accommodates the

selected locations, and high- and conventional-speed cameras. geometry of the locomotive and distributes the load over as

Occupant experiments were included as part of the train- large an area on the integrated end frame as can be reasonably

to-train test of CEM equipment. The interior configurations achieved. As a goal, the collision posts should carry 60

tested included facing seats with an intermediate table, percent of the crushable anti-climber loads and the corner

forward-facing commuter seats, and rear-facing commuter posts 40 percent. The anti-climber is designed to crush in a

seats. All of these interior configurations included features to controlled manner and must avoid forming a ramp or a

increase occupant protection over conventional designs. A catapult by limiting the potential for material failure. The

companion paper describes the results of the occupant anti-climber must sustain off-center impact loads and be able

experiments [19]. to transmit longitudinal loads into the end frame.

The integrated end frame is designed to remain sufficiently

EQUIPMENT TESTED

stiff in transmitting the impact load to the energy absorbers to

Figure 4 shows the FRA prototype cab end crush zone

assure the proper functioning of these elements. The

design that was developed as part of the research. The cab

integrated end frame can appropriately trigger and allow

end crush zone includes four key elements:

crushing of the energy absorbers when the coupler and the

1. A deformable anti-climber arrangement

anti-climber share the impact load, or when the load path is

2. A pushback coupler mechanism

through only the coupler or the crushable anti-climber. The

3. An integrated end frame, which incorporates an

structure attached for assuring survival volume of the operator

operator compartment

can be pushed straight back into space normally designated

4. Roof and primary energy absorbing elements

for electrical and/or brake service closets. The expected

A similar design was developed for non-cab end crush zones.

structural deformation does not interfere with ready egress

The non-cab end design does not include the deformable anti-

from the operator’s compartment before and after the design

climber or incorporate the operator’s compartment. The

crush zone stroke has been exhausted. The structure allows

pushback coupler of the non-cab end crush zone has a shorter

for the operator’s seat to be attached with sufficient security to

stroke than the cab end crush zone. The pushback coupler of

remain attached during the test. (Means of protecting the

the cab end crush zone was designed with sufficient stroke to

operator from the expected decelerations are currently being

accommodate an impact with a conventional cab car or

explored, including the use of inflatable structures [20].)

locomotive.

When the integrated end frame is subject to a high-energy

Roof Energy Absorber

impact load, the cab end crush zone deforms in a controlled

manner, activating the roof and primary energy absorbers.

The energy absorbers are able to properly function while

accommodating deflections of the integrated end frame.

These devices can absorb more than 2 million foot-pounds of

Integrated

End Frame energy.

Deformable A conventional carbody structure between the two body

Anti-Climber Operator’s bolsters (i.e., the underfloor structures at each end of the car

Compartment

Interlocking that provide support for the suspension) is sufficient to

Anti-Climber

support the loads from the cab end crush zone as it crushes

Pushback Coupler

over its design stroke.

Five passenger cars were modified with crush zones for

Primary Energy Absorber

the train-to-train test of CEM equipment. The Pioneer cars

Sliding Sill Fixed Sill

tested in the single-car [15] and two-car test [17] of CEM

equipment were repaired and used again in the train-to-train

Figure 4. Cab End Crush Zone test. The previously tested non-cab end crush zone design

was adapted to the M1 car, and non-cab end car crush zones

The activation of the pushback coupler initiates the crush were retrofitted onto both ends of one M1 car. Two additional

zone and provides a mechanism that allows each component M1 cars had a cab end crush zone on one end and non-cab end

to operate in sequence. When the coupler triggers and pushes crush zone on the other end.

back, an energy-absorbing element crushes. The travel of the

shear-back mechanism accommodates the coupler of the

44 Copyright © 2006 by ASME

Figure 5. Photographs of Crush Distribution in Train-to-Train Tests of Conventional (lower) and CEM Equipment (upper)

SELECTED TEST RESULTS the crush zones. By deducting the stroke of the pushback

Measurements were made of the overall train collision couplers from the total crush, the total shortening of the cars

dynamics during the impact. The train behavior is dependent or loss of space in the train is 5.7 feet. Overall, the energy of

on the response of the crush zones–the kinematics and the the collision was successfully managed.

force/crush characteristic. The behavior of the crush zones in Figure 6 shows the crush distribution for the cars in the

turn is dependent on the proper functioning of the components CEM consist. Crush is shown at the lead end of the cab car

and features that make up the crush zone. and summed at each successive coupled interface. The test

One-dimensional and three-dimensional collision data represent the measurements of the string potentiometers

dynamics models were developed before the test to estimate for total stroke of a crush zone (i.e., the stroke of the pushback

the crush distribution and the gross motions of each of the cars coupler and the carbody energy absorbers). The plot in Figure

in the two trains. The lumped-mass model uses non-linear 6 compares these measurements with the pre-test collision

spring characteristics to represent the crush response of each dynamics model results.

car end during a collision (see Figure 2). The current 6

estimate, based upon the design and crush model of the cab String Potentiometers

end crush zone force/crush characteristic was used for the 5

Collision Dynamics Model

two crush zones contacting locomotive ends. The force/crush

characteristic developed and measured for the non-cab end 4

crush zone [15, 17] was used as the crush behavior for all Crush (ft)

other non-cab end crush zones. The locomotives were 3

assumed to have less than 2 inches of deformation for the

collision conditions and are modeled as linear springs with 2

great stiffness.

1

Train-Level Results

The key measurements of train collision dynamics include 0

the preservation or loss of operator and passenger volume, the Lead Cab Lead Cab - Coach 1- Coach 2 - Coach 3 - Trailing Cab

Coach 1 Coach 2 Coach 3 Trailing Cab

interaction of the colliding and coupled equipment, and the

Coupled Interface

distribution of crush among the passenger cars in the cab car-

led train. Figure 6. Train-to-Train Test Crush Distribution

Figure 5 shows results from the train-to-train tests of (Summed at Coupled Interfaces)

conventional and CEM equipment. In the train-to-train test of

conventional equipment, the impacted end of the leading cab The pushback couplers and sliding sills were triggered in

car crushed by approximately 22 feet, and the impact end of every crush zone. The crush zone of the lead cab car came

the leading locomotive sustained minor structural damage. No closest to being exhausted, but no crush zone was completely

other structural damage was observed in the trailing passenger exhausted. The residual crush in each crush zone allows for

cars of the train. The cab car overrode the locomotive during the CEM system to be effective in a variety of collision

the test. The force/crush characteristic of conventional scenarios.

passenger cars prevents the distribution of crush to successive The crush distribution plot in Figure 6 shows how the

cars. After a single high peak load is exceeded, the car crush was shared between the crush zones of the CEM consist.

continues to crush at a relatively low uniform load. With the At the 30.8 mph impact speed, the crush zone of the lead cab

buckling of the primary longitudinal structural support, the car is crushed the most; crush is passed back to the following

draft sill progressed into ramp formation, which initiated crush zones. Each car in the CEM system is characterized by

override of the locomotive by the cab car (despite the cab car an increasing, stepped force/crush behavior. When the force

underframe beginning substantially lower than the locomotive level on the first crush zone reaches the second step, and the

underframe). primary energy absorbers crush, force levels also begin to be

During the test of CEM equipment, all of the trailing passed to the successive cars, causing those crush zones to

equipment, as well as the impact cab car, sustained structural trigger. Because the pushback couplers trigger at a lower load

crush. The operator and passenger space was preserved. The than the primary energy absorbers, crush is distributed to

initial kinetic energy of the collision was 20.5 million ft-lbs. additional crush zones before the third peak load level is

Each crush zone is designed to absorb at least 2.5 million ft- exceeded at the lead crush zone.

lbs. Approximately 14 feet of crush was distributed among

55 Copyright © 2006 by ASME

The pre-test collision dynamics model captures the trend usually the forward seat, table, or bulkhead. SIV is the

of crush distribution, but it consistently overestimates the total relative velocity difference between the occupant and the rail

crush at each interface. This difference is attributed to the car itself when the occupant strikes the interior. Generally,

material properties assumed for the primary energy absorbers. higher SIVs correlate with increased injury risk, depending on

The crush zones manufactured for the single-car and two-car the details of what the occupant strikes. The SIV gives an

tests of CEM equipment were a batch of steel different from initial indication of the relative severity of the occupant

the 10 crush zones manufactured for the train-to-train test. environment.

When a sample was tested, the material properties were found In Figure 8, the red traces show the data processed from

to be about 10 percent higher than the material specification. the accelerometers, and the blue traces indicate the

Accordingly, the average crush load of the primary energy corresponding model results. The test data is computed from

absorbers would be higher than estimated by the idealized the same accelerometers as used for the velocity-time histories

force/crush curves developed from the previous full-scale in Figure 7. The model results fall within the expected ranges

testing. Correspondingly, the amount of crush of the energy predicted for the cab car and following passenger cars. The

absorbers required to absorb a set amount of energy decreases secondary impact plot is shown out to 2 feet of travel distance.

with an increased average crush load. During a collision, typical commuter seats allow a free-flight

Figure 7 shows the overlay of the test and model results distance of 2 feet.

for the velocity-time histories of each vehicle in the CEM 30.0

passenger consist and the lead locomotive of the initially

Secondary Impact Veloctiy (mph)

stationary freight consist. The red traces are the test 25.0

measurements calculated from the accelerometers at the center

of gravity of each vehicle. The blue traces are the 20.0

corresponding model results. As the lead car impacts the

freight consist and begins to crush, it slows rapidly. As the 15.0

impact load travels through the passenger consist, each crush

10.0

zone progressively triggers and crushes at a similar load,

causing each successive car to slow down at a similar rate to

5.0

the first car. The velocity trace of the initially standing

locomotive is representative of the standing consist, as it

0.0

sustained no damage during the train-to-train test and 0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

essentially moved as a single mass. The model predictions Relative Displacement (feet)

agree with the test results, showing that by 0.75 seconds, all

crush is complete, and the passenger and freight consists are Figure 8. SIV Comparisons

moving together down the tracks at approximately 15 mph.

Figure 7 shows that upon impact with the standing consist, the

The differential between each car’s post-collision velocity

cab car decelerates at the highest rate in the passenger consist.

seen in the test data is associated with the uncoupling of the

The SIV in Figure 8 verifies that the cab car experiences a

cars. The corresponding conventional test took nearly 2

more severe occupant environment than the successive cars.

seconds for the crushing to complete and the two consists to

A more detailed evaluation of the interior environment and the

reach the same speed [18].

occupant experiments conducted during the CEM train-to-

35

train test is presented in a complementary paper [19]. This

30 paper discusses strategies for mitigating the more severe

occupant environment of the CEM cab car.

25

Velocity (mph)

Car-Level Results

20 The principal functions of the cab and non-cab crush zones

are to deform in a controlled manner while providing the

15

appropriate force/crush characteristics to distribute crush

10 appropriately. For the cab end crush zone, deforming in a

controlled manner includes managing the impact interface to

5 prevent override. Three types of car-to-car interfaces were in

0 the test: the colliding interface between the impacting cab car

0.0 0.2 0.4 0.6 0.8 1.0

and locomotive, the coupled interfaces between passenger

cars, and the coupled interface between the last passenger car

Time (seconds) and the trailing locomotive. Figure 9 is comprised of frames

Figure 7. Velocity-Time Histories taken from a high-speed movie of the interaction of the

impacting cab car and locomotive. These frames show the

Figure 8 shows a plot of the secondary impact velocities kinematics of the cab end crush zone as it impacts the standing

(SIVs) in the passenger train. Secondary impact refers to the conventional locomotive. The couplers initially met in state 1.

impact between the occupant and some part of the interior, The stroke of the draft gear was eventually exhausted; the load

66 Copyright © 2006 by ASME

increased on the structural fuse, which then released in state 2. coupled in state 1. The stroke of the draft gear was eventually

In state 3, the deformable anti-climber was engaged, and the exhausted; the load increased on the coupler fuse, which then

load was shared between the anti-climber and the coupler. released in state 2. After sufficient crush of the pushback

When the combined load on the coupler and anti-climber was couplers, the coupled end anti-climbers engaged, and the load

sufficient, the energy absorber structural fuse released in state was shared between the anti-climbers and the couplers. When

4. The primary and roof absorbers crushed and reached state the combined load on the coupler and anti-climber was

5 when crush stopped progressing and sufficient energy was sufficient, the energy absorber structural fuse released in state

absorbed at the impact interface. During the impact, little 3. The primary and roof absorbers crushed, and reached state

deformation of the locomotive occurred; in essence the 4 when crush stopped progressing and sufficient energy had

locomotive acted as if it was rigid. been absorbed at the coupled interface.

Coupled

Initial

Contact

Pushback

Pushback Couplers

Coupler Trigger

Triggers

Deformable Sliding Sill

Anti-climber Fuses

Engages Trigger

Crush Stops

Sliding Sill

Fuse

Triggers

Figure 10. Kinematics of Coupled Non-Cab Crush Zones

Figure 11 shows the kinematics of the trailing cab end

crush zone coupled with the trailing conventional locomotive.

Crush Stops The frames are from a high-speed movie taken with a camera

mounted on board the trailing cab car. The cab car had a

pushback coupler, while the locomotive had a conventional

coupler arrangement. Since it was a cab end crush zone, the

pushback coupler had sufficient stroke to accommodate a

conventional coupler while allowing the ends of the coupled

Figure 9. Kinematics of Impact Crush Zone equipment to come together. The first frame shows this

coupled interface shortly before the impact. The middle frame

Figure 10 is comprised of frames taken from a high-speed

shows the interface shortly after the pushback coupler has

movie of the interaction of two coupled passenger cars. These

triggered. As can be seen in the middle frame, the centerlines

frames are representative of the kinematics of all of the

of the cab car and locomotive are offset by about 4 inches.

coupled passenger car interfaces. The cars were initially

77 Copyright © 2006 by ASME

This offset grew from the initial impact until the pushback suggest that the form of these components could be improved.

coupler shear bolts triggered. Once the shear bolts triggered, Alternative designs could be developed that achieve the same

the offset remained but did not continue to grow. After the function in a more aesthetically pleasing manner.

cab car and locomotive ends came together, the locomotive As shown in Figure 12, the primary energy absorbers

end began to crush in an uncontrolled manner. The exhibited material failure as a result of the test. This material

uncontrolled crush increased the relative lateral displacement failure did not influence the function of the energy absorbers

of the locomotive and the cab car. In addition, the during the test–they absorbed energy as intended. However,

uncontrolled crush of the locomotive caused the end of the material failure is difficult to simulate with fidelity, and does

locomotive to rise and the end of the cab car to be pushed increase the uncertainty in analytic predictions of the mode of

down. This motion did not progress to override, but the deformation and the force/crush characteristic of the energy

associated vertical load was sufficient to cause a crack near absorber design. For the test equipment, this uncertainty was

the back of the end beam and the front of the sliding sill. The reduced by prior component, single-car, and two-car tests. A

details of the conditions that led to this crack are currently similar level of confidence in the force/crush characteristic of

being investigated. It appears that the vertical load imparted alternative designs may be achieved with fewer tests if

by the locomotive significantly exceeded the vertical load that material failure is not expected for such designs.

the end beam was designed to support.

The final frame of Figure 11 shows the final position of

the locomotive relative to the cab end crush zone at maximum

crush. The rear end of the locomotive’s skirt initially

contacted the deformable anti-climber and the consequent

lateral motion caused the locomotive to contact the collision

posts. The integrated end frame accommodated this non-ideal

loading condition and shed the load into the sliding sill,

successfully triggering the sliding sill fuse.

Coupled

Figure 12. Primary Energy Absorber, Post-Test

Photograph Showing Material Failure

The design development and performance of the

deformable anti-climber suggests that material failure in the

primary energy absorbers can be greatly reduced and

potentially eliminated. The deformable anti-climber also

End performed as designed, and, as shown in Figure 13, deformed

Structures as intended without any material failure. The deformable anti-

climber was required to be able to support vertical and lateral

Contact loads that might arise from the interaction with the colliding

locomotive. Consequently, the deformable anti-climber was

required to deform without material failure in order to

maintain the load path for any vertical and lateral loads. Key

differences with the primary energy absorber include thinner,

more ductile material, and annealing of the deformable

components to relieve residual stresses from forming.

Developing primary energy absorbers that incorporate these

Crush Stops features would likely result in a design that is not as prone to

material failure.

Figure 11. Kinematics of Trailing Cab End Crush Zone

and Trailing Locomotive

Component-Level Results

The cab and non-cab crush zone components functioned as

designed. For several of the components, the test results

88 Copyright © 2006 by ASME

and decelerations within survivable limits. Five experiments

were included on the train-to-train impact test of CEM

equipment to measure the occupant response in modified

versions of previously tested seating arrangements: forward-

facing intercity seats, forward- and rear-facing commuter

seats, and facing commuter seats with intervening tables.

These modifications minimize the injury risk to the occupants

[19].

CEM features can be progressively added to existing

equipment to improve crashworthiness incrementally [21]. A

conventional cab car-led train of single level equipment with

end vestibules can protect all of the occupants in a collision

with a locomotive-led train of the same weight for closing

speeds up to approximately 15 mph. Changing from a

conventional cab car to a CEM cab car, such as the cab car

Figure 13. Deformable Anti-climber, Post-Test used in the test, increases the closing speed to 25 mph.

Photograph Showing No Material Failure Further modifying the trailing cars to include pushback

couplers (with conventional carbody structures) increases this

As in some accidents, some of the cars uncoupled during closing speed to 28 mph. The highest level of

the test. This occurred in the test due to the interaction of the crashworthiness is provided by all CEM passenger cars, which

coupler carrier and the coupler pin. As the coupler pushed can protect all of the occupants for closing speeds up to 38

back, the coupler carrier deformed in such a manner as to push mph in this scenario.

the pin up, releasing the coupler. The couplers functioned as Further work is needed to evaluate the use of CEM

designed as long as there was a buff load between cars. The features on locomotives. While the current CEM cab car

ability of the cars to remain coupled could be improved by design accommodates for the features of conventional

modifying the coupler pin lifting mechanism, the coupler locomotives, the robustness of a CEM system would be

carrier, or some combination. Alternative pin arrangements enhanced at the train level by including features such as

are currently in service that are less prone to uncoupling than pushback couplers and deformable anti-climbers on

those used in the test. conventional locomotives.

The side sill of the M1 cars wrinkled during the test. (No

visible permanent deformation of the center sills existed after ACKNOWLEDGEMENTS

the test.) While no measurable occupant volume was lost, the The research described in this paper was performed as part

form could be improved by eliminating the permanent of the Equipment Safety Research Program sponsored by the

deformation of the side sills. The side sills of the M1 cars are FRA’s Office of Research and Development. The authors

open channel sections. In the area where they wrinkled–just would like to thank Claire Orth, Chief, Equipment and

inboard of the reinforcements for the quarter point Operating Practices Division, for her support. Dr. Tom Tsai,

doorframes–the side sill was not attached to the body sheeting Program Manager, led this effort. Gunars Spons, FRA

for about 6 inches. Elsewhere on the car, the side sills are spot Resident Manager at the Transportation Technology Center,

welded approximately every inch. The wrinkling of the side managed the full-scale test effort. Grady Cothen, Deputy

sill could potentially be eliminated by the addition of more Associate Administrator for Safety Standards and Program

spot welds or by closing the cross section. Either approach Development, has coordinated FRA’s regulations development

would reduce the potential for column buckling. and the passenger rail equipment crashworthiness research

The operator space was preserved, and there are no since the inception of this research.

obvious improvements in form for the operator’s The authors would also like to thank Volpe Center

compartment. The end frames for both the cab end and non- colleagues Kristine Severson and Daniel Parent for designing

cab end crush zones performed as intended. These translated and overseeing the implementation of the occupant protection

the loads applied to the car into the loads required to crush the experiments. Michelle Priante, Mechanical Engineer, and

primary and roof energy absorbers. More detailed inspection Michael Carolan, Mechanical Engineer, assisted in oversight

of the crush zone and its components is planned. of the test implementation and documentation of the test

results.

CONCLUSIONS AND DISCUSSION Matthew Witte, Senior Engineer, led the TTCI team that

In the train-to-train test of conventional equipment, the implemented the test. Tom Roderick, Senior Technician, Joe

space for approximately 47 passengers and the operator was Hanratty, Senior Technician, and Bruce Perrin, Senior

destroyed. Under the same impact conditions, the CEM Technician TTCI, integrated the crush zones into the cars. Jay

equipment preserved the space for all of the occupants. Gordon and Chuck Monson, GMH Engineering, installed

In order to reduce the injury risk to the occupants in this much of the instrumentation and acquired all of the data.

more severe environment, modifications to the interior Jerry MacIntire, CineMac Productions, filmed the high-speed

arrangements are being made to keep secondary impact forces movies of the test.

99 Copyright © 2006 by ASME

METROLINK, the Los Angeles commuter railroad, in [11] Tyrell, D.C., Severson, K.J., Mayville, R.A., Stringfellow, R.G.,

their ongoing procurement of passenger rail equipment, has Berry, S., Perlman, A.B., “Evaluation of Cab Car Crashworthiness

applied the results of the research into Crash Energy Design Modifications,” Proceedings of the 1997 IEEE/ASME Joint

Management. Jo Strang, Associate Administrator for Safety, Railroad Conference, Institute of Electrical and Electronics

Engineers, Catalog Number 97CH36047, 1997.

FRA, led an ad hoc CEM Working Group, which was formed

[12] Stringfellow, R.G., Mayville, R.A., Rancatore R., “A Numerical

with FTA, APTA, rail industry suppliers, labor organizations,

Evaluation of Protection Strategies for Railroad Cab Car

and consultants. This Working Group developed a Crashworthiness,” American Society of Mechanical Engineers, AMD

specification based on the results of this research. The authors Vol. 237/BED Vol. 45, 1999.

would like to thank Associate Administrator Strang for [13] Tyrell, D.C., Perlman, A.B., “Evaluation of Rail Passenger

coordinating the activities of the Congressional delegation that Equipment Crashworthiness Strategies,” Transportation Research

attended the test. Record No. 1825, pp. 8-14, National Academy Press, 2003.

The authors would also like to thank Paul Feenstra, Public [14] Tyrell, D., Severson, K., Perlman, A.B., “Single Passenger Rail

Affairs, Research and Innovative Technology Administration, Car Impact Test Volume I: Overview and Selected Results,” U.S.

Steve Kulm, Public Affairs, FRA, and Melissa Cook, Public Department of Transportation, DOT/FRA/ORD-00/02.1, March

Affairs, Office of the Secretary of Transportation, for their 2000.

tireless efforts in coordinating and disseminating information [15] Jacobsen, K., Tyrell, D., Perlman, A.B., “Impact Test of a Crash

on the test to the media, as well as for their efforts to Energy Management Passenger Rail Car,” American Society of

coordinate the attendance of the Secretary of Transportation, Mechanical Engineers, Paper No. RTD2004-66045, April 2004.

Norman Mineta. The authors would like to thank Secretary [16] Tyrell, D., Severson, K., Zolock, J., Perlman, A.B., “Passenger

Mineta for his attendance and interest in the test. Rail Two-Car Impact Test Volume I: Overview and Selected

Results,” U.S. Department of Transportation, DOT/FRA/ORD-

REFERENCES 01/22.I, January 2002.

[1] Cothen, G., Schulte, C., Horn, J., Tyrell, D., “Consensus [17] Jacobsen, K., Tyrell, D., Perlman, A.B., “Impact Tests of Crash

Rulemaking at the Federal Railroad Administration,” TR News, Energy Management Passenger Rail Cars: Analysis and Structural

Transportation Research Board, Number 236, January-February Measurements,” American Society of Mechanical Engineers, Paper

2005. No. IMECE2004-61252, November 2004.

[2] Tyrell, D., “U.S. Rail Equipment Crashworthiness Standards,” [18] Tyrell, D., “Passenger Rail Train-to-Train Impact Test Volume I:

presented at 'What can We Realistically Expect from Overview and Selected Results,” U.S. Department of Transportation,

Crashworthiness?' Rail Equipment Crashworthiness Symposium, DOT/FRA/ORD-03/17.I, July 2003.

Institute of Mechanical Engineers, May 2, 2001, London, England.

[19] Severson, K., Parent, D., “Train-to-Train Impact Test of Crash

[3] U.S. Department of Transportation, Federal Railroad Energy Management Passenger Rail Equipment: Occupant

Administration, “49 CFR Part 216 et al., Passenger Equipment Safety Experiments,” American Society of Mechanical Engineers, Paper No.

Standards; Final Rule,” Federal Register, May 12, 1999. IMECE2006-14420, November 2006.

[4] Tyrell, D.C., Severson, K.J., Marquis, B.J., “Crashworthiness of [20] Zolock, J., Tyrell, D., “Locomotive Cab Occupant Protection,”

Passenger Trains,” U.S. Department of Transportation, American Society of Mechanical Engineers, Paper No. IMECE2003-

DOT/FRA/ORD-97/10, 1998. 44121, November 2003.

[5] Tyrell, D., Martinez, E., Jacobsen, K., Parent, D., Severson, K., [21] Jacobsen, K., Severson, K., Perlman, A.B., “Effectiveness of

Priante, M., Perlman, A.B., “Overview of a Crash Energy Alternative Rail Passenger Equipment Crashworthiness Strategies,”

Management Specification for Passenger Rail Equipment,” American American Society of Mechanical Engineers, Paper No. JRC2006-

Society of Mechanical Engineers, Paper No. JRC2006-94044, April 94043, April 2006.

2006.

[6] American Public Transportation Association, Member Services

Department, Manual of Standards and Recommended Practices for

Passenger Rail Equipment, Issue of May 1, 2004.

[7] Association of American Railroads, Technical Services

Division, Mechanical Section-Manual of Standards and

Recommended Practices, “Locomotive Crashworthiness

Requirements, Standard S-580,” Adopted 1989, Revised 1994,

Revised 2005.

[8] Mayville, R., Johnson, K., Tyrell, D., Stringfellow, R., “Rail

Vehicle Car Cab Collision and Corner Post Designs According to

APTA S-034 Requirements,” American Society of Mechanical

Engineers, Paper No. MECE2003-44114, November 2003.

[9] Martinez, E., Tyrell, D., Rancatore, R., Stringfellow, R., Amar,

G., “A Crush Zone Design for An Existing Passenger Rail Cab Car,”

American Society of Mechanical Engineers, Paper No. IMECE2005-

82769, November 2005.

[10] Mayville, R.A., Stringfellow, R.G., Rancatore, R.J., Hosmer,

T.P., “Locomotive Crashworthiness Research, Volumes 5: Cab Car

Crashworthiness Report” DOT/FRA/ORD-95/08.5, 1996.

10

10 Copyright © 2006 by ASME

View publication stats

You might also like

- Modeling, Dynamics, and Control of Electrified VehiclesFrom EverandModeling, Dynamics, and Control of Electrified VehiclesRating: 5 out of 5 stars5/5 (1)

- The Multibody Systems Approach to Vehicle DynamicsFrom EverandThe Multibody Systems Approach to Vehicle DynamicsRating: 5 out of 5 stars5/5 (2)

- Vehicle Handling Dynamics: Theory and ApplicationFrom EverandVehicle Handling Dynamics: Theory and ApplicationRating: 5 out of 5 stars5/5 (2)

- Internal Combustion EnginesFrom EverandInternal Combustion EnginesConstantine ArcoumanisRating: 3.5 out of 5 stars3.5/5 (5)

- ML350 W164 M272 EWD-Power - and.GroundDistrDocument200 pagesML350 W164 M272 EWD-Power - and.GroundDistrRodolfo Diaz100% (3)

- Hybrid Ship Hulls: Engineering Design RationalesFrom EverandHybrid Ship Hulls: Engineering Design RationalesRating: 4.5 out of 5 stars4.5/5 (3)

- A L L Diagnostic Trouble Codes (DTC) : U Code Charts (DME) Condition For Fault ID - 1Document25 pagesA L L Diagnostic Trouble Codes (DTC) : U Code Charts (DME) Condition For Fault ID - 1rodolfodiazNo ratings yet

- Informe Carro M113Document34 pagesInforme Carro M113ronnychamorroNo ratings yet

- Terramechanics and Off-Road Vehicle Engineering: Terrain Behaviour, Off-Road Vehicle Performance and DesignFrom EverandTerramechanics and Off-Road Vehicle Engineering: Terrain Behaviour, Off-Road Vehicle Performance and DesignRating: 5 out of 5 stars5/5 (1)

- Automotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionFrom EverandAutomotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionRating: 5 out of 5 stars5/5 (3)

- Nonlinear Optimization of Vehicle Safety Structures: Modeling of Structures Subjected to Large DeformationsFrom EverandNonlinear Optimization of Vehicle Safety Structures: Modeling of Structures Subjected to Large DeformationsRating: 5 out of 5 stars5/5 (1)

- CAN ID To J1939 - N2K PGN ConverterDocument260 pagesCAN ID To J1939 - N2K PGN Converterdhanssmart100% (1)

- Railroad Track Mechanics and Technology: Proceedings of a Symposium Held at Princeton University, April 21 - 23, 1975From EverandRailroad Track Mechanics and Technology: Proceedings of a Symposium Held at Princeton University, April 21 - 23, 1975Arnold D. KerrRating: 5 out of 5 stars5/5 (1)

- Metal Fatigue Analysis Handbook: Practical Problem-solving Techniques for Computer-aided EngineeringFrom EverandMetal Fatigue Analysis Handbook: Practical Problem-solving Techniques for Computer-aided EngineeringRating: 3.5 out of 5 stars3.5/5 (5)

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- Embedded Mechatronic Systems, Volume 1: Analysis of Failures, Predictive ReliabilityFrom EverandEmbedded Mechatronic Systems, Volume 1: Analysis of Failures, Predictive ReliabilityNo ratings yet

- Essentials of the Finite Element Method: For Mechanical and Structural EngineersFrom EverandEssentials of the Finite Element Method: For Mechanical and Structural EngineersRating: 3.5 out of 5 stars3.5/5 (9)

- Dynamic Analysis of High-Speed Railway Alignment: Theory and PracticeFrom EverandDynamic Analysis of High-Speed Railway Alignment: Theory and PracticeRating: 4 out of 5 stars4/5 (2)

- Marine Rudders and Control Surfaces: Principles, Data, Design and ApplicationsFrom EverandMarine Rudders and Control Surfaces: Principles, Data, Design and ApplicationsRating: 4.5 out of 5 stars4.5/5 (3)

- Reducing Airlines’ Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemFrom EverandReducing Airlines’ Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemNo ratings yet

- Tese LisboaDocument135 pagesTese LisboaRafaela RibeiroNo ratings yet

- Introduction to Hybrid Vehicle System Modeling and ControlFrom EverandIntroduction to Hybrid Vehicle System Modeling and ControlRating: 4 out of 5 stars4/5 (1)

- Accelerated Bridge Construction: Best Practices and TechniquesFrom EverandAccelerated Bridge Construction: Best Practices and TechniquesRating: 2 out of 5 stars2/5 (4)

- Track/Train Dynamics and Design: Advanced TechniquesFrom EverandTrack/Train Dynamics and Design: Advanced TechniquesGerald J. MoyarNo ratings yet

- A318-21 32 B12 1sep2014Document262 pagesA318-21 32 B12 1sep2014Quynh Nguyen100% (1)

- Non-Linear Structures: Matrix Methods of Analysis and Design by ComputersFrom EverandNon-Linear Structures: Matrix Methods of Analysis and Design by ComputersRating: 4.5 out of 5 stars4.5/5 (2)

- Safety Theory and Control Technology of High-Speed Train OperationFrom EverandSafety Theory and Control Technology of High-Speed Train OperationRating: 5 out of 5 stars5/5 (2)

- Design of High-Speed Railway Turnouts: Theory and ApplicationsFrom EverandDesign of High-Speed Railway Turnouts: Theory and ApplicationsRating: 4.5 out of 5 stars4.5/5 (4)

- Motor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12From EverandMotor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12No ratings yet

- Terramechanics and Off-Road Vehicle Engineering: Terrain Behaviour and Off-Road MobilityFrom EverandTerramechanics and Off-Road Vehicle Engineering: Terrain Behaviour and Off-Road MobilityNo ratings yet

- Wireless Power Transfer for E-Mobility: Fundamentals and Design Guidelines for Wireless Charging of Electric VehiclesFrom EverandWireless Power Transfer for E-Mobility: Fundamentals and Design Guidelines for Wireless Charging of Electric VehiclesNo ratings yet

- EN50126 in the Railway Industry. A Guide for Independent Safety Assessors (ISAs): Safety, #1From EverandEN50126 in the Railway Industry. A Guide for Independent Safety Assessors (ISAs): Safety, #1No ratings yet

- Handbook of Optimization in the Railway IndustryFrom EverandHandbook of Optimization in the Railway IndustryRalf BorndörferNo ratings yet

- Development of Online Hybrid Testing: Theory and Applications to Structural EngineeringFrom EverandDevelopment of Online Hybrid Testing: Theory and Applications to Structural EngineeringRating: 5 out of 5 stars5/5 (1)

- Electric Vehicle Tribology: Challenges and Opportunities for a Sustainable Transportation FutureFrom EverandElectric Vehicle Tribology: Challenges and Opportunities for a Sustainable Transportation FutureLeonardo Israel Farfan CabreraNo ratings yet

- Advances in Motion Sensing and Control for Robotic Applications: Selected Papers from the Symposium on Mechatronics, Robotics, and Control (SMRC’18)- CSME International Congress 2018, May 27-30, 2018 Toronto, CanadaFrom EverandAdvances in Motion Sensing and Control for Robotic Applications: Selected Papers from the Symposium on Mechatronics, Robotics, and Control (SMRC’18)- CSME International Congress 2018, May 27-30, 2018 Toronto, CanadaFarrokh Janabi-SharifiNo ratings yet

- Productivity in U.S. Railroads: Proceedings of a Symposium Held at Princeton University, July 27-28, 1977From EverandProductivity in U.S. Railroads: Proceedings of a Symposium Held at Princeton University, July 27-28, 1977Arnold D. KerrNo ratings yet

- Proposta Avanco Mobilidade Urbana NacionalDocument24 pagesProposta Avanco Mobilidade Urbana NacionalRafaela RibeiroNo ratings yet

- SILVA, Priscila Rúbia Santos Da. A Qualidade Na Prestação de Serviço Do Trem de Passageiros Da Vale. São Luís, UFMA, 2009. 81p.Document82 pagesSILVA, Priscila Rúbia Santos Da. A Qualidade Na Prestação de Serviço Do Trem de Passageiros Da Vale. São Luís, UFMA, 2009. 81p.Rafaela RibeiroNo ratings yet

- Infrastructures: A Review of Numerical Models For Slab-Asphalt Track RailwaysDocument24 pagesInfrastructures: A Review of Numerical Models For Slab-Asphalt Track RailwaysRafaela RibeiroNo ratings yet

- Disser Ta CaoDocument192 pagesDisser Ta CaoRafaela RibeiroNo ratings yet

- 10 11648 J Ajtte 20210603 12Document23 pages10 11648 J Ajtte 20210603 12Rafaela RibeiroNo ratings yet

- yokAcikBilim 10269943Document175 pagesyokAcikBilim 10269943Rafaela RibeiroNo ratings yet

- Wavelet Signal Processing Applied To Railway WheelDocument5 pagesWavelet Signal Processing Applied To Railway WheelRafaela RibeiroNo ratings yet

- Identification of Railway Track Components and Defects by Analysis of Wheel-Rail Interaction NoiseDocument9 pagesIdentification of Railway Track Components and Defects by Analysis of Wheel-Rail Interaction NoiseRafaela RibeiroNo ratings yet

- Algoritmo Genetico Aplicado em Identificacao de Sistemas de Multiplas Entradas e Multiplas SaidasDocument10 pagesAlgoritmo Genetico Aplicado em Identificacao de Sistemas de Multiplas Entradas e Multiplas SaidasRafaela RibeiroNo ratings yet

- Modelo Matemático para Otimização de Dormentes Ferroviários de Concreto ProtendidoDocument30 pagesModelo Matemático para Otimização de Dormentes Ferroviários de Concreto ProtendidoRafaela RibeiroNo ratings yet

- Metodologia para Projetos de Infraestrutura PúblicaDocument48 pagesMetodologia para Projetos de Infraestrutura PúblicaRafaela RibeiroNo ratings yet

- Verification of Stress Components Determined by ExDocument10 pagesVerification of Stress Components Determined by ExRafaela RibeiroNo ratings yet

- Determination of Sleeper Support Conditions: December 2016Document5 pagesDetermination of Sleeper Support Conditions: December 2016Rafaela RibeiroNo ratings yet

- Assessment of Riveted Railway Bridges 2013Document8 pagesAssessment of Riveted Railway Bridges 2013Rafaela RibeiroNo ratings yet

- Sonsino UHC-fatigueDocument13 pagesSonsino UHC-fatigueRafaela RibeiroNo ratings yet

- 8 Askoblar Et AlDocument7 pages8 Askoblar Et AlRafaela RibeiroNo ratings yet

- 17 MontecarloDocument35 pages17 MontecarloRafaela RibeiroNo ratings yet

- SPK Catalogue Rev07 HD PDFDocument20 pagesSPK Catalogue Rev07 HD PDFBudimir AnteNo ratings yet

- Catalogo Mondraker 2014Document104 pagesCatalogo Mondraker 2014bikemtb_netNo ratings yet

- Diagram 3 Body Control ModuleDocument1 pageDiagram 3 Body Control ModuleEladioNo ratings yet

- CB400SF (NC39-100 105) Vtec (1-3)Document202 pagesCB400SF (NC39-100 105) Vtec (1-3)nob71822No ratings yet

- Motores de Combustion Interna Semana 1-1Document27 pagesMotores de Combustion Interna Semana 1-1Edwin SabillonNo ratings yet

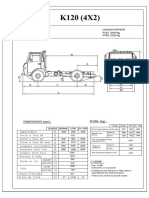

- K120 4x2 2013Document2 pagesK120 4x2 2013AbdouNo ratings yet

- Tema 11: Dinámica VerticalDocument13 pagesTema 11: Dinámica VerticalJuan Miguel PañosNo ratings yet

- 4SDK3Document4 pages4SDK3fauzan datasheetNo ratings yet

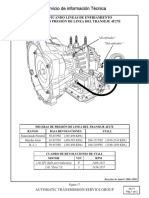

- 4F27-E 00-72 Pressure Test y Identificacion de Las Lineas Del EnfriadorDocument2 pages4F27-E 00-72 Pressure Test y Identificacion de Las Lineas Del EnfriadorAUTOPARTES 1987No ratings yet

- დანართი n2 - სატრანსპორტო საშუალებების ჩამონათვალი (ლოტი n10)Document156 pagesდანართი n2 - სატრანსპორტო საშუალებების ჩამონათვალი (ლოტი n10)Giorgi JinashviliNo ratings yet

- Dividend Policy of Ashok LeylandDocument14 pagesDividend Policy of Ashok LeylandAlokta BhatnagarNo ratings yet

- Interference Verification Check For Ohc EngineDocument2 pagesInterference Verification Check For Ohc EngineAnimemanuel MuñozNo ratings yet

- Expose Sur Les AvionsDocument15 pagesExpose Sur Les AvionsSokol BOZANICNo ratings yet

- Catalogo Ficha Tecnica Chevrolet TrackerDocument19 pagesCatalogo Ficha Tecnica Chevrolet TrackerGeralt DeRiviaNo ratings yet

- Kleen Diesel - IntroductionDocument20 pagesKleen Diesel - IntroductionAhmad Imran100% (1)

- EN How To Change Track Rod End On VW Polo 9n Replacement GuideDocument13 pagesEN How To Change Track Rod End On VW Polo 9n Replacement GuideKovacs ArnoldNo ratings yet

- BWS 2005 2006Document55 pagesBWS 2005 2006Gergely Szabo100% (1)

- Geely Case StudyDocument6 pagesGeely Case StudyMayank Verma100% (1)

- TATA Hexa Case Study: Go Getters Agnimitra Banerjee (1702010) Himanshu Gupta (1702070) Himanshu Kapoor (1702071)Document13 pagesTATA Hexa Case Study: Go Getters Agnimitra Banerjee (1702010) Himanshu Gupta (1702070) Himanshu Kapoor (1702071)Himanshu GuptaNo ratings yet

- Parts Location: 2Tr-Fe Engine Control System - Sfi SystemDocument3 pagesParts Location: 2Tr-Fe Engine Control System - Sfi SystemPedro Javier Castro SanchezNo ratings yet

- 250 Excf 2010Document131 pages250 Excf 2010NIETO HUELVA MOTORNo ratings yet

- Rotate MD-80 Simplified Procedural Steps 1.31.0.3 PDFDocument9 pagesRotate MD-80 Simplified Procedural Steps 1.31.0.3 PDFgochilindaNo ratings yet

- Affidavit Complaint Against Nathaniel XXXXXXXXXXXXDocument2 pagesAffidavit Complaint Against Nathaniel XXXXXXXXXXXXJoshelle B. BanciloNo ratings yet

- EMU Working Direction: Location 1: MR Pipe Broken Before CICDocument33 pagesEMU Working Direction: Location 1: MR Pipe Broken Before CICPrakash MandumulaNo ratings yet

- QSK19 DMDocument2 pagesQSK19 DMboomden100% (1)