Professional Documents

Culture Documents

3755.157 Install

Uploaded by

viksurs0 ratings0% found this document useful (0 votes)

3 views1 pageOriginal Title

3755.157_install

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views1 page3755.157 Install

Uploaded by

viksursCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

®

Important guidelines for mounting and use of 3755.157 d

sight glass fittings, toughened glasses and luminaires:

Before installation and operation/servicing, please read and follow all commissioning and servicing instructions:

1. Installation of sight glass fittings 4. Sight glass wiper

The installation by welding, brazing etc., must be free of distortion 4.1 Check that wiper assembly is correctly installed (see separate

and thus carried out by suitably qualified and authorized personnel. installation instruction)!

4.2 Wipers may only be used within temperature and pressure ranges

2. Installing toughened glass discs into a sight glass assembly specified.

2.1 Operating safety of sight glasses depends to a great extent upon their 4.3 Drive/spindle housing should be periodically checked to ensure a good

correct installation. seal; if necessary tighten threaded bushes/glands, replace defective

2.2 The gasket seating surfaces in the flanges must be plane, flat and seals, clean wiper arms and blades to remove accumulated foreign

smooth. Ensure the gasket edges are not trapped by, or foul, the matter or replace (see installation instruction).

flange gasket recess wall.

2.3 The glass disc, with gaskets appropriate to the process application 5. Spray device

fitted to its top and bottom faces must be located concentrically in The spray fluid temperature should be as near as possible to that of

the flange assembly. vessel contents. On no account use cold spray fluid on hot glass disc

2.4 Only use gaskets which are in good condition, flat and free of dirt (see ‚temperature cycling‘ under point 3).

and grease.

2.5 Before tightening nuts or bolts ensure once more that cover and base 6. Sight glass luminaires

flanges are correctly aligned and surfaces parallel to one another. 6.1 Always ensure that luminaire is connected to correct supply voltage as

2.6 Tighten the nuts or bolts progressively in diametrically opposed pairs. indicated on identity plate.

Tightening moments can be obtained from the relevant data sheets 6.2 All luminaires are purpose designed and exclusively made for moun

accompanying product (or consult supplier). ting onto flanged sight glass assemblies.

2.7 Further tightening down may be required after assembly has bedded 6.3 Never use the luminaire in place of cover flange or a complete sight

down under operating temperature and pressure. glass fitting.

2.8 When installing quartz sight glass discs follow manufacturers’ 6.4 Only certain models of luminaire may be used in continuous ON

instructions! mode; please check before confirming order; if in doubt ask supplier

or manufacturer.

3. Max. loading of toughened sight glass discs 6.5 Luminaires with built in ‚non maintained‘ switches are for intermit

3.1 Correctly fitted sight glass discs must be used within the working tent use and may only be operated with those switches.

temperature and pressure ranges laid down for them otherwise they 6.6 Luminaires intended by the user for continuous ‚ON‘ mode operation

may fail. should be controlled by separate external ON/OFF switch.

3.2 Temperature cycling to be within permitted limits: 6.7 The following should also be noted

• Sodalime glass (DIN 8902), max. permissible temperature: +150°C. • Max. permissible temperature at cable entry not to be exceeded.

Temperature change within one minute max. from 120°C to 20°C • Max. permissible temperature of glass not to be exceeded (vessel

with glass fully immersed. temperature + temperature increase caused by luminaire =

• Borosilicate glass (DIN 7080), max. permissible temp.: + 280°C. sight glass temperature; check by measurement!)

Temperature change within one minute max from 230°C to 20°C 6.8. When replacing lamps use identical type with identical power rating/

with glass fully immersed. voltage; never exceed max. permissible lamp rating recommended for

3.3 Avoid spraying sight glasses which are still hot with cold fluid. any given luminaire.

Warning! This can lead to glass disc breakage. 6.9 When changing lamps, check condition of lamp socket as a matter

3.4 Safety Precautions when using sight glass discs: of course.

3.4.1 Scheduled Maintenance: 6.10 Excessive voltage will shorten lamp life.

Sight glasses must be included in preventive maintenance, and 6.11 Danger: Do not look into light – Danger of impaired eyesight!

regularly checked either visually or by ultra sound measurement of

wall thickness. Where a disc shows any damage it must be exchanged 7. Ex hazardous areas

promptly with the plant shut down. Further, a thorough and regular Ex hazard rated luminaires must not be installed or serviced other

check of the sight glass should lead to a down time to suit the than by suitably qualified and authorised personnel. Data and

particular vessel; this will promote a routine for glass exchange suited instructions contained in relevant approval test certificates (certifi

to the process. cates of conformity) must be adhered to. Some Ex luminaire models

3.4.2 Breakage of glass disc: are works fitted with permanently encapsulated cable entry gland; on

In spite of careful fitting and operation in accordance with instruc no account attempt to unscrew or remove cable entry gland!

tions, it is possible though rare, that due to external effects a glass Any inappropriate change in components of Ex certified luminaires

disc can fail. It is necessary, particularly in the case of critical processes can render the relevant certificate invalid.

such as in the food industry, that the plant manufacturer or operator

takes appropriate safety measures to prevent glass fragments finding 8. Hinged or screwed sight glass assemblies

their way into the product. Before use, ensure the seals are functioning (if necessary tighten

3.5 After dismantling a sight glass assembly, and in accordance with securing nuts/bolts).

DIN 7080 standard requirements for all type of sight glass disc, the The seal between hinged ports and vessel flange is ensured by

glass disc and gaskets are replaced with new ones before the correctly seated components; flanges to mate up parallel by correctly

assembly is put back into operation. This is particularly important adjusted swing-bolt/hinge assembly and undamaged, clean seals free

where pressure vessels and/or aggressive media are concerned. of grease.

The following wording as extracted from DIN 7080 refers: In the case of hinged units, ensure the material of the hinged glass

“Sight glass discs may only be installed by personnel who are surround is compatible with vessel contents. When used on pressure

thoroughly versed about the following requirements: vessels, ensure max. operating pressure specified for the sight glass is

• careful treatment of sight glass discs exceeded.

• cleaning of recesses, discs, gaskets and accessories prior to installa-

tion, i. e. the removal of foreign matter (e. g. machining swarf); If in doubt, consult supplier or manufacturer!

• even tightening up of holding down bolts.

Sight glass discs removed from assemblies following operational

service may not be reused.”

3.6 Completely demineralised water may dissolve glass – especially

intensive periodical inspection required!

All dimensions in mm unless stated otherwise. Subject to change without prior notice. 06.13

F.H. Papenmeier GmbH & Co. KG · division Lumiglas

Talweg 2 · 58239 Schwerte · GERMANY

phone: +49-23 04 205-0 · fax: +49-2304 205-206

info.lumi@papenmeier.de · www.lumiglas.de

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

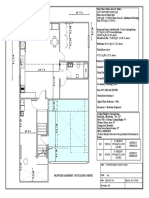

- Basement Floor Plan 1Document1 pageBasement Floor Plan 1viksursNo ratings yet

- 12 Whiteram Hill Drawings and DetailsDocument2 pages12 Whiteram Hill Drawings and DetailsviksursNo ratings yet

- Standard Rupture Disc BrochureDocument10 pagesStandard Rupture Disc BrochureviksursNo ratings yet

- Grundfosliterature 6821622Document2 pagesGrundfosliterature 6821622viksursNo ratings yet

- Aluminum Ladder Flyer 03.30Document1 pageAluminum Ladder Flyer 03.30viksursNo ratings yet

- 508 New r4 01Document1 page508 New r4 01viksursNo ratings yet

- GLOBAL - BeLive Hotels - High Season - 2023Document1 pageGLOBAL - BeLive Hotels - High Season - 2023viksursNo ratings yet

- Grundfosliterature 5564592Document77 pagesGrundfosliterature 5564592viksursNo ratings yet

- 58 Bridlewridge Way SW FinalDocument25 pages58 Bridlewridge Way SW FinalviksursNo ratings yet

- Grundfosliterature 6821585Document4 pagesGrundfosliterature 6821585viksursNo ratings yet

- Grundfosliterature 6014933Document13 pagesGrundfosliterature 6014933viksursNo ratings yet

- Supplemental Ds 1Document2 pagesSupplemental Ds 1viksursNo ratings yet

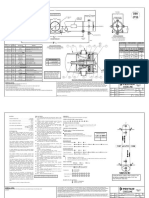

- Keystone-Figure-221-222 - With Part Number-UnlockedDocument2 pagesKeystone-Figure-221-222 - With Part Number-UnlockedviksursNo ratings yet

- Type-61 ElastomerSeatedButterflyValves 10 28 2022Document10 pagesType-61 ElastomerSeatedButterflyValves 10 28 2022viksursNo ratings yet

- SpecificationDocument4 pagesSpecificationviksursNo ratings yet

- AM Evoline MiniBracketPlacementGuidanceDocument5 pagesAM Evoline MiniBracketPlacementGuidanceviksursNo ratings yet

- Orthos 1Document1 pageOrthos 1viksursNo ratings yet

- General Catalogue Section E SprocketsDocument236 pagesGeneral Catalogue Section E SprocketsviksursNo ratings yet

- Orthos eDocument1 pageOrthos eviksursNo ratings yet

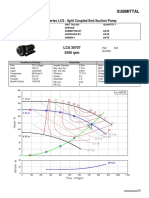

- LC, LCV, LF, LCS: End-Suction Centrifugal PumpsDocument24 pagesLC, LCV, LF, LCS: End-Suction Centrifugal PumpsviksursNo ratings yet

- FSufZW700B-RMS ENDocument3 pagesFSufZW700B-RMS ENviksursNo ratings yet

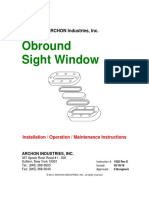

- Inst - 1002 RLG ObDocument10 pagesInst - 1002 RLG ObviksursNo ratings yet

- Codeline Old Product E8L 507003Document2 pagesCodeline Old Product E8L 507003viksursNo ratings yet

- Internal Port Pressure WarningDocument3 pagesInternal Port Pressure WarningviksursNo ratings yet

- Ds-Oe-020 Data Sheet RlgobDocument2 pagesDs-Oe-020 Data Sheet RlgobviksursNo ratings yet

- SB12 Series Back Pressure/Relief Valves: FeaturesDocument6 pagesSB12 Series Back Pressure/Relief Valves: FeaturesviksursNo ratings yet

- Custom Strainer Options Fabricated Basket Strainers - UnlockedDocument1 pageCustom Strainer Options Fabricated Basket Strainers - UnlockedviksursNo ratings yet

- Keystone 222 Datasheet - UnlockedDocument8 pagesKeystone 222 Datasheet - UnlockedviksursNo ratings yet

- DiaphragmValves 04 28 2021Document5 pagesDiaphragmValves 04 28 2021viksursNo ratings yet

- Deck Construction Guide For Detached and Semi-Detached DwellingsDocument11 pagesDeck Construction Guide For Detached and Semi-Detached DwellingsviksursNo ratings yet