Professional Documents

Culture Documents

LEXAN FST3403t

Uploaded by

Jose Ramon Florez OrdizCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LEXAN FST3403t

Uploaded by

Jose Ramon Florez OrdizCopyright:

Available Formats

LEXAN™ COPOLYMER

FST3403T

REGION AMERICAS

DESCRIPTION

Lexan* FST3403T resin is a high flow PC Copolymer Resin, suitable for injection molding. This halogen-free flame retardant

resin is EN45545 R6 HL3 and an ideal candidate for train interior applications. It also meets requirements of NFPA-130

standards. Available in transparent and opaque colors.

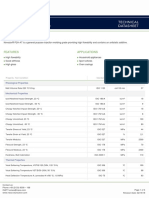

TYPICAL PROPERTY VALUES Revision 20170913

PROPERTIES TYPICAL VALUES UNITS TEST METHODS

MECHANICAL

Tensile Stress, yld, Type I, 50 mm/min 77 MPa ASTM D 638

Tensile Stress, brk, Type I, 50 mm/min 70 MPa ASTM D 638

Tensile Strain, yld, Type I, 50 mm/min 6 % ASTM D 638

Tensile Strain, brk, Type I, 50 mm/min 75 % ASTM D 638

Tensile Modulus, 5 mm/min 2600 MPa ASTM D 638

Flexural Stress, yld, 1.3 mm/min, 50 mm span 115 MPa ASTM D 790

Flexural Modulus, 1.3 mm/min, 50 mm span 2700 MPa ASTM D 790

Tensile Stress, yield, 50 mm/min 77 MPa ISO 527

Tensile Stress, break, 50 mm/min 70 MPa ISO 527

Tensile Strain, yield, 50 mm/min 6 % ISO 527

Tensile Strain, break, 50 mm/min 95 % ISO 527

Tensile Modulus, 1 mm/min 2600 MPa ISO 527

Flexural Stress, yield, 2 mm/min 105 MPa ISO 178

Flexural Modulus, 2 mm/min 2500 MPa ISO 178

IMPACT

Izod Impact, notched, 23°C 120 J/m ASTM D 256

Izod Impact, notched, -30°C 85 J/m ASTM D 256

Multiaxial Impact 130 J ISO 6603

Instrumented Impact Total Energy, 23°C 60 J ASTM D 3763

Izod Impact, unnotched 80*10*3 +23°C NB kJ/m² ISO 180/1U

Izod Impact, unnotched 80*10*3 -30°C NB kJ/m² ISO 180/1U

Izod Impact, notched 80*10*3 +23°C 12 kJ/m² ISO 180/1A

Izod Impact, notched 80*10*4 +23°C 11 kJ/m² ISO 180/1A

Izod Impact, notched 80*10*4 -30°C 9 kJ/m² ISO 180/1A

© 2017 Copyright by SABIC. All rights reserved

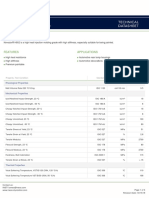

PROPERTIES TYPICAL VALUES UNITS TEST METHODS

Charpy 23°C, V-notch Edgew 80*10*3 sp=62mm NB kJ/m² ISO 179/1eA

Charpy -30°C, V-notch Edgew 80*10*3 sp=62mm NB kJ/m² ISO 179/1eA

Charpy 23°C, Unnotch Edgew 80*10*3 sp=62mm NB kJ/m² ISO 179/1eU

Charpy -30°C, Unnotch Edgew 80*10*3 sp=62mm NB kJ/m² ISO 179/1eU

Charpy 23°C, V-notch Edgew 80*10*4 sp=62mm NB kJ/m² ISO 179/1eA

Charpy -30°C, V-notch Edgew 80*10*4 sp=62mm NB kJ/m² ISO 179/1eA

Charpy 23°C, Unnotch Edgew 80*10*4 sp=62mm NB kJ/m² ISO 179/1eU

Charpy -30°C, Unnotch Edgew 80*10*4 sp=62mm NB kJ/m² ISO 179/1eU

THERMAL

HDT/Bf, 0.45 MPa Flatw 80*10*4 sp=64mm 104 °C ISO 75/Bf

HDT/Af, 1.8 MPa Flatw 80*10*4 sp=64mm 94 °C ISO 75/Af

Vicat Softening Temp, Rate B/50 111 °C ASTM D 1525

HDT, 0.45 MPa, 3.2 mm, unannealed 104 °C ASTM D 648

HDT, 1.82 MPa, 3.2mm, unannealed 94 °C ASTM D 648

CTE, -40°C to 40°C, flow 6.E-05 1/°C ISO 11359-2

CTE, -40°C to 40°C, xflow 6.E-05 1/°C ISO 11359-2

Vicat Softening Temp, Rate B/120 113 °C ISO 306

PHYSICAL

Specific Gravity 1.33 - ASTM D 792

Mold Shrinkage, flow (5) 0.5 – 0.7 % SABIC method

Mold Shrinkage, xflow (5) 0.5 – 0.7 % SABIC method

Melt Flow Rate, 300°C/1.2 kgf 9 g/10 min ASTM D 1238

Density 1.33 g/cm³ ISO 1183

Melt Volume Rate, MVR at 300°C/1.2 kg 10 cm³/10 min ISO 1133

FLAME CHARACTERISTICS

Flame Spread Index (1.52mm) <35 - ASTM E 162

NBS Smoke Density, Flaming, Ds 1.5 min <100 - ASTM E 662

NBS Smoke Density, Flaming, Ds 4 min <200 - ASTM E 662

Heat release, MAHRE, 50 kW/m2, 3 mm <60 kW/m² ISO 5660-1

Smoke Toxicity PASSES - OEM BSS

Smoke density, DS-4, 50 kW/m2, 3mm <150 - ISO 5659-2

Smoke density, VOF4, 50 kW/m2, 3mm <300 - ISO 5659-2

Smoke toxicity, CITG (8 min), 50 kW/m2, 3 mm 0.1 - ISO 5659-2

Fire Safety Hazard Level - Requirement set R6 HL3 - EN EN 45545-2:2013

INJECTION MOLDING

Drying Temperature 95 – 100 °C

Drying Time 6–8 hrs

Melt Temperature 250 – 280 °C

© 2017 Copyright by SABIC. All rights reserved

PROPERTIES TYPICAL VALUES UNITS TEST METHODS

Nozzle Temperature 245 – 275 °C

Front - Zone 3 Temperature 250 – 280 °C

Middle - Zone 2 Temperature 240 – 270 °C

Rear - Zone 1 Temperature 230 – 250 °C

Mold Temperature 50 – 80 °C

Back Pressure 0.3 – 0.7 MPa

Screw Speed 40 – 70 rpm

Shot to Cylinder Size 40 – 60 %

Vent Depth 0.025 – 0.076 mm

DISCLAIMER

Any sale by SABIC, its subsidiaries and affiliates (each a “seller”), is made exclusively under seller’s standard conditions of sale

(available upon request) unless agreed otherwise in writing and signed on behalf of the seller. While the information contained herein

is given in good faith, SELLER MAKES NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY AND

NONINFRINGEMENT OF INTELLECTUAL PROPERTY, NOR ASSUMES ANY LIABILITY, DIRECT OR INDIRECT, WITH RESPECT

TO THE PERFORMANCE, SUITABILITY OR FITNESS FOR INTENDED USE OR PURPOSE OF THESE PRODUCTS IN ANY

APPLICATION. Each customer must determine the suitability of seller materials for the customer’s particular use through appropriate

testing and analysis. No statement by seller concerning a possible use of any product, service or design is intended, or should be

construed, to grant any license under any patent or other intellectual property right.

© 2017 Copyright by SABIC. All rights reserved

You might also like

- CYCOLOY™ Resin - LG9000 - Europe - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - LG9000 - Europe - Technical - Data - SheetmustafaNo ratings yet

- 05 - Monotonic and Cyclic Response of Speed-Lock Connections With Bolts in Storage RacksDocument16 pages05 - Monotonic and Cyclic Response of Speed-Lock Connections With Bolts in Storage RacksJosé Miguel Martínez100% (1)

- Astm G133 - 2005Document9 pagesAstm G133 - 2005Denise Roth100% (1)

- Reference Manual S-CONCRETE R11 PDFDocument127 pagesReference Manual S-CONCRETE R11 PDFSyed RaziuddinNo ratings yet

- SABIC_Cycolac_MG47FDocument3 pagesSABIC_Cycolac_MG47FChu ChuNo ratings yet

- Lexan™ Copolymer 943X: Region AmericasDocument3 pagesLexan™ Copolymer 943X: Region AmericasAdirSchoierNo ratings yet

- CYCOLAC™ Resin - DL100 - Asia - Technical - Data - SheetDocument2 pagesCYCOLAC™ Resin - DL100 - Asia - Technical - Data - SheetKishore Gowda A SNo ratings yet

- CYCOLOY™ Resin - XCY620 - Asia - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - XCY620 - Asia - Technical - Data - SheetAthiwat TriwattanapornNo ratings yet

- LEXAN™ Copolymer - SLX2432T - Americas - Technical - Data - SheetDocument3 pagesLEXAN™ Copolymer - SLX2432T - Americas - Technical - Data - Sheetsonia soniaNo ratings yet

- NORYL™ Resin - SE1GFN2 - Asia - Technical - Data - Sheet PDFDocument3 pagesNORYL™ Resin - SE1GFN2 - Asia - Technical - Data - Sheet PDFbhushansalunkeNo ratings yet

- CYCOLAC™ Resin - MG37EPX - Americas - Technical - Data - SheetDocument2 pagesCYCOLAC™ Resin - MG37EPX - Americas - Technical - Data - SheetmarceloNo ratings yet

- CYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetJoseNo ratings yet

- Sabic 1004RDocument3 pagesSabic 1004Rlcesaksham23No ratings yet

- SABIC® PC Resin - PC1803R - Global - Technical - Data - SheetDocument3 pagesSABIC® PC Resin - PC1803R - Global - Technical - Data - SheetLeandro SalvadorNo ratings yet

- A GD VDBDocument3 pagesA GD VDBthehoang12310No ratings yet

- POLICARBONATO LEXAN™ Resin - 123R - Europe - Technical - Data - SheetDocument2 pagesPOLICARBONATO LEXAN™ Resin - 123R - Europe - Technical - Data - SheetscribdNo ratings yet

- LEXAN™ Resin - 141R - Europe - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 141R - Europe - Technical - Data - SheetMinh Quãng PhạmNo ratings yet

- Noryl Resin Se1X: Region AmericasDocument3 pagesNoryl Resin Se1X: Region AmericasHector GonzalezNo ratings yet

- Elix Pc-Abs 5130Document4 pagesElix Pc-Abs 5130DiegoTierradentroNo ratings yet

- Elix ABS E401: Technical InformationDocument3 pagesElix ABS E401: Technical InformationDiegoTierradentroNo ratings yet

- Elix ABS P2M-AT: Technical InformationDocument3 pagesElix ABS P2M-AT: Technical InformationDiegoTierradentroNo ratings yet

- Elix ABS M220: Technical InformationDocument3 pagesElix ABS M220: Technical InformationDiegoTierradentroNo ratings yet

- Elix Ultra hh4115Document3 pagesElix Ultra hh4115DiegoTierradentroNo ratings yet

- XENOY™ Resin - 5220U - Europe - Technical - Data - SheetDocument2 pagesXENOY™ Resin - 5220U - Europe - Technical - Data - SheetEduardo TreviñoNo ratings yet

- SABIC® PPcompound - G3230A - Americas - Technical - Data - SheetDocument2 pagesSABIC® PPcompound - G3230A - Americas - Technical - Data - SheetAarón González MedinaNo ratings yet

- ULTEM™ Resin - DT1820EV - Global - Technical - Data - SheetDocument2 pagesULTEM™ Resin - DT1820EV - Global - Technical - Data - SheetKishore Gowda A SNo ratings yet

- Lexan FR Resin 505rDocument3 pagesLexan FR Resin 505rShabi HadashNo ratings yet

- LNP+LUBRICOMP+Compound RFL16 Global Technical Data SheetDocument2 pagesLNP+LUBRICOMP+Compound RFL16 Global Technical Data SheetcoroNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- Riteflex 640aDocument3 pagesRiteflex 640aazaleaemersonNo ratings yet

- LEXAN™ Copolymer - 4795R - Americas - Technical - Data - SheetDocument2 pagesLEXAN™ Copolymer - 4795R - Americas - Technical - Data - SheetRamesh KannanNo ratings yet

- LEXAN™ FR Resin - 945 - Asia - Technical - Data - SheetDocument2 pagesLEXAN™ FR Resin - 945 - Asia - Technical - Data - SheetSapphire PolycarbonatesNo ratings yet

- Pulse A 35-105 BlackDocument3 pagesPulse A 35-105 BlackTaoufik KheddarNo ratings yet

- Luran S 777K: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 777K: Acrylonitrile Styrene Acrylate (ASA)Leonardo DguezNo ratings yet

- Zytel® 45HSB NC010-gbDocument14 pagesZytel® 45HSB NC010-gbJuan Fernando CampuzanoNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- Durethan B30S 000000 ISO enDocument3 pagesDurethan B30S 000000 ISO enjujuplasticNo ratings yet

- Vesbo PPR EnglishDocument50 pagesVesbo PPR Englishcool.boys4200No ratings yet

- Zytel® 103HSL NC010-gbDocument15 pagesZytel® 103HSL NC010-gbFaustoNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196asegundoferreiraNo ratings yet

- Durethan B30S 000000: PA 6, Non-Reinforced, Injection Molding ISO Shortname: ISO 1874-PA 6, GR, 14-030Document3 pagesDurethan B30S 000000: PA 6, Non-Reinforced, Injection Molding ISO Shortname: ISO 1874-PA 6, GR, 14-030zoranNo ratings yet

- PC Calibre Technical DataDocument4 pagesPC Calibre Technical DataMitja GorseNo ratings yet

- Zytel® 101L NC010-gbDocument21 pagesZytel® 101L NC010-gbRamiro PredassiNo ratings yet

- Luran S 778T: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 778T: Acrylonitrile Styrene Acrylate (ASA)jineshdmehtaNo ratings yet

- Wonderloy PC 540Document2 pagesWonderloy PC 540Phung LucNo ratings yet

- Zytel® 101 NC010-gbDocument11 pagesZytel® 101 NC010-gbalejandrocharlescollNo ratings yet

- PocanB3235000000 GF30 1Document5 pagesPocanB3235000000 GF30 1rihabNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- PC - Trinseo Emerge 8701HH GF10Document3 pagesPC - Trinseo Emerge 8701HH GF10armandoNo ratings yet

- Luran HH-120: Please SelectDocument3 pagesLuran HH-120: Please SelectDavid Costi da RosaNo ratings yet

- Styro Lution Tds 400900240714Document3 pagesStyro Lution Tds 400900240714vrjrNo ratings yet

- LANXESS Durethan A30SFN31 000000 ISO ENDocument3 pagesLANXESS Durethan A30SFN31 000000 ISO ENNguyen Dinh VinhNo ratings yet

- LANXESS_Durethan_BKV35H2.0_901510_ISO_ENDocument3 pagesLANXESS_Durethan_BKV35H2.0_901510_ISO_ENcristinamss33No ratings yet

- Styrolution PS 158N/L Heat Resistant GPPSDocument3 pagesStyrolution PS 158N/L Heat Resistant GPPSscribdichigoNo ratings yet

- Latigloss 66 H2 G 50 F2 PDFDocument4 pagesLatigloss 66 H2 G 50 F2 PDFBadis ChemaliNo ratings yet

- TASNEE 100 Black PE Resin for Pressure PipesDocument2 pagesTASNEE 100 Black PE Resin for Pressure PipesHassanNo ratings yet

- Lanxess - Pocan B7425Document3 pagesLanxess - Pocan B7425rihabNo ratings yet

- StyrolutionTDS400700190196 PDFDocument3 pagesStyrolutionTDS400700190196 PDFMirella FaresNo ratings yet

- Datasheet-Ultra Hh-4115-Hi-IsoDocument3 pagesDatasheet-Ultra Hh-4115-Hi-IsoDiegoTierradentroNo ratings yet

- PA6-30GF LANXESS Durethan BKV130P 702214 ISO ENDocument2 pagesPA6-30GF LANXESS Durethan BKV130P 702214 ISO ENKalipse FerreiraNo ratings yet

- Dimensional Change Irradiation Creep and ThermalmeDocument30 pagesDimensional Change Irradiation Creep and Thermalmefiver88No ratings yet

- Crack Width CalculationDocument7 pagesCrack Width CalculationSrinivas RegulavalasaNo ratings yet

- The CST PDFDocument10 pagesThe CST PDFk krishna chaitanya0% (1)

- CE 2101: Engineering Materials: Rumana AfrinDocument11 pagesCE 2101: Engineering Materials: Rumana AfrinRumana AfrinNo ratings yet

- JKSSB JE ME 2015 EnglishDocument18 pagesJKSSB JE ME 2015 EnglishGayatriramanaNo ratings yet

- Design of A 3D Printed Concrete Bridge by TestingDocument16 pagesDesign of A 3D Printed Concrete Bridge by Testingibrahim hamzaNo ratings yet

- Al 111 2377-00 Rev 20 28-5-18Document2 pagesAl 111 2377-00 Rev 20 28-5-18Deipak HoleNo ratings yet

- Micrornechanics of Defects SolidsDocument506 pagesMicrornechanics of Defects SolidsCarlos RomeroNo ratings yet

- Beam Bending Tutorial in Abaqus CAEDocument5 pagesBeam Bending Tutorial in Abaqus CAEChristian Chinedu100% (1)

- ABAQUS TutorialsDocument59 pagesABAQUS TutorialsMikael Bezerra Cotias Dos Santos80% (5)

- WholeDocument347 pagesWholeLavinia DamianNo ratings yet

- Journal of Alloys and CompoundsDocument8 pagesJournal of Alloys and CompoundsSyahidah ShikamaruNo ratings yet

- PrEN 14889-1. Steel FibresDocument18 pagesPrEN 14889-1. Steel FibresCleverRamirezNo ratings yet

- Slab Deflections in The Cardington In-Situ Concrete Frame BuildingDocument12 pagesSlab Deflections in The Cardington In-Situ Concrete Frame BuildingwaynectwNo ratings yet

- Modeling Overuse Injuries in Sport As A Mechanical Fatigue PhenomenonDocument8 pagesModeling Overuse Injuries in Sport As A Mechanical Fatigue PhenomenonShaun TylerNo ratings yet

- Stress Strain RelationsDocument22 pagesStress Strain Relationsmustafa1011No ratings yet

- 2017 Tying Capacity of Web Cleat Connections in Fire Part 2Document12 pages2017 Tying Capacity of Web Cleat Connections in Fire Part 2alfonsoNo ratings yet

- Double-Curvature Arch Dams - Planning, Appraisal, and Feasibility Level DesignDocument98 pagesDouble-Curvature Arch Dams - Planning, Appraisal, and Feasibility Level DesignGligor JakovleskiNo ratings yet

- Under Re - Attachment (Elastic Bend)Document4 pagesUnder Re - Attachment (Elastic Bend)ISRAEL PORTILLONo ratings yet

- Ce Prof 4 Midterm OutputDocument3 pagesCe Prof 4 Midterm OutputnuestrojovennuestroNo ratings yet

- Evaluation of Pile Desing Methods Using Static Load Tests For A Dual Railway ProjectDocument295 pagesEvaluation of Pile Desing Methods Using Static Load Tests For A Dual Railway Projectจอม อรรฐาเมศร์No ratings yet

- Strain Thresholds in Soil Dynamics: January 2009Document9 pagesStrain Thresholds in Soil Dynamics: January 2009Gracie AzevedoNo ratings yet

- BMM3532 Assignment 1: Measurement & InstrumentationDocument3 pagesBMM3532 Assignment 1: Measurement & InstrumentationIntan Shafinaz CollinsNo ratings yet

- Van Eekelen Et Al 2011 BS8006 FinalDocument15 pagesVan Eekelen Et Al 2011 BS8006 FinalRaden Budi HermawanNo ratings yet

- Aluminum 2618 T61Document6 pagesAluminum 2618 T61Rakesh S IndiaNo ratings yet

- 1thermal Stresses - 16 Maret 2021Document10 pages1thermal Stresses - 16 Maret 2021Ginanjar Hadi SukmaNo ratings yet

- Polyester Fiber Properties and UsesDocument8 pagesPolyester Fiber Properties and UsesAhasn HabibNo ratings yet