Professional Documents

Culture Documents

Selector 6850 Selector Brush Motors

Uploaded by

Humberto Andrade Dominguez0 ratings0% found this document useful (0 votes)

13 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views3 pagesSelector 6850 Selector Brush Motors

Uploaded by

Humberto Andrade DominguezCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

OTIS ELEVATOR

COMPANY AUSTRALIAN TECHNICAL ARTICLE

ATA No. A-IV-4-20 Dated: 19/6/1975 Revision No. 0

Title: SELECTOR BRUSH MOTORS

Prepared by:

Name: L MURRAY

Title: FIELD ENGINEER

Department: FIELD ENGINEERING

Paper Distribution:

Distribution "B"

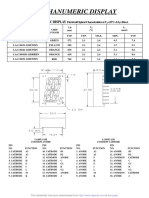

Where troubles, such as "missing floors on short runs" or "running slow", are caused by

erratic selector brush motor operation, the attached circuit modification (sketch no. 1) will

give much improved operation.

It will, of course, be necessary to readjust the brush motor speed to suit the installation. A

good starting point is 0.7 sec per inch of travel.

Future controllers manufactured will have this circuit as standard.

Material required is:-

1 off SO6840A1 Assembly rectifier panel

2 off 180AB1 Holder, fuse

2 off 375P25 Fuse

2 off 339BY2 Clip

2 off 65BD2 Bolt and hardware

20 metres SO3 Wire 1/0.036"

On controllers with no provision for extra fuses, holes similar to the one shown below can

be made in the rectifier panel.

Unpublished Work copyright Otis Elevator Company Page 1 of 3

On some controllers it may be necessary to increase "BM" resistance to obtain satisfactory

"HSL" adjustment.

Cost should be allotted as follows:-

Under construction Contract number per ETR

FOS and within guarantee period Construction guarantee

Contractual maintenance To the contract number

Unpublished Work copyright Otis Elevator Company Page 2 of 3

Unpublished Work copyright Otis Elevator Company Page 3 of 3

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- UT ID 4 - 6 8 ADA PhoneDocument20 pagesUT ID 4 - 6 8 ADA PhoneHumberto Andrade DominguezNo ratings yet

- La8021 11bewrnDocument1 pageLa8021 11bewrnHumberto Andrade DominguezNo ratings yet

- Categoría Cantidad Referencias Valor PCB Package Código AlmacénDocument3 pagesCategoría Cantidad Referencias Valor PCB Package Código AlmacénHumberto Andrade DominguezNo ratings yet

- Pinout Esp32 Wemos Lolin32 by Doc Cool (Cool-Web - De)Document1 pagePinout Esp32 Wemos Lolin32 by Doc Cool (Cool-Web - De)Humberto Andrade Dominguez0% (1)

- Clase 3 CRTLDocument10 pagesClase 3 CRTLHumberto Andrade DominguezNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)