Professional Documents

Culture Documents

US Ballastless

Uploaded by

Akash0 ratings0% found this document useful (0 votes)

20 views5 pagesUS Ballastless track methodology

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentUS Ballastless track methodology

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views5 pagesUS Ballastless

Uploaded by

AkashUS Ballastless track methodology

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

USOO8397642B2

(12) United States Patent (10) Patent No.: US 8,397,642 B2

Miguelez Tapia (45) Date of Patent: Mar. 19, 2013

(54) METHOD FOR THE INSTALLATION OF 3,754,505 A * 8/1973 Dyballa ............................ 104.5

RAILWAY TRACKS ON BALLAST, WITHOUT 4,657,099 A * 4/1987 Baltensperger 1809.28

AN AUXLARY TRACK 5,181,472 A * 1/1993 Scheuchzer ....................... 104/2

5,271,047 A * 12/1993 Freneix .............. ... 376,260

5,520,497 A * 5/1996 Hertelendi et al. ... 414,529

(75) Inventor: Francisco Javier Miguelez Tapia, 5,630,365 A * 5/1997 Hertelendi ........................ 104.5

Madrid (ES) 5,961,271 A * 10/1999 Theurer et al. ..... ... 414,339

6,375,402 B1 * 4/2002 Hertelendi et al. ... 414,373

(73) Assignee: FCC Constructions, S.A., Madrid (ES) 6,981.452 B2 * 1/2006 Herzog et al. .................... 104/2

7,470,871 B2* 12/2008 Theurer et al. . 219,53

7,478,596 B2 * 1/2009 Theurer ......... ... 104/2

(*) Notice: Subject to any disclaimer, the term of this 7,707,943 B2 * 5/2010 Herzog et al. . ... 104/2

patent is extended or adjusted under 35 2007,0199472 A1* 8, 2007 Theurer et al. . 1047.1

U.S.C. 154(b) by 0 days. 2008, OO72783 A1* 3, 2008 McCulloch ........ ... 104/2

2008/0230520 A1* 9/2008 Lichtberger et al. 219,53

2009/0095188 A1* 4, 2009 Bounds .............. ... 104/2

(21) Appl. No.: 12/819,682 2011/0052364 A1 3/2011 McCulloch ................... 414,800

(22) Filed: Jun. 21, 2010 * cited by examiner

(65) Prior Publication Data Primary Examiner — Mark Le

US 2010/032O280 A1 Dec. 23, 2010 (74) Attorney, Agent, or Firm — Sturm & Fix LLP

(30) Foreign Application Priority Data (57) ABSTRACT

A method for installing railway tracks onto ballast beds

Jun. 23, 2009 (ES) ................................... 2009.O148O avoiding the need for installing any type of auxiliary track.

The method comprises successive stages to be carried out

(51) Int. C. after having located the sleepers onto the ballast bed, consist

EOIB 29/05 (2006.01) ing offixing and laying of a pair of rails from a mini train, for

(52) U.S. Cl. ...................................... ... 104/2: 104/7.1 the transport of the rails with the fastening and traction of

(58) Field of Classification Search .................. 104/2, 3, same up to their complete unloading, the operation being

104/4, 5, 7.1, 7.2, 8, 15, 16, 6; 219/53, 54; guided by means of a discharge wagon; Supporting the rails

414/339, 373,395,486,529, 800 on rollers for the longitudinal movement thereof cutting,

See application file for complete search history. squaring and fixing the adjacentends to the consecutive rails;

raising the rail with the help of a crane, and removing the

(56) References Cited rollers; partial fastening of the track and placement of the

rollers for the next cycle, and removing the tractor from the

U.S. PATENT DOCUMENTS mini train, and the final fastening of the rails.

3,557,703 A * 1/1971 Moorefield et al. .............. 1042

3,635,164 A * 1/1972 Patton ........................... 104,307 2 Claims, 1 Drawing Sheet

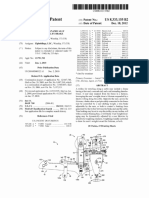

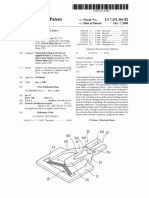

Ballast Bed with Installed Sleepers

Installing Roller Elements to Bridge

Between Sleepers

Providing a Traction Device

Providing a Supply of Rails on the

Mini Train

Unloading Rails from MiniTrain Onto

Roller Elements

Repeating Cycle Until

Job Completed Preparing Rail Ends for Connection

Lifting Forward Ends of Rails

Removing Installed Roller Elements

and Loading on Tractor Means Racks

Fastening Rails to Sleepers

U.S. Patent Mar. 19, 2013 US 8,397,642 B2

Ballast Bed with Installed Sleepers

->

Installing Roller Elements to Bridge

Between Sleepers

Providing a Traction Device

Providing a Supply of Rails on the

Mini Train

Unloading Rails from Mini Train Onto

Roller Elements

Repeating Cycle Until

Job Completed Preparing Rail Ends for Connection

Lifting Forward Ends of Rails

Removing Installed Roller Elements

and Loading on Tractor Means Racks

Fastening Rails to Sleepers

US 8,397,642 B2

1. 2

METHOD FOR THE INSTALLATION OF tracks, Substantially simpler, quicker and cheaper than the

RAILWAY TRACKS ON BALLAST, WITHOUT conventional methods, given that the new method does not

AN AUXLARY TRACK need to resort to the use of any type of auxiliary track.

In effect, in many conventional railway track installation

CROSS REFERENCE TO RELATED methods it is normal that together with the main track a

APPLICATIONS temporary auxiliary track is built that is normally used for the

purposes of supply. This auxiliary track is made up of wooden

This application claims priority of ES Application No. sleepers and secondary use lines, laid along a predetermined

P200901480 filed Jun. 23, 2009, which is incorporated by length and built on the basis of stretches of line having a

reference herein in its entirety. 10 reduced length so as to optimise the transport.

This present invention provides an optimised method for

BACKGROUND OF THE INVENTION the installation of railway tracks on ballast, by means of

which the need for the installation, assembly or use of any

Field of the Invention auxiliary track is eliminated, and in addition is built on the

15 basis of a reduced number of external devices, namely: A

The present invention refers to a method for the installation discharge (unloading) wagon, a tractor device, and a prede

of railway tracks on ballast, without an auxiliary track, that termined number of slide elements for the rails (also called

contributes essential characteristics of novelty and appre rollers, whose main characteristics are stated below.

ciable advantages compared to the other known and used Discharge Wagon:

methods used for the same purposes in the current state of the It consists of a wagon that is coupled to the mini train for

art. the transport of rails, at the unloading end of the rails. The

More specifically, the invention allows a method to be put purpose of this discharge wagon is to prevent deflections of

into practice that has been specially conceived and designed the rail during the unloading, which can bring about perma

to simplify, speed up and to reduce costs in that which refers nent deformities to same. The wagon makes it easier to unload

to the installation processes of railway tracks on ballast, with 25 the rails in pairs with predetermined lengths (for example,

the use of a reduced number of external devices and elements, 270 meters in length), for which purpose it has some devices

that have been modified and adapted for their specific appli to drive the bars in a parallel manner on Supports that take

cation in the proposed object, with the consequent optimisa them and steer them. In the same way, the discharge wagon

tion of the production processes. The installation method can also be used for the transporting of Small sized materials

allows the rails of the railway to be unloaded and positioned 30 and other consumables.

by cycles with a predetermined length, with a net increase in Tractor Device

performance compared to the conventional methods thanks to This device is applicable during the installation of the

the Substantial increase in the number of cycles per produc track, for the carrying out of specific functions such as the

tion day. pulling of the rail during the unloading operation of same, the

The field of application of the invention is clearly to be 35 lifting of the rail for the extraction of the rail slide elements

found within the industrial sector involved in the installation onto which it will be moved during the unloading, and the

and laying of railway tracks on ballast. transporting of the slide elements for the rail, once recovered.

In general, the tractor device can be any conventional

BRIEF SUMMARY OF THE INVENTION device, adapted and fitted for the carrying out of the previ

40 ously stated tasks. On one preferred, simplified embodiment

Over time ballast has formed a particularly suitable base of the tractor device, this was obtained from a mini back shoe

for the laying of railway tracks across the designed and pre excavator, suitably modified to increase the width of same in

viously established distances. The ballast consists of broken Such a way that the side tracks are separated from each other

stones that, appropriately laid, provides a suitable bed for the with enough space between them to allow the laying of the

Support of the sleepers onto which the rails making up the 45 track with the sleepers duly located in their respective posi

railway line can rest, providing stability to the railway track, tions. The tracks allow the tractor device to be able to move

and managing to ensure that it keeps the original geometry and to go along the sides of the ballast bed, or even on the

that was conceived during the construction. In addition, it stones of the residual side parts of same. The tractor device is

fulfils other important functions, such as the appropriate dis also fitted with side trays which, in a manner like panniers

tribution and dispersal of the loads that the track transmits to 50 arranged on the chassis of the original engine, allow the

the land, in Such away that the resulting values are admissible storage and transporting of other components such as, for

for it, and also allows appropriate drainage of the rainwater, example, the slide elements for the rails.

thus preventing the deterioration of the assembly. The tractor is also fitted with some crane device, by means

Hence, the ballast makes up a basic element on which the of which it carries out the rail lifting operation as was alluded

installation of the railway tracks has been based over time, 55 to in the above.

and continues to be a main element in these types of applica Rail Slide Elements

tions in spite of the fact that other support beds are known in Also known as rollers, each one of these elements con

these times that can be particularly suitable under certain sists of a metallic sheet or profile, made of steel, with a length

circumstances, but under no circumstances can the total such that it can be extended between, and fixed to, two con

replacement of ballast be envisaged, at least for the short secutive sleepers like a bridge, for example with a length of 90

60

term. cm. Said profile carries a welded roller which is used to make

Given the favourable characteristics inherent in the ballast the movement easier of the rail that is Supported on it during

beds, there continues to be research in respect of methods that the longitudinal movement in the direction of the installation.

allow for improvements in the installation and assembly pro The elements or rollers are arranged on both sides, for each

cesses of the tracks onto these beds, as occurs in the case of 65 rail. Successively keeping a certain equidistance, for example

the present invention, by means of which an optimised every 18 sleepers, which is a separation of approximately

method has been developed for the installation of railway 10.8 meters between each two consecutive rollers.

US 8,397,642 B2

3 4

With only the aid of the devices and means that have just Finally, the mini train is withdrawn back from the tractor

been described, it is possible to carry out the procedure of the device, and the fastening of the track is finished, all of the

invention, with construction process performance that is components and devices being ready for the commencement

much greater than other conventional methods where the help of a new cycle.

of a greater number of devices is needed. As can be appreciated, the method of the invention in the

above description, considerably simplifies the operating prac

BRIEF DESCRIPTION OF THE DRAWINGS tices of the current methods, with the use of a reduced number

of resources or equipment, with a highly increased perfor

These and other attributes of the invention will become mance as to operativity and costs compared to the methods

more clear upona thorough study of the following description 10 used in the current state of the art.

of the best mode for carrying out the invention, particularly It is not considered as being necessary to make the contents

when reviewed in conjunction with the drawing, wherein: of this present description more extensive as a skilled person

The single drawing is a flow diagram showing the steps of in this field can understand its scope and the advantages that

the method of the present invention. arise from same, likewise how to carry out the practical

15 embodiment of its object. In spite of the above, it must be

DETAILED DESCRIPTION OF THE INVENTION understood that the description given only corresponds to an

example of a preferred embodiment, and therefore it is

In accordance with the above, the detailed description of capable of having changes, modifications or alterations made

the method proposed by the invention is going to be carried both in regard to the construction phases and equally the

methods used, without this meaning any alteration to the

out in the following with express definition of the details that scope of the protection provided by the method of the inven

characterise each one of the construction phases included in tion.

the process. Hence, in the first place the construction of the

ballast bed and the positioning on the same of the plurality of The invention claimed is:

sleepers to help and support the rails is proceeded with, fol 25 1. Installation method for railway tracks on ballast, without

lowing the layout planned for the railway track. auxiliary track, comprising the steps of:

With the sleepers in place, the rail slide elements (rollers) (a) making of a ballast bed and installing a plurality of

are placed on said sleepers, each one of said rollers extended sleepers on the ballast bed;

forming a bridge between two consecutive sleepers as has (b) installing a plurality of roller elements on the already

been said, and with a separation at a previously determined 30 installed sleepers, each roller element being Supported

distance. on two successive sleepers forming a bridge between the

Next, by bringing said mini train nearer towards the con two successive sleepers, consecutively separated from

struction stretch, to make available the sections of rail with a each other at a predetermined distance;

predetermined length (in the example about 270 meters) the (c) providing a tractor device having ground engaging ele

coupling is carried out of the unloading wagon to be used 35 ments that span the installed sleepers and move longitu

during the Supported and guided unloading of said rail sec dinally with respect to the ballast bed;

tions, with said mini train for the transportation of the rails. (d) providing a Supply of rails on a mini train;

After this, in the following phase the operation for the (e) unloading a pair of rails from the mini train onto the

fixing of a pair of rails is carried out on the last wagon of the roller elements, and longitudinally moving the pair of

mini train with the devices used to drive and move the rails in

40 rails on the roller elements up to their placement on the

sleepers;

the discharge direction with the aid of the tractor device. After (f) cutting, squaring and fixing of the rails for connecting

this, a fastening operation is carried out on the pair of rails and adjacent ends of adjacent rails;

traction is exercised on same by the tractor device until the (g) lifting a forward end of each rail;

complete discharge of the rails from the mini train wagon is 45 (h) removing the roller elements;

achieved, as has been said this operation is made easier by the (i) fastening the rails to the sleeper; and

guidance mechanisms fitted to the discharge wagon, and with () repeating steps (b) through (i) until installation of the

the rails being driven and guided they are Supported on the railway tracks is completed.

rollers of movement elements that were previously placed on 2. Installation method for railway tracks on ballast, without

the track sleepers. 50 auxiliary track, comprising the steps of:

With the rails in those conditions an operation for cutting, (a) making of a ballast bed and installing a plurality of

squaring and fixing of same is carried, this is, an operation to sleepers on the ballast bed;

join the ends of the consecutively adjacent rails. (b) installing a plurality of roller elements on the already

Once having finished the previous operation the lifting of installed sleepers, each roller element being Supported

the rails on each side is proceeded with so as to recover the 55 on two successive sleepers forming a bridge between the

rollers (or movement elements) that enabled the longitudinal two Successive sleepers, consecutively separated from

movement of each rail. This operation is carried out with the each other at a predetermined distance, each one of these

lifting devices or crane incorporated into the tractor device, roller elements being fitted with a Support and guidance

and consists of raising each rail, holding it by one end (the free roller for longitudinal movement of a rail up to its cor

end), so as to allow the stated slider elements to be removed, 60 responding placement;

which are in turn loaded onto the tractor device itself, in (c) providing a mini train for transport of rails, and cou

accordance with that said, for its transport to the next working pling the mini train to a discharge wagon fitted with a

position. guidance mechanism for guided unloading and lifting of

Once having completed the previous stage the partial fas rails by pairs;

tening of the track is proceeded with (one sleeper for every so 65 (d) fixing of the pair of rails at an unloading end, and

many units, for example one sleeper for each 7 units), and for fastening them with a traction device for unloading said

the placement of the rollers for the next cycle. pair of rails;

US 8,397,642 B2

5 6

(e) unloading the pair of rails through the discharge wagon (h) removal of the roller elements and the loading the roller

onto said rollers of the roller elements using a tractor elements onto racks disposed on both sides of the tractor

device, which spans the entire width of the track; device;

(f) cutting, squaring and fixing of the rails for connection of 5 (i) partial fastening of every rail to each sleeper, and

adjacent ends of adjacent rails; () repeating steps (b) through (i) until installation of the

railway tracks is completed.

(g) lifting a forward end of each rail with a lifting device

fitted to the tractor device; k . . . .

You might also like

- United States Patent: GuirgisDocument11 pagesUnited States Patent: Guirgisamd mhmNo ratings yet

- Us8844862 PDFDocument11 pagesUs8844862 PDF雷黎明No ratings yet

- 2005 - US006968735B2 - Long Range Data Transmitter For HDDDocument9 pages2005 - US006968735B2 - Long Range Data Transmitter For HDDCường Nguyễn QuốcNo ratings yet

- US8794568Document17 pagesUS8794568雷黎明No ratings yet

- US8069593Document9 pagesUS8069593PUVAN TSTNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7,322,545 B2Document13 pagesUnited States Patent: (12) (10) Patent No.: US 7,322,545 B2rakkaNo ratings yet

- US8421423Document15 pagesUS8421423Bruno LambertNo ratings yet

- (12 Ulllted States Patent (10) Patent N0.: US 6,236,330 B1Document8 pages(12 Ulllted States Patent (10) Patent N0.: US 6,236,330 B1sonyaNo ratings yet

- United States Patent: Hughes Et Al. (45) Date of Patent: Aug. 2, 2011Document14 pagesUnited States Patent: Hughes Et Al. (45) Date of Patent: Aug. 2, 2011Daniel ChudNo ratings yet

- United States Patent: Gaydos Et AlDocument8 pagesUnited States Patent: Gaydos Et AlHugo Mauricio Echeverry HerreraNo ratings yet

- United States Patent (10) Patent No.: US 7827,720 B1: Erdem (45) Date of Patent: Nov. 9, 2010Document24 pagesUnited States Patent (10) Patent No.: US 7827,720 B1: Erdem (45) Date of Patent: Nov. 9, 2010Слэйтер Строительная компанияNo ratings yet

- US7743601Document4 pagesUS7743601Alien GmpNo ratings yet

- United States Patent (10) Patent No.: US 8,794,651 B2Document29 pagesUnited States Patent (10) Patent No.: US 8,794,651 B2swapnil kaleNo ratings yet

- United States Patent (10) Patent No.: US 6,201,180 B1: Meyer Et Al. (45) Date of Patent: Mar. 13, 2001Document18 pagesUnited States Patent (10) Patent No.: US 6,201,180 B1: Meyer Et Al. (45) Date of Patent: Mar. 13, 2001Jherson Denys Contreras RamosNo ratings yet

- United States Patent (10) Patent N0.: US 8,851,163 B2Document15 pagesUnited States Patent (10) Patent N0.: US 8,851,163 B2Diseno VATNo ratings yet

- US8333155Document36 pagesUS8333155han09092001No ratings yet

- US8915116Document15 pagesUS8915116ErockNo ratings yet

- Compact FusionDocument7 pagesCompact Fusionpaperoni iNo ratings yet

- Oleumtech Us8763455 PDFDocument16 pagesOleumtech Us8763455 PDFshadyghanemNo ratings yet

- Laminated ManufactureDocument9 pagesLaminated Manufactureconfused597No ratings yet

- United States Patent (10) Patent No.: US 6,453,528 B1Document9 pagesUnited States Patent (10) Patent No.: US 6,453,528 B1MahnooshNo ratings yet

- US9168104 Intra-Operative SystemDocument45 pagesUS9168104 Intra-Operative Systempaco gonzalezNo ratings yet

- United States Patent (10) Patent No.: US 8.454.296 B2Document18 pagesUnited States Patent (10) Patent No.: US 8.454.296 B2Yu YangNo ratings yet

- US6804943Document6 pagesUS6804943Abdullah KhanNo ratings yet

- Wheel PWR GenerationDocument8 pagesWheel PWR GenerationAsad Ahmed KhanNo ratings yet

- United States Patent: JonesDocument5 pagesUnited States Patent: JonesGhulam MehdiNo ratings yet

- Us8473131 PDFDocument25 pagesUs8473131 PDFPrateek SanghiNo ratings yet

- F1 M U 51 (Z I G 1 3: (12) Ulllted States Patent (10) Patent N0.: US 8,356,503 B2Document7 pagesF1 M U 51 (Z I G 1 3: (12) Ulllted States Patent (10) Patent N0.: US 8,356,503 B2NimalanNo ratings yet

- United States Patent: Osajda Et AlDocument9 pagesUnited States Patent: Osajda Et Almcx_123No ratings yet

- 59 0f1-,-,,é - 1,, M 13,553 $525113ei Iiii?if III Fifit 21811101511121.1118Document22 pages59 0f1-,-,,é - 1,, M 13,553 $525113ei Iiii?if III Fifit 21811101511121.1118Qwerty UiopNo ratings yet

- US8749333Document19 pagesUS8749333Anonymous GIIncAfLRNo ratings yet

- United States Patent (10) Patent No.: US 7,207,268 B2: Brunst (45) Date of Patent: Apr. 24, 2007Document8 pagesUnited States Patent (10) Patent No.: US 7,207,268 B2: Brunst (45) Date of Patent: Apr. 24, 2007Quý Đình Mai MaiNo ratings yet

- United States Patent (10) Patent No.: US 7,759,419 B2: Stoffer Et Al. (45) Date of Patent: Jul. 20, 2010Document24 pagesUnited States Patent (10) Patent No.: US 7,759,419 B2: Stoffer Et Al. (45) Date of Patent: Jul. 20, 2010Alexander Franco CastrillonNo ratings yet

- Threaded Connections With High and Low Friction CoatingsDocument14 pagesThreaded Connections With High and Low Friction CoatingsysuyycNo ratings yet

- US6169135Document13 pagesUS6169135NidaNo ratings yet

- Us 7908972Document23 pagesUs 7908972Abas NjarkhatirNo ratings yet

- Sizii: (12) United States PatentDocument10 pagesSizii: (12) United States PatentrakkaNo ratings yet

- Us8678520 PDFDocument18 pagesUs8678520 PDFIvan ReyesNo ratings yet

- 2010 - US007810582B2 - Counterbalance Enabled Power Generator For HDDDocument20 pages2010 - US007810582B2 - Counterbalance Enabled Power Generator For HDDCường Nguyễn QuốcNo ratings yet

- United States Patent (10) Patent No.: US 7,681,342 B2: Choi (45) Date of Patent: Mar. 23, 2010Document20 pagesUnited States Patent (10) Patent No.: US 7,681,342 B2: Choi (45) Date of Patent: Mar. 23, 2010Ronan RojasNo ratings yet

- US7748122 Knife Blade Opening MechanismDocument16 pagesUS7748122 Knife Blade Opening MechanismE MakinenNo ratings yet

- Is So: (12) United States PatentDocument20 pagesIs So: (12) United States PatentСлэйтер Строительная компанияNo ratings yet

- United States Patent (10) Patent No.: US 6,250,528 B1: Lumpe Et Al. (45) Date of Patent: Jun. 26, 2001Document7 pagesUnited States Patent (10) Patent No.: US 6,250,528 B1: Lumpe Et Al. (45) Date of Patent: Jun. 26, 20014728Vishakha KambleNo ratings yet

- United States Patent: SnawerdtDocument9 pagesUnited States Patent: SnawerdtjsholleyNo ratings yet

- United States Patent (10) Patent No.: US 7,548,032 B2: OO Ooaozad (Ova (OO) (CNA)Document7 pagesUnited States Patent (10) Patent No.: US 7,548,032 B2: OO Ooaozad (Ova (OO) (CNA)Bala RajuNo ratings yet

- Us8758606 - B2 LVMHDocument6 pagesUs8758606 - B2 LVMHsakthivel ArumugamNo ratings yet

- US6185288Document36 pagesUS6185288arungarg_itNo ratings yet

- United States Patent (10) Patent No.: US 7,490,539 B2: Ma (45) Date of Patent: Feb. 17, 2009Document18 pagesUnited States Patent (10) Patent No.: US 7,490,539 B2: Ma (45) Date of Patent: Feb. 17, 2009Mary HullNo ratings yet

- United States Patent: Jensen (10) Patent N0.: (45) Date of PatentDocument9 pagesUnited States Patent: Jensen (10) Patent N0.: (45) Date of PatentSumit WaghmareNo ratings yet

- United States Patent (19) 11 Patent Number: 6,124,044: Swidler (45) Date of Patent: Sep. 26, 2000Document7 pagesUnited States Patent (19) 11 Patent Number: 6,124,044: Swidler (45) Date of Patent: Sep. 26, 2000Alexander Franco CastrillonNo ratings yet

- Ta Co Chceme - US7134255Document5 pagesTa Co Chceme - US7134255hana.hovorkovaNo ratings yet

- United States Patent (10) Patent No.: US 6,725,039 B1: Parmar Et Al. (45) Date of Patent: Apr. 20, 2004Document7 pagesUnited States Patent (10) Patent No.: US 6,725,039 B1: Parmar Et Al. (45) Date of Patent: Apr. 20, 2004aduh haiNo ratings yet

- Us6111198 - Duplex Feedthrough and Method ThereforDocument9 pagesUs6111198 - Duplex Feedthrough and Method ThereforNosfe Matingli DiazNo ratings yet

- United States Patent (10) Patent N0.: US 8,899,217 B2Document7 pagesUnited States Patent (10) Patent N0.: US 8,899,217 B2Teleson MarquesNo ratings yet

- Heated CouplingDocument10 pagesHeated CouplingTUNCAY GUMUSNo ratings yet

- Purification of Difluoromethane by Extractive DistillationDocument13 pagesPurification of Difluoromethane by Extractive DistillationMateo VanegasNo ratings yet

- US7431364Document7 pagesUS7431364Jefferson ChavarríaNo ratings yet

- United States Patent: Cheung Et A) - (45) Date of Patent: Oct. 30, 2007Document19 pagesUnited States Patent: Cheung Et A) - (45) Date of Patent: Oct. 30, 2007Shahzada IrshadNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument20 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentzhenyupanNo ratings yet

- 867 File2213519862Document128 pages867 File2213519862AkashNo ratings yet

- Rail Transporting MachineDocument7 pagesRail Transporting MachineAkashNo ratings yet

- BR Hi: JN L Se (1/TrwDocument13 pagesBR Hi: JN L Se (1/TrwAkashNo ratings yet

- CN105421170ADocument26 pagesCN105421170AAkashNo ratings yet

- EPC Agreement NHAIDocument416 pagesEPC Agreement NHAIAkashNo ratings yet

- Org ChartDocument1 pageOrg Chart2021-101781No ratings yet

- Usha Unit 1 GuideDocument2 pagesUsha Unit 1 Guideapi-348847924No ratings yet

- For Exam ReviewerDocument5 pagesFor Exam ReviewerGelyn Cruz67% (3)

- Technical Engineering PEEDocument3 pagesTechnical Engineering PEEMariano Acosta Landicho Jr.No ratings yet

- SWOT AnalysisDocument6 pagesSWOT AnalysisSSPK_92No ratings yet

- Indirect Teaching Strategy??: Name: Topic: Under SupervisionDocument9 pagesIndirect Teaching Strategy??: Name: Topic: Under SupervisionSeham FouadNo ratings yet

- Solutions To Questions - Chapter 6 Mortgages: Additional Concepts, Analysis, and Applications Question 6-1Document16 pagesSolutions To Questions - Chapter 6 Mortgages: Additional Concepts, Analysis, and Applications Question 6-1--bolabolaNo ratings yet

- Andrews C145385 Shareholders DebriefDocument9 pagesAndrews C145385 Shareholders DebriefmrdlbishtNo ratings yet

- 1.6 Program AdministrationDocument56 pages1.6 Program Administration'JeoffreyLaycoNo ratings yet

- 01 RFI Technical Form BiodataDocument8 pages01 RFI Technical Form BiodataRafiq RizkiNo ratings yet

- China Ve01 With Tda93xx An17821 Stv9302a La78040 Ka5q0765-SmDocument40 pagesChina Ve01 With Tda93xx An17821 Stv9302a La78040 Ka5q0765-SmAmadou Fall100% (1)

- Coca-Cola Summer Intern ReportDocument70 pagesCoca-Cola Summer Intern ReportSourabh NagpalNo ratings yet

- Is 778 - Copper Alloy ValvesDocument27 pagesIs 778 - Copper Alloy ValvesMuthu KumaranNo ratings yet

- Catalog enDocument292 pagesCatalog enSella KumarNo ratings yet

- Failure of A Gasket During A Hydrostatic TestDocument7 pagesFailure of A Gasket During A Hydrostatic TesthazopmanNo ratings yet

- Aisc Research On Structural Steel To Resist Blast and Progressive CollapseDocument20 pagesAisc Research On Structural Steel To Resist Blast and Progressive CollapseFourHorsemenNo ratings yet

- WPGPipingIndex Form 167 PDFDocument201 pagesWPGPipingIndex Form 167 PDFRaj AryanNo ratings yet

- Ril Competitive AdvantageDocument7 pagesRil Competitive AdvantageMohitNo ratings yet

- CPM W1.1Document19 pagesCPM W1.1HARIJITH K SNo ratings yet

- Sec2 8 PDFDocument3 pagesSec2 8 PDFpolistaNo ratings yet

- Fast Binary Counters and Compressors Generated by Sorting NetworkDocument11 pagesFast Binary Counters and Compressors Generated by Sorting Networkpsathishkumar1232544No ratings yet

- Tekla Structures ToturialsDocument35 pagesTekla Structures ToturialsvfmgNo ratings yet

- S200 For Sumber RezekiDocument2 pagesS200 For Sumber RezekiIfan JayusdianNo ratings yet

- Alphacenter Utilities: Installation GuideDocument24 pagesAlphacenter Utilities: Installation GuideJeffersoOnn JulcamanyanNo ratings yet

- Company Law Handout 3Document10 pagesCompany Law Handout 3nicoleclleeNo ratings yet

- CEC Proposed Additional Canopy at Guard House (RFA-2021!09!134) (Signed 23sep21)Document3 pagesCEC Proposed Additional Canopy at Guard House (RFA-2021!09!134) (Signed 23sep21)MichaelNo ratings yet

- TENDER DOSSIER - Odweyne Water PanDocument15 pagesTENDER DOSSIER - Odweyne Water PanMukhtar Case2022No ratings yet

- Modal Case Data Form: GeneralDocument4 pagesModal Case Data Form: GeneralsovannchhoemNo ratings yet

- Ss1169 - Telecom Frameworx l1TMFDocument65 pagesSs1169 - Telecom Frameworx l1TMFPrince SinghNo ratings yet

- Bench VortexDocument3 pagesBench VortexRio FebriantoNo ratings yet