Professional Documents

Culture Documents

بيبسيسيبلسقلسق

Uploaded by

WaleedAL-suheelyDCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

بيبسيسيبلسقلسق

Uploaded by

WaleedAL-suheelyDCopyright:

Available Formats

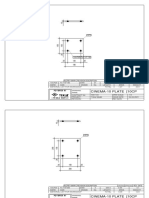

Calculation of Full Strength Fillet Weld (Double Contonuous)

T1

Base Plate: Where Base Plate Thk is

t

t t θ greater than the Abutting Plate Thk,

"T"

Symbols used:

"T" ; Thickness of the thinner abutting Plate

" " : Leg Length of the Fillet Weld

"t" ; Throat thickness of Fillet Weld

For Full Strength Weld 2t = T i.e. Throat Length of Double Fillets = Plate Thicknes

Relation between & t

t = sin(θ )

θ =45° sin(θ ) = 0.707107

t = 0.7071

Substituting in 2t =T

0.7071 T

Conclusion: Leg Length of 70% of the Thinner Abutting Plate Thk "T" is thus the size for FULL COMPENSATION FILLET WELD (Double Continuous)

Compare:

Ref: "Design of Weldments": Handbook by Lincoln Arc Welding Foundation and (AISCJ2.2B)

Full Strength Weld Size, given below

3/4 T 0.7500 T Compare to above, 75% of "T" is thus a Conservative figure!!

NOTES:

1- ACCORDING TO AWS D1.1 / D1.1M

TABLE 7.7 Minimum Fillet weld to be 8 mm when thickness more than 20 mm and maxiumm size not exceesed than the thickness of the thining plate all of this according to the forces

,moment and bending of the designer.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- MTC 2 MM SSQ50Document1 pageMTC 2 MM SSQ50WaleedAL-suheelyDNo ratings yet

- C4 - SingleDocument1 pageC4 - SingleWaleedAL-suheelyDNo ratings yet

- Culture Sequre 5 Cinema Material Excel ListDocument68 pagesCulture Sequre 5 Cinema Material Excel ListWaleedAL-suheelyDNo ratings yet

- Bal. 1200 1200 1200 1200 1200 1200 Slope 6%: A B C DDocument1 pageBal. 1200 1200 1200 1200 1200 1200 Slope 6%: A B C DWaleedAL-suheelyDNo ratings yet

- Boq Rev02Document5 pagesBoq Rev02WaleedAL-suheelyDNo ratings yet

- Cold Formed Steel PoultryDocument17 pagesCold Formed Steel PoultryWaleedAL-suheelyDNo ratings yet

- Ridge Det Vert Corner Det Panel Base Det: Ror-75 Roof Panel (Pir System)Document1 pageRidge Det Vert Corner Det Panel Base Det: Ror-75 Roof Panel (Pir System)WaleedAL-suheelyDNo ratings yet

- Mezz Part PlateDocument17 pagesMezz Part PlateWaleedAL-suheelyDNo ratings yet

- Truss-Losse PlateDocument13 pagesTruss-Losse PlateWaleedAL-suheelyDNo ratings yet

- بالتات سينما أمبير الرياض - الجزء الاولDocument8 pagesبالتات سينما أمبير الرياض - الجزء الاولWaleedAL-suheelyDNo ratings yet

- Column & Axis Plan: Conc BLK Wall (By Others)Document1 pageColumn & Axis Plan: Conc BLK Wall (By Others)WaleedAL-suheelyDNo ratings yet

- Tree Surround DetailsDocument2 pagesTree Surround DetailsWaleedAL-suheelyDNo ratings yet

- Sheeting AccessoriesDocument6 pagesSheeting AccessoriesWaleedAL-suheelyDNo ratings yet

- FITTINGDocument3 pagesFITTINGWaleedAL-suheelyDNo ratings yet

- RUBBERDocument2 pagesRUBBERWaleedAL-suheelyDNo ratings yet

- Sag DeckingDocument232 pagesSag DeckingWaleedAL-suheelyDNo ratings yet

- Single TredDocument3 pagesSingle TredWaleedAL-suheelyDNo ratings yet

- Single Profile RailingDocument117 pagesSingle Profile RailingWaleedAL-suheelyDNo ratings yet

- 2 21T4 No Plate: Created ApprovedDocument8 pages2 21T4 No Plate: Created ApprovedWaleedAL-suheelyDNo ratings yet

- Truss Losse PlateDocument16 pagesTruss Losse PlateWaleedAL-suheelyDNo ratings yet

- Mezz-Plate LosseDocument2 pagesMezz-Plate LosseWaleedAL-suheelyDNo ratings yet

- Single PlatesDocument31 pagesSingle PlatesWaleedAL-suheelyDNo ratings yet

- AUDIT-04-COMPARE-Part ListDocument4 pagesAUDIT-04-COMPARE-Part ListWaleedAL-suheelyDNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)