Professional Documents

Culture Documents

TL30 Basic Tower Light

TL30 Basic Tower Light

Uploaded by

AlisonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TL30 Basic Tower Light

TL30 Basic Tower Light

Uploaded by

AlisonCopyright:

Available Formats

TL30 Basic Tower Light

Datasheet

30 mm Multi-Color General-Purpose or Audible Indicators

• Rugged, affordable, and easy-to-install multi-segment indicators

• Compact 30 mm diameter

• Illuminated segments provide easy-to-see operator guidance and indication of

equipment status

• Uniform indicator segments appear gray when off to eliminate false indication

from ambient light

• Models with 2, 3, 4, and 5 color segments plus audible

• 12 V dc to 30 V dc operation

• No assembly required, mounting nut and gasket supplied

Standard Audible

Models

Color Position Audible Housing

Housing Style 1* 2* 3 4 5 Alarm Color Connection**

TL30 B G Y R X X N X QD

B = Basic G = Green N = None X = Black C1 = 1.2 m (3.9 ft) Integral PVC Cable

Y = Yellow A = Audible QD = Integral 5-, or 8-pin M12/Euro-style

R = Red quick disconnect

B = Blue

W = White *Position 1 and 2 can not be X = No Segment

X = No Segment **Models with quick disconnect require a mating cordset

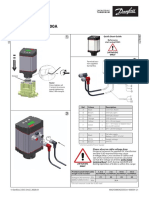

Wiring Diagrams

Note: All models are bimodal and can be wired as PNP or NPN devices.

Original Document 2 January 2019

206089 Rev. C

206089

TL30 Basic Tower Light

5-Pin/Wire Models

Key

1 = Brown

2 = White

5

3 = Blue

C4/A 4 = Black

2

5 = Gray

C3 C1 = Color 1

1 C2 = Color 2

C2 C3 = Color 3

12-30V dc C4 = Color 4

4

C1 A = Audible

or

3 Pin 5 (Gray wire) activates the corresponding

color or the audible function, if available.

2 and 3 segment models only require

associated wires to be connected.

8-Pin / 7-Wire Models

Key

A

8 1 = White

2 = Brown

3 = Green (Not Used)

4

C5

4 = Yellow

5

5 = Gray

C4 6 = Pink

1

7 = Blue

C3 8 = Red

2 C1 = Color 1

C2 C2 = Color 2

12-30V dc

6 C3 = Color 3

C1

or

C4 = Color 4

7 C5 = Color 5

A = Audible

Green wire not used.

Specifications

Supply Voltage and Current Indicators

12 V dc to 30 V dc LEDS are independently selected; 2 to 5 colors depending on model

Maximum current per LED segment: 40 mA

Indicator Response Time

Omni-Directional Sealed Audible Alarm: 20 mA maximum current

Indicator On/Off: 1 millisecond maximum

Supply Protection Circuitry

Indicator Characteristics

Protected against transient voltages

Input Leakage Current Immunity Color Coordinates2

Dominant Wavelength (nm) Lumen Output

400 µA1 Color

or Color Temperature (CCT) (Typical at 25 °C)

x y

Audible Alarm

Omni-Directional Sealed Audible Alarm: 2.8 kHz ± 500 Hz oscillation Green 524 nm 0.160 0.708 7.5

frequency, maximum intensity 90 dB at 1 m (3.3 ft) (typical) Red 620 nm 0.690 0.308 2.5

Operating Conditions Yellow 592 nm 0.582 0.413 6.5

–40 °C to +50 °C (–40 °F to +122 °F) Blue 468 nm 0.136 0.062 2.0

90% maximum relative humidity (non-condensing)

White 5500K 0.332 0.360 7.5

Storage Temperature: –40 °C to +70 °C (–40 °F to +158 °F)

Environmental Rating

All Models:

IEC IP65

UL Type 4X when mounted in a suitable enclosure

Non-Audible: UL Type 13 when mounted in a suitable enclosure

1 Any current above this value may activate the TL30.

2 Refer to CIE 1931 chromaticity diagram or color chart, to show equivalent color with indicated color coordinates.

2 www.bannerengineering.com - Tel: + 1 888 373 6767 P/N 206089 Rev. C

TL30 Basic Tower Light

Construction Required Overcurrent Protection

Base, Segments and Audible: UV stabilized polycarbonate

Grommet: TPV WARNING: Electrical connections must be

Mounting Nut: PBT made by qualified personnel in accordance with

Sealing Gasket: PVC/NBR/CR local and national electrical codes and

regulations.

Mounting

M22 × 1.5 threaded base, maximum torque 2.25 N·m (20 in·lbf) Overcurrent protection is required to be provided by end product

Mounting nut and sealing gasket included application per the supplied table.

Overcurrent protection may be provided with external fusing or via Current

Connections Limiting, Class 2 Power Supply.

Integral 5-pin, or 8-pin M12/Euro-style quick disconnect, or 1.2 m (3.9 ft) Supply wiring leads < 24 AWG shall not be spliced.

integral PVC cable, depending on model For additional product support, go to www.bannerengineering.com.

Models with a quick disconnect require a mating cordset

Supply Wiring (AWG) Required Overcurrent Protection (Amps)

Vibration and Mechanical Shock

Meets IEC 60068-2-6 requirements (Vibration: 10 Hz to 55 Hz, 1.0 mm 20 5.0

amplitude, 5 minutes sweep, 30 minutes dwell) 22 3.0

Meets IEC 60068-2-27 requirements (Shock: 30G 11 ms duration, half sine

wave) 24 2.0

IK07 (EN 60068-2-75 with SMBAMS22RA bracket) 26 1.0

Certifications 28 0.8

30 0.5

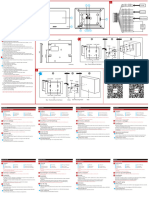

Dimensions

# of colors Tower Height (H)

Non-Audible Omni-Directional Sealed Audible

2 99.7 mm (3.9 in) 145.6 mm (5.7 in)

H

3 126.7 mm (5.0 in) 172.6 mm (6.8 in)

3 x 20.0

[0.79] 4 153.7 mm (6.0 in) 199.6 mm (7.9 in)

5 180.7 mm (7.1 in) 226.6 mm (8.9 in)

M22 x 1.5 18.0

[0.71]

All measurements are listed in millimeters [inches], unless noted otherwise.

M12 x 1

13.0

[0.51]

Accessories

Cordsets

5-Pin Threaded M12/Euro-Style Cordsets—Single Ended

Model Length Style Dimensions Pinout (Female)

MQDC1-501.5 0.50 m (1.5 ft) 2

MQDC1-506 1.83 m (6 ft) 1

44 Typ. 3

MQDC1-515 4.57 m (15 ft)

4 5

Straight

1 = Brown

M12 x 1 2 = White

MQDC1-530 9.14 m (30 ft) ø 14.5 3 = Blue

4 = Black

5 = Gray

P/N 206089 Rev. C www.bannerengineering.com - Tel: + 1 888 373 6767 3

TL30 Basic Tower Light

5-Pin Threaded M12/Euro-Style Cordsets—Single Ended

Model Length Style Dimensions Pinout (Female)

MQDC1-506RA 1.83 m (6 ft)

MQDC1-515RA 4.57 m (15 ft) 32 Typ.

[1.26"]

30 Typ.

Right-Angle [1.18"]

MQDC1-530RA 9.14 m (30 ft)

M12 x 1

ø 14.5 [0.57"]

8-Pin Threaded M12/Euro-Style Cordsets with Open-Shield

Model Length Style Dimensions Pinout (Female)

MQDC2S-806 1.83 m (6 ft)

MQDC2S-815 4.57 m (15 ft) 44 Typ.

MQDC2S-830 9.14 m (30 ft)

2

Straight 3

M12 x 1

1 4

MQDC2S-850 15.2 m (50 ft) ø 14.5

7

5

6

8

MQDC2S-806RA 1.83 m (6 ft)

MQDC2S-815RA 4.57 m (15 ft) 32 Typ. 1 = White

[1.26"] 2 = Brown

MQDC2S-830RA 9.14 m (30 ft)

3 = Green

30 Typ. 4 = Yellow

Right-Angle [1.18"] 5 = Gray

6 = Pink

MQDC2S-850RA 15.2 m (50 ft) 7 = Blue

M12 x 1

ø 14.5 [0.57"] 8 = Red

Brackets

SMB22A 32 SMB22FVK 46

118

• Right-angle bracket with curved slot for • V-clamp, flat bracket and fasteners for

versatile orientation C mounting to pipe or extensions ø22.5

• 12-ga. stainless steel 41 • Clamp accommodates 28 mm diameter

A

• Mounting hole for 22 mm sensor B tubing or 1 in. square extrusions 34

A • 22 mm hole for mounting sensor

46

Hole size: A = ø 22.5

Hole center spacing: A to B = 26.0

Hole size: A = ø 4.6, B = 4.6 x 16.9, C = 22.2

SMB22RAVK SMBAMS22P 45

A

• V-clamp, right-angle bracket and • Flat SMBAMS series bracket with 22 mm C

fasteners for mounting to pipe or 46 hole for mounting sensors

extensions • Articulation slots for 90+° rotation

A

• Clamp accommodates 28 mm diameter • 12-ga. (2.6 mm) cold-rolled steel 93

tubing or 1 in. square extrusions 57 90 B

• 22 mm hole for mounting sensor

Hole size: A = ø 22.5

Hole center spacing: A = 26.0, A to B = 13.0

Hole size: A = 26.8 x 7.0, B = ø 6.5, C = ø 22.5

4 www.bannerengineering.com - Tel: + 1 888 373 6767 P/N 206089 Rev. C

TL30 Basic Tower Light

SMBAMS22RA 45 LMBE12RA35 55

• Right-angle SMBAMS series bracket with • Direct mounting of stand-off pipe, with 35

22 mm hole for mounting sensors C 38.25

common bracket type

• Articulation slots for 90+° rotation 53

A • Zinc-plated steel

• 12-ga. (2.6 mm) cold-rolled steel

B • 1/2-14 NPSM nut

1/2 - 14

• Mounting distance from the wall to the NPSM NUT 57

48

center of the 1/2-14 NPSM nut is 35 mm

2X Ø9

Hole center spacing: A = 26.0, A to B = 13.0 Hole center spacing: 20.0

Hole size: A = 26.8 x 7.0, B = ø 6.5, C = ø 22.5

LMBE12RA45 65

• Direct mounting of stand-off pipe, with 45

38.25

common bracket type

• Zinc-plated steel

• 1/2-14 NPSM nut

1/2 - 14

• Mounting distance from the wall to the NPSM NUT 81

center of the 1/2-14 NPSM nut is 45 mm

2X Ø11

Hole center spacing: 35.0

LMB Sealed Right-Angle Bracket

Model Description Construction

Pipe-Mount Models: Bracket kit with base, ½-14 pipe

LMBE12RA adapter, set screw, fasteners, O-rings, and gaskets. Black polycarbonate

For use with stand-off pipe (listed and sold separately).

Elevated Mount System

Model Features Components

• Streamlined black polycarbonate stand-off pipe

adapter/cover

SA-M22E12 - Black Polycarbonate

• Connects between 22 mm light base and ½ in.

NPSM/DN15 pipe

Polished 304 Stainless Black Anodized Aluminum Clear Anodized

Steel Aluminum

SOP-E12-150SS 150 SOP-E12-150A 150 mm (6 SOP-E12-150AC 150 • Elevated-use stand-off pipe (½ in. NPSM/DN15)

mm (6 in) long in) long mm (6 in) long • Polished 304 stainless steel, black anodized

aluminum, or clear anodized aluminum surface

SOP-E12-300SS 300 SOP-E12-300A 300 mm SOP-E12-300AC 300 • ½ in. NPT thread at both ends

mm (12 in) long (12 in) long mm (12 in) long • Compatible with most industrial environments

SOP-E12-900SS 900 SOP-E12-900A 900 mm SOP-E12-900AC 900

mm (36 in) long (36 in) long mm (36 in) long

• Streamlined black acetal mounting base adapter/

cover

SA-E12M30 - Black Acetal • Connects between ½ in. NPSM/DN15 pipe and 30

mm (1-3/16 in) drilled hole

• Mounting hardware included

P/N 206089 Rev. C www.bannerengineering.com - Tel: + 1 888 373 6767 5

TL30 Basic Tower Light

Pipe Mounting Flange

Pipe Mounting Flange

Model Features Construction

54

• Elevated-use stand-off pipes (½ in, 1/2-14

4x ø5.5

NPSM

NPSM/DN15) Die-cast zinc base with

SA-F12 ø28

• M5 mounting hardware and nitrile gasket black paint

10

included ø70

• Elevated-use stand-off pipes (½ in, 1/2-14 NPSM

ø40

2 x 120°

NPSM/DN15)

SA-F12-3 Black Polycarbonate

• M4 mounting hardware and nitrile blend 29

8.77

gasket included

ø60

Foldable Mounting Bracket

Foldable Mounting Brackets

Model Features Construction

1/2-14 NPSM

• For use with 1/2 inch stand-off pipes 111

SA-FFB12 Black polycarbonate 110°

• Stainless steel hardware

Ø70 4 x Ø5

Banner Engineering Corp. Limited Warranty

Banner Engineering Corp. warrants its products to be free from defects in material and workmanship for one year following the date of shipment. Banner Engineering Corp. will repair or

replace, free of charge, any product of its manufacture which, at the time it is returned to the factory, is found to have been defective during the warranty period. This warranty does not

cover damage or liability for misuse, abuse, or the improper application or installation of the Banner product.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR IMPLIED (INCLUDING, WITHOUT LIMITATION, ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE), AND WHETHER ARISING UNDER COURSE OF PERFORMANCE, COURSE OF DEALING OR TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the discretion of Banner Engineering Corp., replacement. IN NO EVENT SHALL BANNER ENGINEERING CORP. BE LIABLE TO

BUYER OR ANY OTHER PERSON OR ENTITY FOR ANY EXTRA COSTS, EXPENSES, LOSSES, LOSS OF PROFITS, OR ANY INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES

RESULTING FROM ANY PRODUCT DEFECT OR FROM THE USE OR INABILITY TO USE THE PRODUCT, WHETHER ARISING IN CONTRACT OR WARRANTY, STATUTE, TORT,

STRICT LIABILITY, NEGLIGENCE, OR OTHERWISE.

Banner Engineering Corp. reserves the right to change, modify or improve the design of the product without assuming any obligations or liabilities relating to any product previously

manufactured by Banner Engineering Corp. Any misuse, abuse, or improper application or installation of this product or use of the product for personal protection applications when the

product is identified as not intended for such purposes will void the product warranty. Any modifications to this product without prior express approval by Banner Engineering Corp will

void the product warranties. All specifications published in this document are subject to change; Banner reserves the right to modify product specifications or update documentation at

any time. Specifications and product information in English supersede that which is provided in any other language. For the most recent version of any documentation, refer to:

www.bannerengineering.com.

For patent information, see www.bannerengineering.com/patents.

© Banner Engineering Corp. All rights reserved

You might also like

- Jeep Wrangler JK Ripp SDS Wiring DiagramDocument1 pageJeep Wrangler JK Ripp SDS Wiring DiagramAdrian Norejko100% (1)

- 112 Basic Electronics Formula SheetDocument1 page112 Basic Electronics Formula SheetDarksideEE733% (6)

- T5 - Basic - Elec - 2005-7 PDFDocument27 pagesT5 - Basic - Elec - 2005-7 PDFHendra Juliyuloh100% (1)

- Audi A4 1.8lts Turbo Med17.5 CdhaDocument23 pagesAudi A4 1.8lts Turbo Med17.5 CdhanicamarcosNo ratings yet

- CATT TUCT OverviewDocument50 pagesCATT TUCT OverviewTrần RuồiNo ratings yet

- Iec60076 10 2016Document128 pagesIec60076 10 2016chengkkNo ratings yet

- Boss Ve-20 ManualDocument144 pagesBoss Ve-20 ManualCarlo Mauricio González Parra100% (1)

- Ss#torretta Luminosa 30 MM - e PDFDocument2 pagesSs#torretta Luminosa 30 MM - e PDFJaime Basquez PaccoNo ratings yet

- Tower Light 30 MM - A1003850020 - eDocument2 pagesTower Light 30 MM - A1003850020 - eAlberto QuispeNo ratings yet

- Ez-Light SP Series Signal Light: DatasheetDocument8 pagesEz-Light SP Series Signal Light: DatasheetJosé Antonio Solorzano cruzNo ratings yet

- Ez-Light Touch Gen 2 K30 Series Pick-to-Light: DatasheetDocument4 pagesEz-Light Touch Gen 2 K30 Series Pick-to-Light: DatasheetemilioNo ratings yet

- Pro Editor: Family Material K50L2 A1 Audible Alarm Q Connector Rgb7 Color and InputDocument8 pagesPro Editor: Family Material K50L2 A1 Audible Alarm Q Connector Rgb7 Color and InputGADIELNo ratings yet

- Voyant BannerDocument4 pagesVoyant BannerjejeNo ratings yet

- Foco BannerDocument4 pagesFoco BannerCarlos Ivan SalazarNo ratings yet

- FAKRA Number Code: Connector or Housing Only Connector Including Housing 59 K 1 30 - 1 M4 A4 - yDocument2 pagesFAKRA Number Code: Connector or Housing Only Connector Including Housing 59 K 1 30 - 1 M4 A4 - ytony_gstNo ratings yet

- Universal Projector Control (UC) Cable Guide (9 Pin D-to-Bare Wire RS-232 Cable) 9-Pin D Male To Female RS-232 Cable GuideDocument1 pageUniversal Projector Control (UC) Cable Guide (9 Pin D-to-Bare Wire RS-232 Cable) 9-Pin D Male To Female RS-232 Cable GuidePrasetyo KidoNo ratings yet

- 182214Document8 pages182214azzszoNo ratings yet

- Circuito Dado ElectronicoDocument1 pageCircuito Dado ElectronicowilsonNo ratings yet

- Banner EZ Light User ManualDocument6 pagesBanner EZ Light User ManualMahesh NanayakkaraNo ratings yet

- Dosing SignalsDocument1 pageDosing SignalsKundaiNo ratings yet

- UD20195B B - Baseline - Multi Lingual - Video Intercom 6 Series Villa Door Station - QSG - V2.2.3Document4 pagesUD20195B B - Baseline - Multi Lingual - Video Intercom 6 Series Villa Door Station - QSG - V2.2.3Varga AttilaNo ratings yet

- Grounding of The SsasDocument3 pagesGrounding of The SsasEXITNo ratings yet

- AN213086423355en-000501 - Quick Setup Startt Guide IcadDocument2 pagesAN213086423355en-000501 - Quick Setup Startt Guide IcadEdmarNo ratings yet

- t2 Pressure Transducer Installation ManualDocument2 pagest2 Pressure Transducer Installation ManualJairo ColeccionistaNo ratings yet

- Passengers Speakers Audio Connection - v1.2Document1 pagePassengers Speakers Audio Connection - v1.2Beñat LarrañagaNo ratings yet

- Electrical Diagram JT-90 24V CombiDocument5 pagesElectrical Diagram JT-90 24V CombiCatherine RiquelmeNo ratings yet

- Interface - Brad Harrison Plug - 3-Pin For Single Solenoid - 5-Pin For Double SolenoidDocument1 pageInterface - Brad Harrison Plug - 3-Pin For Single Solenoid - 5-Pin For Double Solenoids bNo ratings yet

- Tl70 Wireless Multihop Modular Tower Light: DatasheetDocument12 pagesTl70 Wireless Multihop Modular Tower Light: DatasheetJosé Luis López MéndezNo ratings yet

- Mtpad VXDocument8 pagesMtpad VXfabNo ratings yet

- PINOUT 2dstandard 000 DINA4Document10 pagesPINOUT 2dstandard 000 DINA4Víctor VázquezNo ratings yet

- Renaissance-Hercules Cable Spec 2007Document1 pageRenaissance-Hercules Cable Spec 2007Dale RomanusNo ratings yet

- BC-2200 User Manual Waterproof A4Document6 pagesBC-2200 User Manual Waterproof A4joseNo ratings yet

- Sheet 3 - Charging Wiring Diagram: To Contactor (A1)Document1 pageSheet 3 - Charging Wiring Diagram: To Contactor (A1)Suthahar SundrabaluNo ratings yet

- TL50 Tower Light With IO-Link: DatasheetDocument5 pagesTL50 Tower Light With IO-Link: DatasheetRicardo Daniel Martinez HernandezNo ratings yet

- Fuse AssignmentDocument35 pagesFuse AssignmentJavier GarciaNo ratings yet

- Full HD Multiple Streams Compact Dome IP Camera Quick Guide: Camera's Connectors (For Indoor Only)Document2 pagesFull HD Multiple Streams Compact Dome IP Camera Quick Guide: Camera's Connectors (For Indoor Only)وائل ناظم كبهNo ratings yet

- 4 CylDocument1 page4 CylMumba MathewsNo ratings yet

- Rev00 - Installation Manual Capacitive Sensor PDFDocument2 pagesRev00 - Installation Manual Capacitive Sensor PDFchinck83No ratings yet

- ACA Wiring - All Together - V18Document1 pageACA Wiring - All Together - V18TrungKiênTrầnNo ratings yet

- 6207 Connection Box For Parallel Handsets Installation Guide PDFDocument2 pages6207 Connection Box For Parallel Handsets Installation Guide PDFcarlosorizabaNo ratings yet

- ZF 4HP24 4sol 4speed Connection LayoutDocument1 pageZF 4HP24 4sol 4speed Connection LayoutEdwinNo ratings yet

- Structure and Explanations Wiring Diagram EngDocument14 pagesStructure and Explanations Wiring Diagram EngЕвгений Мороко100% (1)

- Qa 0071 Man BCK KFGS 001Document3 pagesQa 0071 Man BCK KFGS 001li geneNo ratings yet

- idSX RA IncrementalDocument2 pagesidSX RA IncrementalMACKENZY GONZALEZNo ratings yet

- Acdelco E78 Irom Mpc5565 Bam GMDocument5 pagesAcdelco E78 Irom Mpc5565 Bam GMmanuel espinalezNo ratings yet

- WLS27 Multicolor LED Strip Light With EZ-Status: DatasheetDocument3 pagesWLS27 Multicolor LED Strip Light With EZ-Status: DatasheetKathy MorgendorfferNo ratings yet

- 3.5 CN2 Connector: The Terminal Block of The Connector and Pin Number Are As FollowsDocument3 pages3.5 CN2 Connector: The Terminal Block of The Connector and Pin Number Are As FollowsuthmaansNo ratings yet

- Use of Wiring DiagramsDocument2 pagesUse of Wiring DiagramsMuhammad AlwiNo ratings yet

- Zte Alarm Cable Connection BTSMW E1 Details PDFDocument8 pagesZte Alarm Cable Connection BTSMW E1 Details PDFMitul RahmanNo ratings yet

- UD20183B Baseline Multi-Lingual Video-Intercom-Network-Indoor-Station6320 QSG V2.1.10Document4 pagesUD20183B Baseline Multi-Lingual Video-Intercom-Network-Indoor-Station6320 QSG V2.1.10eskimos81No ratings yet

- Analog Extra EngDocument8 pagesAnalog Extra EngĐức LêNo ratings yet

- Audio 10 Pin OutsDocument1 pageAudio 10 Pin OutsfranpNo ratings yet

- LEFT USB Sockets RIGHT USB Sockets: Usb A Pin & Function Usb A Wire ColourDocument1 pageLEFT USB Sockets RIGHT USB Sockets: Usb A Pin & Function Usb A Wire Colourcollie de kloeNo ratings yet

- 2 - Fast Installation manual-mill-TAC2000MDocument16 pages2 - Fast Installation manual-mill-TAC2000MartZara 12No ratings yet

- k00589850100 1ac3fd4Document25 pagesk00589850100 1ac3fd4Wąski3DNo ratings yet

- Compact FieldPoint Accessories (323493A-01)Document13 pagesCompact FieldPoint Accessories (323493A-01)BoyzannazNo ratings yet

- AC003 Pigtails PDFDocument2 pagesAC003 Pigtails PDFMaco FrancoNo ratings yet

- Quick Start Guide: Midi LOGGERDocument24 pagesQuick Start Guide: Midi LOGGERTaNo ratings yet

- Audi A6 No. 4 / 1: Central Locking With Anti-Theft Alarm System With Interior MonitoringDocument16 pagesAudi A6 No. 4 / 1: Central Locking With Anti-Theft Alarm System With Interior MonitoringСергей СтародубецNo ratings yet

- TB38M20 Wiring Manual V1.0Document9 pagesTB38M20 Wiring Manual V1.0hossein gholamiNo ratings yet

- SF-VIDISP01 (IP) - Quick Start GuideDocument4 pagesSF-VIDISP01 (IP) - Quick Start GuidebookNo ratings yet

- Sure Cross® DXM1000-B1 Wireless ControllerDocument8 pagesSure Cross® DXM1000-B1 Wireless ControllerAlisonNo ratings yet

- Q60AF SensorsDocument10 pagesQ60AF SensorsAlisonNo ratings yet

- DX80N2X6S P2Document8 pagesDX80N2X6S P2AlisonNo ratings yet

- EZ-LIGHT® K70 Wireless Touch ButtonDocument8 pagesEZ-LIGHT® K70 Wireless Touch ButtonAlisonNo ratings yet

- Sure Cross® Wireless Q45 Sensor - Button - LightDocument4 pagesSure Cross® Wireless Q45 Sensor - Button - LightAlisonNo ratings yet

- S18-2 Plastic 18 MM Barrel Sensors: DatasheetDocument10 pagesS18-2 Plastic 18 MM Barrel Sensors: DatasheetAlisonNo ratings yet

- K90FDLGPQDocument6 pagesK90FDLGPQAlisonNo ratings yet

- B8151-0 Accessories For Sensors and Actuators - Field-Wireable Connector M12 × 1 Female Connector, StraightDocument2 pagesB8151-0 Accessories For Sensors and Actuators - Field-Wireable Connector M12 × 1 Female Connector, StraightAlisonNo ratings yet

- BI10-M30-AP6X-H1141 Inductive Sensor: FeaturesDocument3 pagesBI10-M30-AP6X-H1141 Inductive Sensor: FeaturesAlisonNo ratings yet

- K50 - EZ-LIGHT® Indicators - 4-ColorDocument6 pagesK50 - EZ-LIGHT® Indicators - 4-ColorAlisonNo ratings yet

- Sure Cross® DXM700-B1Document7 pagesSure Cross® DXM700-B1AlisonNo ratings yet

- Voice Activated Chess Set PDFDocument113 pagesVoice Activated Chess Set PDFBalajee DeveshaNo ratings yet

- Advance Mobile Course SyllabusDocument8 pagesAdvance Mobile Course SyllabusRaviNo ratings yet

- Comparing Results of Using Iso 140-4:1998 To Iso 16283-1:2014Document9 pagesComparing Results of Using Iso 140-4:1998 To Iso 16283-1:2014Airton José MonteiroNo ratings yet

- H3312 Data SheetDocument1 pageH3312 Data SheetDario GuerraNo ratings yet

- Lab Manual AVSDocument44 pagesLab Manual AVSKarishma Sav33% (3)

- Acoustics Report: Evaluation and Mitigation of Airborne and Structure-Borne Noise Emitted by 3D PrinterDocument34 pagesAcoustics Report: Evaluation and Mitigation of Airborne and Structure-Borne Noise Emitted by 3D PrinterAwan AJaNo ratings yet

- Texas Ranger TR-936 Owners ManualDocument8 pagesTexas Ranger TR-936 Owners ManualbellscbNo ratings yet

- Axxess IP SoftPhone User Guide PDFDocument86 pagesAxxess IP SoftPhone User Guide PDFRichNo ratings yet

- ISD1820 Voice Recorder Module User Guide: Rev 1.0, Oct 2012Document5 pagesISD1820 Voice Recorder Module User Guide: Rev 1.0, Oct 2012HARFA industriesNo ratings yet

- 98 139077 Installguideexplorerptt V CDocument2 pages98 139077 Installguideexplorerptt V CagbalouNo ratings yet

- V T-7 3 7 S P: Operation ManualDocument58 pagesV T-7 3 7 S P: Operation ManualJuan Carlos FiallosNo ratings yet

- Easy To Use, Rugged and Compact With Icom's "V Speed" Audio!Document2 pagesEasy To Use, Rugged and Compact With Icom's "V Speed" Audio!Ojeda O GerardNo ratings yet

- MIMO Beamforming System For Speech Enhancement in RealisticDocument10 pagesMIMO Beamforming System For Speech Enhancement in RealisticNavneetUpadhyayNo ratings yet

- Inbound 3596295734346482645Document3 pagesInbound 3596295734346482645Nay Oake KyawNo ratings yet

- Galaxy Owners Manual dx2517Document9 pagesGalaxy Owners Manual dx2517bellscb100% (1)

- SDC ManualDocument7 pagesSDC ManualfjserranogNo ratings yet

- VR-3000 WEB Config Only Ver 1.xxDocument32 pagesVR-3000 WEB Config Only Ver 1.xxgNo ratings yet

- Communications Systems - Ple 1mexx0 XX Plena Mixer AmplifierDocument3 pagesCommunications Systems - Ple 1mexx0 XX Plena Mixer AmplifierAbdul AhadNo ratings yet

- Lundahl TransformersDocument9 pagesLundahl TransformersHutanu GabrielNo ratings yet

- Mode D'emploi JVC KD-R731BT Wiring DiagramDocument58 pagesMode D'emploi JVC KD-R731BT Wiring DiagramPhilippe MalpasNo ratings yet

- Lecture Notes in Computer Science - Mutimodal CorporaDocument231 pagesLecture Notes in Computer Science - Mutimodal CorporaJoyce Joy100% (2)

- Optical Communication Project PDFDocument34 pagesOptical Communication Project PDFge120120100% (1)

- R7 Brochure ENGDocument8 pagesR7 Brochure ENGSyed Ahmed RezaNo ratings yet

- User's ManualDocument12 pagesUser's ManualmatikosciechaNo ratings yet

- Amphion Loudspeakers FinlandDocument11 pagesAmphion Loudspeakers FinlandAmphion100% (2)

- dsk6416 TechRefDocument56 pagesdsk6416 TechRefAizaz Hussain ShahNo ratings yet

- AKG Wms CatalogDocument81 pagesAKG Wms CatalogCsaba LangerNo ratings yet