Professional Documents

Culture Documents

Material Duplex Stainless Steel

Uploaded by

Ikhsan LyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Duplex Stainless Steel

Uploaded by

Ikhsan LyCopyright:

Available Formats

Duplex Stainless Steel - Grades

The high corrosion resistance and the excellent mechanical properties combination of duplex stainless steels can

be explained by their chemical composition and balanced ('duplex') microstructure of approximately equivalent

volume fractions of ferrite and austenite. Firstly, the chemical composition based on high contents of Cr

and Mo, improves intergranular and pitting corrosion resistance, respectively. Moreover, additions of

nitrogen can promote structural hardening by interstitial solid solution mechanism, which raises the yield strength

and ultimate strength values without impairing toughness. Secondly, the two-phase microstructure

guarantees higher resistance to pitting and stress corrosion cracking in comparison with conventional

stainless steels. The duplex stainless steels comprise a family of grades with a range in corrosion performance

depending on their alloy content. Modern duplex stainless steels are often addressed in four groups :

1. Lean duplex, such as 2304 (S32304), which contain little or no deliberate Mo addition;

2. 2205 (S32205), the workhorse grade accounting for more than 80% of duplex use;

3. 25 Cr duplex, such as 255 (S32550) and S31260;

4. Superduplex, with 25-26 Cr and increased Mo and N, such as 2507 (S32750).

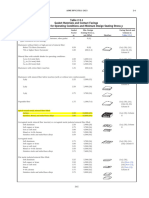

The table lists the duplex stainless steels covered in ASTM specifications for plate, sheet, and bar products.

Although few of the duplex grades are patented, many of these grades are closely associated with particular steel

producers as proprietary developments. This situation is often reflected in the naming of the grades. Only one

duplex stainless steel has an AISI designation, Type 329, a first generation duplex stainless steel without

intentional nitrogen addition. Many of the grades have become commonly known by a number that

reflects their typical chromium and nickel contents, e.g., 2205 with 22% Cr and 5% Ni. These

composition-based names, used by many producers, have recently been added to A 240 and are being added to

the ASTM specifications for other product forms. Trademarks of individual producers are not permitted in the

ASTM specifications. All grades in the ASTM specifications are all listed by their designations in the Unified

Numbering System (UNS). It is important to reference the UNS number when ordering to the standard

specifications in order to get the desired grade.

Composition of Duplex Stainless Steelsa

UNS Number Typeb C Mn P S Si Cr Ni Mo N Cu Other

Duplex

Grades

S31200 ... 0.030 2.00 0.045 0.030 1.00 24.0- 5.5-6.5 1.20- 0.14- ... ...

26.0 2.00 0.20

S31260 ... 0.03 1.00 0.030 0.030 0.75 24.0- 5.5-7.5 2.5-3.5 0.10- 0.20- W0.10-

26.0 0.20 0.80 0.20

S31803 ... 0.030 2.00 0.030 0.020 1.00 21.0- 4.5-6.5 2.5-3.5 0.08- ...

23.0 0.20

S32001 ... 0.030 4.0- 0.040 0.030 1.00 19.5- 1.00- 0.60 0.05- 1.00

6.0 21.5 3.00 0.17

S32205 2205 0.030 2.00 0.030 0.020 1.00 22.0- 4.5-6.5 3.0-3.5 0.14- ...

23.0 0.20

S32304 2304 0.030 2.50 0.040 0.030 1.00 21.5- 3.0-5.5 0.05- 0.05- 0.05-

24.5 0.60 0.20 0.60

S32520 ... 0.030 1.50 0.035 0.020 0.80 24.0- 5.5-8.0 3.0-4.0 0.20- 0.50-

26.0 0.35 2.00

S32550 255 0.04 1.50 0.040 0.030 1.00 24.0- 4.5-6.5 2.9-3.9 0.10- 1.5-2.5

27.0 0.25

S32750 2507 0.030 1.20 0.035 0.020 0.80 24.0- 6.0-8.0 3.0-5.0 0.24- 0.50

26.0 0.32

c

S32760 ... 0.030 1.00 0.030 0.010 1.00 24.0- 6.0-8.0 3.0-4.0 0.20- 0.50-

26.0 0.30 1.00

S32900 329d 0.06 1.00 0.040 0.030 0.75 23.0- 2.5-5.0 1.0-2.0 ... ...

28.0

S32950 ... 0.03 2.00 0.035

a

Weight percent, maximum unless otherwise noted.

b

Unless otherwise indicated, a common name, not a trademark, widely used, not associated with any one

producer, as listed in ASTM A 240.

c

W 0.50-1.00; Cr+3.3Mo+16N=40 min.

d

AISI designation

You might also like

- Steam Reforming Common ProblemsDocument61 pagesSteam Reforming Common ProblemsBilalNo ratings yet

- Cuel CPT ReportDocument103 pagesCuel CPT ReportIkhsan Ly100% (1)

- Term of Coating FailuresDocument21 pagesTerm of Coating FailuresIkhsan LyNo ratings yet

- Magnetic Effects of Stainless SteelDocument2 pagesMagnetic Effects of Stainless SteelIkhsan LyNo ratings yet

- Preparation Steel Substrates Before Paints and Related Products Specifications For Metallic Blast-Cleaning AbrasivesDocument25 pagesPreparation Steel Substrates Before Paints and Related Products Specifications For Metallic Blast-Cleaning AbrasivesIkhsan LyNo ratings yet

- Paint Consumption & Cost Calculation: Instruction: Fill-Up The Value in The Blue ColumnDocument1 pagePaint Consumption & Cost Calculation: Instruction: Fill-Up The Value in The Blue ColumnIkhsan LyNo ratings yet

- Norsok Surface Preparation M-501Document28 pagesNorsok Surface Preparation M-501Ricky WCK100% (2)

- Turnkey Boiler Burner SolutionsDocument5 pagesTurnkey Boiler Burner SolutionsIkhsan LyNo ratings yet

- ASME Training Programs: For Engineers and Technical ProfessionalsDocument28 pagesASME Training Programs: For Engineers and Technical ProfessionalsIkhsan LyNo ratings yet

- Author Manuscript: Performance of Metal and Polymeric O-Ring Seals During Beyond-Design-Basis Thermal ConditionsDocument18 pagesAuthor Manuscript: Performance of Metal and Polymeric O-Ring Seals During Beyond-Design-Basis Thermal ConditionsIkhsan LyNo ratings yet

- Schedule 2016 New 1Document5 pagesSchedule 2016 New 1Ikhsan LyNo ratings yet

- Transformer Oil Testing: Dissolved Gas AnalysisDocument18 pagesTransformer Oil Testing: Dissolved Gas AnalysisIkhsan LyNo ratings yet

- 131 - 1.9.1.2-04T Babbitt WireDocument4 pages131 - 1.9.1.2-04T Babbitt WireRobin SanjayaNo ratings yet

- Tafa Arc Spray Wire 1.9.1.2-01T - Aluminum Wire 01TDocument4 pagesTafa Arc Spray Wire 1.9.1.2-01T - Aluminum Wire 01TIkhsan LyNo ratings yet

- Generate Reliability Block Diagrams (RBDDocument9 pagesGenerate Reliability Block Diagrams (RBDIkhsan Ly100% (1)

- EagleBurgmann - DMS - TSE - E5 - Brochure Mechnical Seal Technology and Selection - EN - 16.05.2017 PDFDocument58 pagesEagleBurgmann - DMS - TSE - E5 - Brochure Mechnical Seal Technology and Selection - EN - 16.05.2017 PDFImmanuel AutomatonNo ratings yet

- Make PAS-55 and ISO-55001 SuccessfulDocument8 pagesMake PAS-55 and ISO-55001 SuccessfulArvion WinchesterNo ratings yet

- Basicpartialdischarge 151203094937 Lva1 App6891Document78 pagesBasicpartialdischarge 151203094937 Lva1 App6891Ikhsan LyNo ratings yet

- GuidelinesfortheWeldedFGuidelinesfortheWeldedFabricationofNickelAlloysforCorrosion ResistantServiceabricationofNickelAlloysforCorrosion ResistantService 11012Document43 pagesGuidelinesfortheWeldedFGuidelinesfortheWeldedFabricationofNickelAlloysforCorrosion ResistantServiceabricationofNickelAlloysforCorrosion ResistantService 11012emanNo ratings yet

- Belajar Menghitung ReliabilityDocument103 pagesBelajar Menghitung ReliabilityIkhsan LyNo ratings yet

- 77-2003-TypeB Solid Metal Rupture Disk PDFDocument8 pages77-2003-TypeB Solid Metal Rupture Disk PDFIkhsan LyNo ratings yet

- Fundamentals of Welding - TechnologyDocument27 pagesFundamentals of Welding - TechnologyArvinth KumarNo ratings yet

- 2.1 Structure and Properties of MetalsDocument1 page2.1 Structure and Properties of MetalsIkhsan LyNo ratings yet

- Carbon EquivalentDocument21 pagesCarbon Equivalentchhakula07No ratings yet

- Flexible Eddy Current Array Probe For Weld Inspections June 2011 2Document2 pagesFlexible Eddy Current Array Probe For Weld Inspections June 2011 2Ikhsan LyNo ratings yet

- O RingsDocument211 pagesO RingsIkhsan LyNo ratings yet

- Neles Seat Leakage SpecDocument9 pagesNeles Seat Leakage SpecIkhsan Ly100% (1)

- Pctfe (Polychlorotrifluoroethylene) : PhysicalDocument1 pagePctfe (Polychlorotrifluoroethylene) : PhysicalIkhsan LyNo ratings yet

- PTFEDocument1 pagePTFEIkhsan LyNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Appuis ponctuels et linéaires de glissement et de déformation pour bâtimentDocument10 pagesAppuis ponctuels et linéaires de glissement et de déformation pour bâtimentSopheaNo ratings yet

- Unit - Iii: Ferrous and Non Ferrous MetalsDocument101 pagesUnit - Iii: Ferrous and Non Ferrous Metalssenthilkumar tsNo ratings yet

- Stainless Steel Grade 409 Properties and ApplicationsDocument4 pagesStainless Steel Grade 409 Properties and ApplicationsAMBICA GroupNo ratings yet

- AISI 4130 Alloy Steel (UNS G41300) 1Document4 pagesAISI 4130 Alloy Steel (UNS G41300) 1shubham soni100% (1)

- Eglin SteelDocument3 pagesEglin SteelShaun LeeNo ratings yet

- TornilleriaDocument26 pagesTornilleriacorpSIG corpSIGNo ratings yet

- Steel Grade Equivalent Table (EN, SAE - AISI, UNS, DIN, BS, UNI, JIS) - DFW MachineDocument5 pagesSteel Grade Equivalent Table (EN, SAE - AISI, UNS, DIN, BS, UNI, JIS) - DFW MachineMuhammad Adnan HafeezNo ratings yet

- Steel Grades Equivalence Table1 PDFDocument13 pagesSteel Grades Equivalence Table1 PDFVictor ParvanNo ratings yet

- Asme Bpe 2019 - Compress 133 147Document15 pagesAsme Bpe 2019 - Compress 133 147Alex SanttosNo ratings yet

- Asme Sec Viii Div.1-2023Document1 pageAsme Sec Viii Div.1-2023karthickmectrNo ratings yet

- ASME-B-31.3-2016-Table 302.3.5-Weld Joint Strength Reduction Factor (W)Document1 pageASME-B-31.3-2016-Table 302.3.5-Weld Joint Strength Reduction Factor (W)groshan20No ratings yet

- SteelDocument8 pagesSteelvivek463No ratings yet

- Aluminium Alloy 7075Document3 pagesAluminium Alloy 7075jcetmechanicalNo ratings yet

- Metals and AlloysDocument34 pagesMetals and AlloyszenrockNo ratings yet

- Mini FocusDocument52 pagesMini FocusLmn TrixNo ratings yet

- Welding BrassDocument5 pagesWelding BrassMohammed NazeerNo ratings yet

- Effect of Alloying Elements On Steel Properties (SubsTech)Document2 pagesEffect of Alloying Elements On Steel Properties (SubsTech)hguptabhel100% (1)

- Kiswel K-309LTDocument1 pageKiswel K-309LTOmer IkhlasNo ratings yet

- Steel Designation0Document13 pagesSteel Designation0Palak NaikNo ratings yet

- Piping dimensions and materialsDocument6 pagesPiping dimensions and materialsFREDYTOAPANTANo ratings yet

- Astm A194Document1 pageAstm A194Tee Klong RungNo ratings yet

- Hobart CatalogDocument138 pagesHobart CatalogHuỳnh TrươngNo ratings yet

- List of Battery RecyclersDocument1 pageList of Battery RecyclersKrishna MylavarapuNo ratings yet

- Carbon&Low-Alloy Steel Sheet and StripDocument5 pagesCarbon&Low-Alloy Steel Sheet and Stripducthien_80No ratings yet

- NLMK in Hot Rolled ProductsDocument7 pagesNLMK in Hot Rolled Productsafraz_xecNo ratings yet

- UNIT 3 Ferrous and Non Ferrous MetalsDocument68 pagesUNIT 3 Ferrous and Non Ferrous MetalsAmutha PSGRKCWNo ratings yet

- Asme b31.3 Table A 1 Basic Allowable Stress Carbon Steel Pipe and Tube Data Table 1Document1 pageAsme b31.3 Table A 1 Basic Allowable Stress Carbon Steel Pipe and Tube Data Table 1Crazy CNo ratings yet

- Material Composition Analysis ReportDocument28 pagesMaterial Composition Analysis ReportBinay ChaudharyNo ratings yet

- 03.effects of Alloying ElementsDocument8 pages03.effects of Alloying Elementsandrian hermanNo ratings yet

- OQ AVL-ValvesDocument3 pagesOQ AVL-ValvesMDhana SekarNo ratings yet