Professional Documents

Culture Documents

1 H

Uploaded by

Yoann RIZKIOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 H

Uploaded by

Yoann RIZKICopyright:

Available Formats

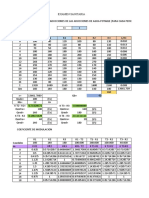

D S T C O M P U T E R S E R V I C E S S. A.

R-4b PAGE NO. 1255

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [2395]

LOADING CASE NO. 100 TEST WEIGHT ANALYSIS - PP - Pr Epreuve 2.19 bar

EQUATION 3223 OCCASIONAL LOAD - LEVEL B DU(h)= 10.000

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX+PRE MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICK. DIAM. MODULUS

B1 STRESS B2 STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 330 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 6.33 1.380 0.45 0.976

2 320 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 6.33 1.380 0.45 0.976

3 870 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 6.33 1.380 0.44 0.975

4 380 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 6.33 1.380 0.44 0.975

5 280 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 6.33 1.380 0.44 0.975

6 360 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 6.33 1.380 0.44 0.975

7 340 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 6.33 1.380 0.44 0.975

8 350 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 6.33 1.380 0.44 0.975

9 Y850 320 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 6.31 1.380 0.42 0.970

10 Y850 330 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 6.31 1.380 0.42 0.970

11 Y835 870 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 6.31 1.380 0.41 0.969

12 Y835 280 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 6.31 1.380 0.41 0.969

13 Y905 360 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 6.31 1.380 0.41 0.969

14 Y905 380 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 6.31 1.380 0.41 0.969

15 Y890 350 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 6.31 1.380 0.41 0.969

16 Y890 340 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 6.31 1.380 0.41 0.969

17 220 Y076 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 6.19 1.380 0.24 0.927

18 200 Y076 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 6.19 1.380 0.24 0.927

19 %670 E060 BEND MIN. 10.000 19.710 160.000 0.27241E+06

0.690 6.43 1.380 0.00 0.927

20 %667 E050 BEND MIN. 10.000 19.710 160.000 0.27241E+06

0.690 6.43 1.380 0.00 0.927

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

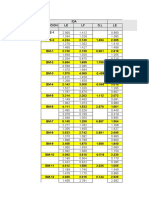

D S T C O M P U T E R S E R V I C E S S. A.

R-4b PAGE NO. 1895

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [3035]

LOADING CASE NO. 11 DYNAM(SHUT) ANALYSIS - PP - Pr Normale 5 bar

X = 0.00G Y = 0.00G Z = 0.00G

EQUATION 3223 SUSTAINED LOAD LEVEL 0 & A DU(h)=262800.000

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX+PRE MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICK. DIAM. MODULUS

B1 STRESS B2 STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 320 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 1.52 1.380 0.23 0.375

2 330 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 1.52 1.380 0.23 0.375

3 280 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 1.52 1.380 0.23 0.375

4 870 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 1.52 1.380 0.23 0.375

5 360 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 1.52 1.380 0.23 0.375

6 380 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 1.52 1.380 0.23 0.375

7 350 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 1.52 1.380 0.23 0.375

8 340 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 1.52 1.380 0.23 0.375

9 Y850 320 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 1.52 1.380 0.21 0.370

10 Y850 330 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 1.52 1.380 0.21 0.370

11 Y905 360 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 1.52 1.380 0.21 0.369

12 Y890 350 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 1.52 1.380 0.21 0.369

13 Y835 280 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 1.52 1.380 0.21 0.369

14 Y835 870 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 1.52 1.380 0.21 0.369

15 Y905 380 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 1.52 1.380 0.21 0.369

16 Y890 340 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 1.52 1.380 0.21 0.369

17 %638 %639 BEND MIN. 10.000 19.710 160.000 0.27241E+06

0.690 1.68 1.380 0.00 0.361

18 %642 %641 BEND MIN. 10.000 19.710 160.000 0.27241E+06

0.690 1.68 1.380 0.00 0.361

19 %640 %639 BEND MIN. 10.000 19.710 160.000 0.27241E+06

0.690 1.68 1.380 0.00 0.361

20 %640 %641 BEND MIN. 10.000 19.710 160.000 0.27241E+06

0.690 1.68 1.380 0.00 0.361

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

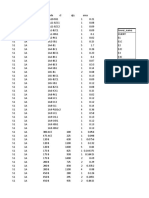

D S T C O M P U T E R S E R V I C E S S. A.

R-4b PAGE NO. 2535

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [3675]

LOADING CASE NO. 12 DYNAM(SHUT) ANALYSIS - PP - Pr Normale 14.6 bar

X = 0.00G Y = 0.00G Z = 0.00G

EQUATION 3223 SUSTAINED LOAD LEVEL 0 & A DU(h)= 1.000

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX+PRE MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICK. DIAM. MODULUS

B1 STRESS B2 STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 330 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 4.35 1.380 0.62 0.814

2 320 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 4.35 1.380 0.62 0.814

3 870 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 4.35 1.380 0.62 0.813

4 380 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 4.35 1.380 0.62 0.813

5 280 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 4.35 1.380 0.62 0.813

6 360 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 4.35 1.380 0.62 0.813

7 340 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 4.35 1.380 0.62 0.813

8 350 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 4.35 1.380 0.62 0.813

9 Y850 320 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 4.34 1.380 0.58 0.804

10 Y850 330 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 4.34 1.380 0.58 0.804

11 Y835 870 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 4.34 1.380 0.57 0.803

12 Y835 280 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 4.34 1.380 0.57 0.803

13 Y905 360 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 4.34 1.380 0.57 0.803

14 Y905 380 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 4.34 1.380 0.57 0.803

15 Y890 350 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 4.34 1.380 0.57 0.803

16 Y890 340 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

0.690 4.34 1.380 0.57 0.803

17 %641 %640 BEND MIN. 10.000 19.710 160.000 0.27241E+06

0.690 4.77 1.380 0.01 0.782

18 %639 %640 BEND MIN. 10.000 19.710 160.000 0.27241E+06

0.690 4.77 1.380 0.01 0.782

19 %642 %641 BEND MIN. 10.000 19.710 160.000 0.27241E+06

0.690 4.77 1.380 0.01 0.782

20 %638 %639 BEND MIN. 10.000 19.710 160.000 0.27241E+06

0.690 4.77 1.380 0.01 0.782

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

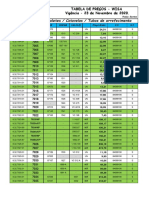

D S T C O M P U T E R S E R V I C E S S. A.

R-4a PAGE NO. 3175

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [4315]

LOADING CASE NO. 51 THERMAL ANALYSIS - Tmin 0�C

NUMBER OF CYCLES = 1000

EQUATION 3311.4 THERMAL EXPANSION DU(h)= 1000.000

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX.+PRES MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICKNESS DIAMETER MODULUS

SIF STRESS STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 330 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 1.18 6.93 0.299

2 320 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.436 1.17 6.93 0.299

3 870 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 1.18 6.34 0.278

4 380 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 1.18 6.34 0.278

5 340 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 1.18 6.34 0.278

6 360 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 1.17 6.34 0.277

7 280 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 1.17 6.34 0.277

8 350 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 1.17 6.34 0.277

9 Y850 330 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 1.11 6.38 0.276

10 Y851 330 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 1.11 6.38 0.276

11 Y849 320 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 1.10 6.37 0.276

12 Y850 320 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 1.10 6.37 0.276

13 Y834 870 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.258

14 Y835 870 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.258

15 Y905 380 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.258

16 Y906 380 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.258

17 Y889 340 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.257

18 Y890 340 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.257

19 Y905 360 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 1.10 5.87 0.257

20 Y835 280 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.10 5.86 0.257

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

D S T C O M P U T E R S E R V I C E S S. A.

R-4a PAGE NO. 3815

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [4955]

LOADING CASE NO. 52 THERMAL ANALYSIS - Tmax 35�C

NUMBER OF CYCLES = 1000

EQUATION 3311.4 THERMAL EXPANSION DU(h)= 1000.000

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX.+PRES MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICKNESS DIAMETER MODULUS

SIF STRESS STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 330 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 0.34 1.61 0.080

2 320 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.436 0.34 1.61 0.080

3 360 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.34 1.47 0.075

4 870 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.34 1.47 0.075

5 350 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.34 1.47 0.075

6 380 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.34 1.47 0.075

7 280 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.34 1.47 0.075

8 340 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.34 1.47 0.075

9 Y849 320 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.32 1.47 0.073

10 Y850 320 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.32 1.47 0.073

11 Y850 330 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.32 1.47 0.073

12 Y851 330 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.32 1.47 0.073

13 Y905 360 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.32 1.35 0.069

14 Y891 350 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.32 1.35 0.069

15 Y890 350 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.32 1.35 0.069

16 Y835 280 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.32 1.35 0.069

17 Y836 280 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.32 1.35 0.069

18 Y834 870 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.32 1.35 0.069

19 Y835 870 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.32 1.35 0.069

20 Y905 380 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.32 1.35 0.069

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

D S T C O M P U T E R S E R V I C E S S. A.

R-4a PAGE NO. 4455

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [5595]

LOADING CASE NO. 20 THERMAL ANALYSIS - a d�b a�r 20�C ent 20�C

NUMBER OF CYCLES = 1000

EQUATION 3311.4 THERMAL EXPANSION DU(h)= 0.067

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX.+PRES MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICKNESS DIAMETER MODULUS

SIF STRESS STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 320 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.436 0.00 0.00 0.000

2 330 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 0.00 0.00 0.000

3 Y834 870 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.00 0.00 0.000

4 Y835 870 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.00 0.00 0.000

5 870 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.00 0.00 0.000

6 280 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.00 0.00 0.000

7 Y835 280 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.00 0.00 0.000

8 Y836 280 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.00 0.00 0.000

9 Y849 320 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.00 0.00 0.000

10 Y850 320 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.00 0.00 0.000

11 Y850 330 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.00 0.00 0.000

12 Y851 330 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.00 0.00 0.000

13 Y889 340 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.00 0.00 0.000

14 Y890 340 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.00 0.00 0.000

15 340 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.00 0.00 0.000

16 350 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.00 0.00 0.000

17 Y890 350 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.00 0.00 0.000

18 Y891 350 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.00 0.00 0.000

19 Y905 360 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.00 0.00 0.000

20 360 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.00 0.00 0.000

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

D S T C O M P U T E R S E R V I C E S S. A.

R-4a PAGE NO. 5095

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [6235]

LOADING CASE NO. 21 THERMAL ANALYSIS - a fin a�r 35�C ent 35�C

NUMBER OF CYCLES = 1000

EQUATION 3311.4 THERMAL EXPANSION DU(h)= 0.067

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX.+PRES MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICKNESS DIAMETER MODULUS

SIF STRESS STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 330 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 0.98 6.03 0.289

2 320 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.436 0.98 6.03 0.288

3 870 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.98 5.53 0.268

4 380 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.98 5.52 0.268

5 340 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.98 5.52 0.268

6 280 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.98 5.52 0.267

7 360 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.98 5.52 0.267

8 350 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.98 5.52 0.267

9 Y850 330 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.92 5.56 0.267

10 Y851 330 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.92 5.56 0.267

11 Y849 320 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.91 5.56 0.266

12 Y850 320 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.91 5.56 0.266

13 Y834 870 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.92 5.13 0.249

14 Y835 870 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.92 5.13 0.249

15 Y905 380 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.92 5.13 0.249

16 Y906 380 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.92 5.13 0.249

17 Y889 340 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.92 5.12 0.249

18 Y890 340 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.92 5.12 0.249

19 Y905 360 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.91 5.12 0.248

20 Y835 280 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.91 5.12 0.248

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

D S T C O M P U T E R S E R V I C E S S. A.

R-4a PAGE NO. 5735

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [6875]

LOADING CASE NO. 22 THERMAL ANALYSIS - b d�b a�r 20�C ent 20�C

NUMBER OF CYCLES = 1000

EQUATION 3311.4 THERMAL EXPANSION DU(h)= 0.067

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX.+PRES MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICKNESS DIAMETER MODULUS

SIF STRESS STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 320 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.436 0.00 0.00 0.000

2 330 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 0.00 0.00 0.000

3 Y834 870 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.00 0.00 0.000

4 Y835 870 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.00 0.00 0.000

5 870 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.00 0.00 0.000

6 280 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.00 0.00 0.000

7 Y835 280 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.00 0.00 0.000

8 Y836 280 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.00 0.00 0.000

9 Y849 320 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.00 0.00 0.000

10 Y850 320 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.00 0.00 0.000

11 Y850 330 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.00 0.00 0.000

12 Y851 330 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.00 0.00 0.000

13 Y889 340 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.00 0.00 0.000

14 Y890 340 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.00 0.00 0.000

15 340 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.00 0.00 0.000

16 350 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.00 0.00 0.000

17 Y890 350 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.00 0.00 0.000

18 Y891 350 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.00 0.00 0.000

19 Y905 360 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.00 0.00 0.000

20 360 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.00 0.00 0.000

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

D S T C O M P U T E R S E R V I C E S S. A.

R-4a PAGE NO. 6375

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [7515]

LOADING CASE NO. 23 THERMAL ANALYSIS - b fin a�r 0�C ent 0�C

NUMBER OF CYCLES = 1000

EQUATION 3311.4 THERMAL EXPANSION DU(h)= 0.067

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX.+PRES MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICKNESS DIAMETER MODULUS

SIF STRESS STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 220 Y076 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 2.02 26.96 1.070 *

2 200 Y076 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 2.00 26.96 1.069 *

3 330 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 3.20 24.40 1.019 *

4 320 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.436 3.18 24.40 1.018 *

5 870 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 3.24 22.65 0.955

6 380 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 3.24 22.64 0.955

7 280 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 3.21 22.64 0.954

8 360 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 3.21 22.64 0.954

9 Y850 330 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 3.00 22.81 0.953

10 Y851 330 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 3.00 22.81 0.953

11 480 %559 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 1.97 23.67 0.947

12 Y849 320 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 2.95 22.66 0.945

13 Y850 320 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 2.95 22.66 0.945

14 490 %559 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 1.91 23.67 0.944

15 340 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 3.20 22.37 0.944

16 350 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 3.17 22.37 0.943

17 Y076 220 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 1.59 23.91 0.941

18 Y077 220 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 1.59 23.91 0.941

19 Y075 200 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 1.55 23.79 0.935

20 Y076 200 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 1.55 23.79 0.935

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

D S T C O M P U T E R S E R V I C E S S. A.

R-4a PAGE NO. 7015

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [8155]

LOADING CASE NO. 24 THERMAL ANALYSIS - c d�b a�r 0�C ent 0�C

NUMBER OF CYCLES = 1000

EQUATION 3311.4 THERMAL EXPANSION DU(h)= 1000.000

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX.+PRES MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICKNESS DIAMETER MODULUS

SIF STRESS STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 330 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 1.18 6.93 0.299

2 320 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.436 1.17 6.93 0.299

3 870 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 1.18 6.34 0.278

4 380 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 1.18 6.34 0.278

5 340 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 1.18 6.34 0.278

6 360 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 1.17 6.34 0.277

7 280 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 1.17 6.34 0.277

8 350 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 1.17 6.34 0.277

9 Y850 330 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 1.11 6.38 0.276

10 Y851 330 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 1.11 6.38 0.276

11 Y849 320 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 1.10 6.37 0.276

12 Y850 320 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 1.10 6.37 0.276

13 Y834 870 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.258

14 Y835 870 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.258

15 Y905 380 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.258

16 Y906 380 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.258

17 Y889 340 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.257

18 Y890 340 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.257

19 Y905 360 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 1.10 5.87 0.257

20 Y835 280 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.10 5.86 0.257

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

D S T C O M P U T E R S E R V I C E S S. A.

R-4a PAGE NO. 7655

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [8795]

LOADING CASE NO. 25 THERMAL ANALYSIS - c fin a�r 35�C ent 35�C

NUMBER OF CYCLES = 1000

EQUATION 3311.4 THERMAL EXPANSION DU(h)= 1000.000

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX.+PRES MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICKNESS DIAMETER MODULUS

SIF STRESS STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 330 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 0.34 1.61 0.080

2 320 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.436 0.34 1.61 0.080

3 360 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.34 1.47 0.075

4 870 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.34 1.47 0.075

5 350 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.34 1.47 0.075

6 380 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.34 1.47 0.075

7 280 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.34 1.47 0.075

8 340 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.34 1.47 0.075

9 Y849 320 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.32 1.47 0.073

10 Y850 320 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.32 1.47 0.073

11 Y850 330 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.32 1.47 0.073

12 Y851 330 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.32 1.47 0.073

13 Y905 360 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.32 1.35 0.069

14 Y891 350 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.32 1.35 0.069

15 Y890 350 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.32 1.35 0.069

16 Y835 280 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.32 1.35 0.069

17 Y836 280 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.32 1.35 0.069

18 Y834 870 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.32 1.35 0.069

19 Y835 870 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.32 1.35 0.069

20 Y905 380 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.32 1.35 0.069

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

D S T C O M P U T E R S E R V I C E S S. A.

R-4a PAGE NO. 8295

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [9435]

LOADING CASE NO. 30 THERMAL ANALYSIS - d d�b a�r 0�C ent 0�C

NUMBER OF CYCLES = 1000

EQUATION 3311.4 THERMAL EXPANSION DU(h)= 1000.000

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX.+PRES MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICKNESS DIAMETER MODULUS

SIF STRESS STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 330 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 1.18 6.93 0.299

2 320 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.436 1.17 6.93 0.299

3 870 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 1.18 6.34 0.278

4 380 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 1.18 6.34 0.278

5 340 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 1.18 6.34 0.278

6 360 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 1.17 6.34 0.277

7 280 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 1.17 6.34 0.277

8 350 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 1.17 6.34 0.277

9 Y850 330 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 1.11 6.38 0.276

10 Y851 330 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 1.11 6.38 0.276

11 Y849 320 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 1.10 6.37 0.276

12 Y850 320 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 1.10 6.37 0.276

13 Y834 870 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.258

14 Y835 870 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.258

15 Y905 380 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.258

16 Y906 380 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.258

17 Y889 340 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.257

18 Y890 340 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.257

19 Y905 360 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 1.10 5.87 0.257

20 Y835 280 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.10 5.86 0.257

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

D S T C O M P U T E R S E R V I C E S S. A.

R-4a PAGE NO. 8935

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [****]

LOADING CASE NO. 31 THERMAL ANALYSIS - d fin a�r 33�C ent 25�C

NUMBER OF CYCLES = 1000

EQUATION 3311.4 THERMAL EXPANSION DU(h)= 1000.000

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX.+PRES MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICKNESS DIAMETER MODULUS

SIF STRESS STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 330 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 0.13 0.63 0.029

2 320 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.436 0.13 0.63 0.029

3 870 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.13 0.58 0.027

4 280 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.13 0.58 0.027

5 360 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.13 0.58 0.027

6 380 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.13 0.58 0.027

7 350 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.13 0.58 0.027

8 340 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.13 0.58 0.027

9 Y849 320 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.12 0.58 0.026

10 Y850 320 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.12 0.58 0.026

11 Y850 330 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.12 0.57 0.026

12 Y851 330 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.12 0.57 0.026

13 Y003 150 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.09 0.58 0.026

14 Y004 150 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.09 0.58 0.026

15 150 Y004 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 0.09 0.58 0.026

16 Y905 360 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.12 0.53 0.025

17 Y835 280 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.12 0.53 0.025

18 Y836 280 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.12 0.53 0.025

19 Y834 870 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.12 0.53 0.025

20 Y835 870 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.12 0.53 0.025

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

D S T C O M P U T E R S E R V I C E S S. A.

R-4a PAGE NO. 9575

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [****]

LOADING CASE NO. 32 THERMAL ANALYSIS - e d�b a�r 0�C ent 0�C

NUMBER OF CYCLES = 1000

EQUATION 3311.4 THERMAL EXPANSION DU(h)= 1000.000

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX.+PRES MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICKNESS DIAMETER MODULUS

SIF STRESS STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 330 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 1.18 6.93 0.299

2 320 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.436 1.17 6.93 0.299

3 870 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 1.18 6.34 0.278

4 380 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 1.18 6.34 0.278

5 340 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 1.18 6.34 0.278

6 360 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 1.17 6.34 0.277

7 280 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 1.17 6.34 0.277

8 350 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 1.17 6.34 0.277

9 Y850 330 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 1.11 6.38 0.276

10 Y851 330 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 1.11 6.38 0.276

11 Y849 320 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 1.10 6.37 0.276

12 Y850 320 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 1.10 6.37 0.276

13 Y834 870 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.258

14 Y835 870 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.258

15 Y905 380 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.258

16 Y906 380 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.258

17 Y889 340 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.257

18 Y890 340 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.11 5.87 0.257

19 Y905 360 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 1.10 5.87 0.257

20 Y835 280 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 1.10 5.86 0.257

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

D S T C O M P U T E R S E R V I C E S S. A.

R-4a PAGE NO. 10215

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [****]

LOADING CASE NO. 33 THERMAL ANALYSIS - e fin a�r 42.2�C ent 25�C

NUMBER OF CYCLES = 1000

EQUATION 3311.4 THERMAL EXPANSION DU(h)= 1000.000

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX.+PRES MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICKNESS DIAMETER MODULUS

SIF STRESS STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 Y003 150 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.15 1.01 0.044

2 Y004 150 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.15 1.01 0.044

3 150 Y004 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 0.15 0.99 0.043

4 155 Y004 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 0.09 0.99 0.041

5 330 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 0.13 0.63 0.029

6 320 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.436 0.13 0.63 0.029

7 Y004 155 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.04 0.69 0.028

8 Y005 155 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.04 0.69 0.028

9 870 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.13 0.58 0.027

10 280 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.13 0.58 0.027

11 360 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.13 0.58 0.027

12 380 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.13 0.58 0.027

13 350 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.13 0.58 0.027

14 340 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.13 0.58 0.027

15 Y849 320 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.12 0.58 0.026

16 Y850 320 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.12 0.58 0.026

17 Y850 330 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.12 0.57 0.026

18 Y851 330 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.12 0.57 0.026

19 F30 F60 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.55 0.03 0.025

20 F10 F30 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.55 0.02 0.025

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

D S T C O M P U T E R S E R V I C E S S. A.

R-4a PAGE NO. 10855

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [****]

LOADING CASE NO. 26 THERMAL ANALYSIS - OS : Th seisme 24.00�C_SND

NUMBER OF CYCLES NOT ENTERED

EQUATION 3410 SEISMIC INDUCED DU(h)= 0.017

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX.+PRES MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICKNESS DIAMETER MODULUS

SIF STRESS STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 330 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 0.25 1.61 0.070

2 320 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.436 0.24 1.61 0.070

3 870 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.25 1.48 0.065

4 380 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.25 1.48 0.065

5 280 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.25 1.48 0.065

6 360 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.25 1.48 0.065

7 340 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.25 1.48 0.065

8 350 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.25 1.48 0.065

9 Y850 330 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.23 1.49 0.065

10 Y851 330 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.23 1.49 0.065

11 Y849 320 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.23 1.49 0.065

12 Y850 320 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.23 1.49 0.065

13 Y905 360 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.23 1.38 0.061

14 Y834 870 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.23 1.37 0.061

15 Y835 870 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.23 1.37 0.061

16 Y905 380 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.23 1.37 0.061

17 Y906 380 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.23 1.37 0.061

18 Y835 280 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.23 1.37 0.060

19 Y836 280 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.23 1.37 0.060

20 Y889 340 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.23 1.37 0.060

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

D S T C O M P U T E R S E R V I C E S S. A.

R-4a PAGE NO. 11495

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [****]

LOADING CASE NO. 27 THERMAL ANALYSIS - OS : Th seisme 16.00�C_SND

NUMBER OF CYCLES NOT ENTERED

EQUATION 3410 SEISMIC INDUCED DU(h)= 0.017

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX.+PRES MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICKNESS DIAMETER MODULUS

SIF STRESS STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 330 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 0.29 2.00 0.084

2 320 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.436 0.29 2.00 0.084

3 870 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.29 1.83 0.078

4 380 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.29 1.83 0.078

5 340 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.29 1.83 0.078

6 280 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.29 1.83 0.078

7 360 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.29 1.83 0.078

8 350 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.29 1.83 0.078

9 Y850 330 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.27 1.85 0.078

10 Y851 330 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.27 1.85 0.078

11 Y849 320 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.27 1.85 0.078

12 Y850 320 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.27 1.85 0.078

13 Y834 870 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.27 1.71 0.073

14 Y835 870 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.27 1.71 0.073

15 Y905 360 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.27 1.71 0.073

16 Y905 380 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.27 1.71 0.073

17 Y906 380 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.27 1.71 0.073

18 Y889 340 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.27 1.71 0.073

19 Y890 340 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.27 1.71 0.073

20 Y835 280 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.27 1.71 0.073

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

D S T C O M P U T E R S E R V I C E S S. A.

R-4a PAGE NO. 12135

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [****]

LOADING CASE NO. 28 THERMAL ANALYSIS - OS : Th seisme 22.00�C_SMS

NUMBER OF CYCLES NOT ENTERED

EQUATION 3410 SEISMIC INDUCED DU(h)= 0.017

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX.+PRES MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICKNESS DIAMETER MODULUS

SIF STRESS STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 330 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 0.12 0.77 0.033

2 320 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.436 0.12 0.77 0.033

3 870 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.12 0.70 0.030

4 380 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.12 0.70 0.030

5 280 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.12 0.70 0.030

6 360 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.12 0.70 0.030

7 340 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.12 0.70 0.030

8 350 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.12 0.70 0.030

9 Y850 330 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.11 0.71 0.030

10 Y851 330 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.11 0.71 0.030

11 Y849 320 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.11 0.71 0.030

12 Y850 320 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.11 0.71 0.030

13 Y905 360 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.11 0.66 0.028

14 Y834 870 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.11 0.66 0.028

15 Y835 870 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.11 0.66 0.028

16 Y905 380 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.11 0.66 0.028

17 Y906 380 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.11 0.66 0.028

18 Y835 280 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.11 0.66 0.028

19 Y836 280 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.11 0.66 0.028

20 Y889 340 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.11 0.66 0.028

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

D S T C O M P U T E R S E R V I C E S S. A.

R-4a PAGE NO. 12775

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [****]

LOADING CASE NO. 29 THERMAL ANALYSIS - OS : Th seisme 18.00�C_SMS

NUMBER OF CYCLES NOT ENTERED

EQUATION 3410 SEISMIC INDUCED DU(h)= 0.017

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX.+PRES MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICKNESS DIAMETER MODULUS

SIF STRESS STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 330 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 0.12 0.84 0.036

2 320 Y850 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.436 0.12 0.84 0.036

3 870 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.12 0.77 0.033

4 380 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.12 0.77 0.033

5 280 Y835 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.12 0.77 0.033

6 360 Y905 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.12 0.77 0.033

7 340 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.252 0.12 0.77 0.033

8 350 Y890 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.12 0.77 0.033

9 Y850 330 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.12 0.78 0.033

10 Y851 330 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.12 0.78 0.033

11 Y849 320 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.12 0.78 0.033

12 Y850 320 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.12 0.78 0.033

13 Y905 360 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.253 0.12 0.72 0.031

14 Y834 870 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.12 0.72 0.031

15 Y835 870 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.12 0.72 0.031

16 Y905 380 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.12 0.72 0.031

17 Y906 380 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.12 0.72 0.031

18 Y889 340 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.12 0.72 0.031

19 Y890 340 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.12 0.72 0.031

20 Y835 280 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.250+ 0.12 0.72 0.031

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

D S T C O M P U T E R S E R V I C E S S. A.

R-4a PAGE NO. 13415

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [****]

LOADING CASE NO. 61 DISPL(SEIS) ANALYSIS - DDS DX SMS

NUMBER OF CYCLES NOT ENTERED

EQUATION 3410 SEISMIC INDUCED DU(h)= 0.017

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX.+PRES MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICKNESS DIAMETER MODULUS

SIF STRESS STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 Z001 110 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.10 0.004

2 Y002 Y001 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.10 0.004

3 F60 Y001 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.10 0.004

4 F30 F60 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.07 0.003

5 Y001 F60 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.07 0.003

6 Y003 Y002 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.07 0.003

7 Y001 Y002 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.07 0.003

8 110 Z001 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.07 0.002

9 F10 Z001 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.07 0.002

10 Z001 F10 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.03 0.001

11 F30 F10 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.03 0.001

12 150 Y003 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.03 0.001

13 Y002 Y003 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.03 0.001

14 Y003 150 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.00 0.02 0.001

15 Y004 150 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.00 0.02 0.001

16 F10 F30 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.02 0.001

17 F60 F30 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.02 0.001

18 150 Y004 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 0.00 0.01 0.000

19 155 Y004 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 0.00 0.01 0.000

20 Y004 155 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.00 0.00 0.000

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

D S T C O M P U T E R S E R V I C E S S. A.

R-4a PAGE NO. 14055

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [****]

LOADING CASE NO. 62 DISPL(SEIS) ANALYSIS - DDS DY SMS

NUMBER OF CYCLES NOT ENTERED

EQUATION 3410 SEISMIC INDUCED DU(h)= 0.017

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX.+PRES MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICKNESS DIAMETER MODULUS

SIF STRESS STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 Y003 150 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.13 1.14 0.047

2 Y004 150 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.13 1.14 0.047

3 150 Y004 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 0.12 1.08 0.044

4 155 Y004 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 0.07 1.08 0.042

5 Y004 155 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.01 0.74 0.028

6 Y005 155 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.01 0.74 0.028

7 Y002 Y003 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.27 0.30 0.021

8 F60 Y001 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.53 0.02 0.020

9 F30 F60 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.53 0.02 0.020

10 Y001 F60 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.53 0.02 0.020

11 F10 F30 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.53 0.02 0.020

12 F60 F30 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.53 0.02 0.020

13 Z001 F10 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.53 0.01 0.020

14 F30 F10 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.53 0.01 0.020

15 110 Z001 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.53 0.01 0.020

16 F10 Z001 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.53 0.01 0.020

17 Z001 110 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.53 0.01 0.020

18 Y001 Y002 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.40 0.07 0.017

19 150 Y003 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.13 0.30 0.016

20 Y002 Y001 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.40 0.02 0.015

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

D S T C O M P U T E R S E R V I C E S S. A.

R-4a PAGE NO. 14695

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [****]

LOADING CASE NO. 63 DISPL(SEIS) ANALYSIS - DDS DZ SMS

NUMBER OF CYCLES NOT ENTERED

EQUATION 3410 SEISMIC INDUCED DU(h)= 0.017

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX.+PRES MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICKNESS DIAMETER MODULUS

SIF STRESS STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 Z001 110 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.14 0.005

2 F60 Y001 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.14 0.005

3 Y002 Y001 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.14 0.005

4 F30 F60 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.10 0.004

5 Y001 F60 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.10 0.004

6 Y001 Y002 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.10 0.004

7 Y003 Y002 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.10 0.004

8 110 Z001 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.09 0.003

9 F10 Z001 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.09 0.003

10 Z001 F10 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.04 0.002

11 F30 F10 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.04 0.002

12 Y002 Y003 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.03 0.001

13 150 Y003 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.03 0.001

14 F10 F30 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.03 0.001

15 F60 F30 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.03 0.001

16 Y003 150 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.00 0.02 0.001

17 Y004 150 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.00 0.02 0.001

18 Y004 155 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.00 0.01 0.000

19 Y005 155 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

2.400+ 0.00 0.01 0.000

20 150 Y004 SR ELBOW MIN. 10.000 19.710 160.000 0.27241E+06

2.437 0.00 0.01 0.000

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

D S T C O M P U T E R S E R V I C E S S. A.

R-4a PAGE NO. 15335

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [****]

LOADING CASE NO. 64 DISPL(SEIS) ANALYSIS - DDS DX DSD

NUMBER OF CYCLES NOT ENTERED

EQUATION 3410 SEISMIC INDUCED DU(h)= 0.017

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX.+PRES MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICKNESS DIAMETER MODULUS

SIF STRESS STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 Z001 110 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

2 110 Z001 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

3 F10 Z001 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

4 Z001 F10 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

5 F30 F10 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

6 F10 F30 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

7 F60 F30 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

8 F30 F60 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

9 Y001 F60 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

10 F60 Y001 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

11 Y002 Y001 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

12 Y001 Y002 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

13 Y003 Y002 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

14 Y002 Y003 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

15 150 Y003 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

16 Y003 150 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

2.400+ 0.00 0.00 0.000

17 Y004 150 SR ELBOW NOM. 0.000 21.900 160.000 0.29026E+06

2.400+ 0.00 0.00 0.000

18 150 Y004 SR ELBOW NOM. 0.000 21.900 160.000 0.29026E+06

2.437 0.00 0.00 0.000

19 155 Y004 SR ELBOW NOM. 0.000 21.900 160.000 0.29026E+06

2.437 0.00 0.00 0.000

20 Y004 155 SR ELBOW NOM. 0.000 21.900 160.000 0.29026E+06

2.400+ 0.00 0.00 0.000

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

D S T C O M P U T E R S E R V I C E S S. A.

R-4a PAGE NO. 15975

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [****]

LOADING CASE NO. 65 DISPL(SEIS) ANALYSIS - DDS DY DSD

NUMBER OF CYCLES NOT ENTERED

EQUATION 3410 SEISMIC INDUCED DU(h)= 0.017

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX.+PRES MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICKNESS DIAMETER MODULUS

SIF STRESS STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 Z001 110 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

2 110 Z001 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

3 F10 Z001 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

4 Z001 F10 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

5 F30 F10 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

6 F10 F30 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

7 F60 F30 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

8 F30 F60 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

9 Y001 F60 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

10 F60 Y001 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

11 Y002 Y001 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

12 Y001 Y002 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

13 Y003 Y002 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

14 Y002 Y003 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

15 150 Y003 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

16 Y003 150 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

2.400+ 0.00 0.00 0.000

17 Y004 150 SR ELBOW NOM. 0.000 21.900 160.000 0.29026E+06

2.400+ 0.00 0.00 0.000

18 150 Y004 SR ELBOW NOM. 0.000 21.900 160.000 0.29026E+06

2.437 0.00 0.00 0.000

19 155 Y004 SR ELBOW NOM. 0.000 21.900 160.000 0.29026E+06

2.437 0.00 0.00 0.000

20 Y004 155 SR ELBOW NOM. 0.000 21.900 160.000 0.29026E+06

2.400+ 0.00 0.00 0.000

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

D S T C O M P U T E R S E R V I C E S S. A.

R-4a PAGE NO. 16615

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [****]

LOADING CASE NO. 66 DISPL(SEIS) ANALYSIS - DDS DZ DSD

NUMBER OF CYCLES NOT ENTERED

EQUATION 3410 SEISMIC INDUCED DU(h)= 0.017

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX.+PRES MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICKNESS DIAMETER MODULUS

SIF STRESS STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 Z001 110 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

2 110 Z001 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

3 F10 Z001 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

4 Z001 F10 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

5 F30 F10 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

6 F10 F30 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

7 F60 F30 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

8 F30 F60 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

9 Y001 F60 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

10 F60 Y001 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

11 Y002 Y001 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

12 Y001 Y002 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

13 Y003 Y002 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

14 Y002 Y003 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

15 150 Y003 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

1.000 0.00 0.00 0.000

16 Y003 150 TANGENT NOM. 0.000 21.900 160.000 0.29026E+06

2.400+ 0.00 0.00 0.000

17 Y004 150 SR ELBOW NOM. 0.000 21.900 160.000 0.29026E+06

2.400+ 0.00 0.00 0.000

18 150 Y004 SR ELBOW NOM. 0.000 21.900 160.000 0.29026E+06

2.437 0.00 0.00 0.000

19 155 Y004 SR ELBOW NOM. 0.000 21.900 160.000 0.29026E+06

2.437 0.00 0.00 0.000

20 Y004 155 SR ELBOW NOM. 0.000 21.900 160.000 0.29026E+06

2.400+ 0.00 0.00 0.000

TYPE FLEXIBILITY MATRICES + SIF -------SECT. MOD. + PRES.

STRESS-------

WALL THICK. OUTER DIAM. INNER

DIAM.

NOM. NOMINAL NOMINAL NOMINAL

NOMINAL

MIN. NOMINAL REDUCED REDUCED

INCREASED

D S T C O M P U T E R S E R V I C E S S. A.

R-4a PAGE NO. 17255

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

++ DST/PIPESTRESS ++ APD des VRD CNPE Paluel

Version 4.1.0 PC-WIBU-32b Release: Dec 2020

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

CALCULATION NUMBER 1 CODE ASME APPENDIX XXVI 2017

2022/05/24 17:02:11 [****]

LOADING CASE NO. 67 DISPL(SEIS) ANALYSIS - DDS DX SND

NUMBER OF CYCLES NOT ENTERED

EQUATION 3410 SEISMIC INDUCED DU(h)= 0.017

- - - - - HIGHEST STRESS POINTS - - - - -

--POINTS-- CORROSION WALL OUTER SECTION

AX.+PRES MOMENT STRESS

RANK FROM AT ELEMENT TYPE PERCENT THICKNESS DIAMETER MODULUS

SIF STRESS STRESS RATIO

MM MM MM**3

N/MM**2 N/MM**2

1 Z001 110 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.15 0.006

2 Y002 Y001 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.15 0.005

3 F60 Y001 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.15 0.005

4 F30 F60 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.11 0.004

5 Y001 F60 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.11 0.004

6 Y003 Y002 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.11 0.004

7 Y001 Y002 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.11 0.004

8 110 Z001 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.10 0.004

9 F10 Z001 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.10 0.004

10 Z001 F10 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.05 0.002

11 F30 F10 TANGENT MIN. 10.000 19.710 160.000 0.27241E+06

1.000 0.00 0.05 0.002