Professional Documents

Culture Documents

Ground Vibrations Associated With Installing Enlar

Uploaded by

vttrlcOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ground Vibrations Associated With Installing Enlar

Uploaded by

vttrlcCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/242395428

Ground Vibrations Associated With Installing Enlarged-Base Driven Cast-In-

Situ Piles

Article · March 2002

CITATIONS READS

6 717

3 authors, including:

Mark B. Jaksa M. C. Griffith

University of Adelaide University of Adelaide

208 PUBLICATIONS 4,229 CITATIONS 223 PUBLICATIONS 5,197 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

PhD research on Feasibility Assessment of Robotically Assisted 3D Printing of Cob Walls View project

Prediction of Pile Behaviour Using Artificial Neural Networks Based on Standard Penetration Test Data View project

All content following this page was uploaded by M. C. Griffith on 28 May 2014.

The user has requested enhancement of the downloaded file.

GROUND VIBRATIONS ASSOCIATED WITH INSTALLING ENLARGED-

BASE DRIVEN CAST-IN-SITU PILES

Mark B. Jaksa, Michael C. Griffith

Department of Civil and Environmental Engineering, Adelaide University

Roger W. Grounds

Coffey Geosciences, Adelaide

ABSTRACT

Ground vibrations associated with pile construction have long been regarded as a significant drawback of driven piles.

This paper presents measured ground vibrations associated with the construction of enlarged-base driven cast-in-situ

piles. Data were obtained using servo accelerometers measuring acceleration in three orthogonal directions, and at

varying lateral distances from the driven pile. The accelerations are converted to peak particle velocities; the widely

accepted measure of ground-vibration damage. The peak particle velocities are compared to recommended maximum

values, data presented by others, as well as human perception of ground vibration. The maximum measured peak

particle velocity of 8.8 mm/s was associated with the development of the enlarged base, at a lateral distance of 3.5 m

from the pile. The data suggest that enlarged-base driven cast-in-situ piles can be used successfully in the urban

environment. The measurements are, however, site-specific and should be used with caution in different soil profiles.

1 INTRODUCTION

Enlarged-base driven cast-in-situ piles have several advantages over traditional bored piles and driven precast piles.

These include superior end-bearing capacity and settlement performance, less noise and vibration than other driven

piles due to bottom driving and, as driven piles do not allow elastic rebound, the load is carried more efficiently

(Tchepak 1986). However, noise and particularly ground vibration, are often regarded as significant drawbacks

associated with this type of pile construction. The aim of this paper is to present, discuss and compare measured ground

vibrations associated with the construction of enlarged-base driven cast-in-situ piles. Prior to presenting these data, it is

first necessary to discuss the sequence adopted in the construction of these piles, and the measure used to quantify

ground vibrations.

1.1 CONSTRUCTION SEQUENCE OF ENLARGED-BASE DRIVEN CAST-IN-SITU PILES

The construction sequence of enlarged-base driven cast-in-situ piles is shown in Figure l, and involves the following

stages (Tchepak 1986):

1. A layer of sand and gravel is placed at the base of a thick-walled temporary piling tube and compacted using a drop

hammer in order to form a plug;

2. The piling tube is driven into the ground by bottom driving on the compacted plug;

3. When the required founding level is reached (as determined from site investigation information and observations of

the driving resistance of the piling tube), the piling tube is restrained and the plug pushed out. The enlarged base is

subsequently formed by hammering out successive small charges of dry-mix concrete.

4. The drop hammer is then withdrawn from the piling tube and a cylindrical reinforcing cage is inserted. The

concrete shaft is then formed by filling the tube with a high slump concrete and then slowly withdrawing the tube.

1.2 QUANTIFYING GROUND VIBRATIONS

The commonly accepted criterion for quantifying damage as a result of ground vibration and human evaluation of

transient vibration is the peak particle velocity (Wiss 1981, Tchepak 1986, Standards Australia 1993). Ground vibration

is generally measured in three orthogonal directions, usually by means of accelerometers in the vertical, transverse and

longitudinal directions. The peak particle velocity is generally taken as the vector sum of these three directional

components (Standards Australia 1993, Amick and Gendreau 2000).

Several national and international bodies have published recommended maximum peak particle velocities for different

structural types. Amick and Gendreau (2000) presented a summary of these, as given in Table 1. In addition, Wiss

(1981) reported that, while damage to structures is important, it is rare that these ‘safe’ criteria are reached before

complaints or claims are filed. He stated that the human body is an excellent detector of vibration, but a poor measuring

Australian Geomechanics March 2002 67

VIBRATIONS ASSOCIATED WITH DRIVEN PILES JAKSA et al

device. Wiss (1981) reported that, for transient or impact vibration, the threshold of human perception is 0.3 mm/s,

becomes ‘disturbing’ at 7 mm/s and ‘very disturbing’ above approximately 25 mm/s. In addition, Wiss (1981)

presented a chart of measured ground vibrations associated with several different types of construction equipment,

including pile drivers. Wiss’ chart is reproduced in Figure 2.

2 FIELD STUDY

The ground vibration data associated with the installation of the enlarged-base driven cast-in-situ piles were obtained

from the site of the construction of the Institute of Medical and Veterinary Science Car Park Building, Frome Road,

Adelaide. The site is located within a region underlain by Torrens Alluvium, which consist of sediments deposited in a

1 km wide buried valley by the ancestral River Torrens (Selby and Lindsay 1982). Investigative drilling performed by

Coffey Geosciences (2000) identified two major units within the upper 14.5 metres:

• Unit 1: Upper Alluvial Soils, comprising very weak sandy clay, silty clay and sand. Approximate thickness of the

unit is 10.5 metres which varies across the site.

• Unit 2: Lower Alluvial Soils, comprising sandy gravel with some interbedded layers of gravelly sands. Standard

penetration tests indicated a dense to very-dense in situ condition. The base of the unit was not intersected over the

depth range investigated (14.5 m).

In this region the Tertiary sediments of the Blanche Point Formation and the South Maslin Sand generally underlie the

Torrens Alluvium (Selby and Lindsay 1982). The groundwater table was encountered at an approximate depth of 4.5 m

below the ground surface.

Figure 1: Construction sequence of enlarged-base driven cast-in-situ piles (Frankipile Australia).

Category Particle Velocity (mm/s)

Industrial Buildings 100

Buildings of Substantial Construction 100

Residential 50

Residential, New Construction 50

Residential, Poor Condition 25

Residential, Very Poor Condition 12.5

Buildings Visibly Damaged 4

Historic Buildings 3

Historic and Ancient Buildings 2

Table 1: Typical vibration criteria addressing building damage (Amick and Gendreau 2000).

68 Australian Geomechanics March 2002

VIBRATIONS ASSOCIATED WITH DRIVEN PILES JAKSA et al

Figure 2: Relative intensities of construction vibration as a function of lateral distance (Wiss 1981).

The enlarged-base driven cast-in-situ piles were driven until the piling tube reached the dense gravel layer (Unit 2).

The enlarged base was then formed within this layer. The pile driving equipment consisted of a 3.5 tonne hammer with

a 10 m drop and 10. 8 m long, 500 mm diameter piling tube.

Ground vibrations were measured in the vertical, transverse and longitudinal directions by means of three servo-

accelerometers mounted on a rigid base plate and seated on the ground surface. The data were acquired at a sampling

frequency of 1 kHz and an 11 Hz double –pole, low-pass filter was used to eliminate higher frequency noise,

particularly on-site traffic. Klopp and Griffith (1993) presented a summary of the dynamic characteristics of several

unreinforced masonry structures; those which are most likely to be affected by pile-induced ground vibrations. The

majority of these structures exhibited a natural frequency typically in the range 3 to7 Hz. Whilst an 11 Hz filter was

used, and was appropriate given the on-site conditions, it is nevertheless, possible that higher frequency vibrations (in

the range of 10 to 50 Hz) may cause damage, if present in sufficient amplitude. Measurements of ground vibrations

were obtained at horizontal distances of 3.5, 7, 15 and 30 metres from the driven pile. At each of these lateral distances

vibrations were measured throughout the complete pile construction sequence, that is, from pile driving at the ground

surface, to forming the pile’s enlarged base.

3 ANALYSIS, RESULTS AND DISCUSSION

Particle velocities were calculated by integrating the measured acceleration time histories. Typical particle velocity

data are given in Figures 3 to 6.

The complete results of the ground vibration measurements, in terms of peak particle velocities with respect to depth of

the base of the piling tube and lateral distance from the pile, are shown in Figures 7 and 8. It can be seen from these

figures that the maximum measured peak particle velocity was 8.8 mm/s and was associated with the formation of the

enlarged base at a lateral distance of 3.5 m from the perimeter of the piling tube. In addition, Figures 7 and 8 show the

maximum peak particle velocities decrease with lateral distance, as one would expect and, at each lateral distance, the

maximum value measured was associated with the establishment of the enlarged bases.

Comparing this maximum value of 8.8 mm/s to the maximum recommended values shown in Table 1, indicate that the

pile driving activity would only be of concern to very sensitive structures such as ancient and historic buildings or

structures which are damaged or in poor condition. Whilst the majority of measurements are above the perception

threshold of 0.3 mm/s (Wiss 1981), only 3 measurements, recorded at a lateral distance of 3.5 m, are regarded as

‘disturbing.’

Australian Geomechanics March 2002 69

VIBRATIONS ASSOCIATED WITH DRIVEN PILES JAKSA et al

10

Particle Velocity (mm/s)

-5

-10

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Time (s)

Figure 3: Typical particle velocity time history – vertical direction (filtered).

10

Particle Velocity (mm/s)

-5

-10

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Time (s)

Figure 4: Typical particle velocity time history – transverse direction (filtered).

10

Particle Velocity (mm/s)

-5

-10

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Time (s)

Figure 5: Typical particle velocity time history – longitudinal direction (filtered).

70 Australian Geomechanics March 2002

VIBRATIONS ASSOCIATED WITH DRIVEN PILES JAKSA et al

10

Particle Velocity (mm/s)

0

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Time (s)

Figure 6: Resultant particle velocity time history for data in Figures 3 to 5 (filtered).

Peak Particle Velocity, Vmax (mm/s)

0 1 2 3 4 5 6 7 8 9

0

8 30 m 15 m 7m 3.5 m

9

Enlarged Base

10

Figure 7: Peak particle velocities plotted against depth of the piling tube base and lateral distance.

(The depth associated with the enlarged base is not shown to scale).

Attewell and Farmer (1973) observed that the pile driving involves the generation of compression waves that propagate

from the area of the pile toe and expand outwards over a spherical front. In addition, vertical shear waves emanate from

shaft friction around a conical surface. Figure 9 shows the variation of particle motions with time for the data presented

in Figures 3 to 6. It is evident from Figure 9 that the motion is predominantly vertical, as one would expect with driven

friction piles (Kim and Lee 2000). As a result, the vibration source can be regarded as a point source generating body

waves and the travel distance can be approximated to the horizontal distance (Kim and Lee 2000).

Australian Geomechanics March 2002 71

VIBRATIONS ASSOCIATED WITH DRIVEN PILES JAKSA et al

Lateral Distance (m)

3.5 5 10 15 20 25 30

0

9

1

8

2

7

3

6

4

5

5

4

6 3

7 2

8 1

9 0

9.5

Figure 8: Longitudinal cross-section of contours of peak particle velocities.

10 Vertical 10 Vertical

(mm/s) (mm/s)

5 5

0 0

-10 -5 0 5 10 -10 -5 0 5 10

Transverse Longitudinal

(mm/s) (mm/s)

-5 -5

-10 -10

Figure 9: Particle motion associated with installing enlarged-base driven cast-in-situ piles.

Figure 10 superimposes the data from Figure 7 on to Wiss’ Chart (Figure 2). In addition, Figure 10 includes the upper-

bound envelope of a large number of ground vibration measurements, related to pile driving, and reported by Tchepak

(1986). It can be seen from this figure that all of the measured values are in the vicinity of, but plot below, both of

Wiss’ pile-related relationships, as well as Tchepak’s upper-bound envelope.

4 CONCLUSIONS

The paper has presented measurements of ground vibration associated with the construction of enlarged-base driven

cast-in-situ piles. Data were obtained using servo accelerometers measuring acceleration in three orthogonal directions,

and at varying lateral distances from the driven pile. Vibration was found to be predominantly vertical, as one would

expect for this type of pile. The measured peak particle velocities are in general agreement with data published by

others, and the maximum measured peak particle velocity of 8.8 mm/s was associated with the development of the

enlarged base, at a lateral distance of 3.5 m from the pile. This maximum peak particle velocity may result in damage

to ancient or historic buildings, or structures which are damaged or in poor condition. As expected, the measured

vibrations decreased with increasing lateral distance from the pile. At a distance of 15 m, the measured peak particle

velocities were significantly lower than the threshold value which would be expected to cause damage to visibly-

72 Australian Geomechanics March 2002

VIBRATIONS ASSOCIATED WITH DRIVEN PILES JAKSA et al

damaged structures. The data presented herein suggest that enlarged-base driven cast-in-situ piles can be used

successfully in the urban environment. The measurements are, however, site-specific and should be used with caution

in different soil profiles.

Figure 10: Comparison of measured peak particle velocities.

5 ACKNOWLEDGMENTS

The authors are grateful to Ian Cates from the Department of Civil and Environmental Engineering, Adelaide

University, for his instrumentation expertise and assistance; McMillan Contracting and, in particular, Richard Bartlett

and Kerry Clunes, for enabling the data to be acquired; John Hindmarsh (South Australia) for providing access to the

site; and Frankipile Australia for allowing Figure 1 to be reproduced. Comments by Bob Whiteley, Coffey

Geosciences, Sydney, are also gratefully acknowledged.

6 REFERENCES

Amick, H. and Gendreau, M. (2000). Construction Vibrations and Their Impact on Vibration-Sensitive Facilities.

Proc. Construction Congress 6, ASCE, Orlando, Florida, February, pp. 758–767.

Attewell, P. B. and Farmer, I. W. (1973). Attenuation of Ground Vibrations from Pile Driving. Ground Engineering,

Vol. 6, No. 4, pp. 26–29.

Coffey Geosciences (2000). Geotechnical Investigation Report, IMVS Car Park Building, Frome Road, A3211/2

(unpublished).

Frankipile Australia (undated). Franki Piles Brochure, Sydney, NSW.

Kim, D.-S. and Lee, J.-S. (2000). Propagation and Attenuation Characteristics of Various Ground Vibrations. Soil

Dynamics and Earthquake Engineering, Vol. 19, pp. 115–126.

Klopp, G. M. and Griffith, M. C. (1993). Dynamic Characteristics of Unreinforced Masonry Buildings. Australian

Civil Engineering Transactions, I.E.Aust., Vol. CE35, No. 1, pp. 59–68.

Selby, J. and Lindsay, J. M. (1982). Engineering Geology of the Adelaide City Area. Bulletin 51, S.A. Dept. Mines

and Energy, Adelaide.

Standards Australia (1993). Explosives – Storage, Transport and Use, Part 2: Use of Explosives, AS 2187.2.

Tchepak, S. (1986). Design and Construction Aspects of Enlarged Base Frankipiles. Speciality Geomechanics

Symposium, Adelaide, August, pp. 160–165.

Wiss, J. F. (1981). Construction Vibrations: State of the Art. Journal of the Geotechnical Division, ASCE, Vol. 94 No.

9, pp. 167–181.

Australian Geomechanics March 2002 73

View publication stats

You might also like

- Newton's Laws of Motion and Force ConceptsDocument59 pagesNewton's Laws of Motion and Force ConceptsAndrea Perez92% (24)

- Design and Performance of Retaining WallsDocument12 pagesDesign and Performance of Retaining Wallssouzanamel0% (1)

- 2015 Al Ani Et Al XviecsmgeDocument7 pages2015 Al Ani Et Al XviecsmgeYannick ChoffoNo ratings yet

- Soil Inclusions in Jet Grout Columns Often Exceed ExpectationsDocument13 pagesSoil Inclusions in Jet Grout Columns Often Exceed Expectationsdiana cristina arias aldanaNo ratings yet

- Behavior of Circular Footings Resting on ConfinedDocument9 pagesBehavior of Circular Footings Resting on ConfinedAhmed Abd el shakourNo ratings yet

- Geotechnical Design of Shallow FoundationsDocument35 pagesGeotechnical Design of Shallow FoundationsAndré OliveiraNo ratings yet

- Design of jet grouting cut-offs for damsDocument13 pagesDesign of jet grouting cut-offs for damsThaung Myint OoNo ratings yet

- Project OnDocument9 pagesProject On2251 Santosh VhananavarNo ratings yet

- David White: Relevant Experience and ProjectsDocument2 pagesDavid White: Relevant Experience and ProjectsDavid WhiteNo ratings yet

- Micro Piles For Structural DesignDocument25 pagesMicro Piles For Structural DesignPedro Cedeño100% (1)

- Grouted Micropiles for Foundation Remediation in Expansive SoilDocument22 pagesGrouted Micropiles for Foundation Remediation in Expansive SoilMujahed NajıNo ratings yet

- Soil Exploration: GENERAL: Soil Is Used AsDocument16 pagesSoil Exploration: GENERAL: Soil Is Used AsPaulo Parenas100% (1)

- Parametric Study On Analysis and Design of Permanently Anchored Secant Pile Wall For Earthquake LoadingDocument16 pagesParametric Study On Analysis and Design of Permanently Anchored Secant Pile Wall For Earthquake LoadingInternational Journal of computational Engineering research (IJCER)No ratings yet

- FOUNDATIONDocument66 pagesFOUNDATIONMohamed AliNo ratings yet

- TP36 Geopier Vs SC Performance Dr. David WhiteDocument8 pagesTP36 Geopier Vs SC Performance Dr. David WhiteToby BobyNo ratings yet

- An Extension of Analytical Methods For Building Damage Evaluation in Subsidence Regions To Anisotropic BeamsDocument30 pagesAn Extension of Analytical Methods For Building Damage Evaluation in Subsidence Regions To Anisotropic BeamsThaung Myint OoNo ratings yet

- 2005 Ground Vibration Due To Dynamic CompactionDocument10 pages2005 Ground Vibration Due To Dynamic CompactionTen FreireNo ratings yet

- FEA-Secant Pile Wall InstallationDocument12 pagesFEA-Secant Pile Wall InstallationAlwin Antony100% (1)

- Ground Improvement Using The Vibro-Replacement Technique: March 2007Document13 pagesGround Improvement Using The Vibro-Replacement Technique: March 2007Tsalis SalsabilaNo ratings yet

- Direct Design Approach For Excavation Support SystemsDocument9 pagesDirect Design Approach For Excavation Support SystemsChh Song ZpermzNo ratings yet

- Sand Deformation Around An Uplift Plate Anchor: Jinyuan Liu, P.E., P.Eng., M.ASCE Mingliang Liu and Zhende ZhuDocument10 pagesSand Deformation Around An Uplift Plate Anchor: Jinyuan Liu, P.E., P.Eng., M.ASCE Mingliang Liu and Zhende ZhurkNo ratings yet

- Recent Developments in Ground Improvement Techniques-A ReviewDocument12 pagesRecent Developments in Ground Improvement Techniques-A ReviewANJITHA A RNo ratings yet

- Seismic Analysis of Multi Storey Building On Sloping Ground and Flat Ground by Using ETABSDocument13 pagesSeismic Analysis of Multi Storey Building On Sloping Ground and Flat Ground by Using ETABSUttam ShresthaNo ratings yet

- Foundations Structures Railway BridgesDocument166 pagesFoundations Structures Railway BridgesvinujohnpanickerNo ratings yet

- J2 Zevgolis and Bourdeau 2008 Mineral WealthDocument14 pagesJ2 Zevgolis and Bourdeau 2008 Mineral Wealthjmhs31No ratings yet

- A Case Study of Stone Column Ground Improvement Performance During A Sequence of Seismic EventsDocument9 pagesA Case Study of Stone Column Ground Improvement Performance During A Sequence of Seismic EventsZOUABINo ratings yet

- Ground Improvement Using The Vibro-Replacement Technique: March 2007Document13 pagesGround Improvement Using The Vibro-Replacement Technique: March 2007Javiera MoralesNo ratings yet

- Behavior of Single Pile and Pile Groups Subjected To Abrupt Collapse of A Retaining WallDocument6 pagesBehavior of Single Pile and Pile Groups Subjected To Abrupt Collapse of A Retaining WallRaja RajanNo ratings yet

- Performance of Soil Nailing for Slope StabilizationDocument15 pagesPerformance of Soil Nailing for Slope StabilizationKingsley OchiengNo ratings yet

- Retrofit MicropileDocument18 pagesRetrofit MicropileMahmoud HamedNo ratings yet

- P3/12 Review of Theoretical Models For Soil NailingDocument11 pagesP3/12 Review of Theoretical Models For Soil NailingLaura SilviNo ratings yet

- Foundation Design and Performance of The Worlds Tallest BuildingDocument14 pagesFoundation Design and Performance of The Worlds Tallest BuildingmdalgamouniNo ratings yet

- Soil Exploration Methods for Foundation DesignDocument13 pagesSoil Exploration Methods for Foundation DesignpengniumNo ratings yet

- Josh Barrett 194537 Unit 02 Construction Technology Assignment 2Document25 pagesJosh Barrett 194537 Unit 02 Construction Technology Assignment 2DineshNo ratings yet

- Ground Control for Deep Basement in Fault ZoneDocument14 pagesGround Control for Deep Basement in Fault Zonedafo407No ratings yet

- UTM Paper Uplift Capacity of Enlarge Base Pile in SandDocument18 pagesUTM Paper Uplift Capacity of Enlarge Base Pile in SandAmir JiggyNo ratings yet

- 2008 Suby BulletinDocument40 pages2008 Suby BulletinPiyush MohantyNo ratings yet

- GingeryMerry2008 GeogridDocument11 pagesGingeryMerry2008 GeogridMario Colil BenaventeNo ratings yet

- Design Construction and Performance of A Deep Braced ExcavationDocument11 pagesDesign Construction and Performance of A Deep Braced ExcavationGeotechnical ConsultanciesNo ratings yet

- Three-Dimensional Modelling of The Interaction Between Buildings and Tunnelling OperationsDocument10 pagesThree-Dimensional Modelling of The Interaction Between Buildings and Tunnelling OperationsLTE002No ratings yet

- ItdcemDocument18 pagesItdcemTarun Kant GoyalNo ratings yet

- Issues and Aspects of Soil Nailing TechniqueDocument22 pagesIssues and Aspects of Soil Nailing TechniqueUni UniNo ratings yet

- Cantilever Contiguous Pile Wall For Supporting Excavation in ClayDocument14 pagesCantilever Contiguous Pile Wall For Supporting Excavation in ClaysonNo ratings yet

- Soil Nailing For Slope Stabilization: An Overview: December 2016Document7 pagesSoil Nailing For Slope Stabilization: An Overview: December 2016Dhareppa malageNo ratings yet

- Friction Fatigue On Displacement Piles in SandDocument15 pagesFriction Fatigue On Displacement Piles in SandParvatha Vardhan GandrakotaNo ratings yet

- Dynamic Behavior of Sheet Pile in Sand Under The IDocument8 pagesDynamic Behavior of Sheet Pile in Sand Under The Iomed muhammadNo ratings yet

- DFI 2016 Innovative Deep Foundation Support Using Ductile Iron Piles PrintDocument10 pagesDFI 2016 Innovative Deep Foundation Support Using Ductile Iron Piles PrintDaniel MarínNo ratings yet

- Lateral Earth Pressure Due To Vibratory Rollers PDFDocument11 pagesLateral Earth Pressure Due To Vibratory Rollers PDFchutton681No ratings yet

- Reinforced Soil Structures With Poorly Draining BackfillsDocument43 pagesReinforced Soil Structures With Poorly Draining BackfillsHUGINo ratings yet

- Review of Design Methods For ExcavationsDocument196 pagesReview of Design Methods For ExcavationsDoan Duy Thinh100% (1)

- T C H B E I G: WO ASE Istories of Asement Xcavation With Nfluence On RoundwaterDocument19 pagesT C H B E I G: WO ASE Istories of Asement Xcavation With Nfluence On Roundwaterjinwook75No ratings yet

- Analysis of Roof Bolt Systems: January 2005Document9 pagesAnalysis of Roof Bolt Systems: January 2005Kushana SaikirannNo ratings yet

- Uplift Test MPDocument11 pagesUplift Test MP박병권No ratings yet

- Vibration Serviceability of Long-Span Concrete BuiDocument82 pagesVibration Serviceability of Long-Span Concrete BuiDaniel A. FlorêncioNo ratings yet

- Soil Investigation and Foundation DesignFrom EverandSoil Investigation and Foundation DesignRating: 4.5 out of 5 stars4.5/5 (9)

- RR207Document48 pagesRR207vttrlcNo ratings yet

- Impacts From Three-Dimensional Effect On The Wall Deflection Induced by A Deep Excavation in Kaohsiung, TaiwanDocument6 pagesImpacts From Three-Dimensional Effect On The Wall Deflection Induced by A Deep Excavation in Kaohsiung, TaiwanvttrlcNo ratings yet

- Profile Front MinimizationDocument12 pagesProfile Front MinimizationvttrlcNo ratings yet

- Svinkin 2006Document15 pagesSvinkin 2006vttrlcNo ratings yet

- Rosk Slope StabilityDocument2 pagesRosk Slope StabilityvttrlcNo ratings yet

- Angular Distortion Structures Pointv Linear GuideDocument13 pagesAngular Distortion Structures Pointv Linear GuideFrancisco Ordoñez MuñozNo ratings yet

- The PAntheon in RomeDocument14 pagesThe PAntheon in Romevttrlc100% (1)

- Design of The Foundations Loaded by Overturning Moment Stabilite Des Fondations de Blocs Soumis A Un MomentDocument4 pagesDesign of The Foundations Loaded by Overturning Moment Stabilite Des Fondations de Blocs Soumis A Un MomentvttrlcNo ratings yet

- Dynamic Increase Factors For ConcreteDocument18 pagesDynamic Increase Factors For ConcreteSindy Puello LópezNo ratings yet

- Dynamic Increase Factors For ConcreteDocument18 pagesDynamic Increase Factors For ConcreteSindy Puello LópezNo ratings yet

- Underground Concrete Shelters Withstand Nuclear BlastDocument148 pagesUnderground Concrete Shelters Withstand Nuclear BlastvttrlcNo ratings yet

- Dynamic Increase Factors For ConcreteDocument18 pagesDynamic Increase Factors For ConcreteSindy Puello LópezNo ratings yet

- MULTIPLE ROOTS REVERSE CUTHILL-McKEE MET PDFDocument10 pagesMULTIPLE ROOTS REVERSE CUTHILL-McKEE MET PDFvttrlcNo ratings yet

- Remap:: A Computer Code That TransfersDocument26 pagesRemap:: A Computer Code That TransfersvttrlcNo ratings yet

- Dtic Ada114540 PDFDocument151 pagesDtic Ada114540 PDFvttrlcNo ratings yet

- A146814 PDFDocument82 pagesA146814 PDFvttrlcNo ratings yet

- MP Avt 265 06 PDFDocument18 pagesMP Avt 265 06 PDFvttrlcNo ratings yet

- Explosion Damage Assessment - and Structural Inte'Lpity EvaluationDocument46 pagesExplosion Damage Assessment - and Structural Inte'Lpity EvaluationvttrlcNo ratings yet

- Dtic Ada066998Document274 pagesDtic Ada066998vttrlcNo ratings yet

- MP Avt 265 06 PDFDocument18 pagesMP Avt 265 06 PDFvttrlcNo ratings yet

- Excavation Induced Building Response by Laminate Beam MethodDocument6 pagesExcavation Induced Building Response by Laminate Beam MethodvttrlcNo ratings yet

- STR95029FU2Document7 pagesSTR95029FU2vttrlcNo ratings yet

- DemDocument1 pageDemvttrlcNo ratings yet

- Fahrman BP D 2016Document206 pagesFahrman BP D 2016vttrlcNo ratings yet

- Plastic-Damage Macro-Model For Non-Linear Masonry Structures Subjected To Cyclic or Dynamic LoadsDocument8 pagesPlastic-Damage Macro-Model For Non-Linear Masonry Structures Subjected To Cyclic or Dynamic LoadsvttrlcNo ratings yet

- Egu2016 11390Document1 pageEgu2016 11390vttrlcNo ratings yet

- Explosion Damage Assessment - and Structural Inte'Lpity EvaluationDocument46 pagesExplosion Damage Assessment - and Structural Inte'Lpity EvaluationvttrlcNo ratings yet

- Cur Map Grade 7 Q3Document3 pagesCur Map Grade 7 Q3Malicah MamaNo ratings yet

- GP1 Q1W1-2Document25 pagesGP1 Q1W1-2Denver CabiaoNo ratings yet

- School Admission Test - 2024-25 - InstructionsDocument5 pagesSchool Admission Test - 2024-25 - Instructionsgurulearning0303No ratings yet

- MEC420 Mybook Ch2 KineticsParticles STDVDocument126 pagesMEC420 Mybook Ch2 KineticsParticles STDVKamarudinNo ratings yet

- ClassMarker - Professional Online TestingDocument12 pagesClassMarker - Professional Online TestingDileep ElangovanNo ratings yet

- Honors Physics 2020-2021 SyllabusDocument2 pagesHonors Physics 2020-2021 Syllabusapi-538449408No ratings yet

- Dynamics11lecture PDFDocument89 pagesDynamics11lecture PDFEngra FithreeaNo ratings yet

- Projectiles and TrajectoryDocument24 pagesProjectiles and TrajectoryAlicia PerezNo ratings yet

- Thermodynamics of Astrology Prof DR A.P.RaoDocument2 pagesThermodynamics of Astrology Prof DR A.P.RaoRavi GoyalNo ratings yet

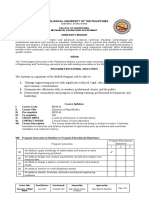

- Technological University of The Philippines: The Students As A Graduate of The BSME Program Will Be Able ToDocument4 pagesTechnological University of The Philippines: The Students As A Graduate of The BSME Program Will Be Able ToMarvin Sarmiento TalimonganNo ratings yet

- SLO BASED MCQS AND QUESTIONS - IX PhysicsDocument60 pagesSLO BASED MCQS AND QUESTIONS - IX PhysicsWaheedkhanNo ratings yet

- Waves 5 QP 2Document83 pagesWaves 5 QP 2Kirsten AntonioNo ratings yet

- Atom and Individual in the Age of NewtonDocument281 pagesAtom and Individual in the Age of NewtonJoão Francisco PinhoNo ratings yet

- First Summative Test in Science 5Document3 pagesFirst Summative Test in Science 5Cherry Amor Betita Madrona100% (1)

- Vedantu NCERT 11&12 Physics, Chemistry, Maths, and Biology playlistsDocument13 pagesVedantu NCERT 11&12 Physics, Chemistry, Maths, and Biology playlistsKshreeNo ratings yet

- Physic BS Syllabus Semester 2016 PassedDocument26 pagesPhysic BS Syllabus Semester 2016 PassedBial AhmedNo ratings yet

- Fluid Mechanics ActivityDocument7 pagesFluid Mechanics ActivitySanta mariaNo ratings yet

- Energy and TransformationDocument66 pagesEnergy and TransformationYves CaraangNo ratings yet

- Phy Motion and Time Wind, Storm and Cyclones Heat Electricity Light 7th WA SplitDocument36 pagesPhy Motion and Time Wind, Storm and Cyclones Heat Electricity Light 7th WA Splitnihal.sushma10No ratings yet

- BSC Syllabus PhysicsDocument9 pagesBSC Syllabus PhysicsMax TNo ratings yet

- 9 Class PhysicsDocument222 pages9 Class PhysicsDauren KamshybekovNo ratings yet

- Mechanics: Physics 151Document31 pagesMechanics: Physics 151AlaNo ratings yet

- Section 2: Velocity and MomentumDocument11 pagesSection 2: Velocity and MomentumaiaNo ratings yet

- Abm Q4W2 ModuleDocument50 pagesAbm Q4W2 ModuleJazer LeuterioNo ratings yet

- Physics Definition Form 4Document2 pagesPhysics Definition Form 4WillSeekerNo ratings yet

- Moving Man LabDocument3 pagesMoving Man LabMaite GoycoNo ratings yet

- CLASS-XI-PHYSICS-revision WorksheetDocument4 pagesCLASS-XI-PHYSICS-revision WorksheetRaniaNo ratings yet

- UJ General Physics Course SyllabusDocument6 pagesUJ General Physics Course Syllabusmamoun mufarraqNo ratings yet

- Dynamics of System of ParticlesDocument16 pagesDynamics of System of ParticlesHarishNo ratings yet