Professional Documents

Culture Documents

Dewatering 2

Uploaded by

Tousif AhmedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dewatering 2

Uploaded by

Tousif AhmedCopyright:

Available Formats

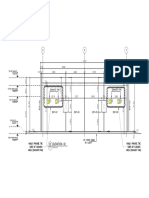

Pre-drilling will be carried out prior to installation of the well point, followed

by high-pressure water jetting, to flush out sand and create mini well.

Provide extra pump encase of breakdown may happen, it can be replaced

immediately and without interruption of dewatering.

A filter media of 3/16 inches (3 — 5 mm) screened black sand shall be inserted

around the 3/4 depth of the wells to act as barrier against fines and prevent

choking of well points.

Operate the dewatering system continuously 24 hours a day until drain and

structures have been constructed to fill material and until written by

authorization to cease dewatering.

All the header pipes will be connected to discharge pipe running over land to

the approved area by authority’s jurisdiction.

Dispose the water removed in a manner to avoid endangering public health,

environment, and neighboring property.

For safety purpose, provide safety barrier along the perimeter of the excavated

area to prevent fall hazards.

4. Safety

1. All works shall comply with the safety procedure or instruction as set out in project

safety plan and municipality rules and regulations.

2. Basic Personal Protective Equipment (PPE) shall be worn by all staff or laborers.

3. All operatives shall be inducted before entering the site.

4. Tool box talk shall be conducted before the activity.

5. Equipments and Tools

1. 1 no. of 6" Centrifugal Vacuum assisted pumps

2. 8' Header pipes approximately equal to 120 linear meters with fittings.

3. 3000-gallon water tank

4. 1000-gallon settlement tank

5. Rotary auger drilling machine

6. 6-meter pipes as well points 2' diameter

7. High pressure water jetting pump

8. 10" flexible hose for discharge

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Arabic Worksheet - Birds: International Indian School, Dammam Kindergarten SectionDocument1 pageArabic Worksheet - Birds: International Indian School, Dammam Kindergarten SectionTousif AhmedNo ratings yet

- Supplier ListDocument16 pagesSupplier ListTousif AhmedNo ratings yet

- Dewatering 1Document2 pagesDewatering 1Tousif AhmedNo ratings yet

- Sapmt Al Shalawi Site Office: Traffic Flow Plan Layout For Site AccessDocument1 pageSapmt Al Shalawi Site Office: Traffic Flow Plan Layout For Site AccessTousif AhmedNo ratings yet

- Structure Work - Method StatementDocument8 pagesStructure Work - Method StatementTousif AhmedNo ratings yet

- Structure Work - Method StatementDocument8 pagesStructure Work - Method StatementTousif AhmedNo ratings yet

- Hydraulic CalculationsDocument7 pagesHydraulic CalculationsTousif AhmedNo ratings yet

- Exhaust Fan Opening SizeDocument1 pageExhaust Fan Opening SizeTousif AhmedNo ratings yet

- Manual de Instalación Acometidas Ing.Document32 pagesManual de Instalación Acometidas Ing.Tousif AhmedNo ratings yet

- API Tank Inspection FormDocument4 pagesAPI Tank Inspection FormNavya Puttagunta50% (2)

- 2sc-Pco - Dual Solenoid Control ValveDocument34 pages2sc-Pco - Dual Solenoid Control ValveTousif AhmedNo ratings yet

- 2sc-Pco - Dual Solenoid Control ValveDocument3 pages2sc-Pco - Dual Solenoid Control Valveshan07011984No ratings yet

- Liquid Waste ManagementDocument12 pagesLiquid Waste ManagementTidus FarronNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)