Professional Documents

Culture Documents

CPM Europe Pellet Mill Series WOOD

Uploaded by

Alam KusumaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CPM Europe Pellet Mill Series WOOD

Uploaded by

Alam KusumaCopyright:

Available Formats

The various available CPM

Wood Pellet Mill series CPM Europe.

Providing you with the

with recommended process flow diagram

optimal wood pelleting solution

Motor

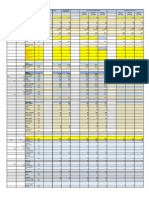

Pellet mill Pellet mill Die diameter Die width Die surface Die speed Die linear speed

1500 rpm

series type ø (mm) (mm) (cm2) (rpm) (m/sec)

Pmax (kW)

2000 2016-2 407 57 729 90 212 4,5

3000 3022-2.5 572 60 1078 130 210 6,3

7700 7722-2.5 572 60 1078 160 150 4,5

7700 7730-4 762 94 2250 200 150 5,9

7900 7930-4 762 94 2250 315 150 5,9

7900 7932-5 825 115 2980 355 150 6,4

Contact us to receive your genuine CPM parts The best

at the best price and delivery conditions wood pellet

CPM EUROPE BV qualities GLOBAL PARTNER

SINCE 1883

Rijder 2

1507 DN Zaandam

The Netherlands

+31 (0) 75 65 12 611

Info@cpmeurope.nl

www.cpmeurope.nl

CPM Europe. Your Partner in Productivity CPM Europe. Your Partner in Productivity

2.10.2 Pellet Mill Serie Wood.indd 1 26-09-19 09:59

Automatic knife adjustment

Providing you with theWear

optimal wood

parts and pelleting solution

spare parts for Pellet Mills

How is CPMWe

assisting

are you to

assistingcontrol

you to the pellet

select length?

How to maximize your profitability with CPM?

the optimal Pellet Mill size

CPM 2016-2 CPM 3022-2.5 CPM 7730-4 CPM knife concept

We offer a lot of attention to We maximize your profitability in

1. Die

the following matters: t2.

heRollers

following ways:

- The pellet quality you want to produce -3. Assisting

Product compression

you to produce the best pellet qualities

point

- Which allows you to produce the highest capacities with your CPM equipment

- The raw materials you apply

-4. Training

Productyour

layerpersonnel to become experts working with our equipment

- The expansion of your pellets allowing

- Supplying you with wear parts and spare parts

us to drill the die holes adequately 5. Knife

Multiple knife positions which provide a very long service life

6. Warm pellets

- Reducing cut to size

your energy consumption due to the

at the pellet chamber

high efficient CPM gear reduction

• For easy adjustment of the pellet length

• Knife fabricated from heat treated CPM 7930-4 CPM 7932-5

Genuine CPM Dies and Rollers

steel for an improved service life

- Produced with attention for your requirements

90 kW 130 kW 200 kW

We are advising you:

Optional

- Which circumferential pellet

roller surface finish to apply knives

for the best Extended service

- Forpelleting efficiencies

a very regular woodinpellet

relation to your

lenght

raw materials life by attention for

Automatic adjustment to your requirements

What is the difference of

control the pellet length and concept

Optional closed loop oil lubricated rollers efficiency

a CPM Pellet Mill?

- For very long service life of roller bearings

The die is directly connected with

The

thedie is directly

main motor connected

by a singlewith the

helical 315 kW 355 kW

main motorManual

by a single helical gear

adjustment to

gear reduction

reduction set set:

control the pellet length

- -NoNoproduction

production stops

stopsduedueto to

a temporarily Pellet Mill

a temporarily

Please consult with the CPM specialists to study your pellet

overload

Pellet Mill overload CPM multiple knives concept around the die

- -Very efficient

Very transfer

efficient transfer of energy

of energy quality and pelleting capacity requirements

- -Compact design

Compact design

- -Closed loop

Closed oil oil

loop lubrication

lubrication system

system applying food

gradeservice

lubricants

- Typical life oil seals: 3 years

CPM Europe. Your partner in Productivity

- -Our gears service

Typical are warranted for life3 years

life oil seals: CPM Europe. Your partner in Productivity

- Our gears are warranted for life

2.10.2 Pellet Mill Serie Wood.indd 2

CPM Europe. Your partner in Productivity 26-09-19 09:59

The various available CPM

Wood Pellet Mill series CPM Europe.

Providing you with the

with recommended process flow diagram

optimal wood pelleting solution

Motor

Pellet mill Pellet mill Die diameter Die width Die surface Die speed Die linear speed

1500 rpm

series type ø (mm) (mm) (cm2) (rpm) (m/sec)

Pmax (kW)

2000 2016-2 407 57 729 90 212 4,5

3000 3022-2.5 572 60 1078 130 210 6,3

7700 7722-2.5 572 60 1078 160 150 4,5

7700 7730-4 762 94 2250 200 150 5,9

7900 7930-4 762 94 2250 315 150 5,9

7900 7932-5 825 115 2980 355 150 6,4

Contact us to receive your genuine CPM parts The best

at the best price and delivery conditions wood pellet

CPM EUROPE BV qualities GLOBAL PARTNER

SINCE 1883

Rijder 2

1507 DN Zaandam

The Netherlands

+31 (0) 75 65 12 611

Info@cpmeurope.nl

www.cpmeurope.nl

CPM Europe. Your Partner in Productivity CPM Europe. Your Partner in Productivity

2.10.2 Pellet Mill Serie Wood.indd 1 26-09-19 09:59

You might also like

- SP588 3英文 PDFDocument59 pagesSP588 3英文 PDFWeni RizkilahNo ratings yet

- Compressor: PDS175 (S) PDS655 (S)Document1 pageCompressor: PDS175 (S) PDS655 (S)Kamal SemboyNo ratings yet

- MEIL Standard Fuel Consumption & Utilisation of Vehicles & Equipments - Version 1.1 (30062022)Document28 pagesMEIL Standard Fuel Consumption & Utilisation of Vehicles & Equipments - Version 1.1 (30062022)Krishna MohanNo ratings yet

- g3616 A4 Lehw0198 FinalDocument4 pagesg3616 A4 Lehw0198 FinalVictor NunezNo ratings yet

- COFMOW Compendium 2021-22 & 2022-23Document36 pagesCOFMOW Compendium 2021-22 & 2022-23Senior Divisional Mechanical Engineer100% (4)

- SMS#1 SMS#2: PERFROMANCE DATA (Refractory & Operation)Document14 pagesSMS#1 SMS#2: PERFROMANCE DATA (Refractory & Operation)Binod Kumar PadhiNo ratings yet

- Trellex Mill Lining SystemsDocument17 pagesTrellex Mill Lining SystemsJesus CHNo ratings yet

- Morgan SiemensVAI LubricationDocument45 pagesMorgan SiemensVAI LubricationRamesh Timmanagoudar100% (2)

- T8 EnglishDocument12 pagesT8 Englishgustavo puentes hidalgoNo ratings yet

- Washing Spares Book - Layout 1Document54 pagesWashing Spares Book - Layout 1eaglego00No ratings yet

- Ball Mill Standard Product Definition-Rev0Document12 pagesBall Mill Standard Product Definition-Rev0krishnabijuNo ratings yet

- CPMDocument3 pagesCPMSergey Medvedev100% (1)

- Screening Spares Book - Layout 1Document81 pagesScreening Spares Book - Layout 1eaglego00100% (1)

- 15th NCB Technical PaperDocument10 pages15th NCB Technical PaperSalah RomdaniNo ratings yet

- Motoren z4 EnglischDocument2 pagesMotoren z4 Englischwilde.coyNo ratings yet

- Men's Clothing-ShirtsDocument58 pagesMen's Clothing-ShirtsMiry ashrafNo ratings yet

- Safety Safety: No Near Miss Logged 20-21 FY in Assembly & Machine ShopDocument17 pagesSafety Safety: No Near Miss Logged 20-21 FY in Assembly & Machine ShopSudip RoyNo ratings yet

- CCR Logsheet BbciDocument1 pageCCR Logsheet BbciherwinNo ratings yet

- Pellet Mill 7700 Series WebDocument4 pagesPellet Mill 7700 Series WebJavier Moises CastroNo ratings yet

- Avelair Oil Water Separators PDFDocument3 pagesAvelair Oil Water Separators PDFNuno PaivaNo ratings yet

- PDF 1440580617Document1 pagePDF 1440580617skf urbanoNo ratings yet

- Air - Jet Loom (Suza)Document14 pagesAir - Jet Loom (Suza)Suza Ahmed Auporbo67% (3)

- 47KSCDocument44 pages47KSCcesarruanojrNo ratings yet

- Lapping AUSDocument34 pagesLapping AUSGia huy Nguyen huynhNo ratings yet

- Brijmech Engineering Pvt. LTD.: Driven by Quality..Document8 pagesBrijmech Engineering Pvt. LTD.: Driven by Quality..Roberto BentoNo ratings yet

- Spin Plan & Report by Group 3 - 20231110 - 112237 - 0000Document15 pagesSpin Plan & Report by Group 3 - 20231110 - 112237 - 0000Zea LiselaNo ratings yet

- XLAM XtremeMats FlyerDocument2 pagesXLAM XtremeMats Flyersant1411No ratings yet

- Replacement Parts For Amada Machinery: Part NumberDocument40 pagesReplacement Parts For Amada Machinery: Part NumberSv KoNo ratings yet

- CAT Engine Specifications: G3306B TA Gas Petroleum EngineDocument4 pagesCAT Engine Specifications: G3306B TA Gas Petroleum EngineSrija sagiNo ratings yet

- حلزونى ١٥بار FINIDocument5 pagesحلزونى ١٥بار FINIradwan.hueckmakmaxNo ratings yet

- Atlas Copco: Small Portable Air CompressorsDocument2 pagesAtlas Copco: Small Portable Air CompressorsAsad AijazNo ratings yet

- Caterpillar G3306B NA Hoja de Datos PDFDocument4 pagesCaterpillar G3306B NA Hoja de Datos PDFJUAN CARLOS velazquez hernandezNo ratings yet

- Portable Diesel Air Compressors: AIRMAN 50 CFM - 1,400 CFM, 125PSI - 350 PSIDocument12 pagesPortable Diesel Air Compressors: AIRMAN 50 CFM - 1,400 CFM, 125PSI - 350 PSILouie SerranoNo ratings yet

- Ghid Rapid Aluminiu 25.04.2019Document40 pagesGhid Rapid Aluminiu 25.04.2019iulian.mihai.diaconuNo ratings yet

- Engine PumpsDocument4 pagesEngine PumpsAnonymous CMS3dL1TNo ratings yet

- Steam Requirement.Document2 pagesSteam Requirement.deepener52No ratings yet

- Maruti Eeco 5 Seater STD BrochureDocument2 pagesMaruti Eeco 5 Seater STD BrochurePrateek PareekNo ratings yet

- Item No. Description Unit Rate (RS.) Quantity Labour Cost (RS.) Material Cost (RS.) Labour & Material Cost (RS.) RemarksDocument1 pageItem No. Description Unit Rate (RS.) Quantity Labour Cost (RS.) Material Cost (RS.) Labour & Material Cost (RS.) Remarksj krishnanNo ratings yet

- Molinos SkioldDocument227 pagesMolinos SkioldDarwin Barra TorresNo ratings yet

- NewS40 Sept 2003Document2 pagesNewS40 Sept 2003shick95No ratings yet

- Daemo Eng (2ba)Document20 pagesDaemo Eng (2ba)Jairresistenciagt123No ratings yet

- Plastic Injection Moulding Machines: Mega NH SeriesDocument12 pagesPlastic Injection Moulding Machines: Mega NH SeriesMarcelo BoneNo ratings yet

- CP Range Metric Dimension Data - Double ActingDocument9 pagesCP Range Metric Dimension Data - Double ActingQUALITY12No ratings yet

- COO Maintenance-PM7-3Years (1april2013) - Retail PriceDocument10 pagesCOO Maintenance-PM7-3Years (1april2013) - Retail Pricediqmp100% (1)

- C15 Acert Petroleum Engine: Tier 4 Interim/Stage Iiib 354-433 Bkw/475-580 BHP at 1800-2100 RPMDocument4 pagesC15 Acert Petroleum Engine: Tier 4 Interim/Stage Iiib 354-433 Bkw/475-580 BHP at 1800-2100 RPMAbd Alkarem SalamhNo ratings yet

- Flexible Polyurethane Foam Plant: An ISO 9001:2015 Certified & CSA Canada CertifiedDocument16 pagesFlexible Polyurethane Foam Plant: An ISO 9001:2015 Certified & CSA Canada CertifiedJohn TesfamariamNo ratings yet

- BMG-BMG/X: Single Channel Square PlansifterDocument4 pagesBMG-BMG/X: Single Channel Square PlansifterToufik Ahmed Emon100% (1)

- 1401375295Document4 pages1401375295tomjones77No ratings yet

- Higher Density in A Smaller Body Displacement Range: 479cc N 898cc Output Range: 9.3 KW N 17.5 KW 12.5HPN23.5HPDocument12 pagesHigher Density in A Smaller Body Displacement Range: 479cc N 898cc Output Range: 9.3 KW N 17.5 KW 12.5HPN23.5HPNelson OsbornneNo ratings yet

- Super-Mini-Series Z482 Z602 D722 D902Document12 pagesSuper-Mini-Series Z482 Z602 D722 D902Anonymous 9xvU1F100% (1)

- FL HighfeedDocument48 pagesFL Highfeedbob smithNo ratings yet

- Technical Comparision of Cutting MachineDocument6 pagesTechnical Comparision of Cutting MachinechandraNo ratings yet

- Challenge CMT 330Document2 pagesChallenge CMT 330KBR Graphics Canada100% (1)

- Cat 3612leDocument4 pagesCat 3612letomjones77100% (1)

- Leaflet Utility ENDocument4 pagesLeaflet Utility ENFso servicio tecnico 2021No ratings yet

- Máy Định Hình MonfongsDocument32 pagesMáy Định Hình MonfongsPhan Quốc ThịnhNo ratings yet

- Bonded App Gear GrindingDocument7 pagesBonded App Gear GrindingvengadeshNo ratings yet

- Volvo V60 Model Year 2017 - Technical Specifications-1Document7 pagesVolvo V60 Model Year 2017 - Technical Specifications-1ejfjhhrjdjejNo ratings yet