Professional Documents

Culture Documents

JM Piezoproducts 102eng Functionality Bending Actuator

JM Piezoproducts 102eng Functionality Bending Actuator

Uploaded by

Luan Engenharia BackupOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JM Piezoproducts 102eng Functionality Bending Actuator

JM Piezoproducts 102eng Functionality Bending Actuator

Uploaded by

Luan Engenharia BackupCopyright:

Available Formats

Johnson Matthey Piezo Products GmbH

Bahnhofstrasse 43, 96257 Redwitz

Germany

piezoproducts@matthey.com

www.piezoproducts.com

T +49 9574 81-453

F +49 9574 81-618

Functionality

Date: 2017-12-22

Piezoceramic Bending Actuator Page: 1 / 1

We manufacture piezoceramic bending elements since the 80´s and we are one of the leading

market suppliers in several branches of industry, in particular in the field of actuators. Generally

bending elements are differentiated into actuators and sensors.

Bending actuators are predestined to replace magnets in the form of control elements. A special

actuator design, but also the use of highly effective ceramics make it possible to meet

requirements relating to regulating deflection and controlling force. The advantages here include

low energy requirement, a higher regulating speed, almost no heat evolution, silent operation

and smaller space requirements. Since our bending actuators are only operated in the direction

of polarization, these actuators experience a refreshment during each bending process so that

the regulating deflection and the controlling force are maintained throughout the entire working

life. This kind of actuation consequently guarantees a very long working life and represents the

The reproduction, distribution and utilization of this document as well as the communication of its

contents to others without express authorization is prohibited. Offenders will be held liable for the

payment of damages. All rights reserved in the event of the grant of a patent, utility model or design.

main advantage of our actuators.

For application under special climatic conditions our bending units are additionally provided with

a sealant consisting of a specially developed protective coating.

The standard bending actuator is a compound of two piezoceramics with or without an

intermediate layer, the so-called Bimorph or Trimorph. For certain applications monomorphic

bending actuators in which one of the two ceramics is not included and multimorphic bending

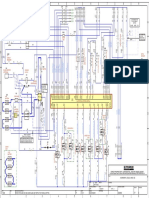

actuators which include numerous active layers are also used (see Fig.).

One-sided clamping is normally chosen to make use of the deflection and controlling force at the

other end of the bending actuator. The ceramic layers are actuated electrically. The inverse

piezoelectric effect gives rise to mechanical stress which results in a bending of the compound.

***

You might also like

- 2009 F150 LightingDocument15 pages2009 F150 LightingPiotr GrzechnikNo ratings yet

- Schematic Electric GS DCDocument2 pagesSchematic Electric GS DCJC HEAVY SERVICENo ratings yet

- DH Hoist Brochure PDFDocument22 pagesDH Hoist Brochure PDFMahmoud Allam100% (2)

- Din 555 1983Document6 pagesDin 555 1983Manuel OrtizNo ratings yet

- IGCSE Biology Notesss YehahahaDocument133 pagesIGCSE Biology Notesss YehahahaDIO yesNo ratings yet

- SealDocument80 pagesSealsandeshpetareNo ratings yet

- MCi 50 STC - GB FiniDocument18 pagesMCi 50 STC - GB FinisebastianNo ratings yet

- Start-Up and Shut-Down Instructions - OSD With Control Unit D10 or D20 - Ed. 206Document64 pagesStart-Up and Shut-Down Instructions - OSD With Control Unit D10 or D20 - Ed. 206Centrifugal SeparatorNo ratings yet

- AgitatingDocument24 pagesAgitatingBánh Cuốn Tôm ThịtNo ratings yet

- 1500 Series in EnglishDocument24 pages1500 Series in EnglishDjebali MouradNo ratings yet

- Brochure Mechanical Seal Technology and SelectionDocument58 pagesBrochure Mechanical Seal Technology and SelectionarjunNo ratings yet

- TOX Clinching-Technology 80 enDocument24 pagesTOX Clinching-Technology 80 enKIRANNo ratings yet

- Demag Hoists CatalogDocument62 pagesDemag Hoists CatalogDante WilliamsNo ratings yet

- Water Quality IndexDocument3 pagesWater Quality IndexAKHILA SURENDRAN SM21-23No ratings yet

- Rexroth D&C For Wind TurbinesDocument16 pagesRexroth D&C For Wind TurbinesxxshNo ratings yet

- E2. Boiler Tube Failure Part 2Document77 pagesE2. Boiler Tube Failure Part 2Rajendran Srn100% (5)

- Castflex EngDocument12 pagesCastflex EngJuanNo ratings yet

- Processing Technology: Processing of Polymer Melts Made in GermanyDocument24 pagesProcessing Technology: Processing of Polymer Melts Made in GermanyRobel MTNo ratings yet

- 1 - Grinding Media Catalogue PDFDocument14 pages1 - Grinding Media Catalogue PDFmahreza189No ratings yet

- Tunnel DamperDocument8 pagesTunnel DamperIvanNo ratings yet

- HYGUARD Safety CouplingsDocument32 pagesHYGUARD Safety CouplingsropmachadoNo ratings yet

- Internal Heat of The EarthDocument2 pagesInternal Heat of The EarthANNA BABONNo ratings yet

- Chapter16.Capital Expenditure DecisionsDocument44 pagesChapter16.Capital Expenditure DecisionsErdjol Yzeiri63% (8)

- Pneumatic HandbookDocument34 pagesPneumatic Handbookseid negashNo ratings yet

- Hydraulic Seal Catalogue 2022Document423 pagesHydraulic Seal Catalogue 2022tepu msosa100% (1)

- Reverberi Full Clave B16, B20 - Service ManualDocument34 pagesReverberi Full Clave B16, B20 - Service ManualMoyses Moy100% (2)

- Dispersing Without Grinding Media: Production TechnologyDocument5 pagesDispersing Without Grinding Media: Production TechnologyAbd Al-Rahmman Al-qatananiNo ratings yet

- Flupec - Catalog Simeringuri PDFDocument315 pagesFlupec - Catalog Simeringuri PDFman666onNo ratings yet

- 920-01-643 HWL EN 06.17 WebDocument2 pages920-01-643 HWL EN 06.17 WebMohsenNo ratings yet

- Machine Profile: Vertical Form Fill SealDocument12 pagesMachine Profile: Vertical Form Fill SealAhmad عfiaNo ratings yet

- Brochure Modus BabyDocument2 pagesBrochure Modus BabyGabriel LeonNo ratings yet

- EagleBurgmann - Mechnical Seal Technology and Selection - EN - 16.05.2017 PDFDocument58 pagesEagleBurgmann - Mechnical Seal Technology and Selection - EN - 16.05.2017 PDFAnh VoNo ratings yet

- EagleBurgmann - DMS - TSE - E5 - Brochure Mechnical Seal Technology and Selection - EN - 16.05.2017 PDFDocument58 pagesEagleBurgmann - DMS - TSE - E5 - Brochure Mechnical Seal Technology and Selection - EN - 16.05.2017 PDFImmanuel AutomatonNo ratings yet

- 1 Part 1 Catalogue en LocknutDocument22 pages1 Part 1 Catalogue en Locknutehtisham khanNo ratings yet

- MKT Apac Tds Fleximesh Feb 2022 enDocument2 pagesMKT Apac Tds Fleximesh Feb 2022 enIvanRomanovićNo ratings yet

- Overhaul of Raw Material Mill Gearbox Saves More Than 300,000 EurosDocument5 pagesOverhaul of Raw Material Mill Gearbox Saves More Than 300,000 Eurosjesus rodriguezNo ratings yet

- MAS MEXturn enDocument124 pagesMAS MEXturn enRoberto LimaNo ratings yet

- JM Piezo Products Company BrochureDocument13 pagesJM Piezo Products Company BrochureLuan Engenharia BackupNo ratings yet

- Ground-Breaking Solutions For Power Transmissions EngineeringDocument8 pagesGround-Breaking Solutions For Power Transmissions EngineeringkazemiNo ratings yet

- Seal ModuleDocument4 pagesSeal ModuleDanhVôNo ratings yet

- Multi Head ExtrusionDocument12 pagesMulti Head Extrusionsuoya14No ratings yet

- Operator For Sliding Gates Weighing Up To 2,200 KG (4,500 LB)Document4 pagesOperator For Sliding Gates Weighing Up To 2,200 KG (4,500 LB)Budi PrakosoNo ratings yet

- APMShortCatalog HEX SC 01 Rev. 06.19.19Document8 pagesAPMShortCatalog HEX SC 01 Rev. 06.19.19Muthukumar RadhakrishnanNo ratings yet

- Merkel Technical Manual: Merkel Freudenberg Fluidtechnic GMBHDocument106 pagesMerkel Technical Manual: Merkel Freudenberg Fluidtechnic GMBHBagus AdiriantoNo ratings yet

- EM5 Eng Chinese DefinitivoDocument8 pagesEM5 Eng Chinese DefinitivoAjiStwnNo ratings yet

- Pro Evolution MXE Panel User ManualDocument20 pagesPro Evolution MXE Panel User ManualcleoaminNo ratings yet

- CaseStudy EagleBurgmann SeccoLip-for-roller-dryers EN 23-05Document2 pagesCaseStudy EagleBurgmann SeccoLip-for-roller-dryers EN 23-05edavidNo ratings yet

- Luk k7 Chap12 PDFDocument14 pagesLuk k7 Chap12 PDFMarran AlmarraniNo ratings yet

- Sello Energizados PDFDocument24 pagesSello Energizados PDFhufuents-1No ratings yet

- Roller Head LinesDocument5 pagesRoller Head LinesMuhammad ShofiyansyahNo ratings yet

- PD-2.9-WT - WT.01-B-A-EN Product Description (MM92 50Hz 2050kW)Document27 pagesPD-2.9-WT - WT.01-B-A-EN Product Description (MM92 50Hz 2050kW)iuliamovNo ratings yet

- 262 B 003 Insulation Blower CatalogDocument20 pages262 B 003 Insulation Blower CatalogAashir YaqubNo ratings yet

- BA Maxicat-GB Juni 2015 PDFDocument14 pagesBA Maxicat-GB Juni 2015 PDFKheiro BelhadiaNo ratings yet

- Automatic Adjustment of Car Body Fixtures Using ArDocument6 pagesAutomatic Adjustment of Car Body Fixtures Using ArGhani AzizNo ratings yet

- Catalogo HydrokompDocument6 pagesCatalogo HydrokompJunior RodriguesNo ratings yet

- VERO-S - SPM-Fixacao - Por MembranaDocument6 pagesVERO-S - SPM-Fixacao - Por MembranaWilson DantasNo ratings yet

- DS2301-Válvula GloboDocument39 pagesDS2301-Válvula Globolorena.florez.iqNo ratings yet

- 2009 PI Piezo Actuators Components Nano Positioning CatalogDocument48 pages2009 PI Piezo Actuators Components Nano Positioning CatalogburakbalciNo ratings yet

- YLB Mobile Asphalt Mixing Plant: Henan Sinoroader Heavy Industry CorporationDocument14 pagesYLB Mobile Asphalt Mixing Plant: Henan Sinoroader Heavy Industry CorporationMohammad Daoud100% (1)

- Acoplamientos Flexibles TB Wood's P-1690-TBW PDFDocument98 pagesAcoplamientos Flexibles TB Wood's P-1690-TBW PDFfaundesNo ratings yet

- CTV WT8344 Good-Vibrations enDocument9 pagesCTV WT8344 Good-Vibrations enAhmet HamamcıoğluNo ratings yet

- Conturbex: The Worm/screen CentrifugeDocument12 pagesConturbex: The Worm/screen CentrifugeLeonan CaréliNo ratings yet

- PDF - Selection and Application Guide MeteringDocument112 pagesPDF - Selection and Application Guide MeteringjosepitbulNo ratings yet

- Dia Com Corporation Dia Com Corporation: The Diaphragm CompanyDocument28 pagesDia Com Corporation Dia Com Corporation: The Diaphragm CompanyMasood AlamNo ratings yet

- 7 - Uzvyniojimo Ir Nuvyniojimo SprendimasDocument16 pages7 - Uzvyniojimo Ir Nuvyniojimo SprendimasproteomxNo ratings yet

- Tds Flexi-Stop Aus 29april2019Document2 pagesTds Flexi-Stop Aus 29april2019IvanRomanovićNo ratings yet

- TBW - FC Acoplamiento FrickDocument88 pagesTBW - FC Acoplamiento Frickjuan leyyonNo ratings yet

- 4.2-VIB Strukturverformung LIT 01.312 enDocument2 pages4.2-VIB Strukturverformung LIT 01.312 enFrancisco Andres MuñozNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Gma1 2 2012 ContinutDocument60 pagesGma1 2 2012 ContinutGeorge TurcasNo ratings yet

- From HALT Results To An Accurate Field MTBF - PresentationDocument27 pagesFrom HALT Results To An Accurate Field MTBF - Presentationsleepanon4362No ratings yet

- Performance Tuning For The InfiniDB Analytics Database (For Version 1.0.3)Document72 pagesPerformance Tuning For The InfiniDB Analytics Database (For Version 1.0.3)Dmytro Shteflyuk100% (1)

- MT Embedded Diploma ContentsDocument8 pagesMT Embedded Diploma ContentsAhmed HamoudaNo ratings yet

- Santos LinearalgebraDocument269 pagesSantos LinearalgebraGiovania NascimentoNo ratings yet

- Detecting Alzheimers Disease Using Artificial Neural NetworksDocument56 pagesDetecting Alzheimers Disease Using Artificial Neural NetworkshodNo ratings yet

- 2.5 - ICR Dec 06 - Wear Technology LeadershipDocument2 pages2.5 - ICR Dec 06 - Wear Technology LeadershipKreshnik StratiNo ratings yet

- Grade 3 Araling Panlipunan Q1 Ep3: Kinalalagyan NG Mga Lalawigan Sa RehiyonDocument1 pageGrade 3 Araling Panlipunan Q1 Ep3: Kinalalagyan NG Mga Lalawigan Sa RehiyonJober MerencillaNo ratings yet

- Kinetics and Mechanism of Urea FormaldehydeDocument5 pagesKinetics and Mechanism of Urea FormaldehydeDessy A. SariNo ratings yet

- Factors Affecting Slope StabilityDocument9 pagesFactors Affecting Slope StabilitySrithar KrishnanNo ratings yet

- Interview Questions - C# - DeveloperDocument5 pagesInterview Questions - C# - DeveloperPhani PrudhviNo ratings yet

- Cycle Time Reduction PrinciplesDocument3 pagesCycle Time Reduction PrinciplesDhatrpriya Rao NallacheruvuNo ratings yet

- PGHU-EH-LSPDS-001209 R1 General Requirement For ValvesDocument13 pagesPGHU-EH-LSPDS-001209 R1 General Requirement For ValvesRiyan EsapermanaNo ratings yet

- under NDA: 泰凌 Kite BLE SDK 开发指南Document317 pagesunder NDA: 泰凌 Kite BLE SDK 开发指南毛增No ratings yet

- $ Cat Welcome.c: Welcome To COS 217 Introduction To Programming Systems Fall 2019Document55 pages$ Cat Welcome.c: Welcome To COS 217 Introduction To Programming Systems Fall 2019Hiroshi TakeshiNo ratings yet

- 7400-Series Integrated Circuits - WikipediaDocument90 pages7400-Series Integrated Circuits - Wikipediazeshan shakirNo ratings yet

- 9th - Summer Vacation HomeworkDocument3 pages9th - Summer Vacation HomeworkEducation PointNo ratings yet

- How To Determine Correct Number of Earthing Electrodes Strips Plates and Pipes Part 1Document6 pagesHow To Determine Correct Number of Earthing Electrodes Strips Plates and Pipes Part 1Francisco MartinezNo ratings yet

- Green Chemistry ProjectDocument4 pagesGreen Chemistry Projectapi-320290632No ratings yet

- Design Patterns - Embedded Software Design - A Practical Approach To Architecture, Processes, and Coding TechniquesDocument30 pagesDesign Patterns - Embedded Software Design - A Practical Approach To Architecture, Processes, and Coding TechniquesamiteshanandNo ratings yet