Professional Documents

Culture Documents

Area of Reinforcement For Slabs & Footing

Uploaded by

loft diamondOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Area of Reinforcement For Slabs & Footing

Uploaded by

loft diamondCopyright:

Available Formats

102 STRUCTURAL CONCRETE BUILDING CODE (ACI 318M-11) AND COMMENTARY

CODE COMMENTARY

slab. Consideration should be given to strain demands on

reinforcement crossing joints of precast elements where most

of the restraint is likely to be relieved. Top and bottom rein-

forcement are both effective in controlling cracks. Control

strips during the construction period, which permit initial

shrinkage to occur without causing an increase in stresses, are

also effective in reducing cracks caused by restraint.

7.12.2 — Deformed reinforcement conforming to 3.5.3 R7.12.2 — The amounts specified for deformed bars and

used for shrinkage and temperature reinforcement welded wire reinforcement are empirical but have been used

shall be provided in accordance with the following: satisfactorily for many years. The area of reinforcement

7 given by 7.12.2.1 may be distributed near the top or bottom

7.12.2.1 — Area of shrinkage and temperature of the slab, or may be allocated between the two faces of the

reinforcement shall provide at least the following ratios slab as deemed appropriate for specific conditions. Splices

of reinforcement area to gross concrete area, but not and end anchorages of shrinkage and temperature reinforce-

less than 0.0014: ment are to be designed for the full specified yield strength

in accordance with 12.1, 12.15, 12.18, and 12.19.

(a) Slabs where Grade 280 or 350

deformed bars are used .................................0.0020

(b) Slabs where Grade 420

deformed bars or welded wire

reinforcement are used...................................0.0018

(c) Slabs where reinforcement

with yield stress exceeding 420 MPa

measured at a yield strain of

0.0018 × 420

0.35 percent is used ........................... -----------------------------------

fy

7.12.2.2 — Shrinkage and temperature reinforcement

shall be spaced not farther apart than five times the

slab thickness, nor farther apart than 450 mm.

7.12.2.3 — At all sections where required, reinforce-

ment to resist shrinkage and temperature stresses shall

develop fy in tension in accordance with Chapter 12.

7.12.3 — Prestressing steel conforming to 3.5.6 used R7.12.3 — Prestressed reinforcement requirements have

for shrinkage and temperature reinforcement shall be been selected to provide an effective force on the slab

provided in accordance with the following: approximately equal to the yield strength force for

nonprestressed shrinkage and temperature reinforcement. This

7.12.3.1 — Tendons shall be proportioned to provide amount of prestressing, 0.7 MPa on the gross concrete area,

a minimum average compressive stress of 0.7 MPa on has been successfully used on a large number of projects. In

gross concrete area using effective prestress, after monolithic beam-and-slab construction, a minimum of one

losses, in accordance with 18.6. shrinkage and temperature tendon is required between

beams, even if the beam tendons alone provide at least 0.7 MPa

7.12.3.2 — For monolithic cast-in-place post- average compression stress on the gross concrete area as

tensioned beam-and-slab construction, gross concrete defined in 7.12.3.2. Any size tendon is permissible as long as

area of a beam and tributary slab shall consist of the all other requirements of 7.12.3 are satisfied. Application of the

total beam area including the slab thickness and the provisions of 7.12.3.2 to monolithic cast-in-place post-

slab within half the clear distance to adjacent beam tensioned beam-and-slab construction is illustrated in

webs. It shall be permitted to include the effective force Fig. R7.12.3(a).

in beam tendons in the calculation of total prestress

force acting on gross concrete area. Where the spacing of slab tendons used for shrinkage and

temperature reinforcement exceeds 1.4 m, additional nonpre-

stressed reinforcement is required to extend from the slab

American Concrete Institute Copyrighted Material—www.concrete.org

You might also like

- Banglo IBS Setingkat RM155KDocument33 pagesBanglo IBS Setingkat RM155KZulKhalili67% (3)

- Development Length AASHTODocument4 pagesDevelopment Length AASHTOpicottNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- CE155 Estimating Lecture 3 PDFDocument71 pagesCE155 Estimating Lecture 3 PDFArly Tolentino100% (1)

- 123 - Concrete CoverDocument2 pages123 - Concrete CoverrealchicNo ratings yet

- Shrinkage and Temperature ReinforcementDocument5 pagesShrinkage and Temperature ReinforcementMustafaNo ratings yet

- Table 12.1 Response Reduction Factor, R, For Building SystemDocument7 pagesTable 12.1 Response Reduction Factor, R, For Building SystemsandeepuaeNo ratings yet

- Coltman Technical SpecificationDocument10 pagesColtman Technical SpecificationltslloydNo ratings yet

- WDF 2006 SeismicChangesASCE7IBC 0604Document3 pagesWDF 2006 SeismicChangesASCE7IBC 0604JuanGrandonGoddardNo ratings yet

- Appendix To Chapter 9 Untopped Precast DiaphragmsDocument4 pagesAppendix To Chapter 9 Untopped Precast DiaphragmsEnrique AbayNo ratings yet

- Code Feature Section Maximum Yield Stress in Reinforced Concrete FramesDocument3 pagesCode Feature Section Maximum Yield Stress in Reinforced Concrete FramesSameh LotfyNo ratings yet

- CRSI Manual To Design RC Diaphragms - Part3Document4 pagesCRSI Manual To Design RC Diaphragms - Part3Adam Michael GreenNo ratings yet

- Design and Detailing For Earthquake LoadsDocument5 pagesDesign and Detailing For Earthquake Loadsbridge cell dopNo ratings yet

- Design of Anchorages To Concrete: Comm. B3.) Design BasisDocument390 pagesDesign of Anchorages To Concrete: Comm. B3.) Design Basisedginton1comedorNo ratings yet

- Are Accidental-Eccentricity Load Cases Not Required When Using Semi-Rigid Diaphragms?Document1 pageAre Accidental-Eccentricity Load Cases Not Required When Using Semi-Rigid Diaphragms?Aafan ShahidNo ratings yet

- Ibc DeflectionDocument3 pagesIbc Deflectiongraziella njeimNo ratings yet

- Moment FrameDocument2 pagesMoment Framefreeloadtailieu2017100% (1)

- Blast Protection For Facade's Part 3Document7 pagesBlast Protection For Facade's Part 3psychotrackerNo ratings yet

- Ce 479 Reinforced Masonry Fall 2004Document9 pagesCe 479 Reinforced Masonry Fall 2004Reinaldo Andrei SalazarNo ratings yet

- Diaphragm Design GuideDocument29 pagesDiaphragm Design GuideJaher Wasim100% (1)

- Long Term CurvatureDocument21 pagesLong Term CurvatureArlandooNo ratings yet

- PROMATECT® H Double Layer Steel Stud PartitionsDocument14 pagesPROMATECT® H Double Layer Steel Stud PartitionsjeffNo ratings yet

- 2006 Beam Column Joint ICJ PDFDocument9 pages2006 Beam Column Joint ICJ PDFSanjeev MishraNo ratings yet

- 2006 Beam Column Joint ICJDocument9 pages2006 Beam Column Joint ICJvishalgoreNo ratings yet

- Composite Deck Technical Manual: 3WH-36 Hi FormDocument33 pagesComposite Deck Technical Manual: 3WH-36 Hi FormVinod Kumar ReddyNo ratings yet

- PTH Internal Partition PDFDocument17 pagesPTH Internal Partition PDFMartin KwanNo ratings yet

- CE Board Nov 2020 - RCD - Set 6 ColoredDocument3 pagesCE Board Nov 2020 - RCD - Set 6 ColoredDale MalazzabNo ratings yet

- Ohiodot - Summary of Deck Placement IssuesDocument3 pagesOhiodot - Summary of Deck Placement IssuesOlivier GauthierNo ratings yet

- AASHTO LRFD Bridge Design Specifications 7th Ed. 2014 CL 5.11.5.3Document3 pagesAASHTO LRFD Bridge Design Specifications 7th Ed. 2014 CL 5.11.5.3JohnNo ratings yet

- Innovative Ways To Reinforce Slabs On GroundDocument8 pagesInnovative Ways To Reinforce Slabs On GroundScooby DooNo ratings yet

- On Brick Construction: Technical NotesDocument10 pagesOn Brick Construction: Technical NotesKawrw DgedeaNo ratings yet

- RCD Project AsuncionDocument7 pagesRCD Project AsuncionFrancis AsuncionNo ratings yet

- Pages From ASME B31.1-2018Document2 pagesPages From ASME B31.1-2018Alexey BerkovskiyNo ratings yet

- Seismic Performance of Reinforced Concrete Slab-Column Connections With Thin Plate StirrupsDocument9 pagesSeismic Performance of Reinforced Concrete Slab-Column Connections With Thin Plate StirrupsangthiankongNo ratings yet

- The Reinforced Concrete Buildings Design: For Wind and Earthquake Loads ResilienceDocument62 pagesThe Reinforced Concrete Buildings Design: For Wind and Earthquake Loads Resiliencemido medoNo ratings yet

- BS5400 Part 4 Training Course - TE EpsomDocument19 pagesBS5400 Part 4 Training Course - TE EpsomjologscresenciaNo ratings yet

- Promat Wall SystemDocument12 pagesPromat Wall SystemBaljit SinghNo ratings yet

- Pipe Support As Per Asme 31.1Document1 pagePipe Support As Per Asme 31.1udaysaichand kollipara100% (1)

- Structural Design Highlights of ACI 318 19 Part 2 of 2 ChaptersDocument240 pagesStructural Design Highlights of ACI 318 19 Part 2 of 2 ChaptersanonymNo ratings yet

- ACI Tolerances On D and SpecifiedDocument1 pageACI Tolerances On D and Specifiedhz135874No ratings yet

- 130129-Journal Reprint-Bondy-Two-Way PT Slabs With Bonded TendonsDocument7 pages130129-Journal Reprint-Bondy-Two-Way PT Slabs With Bonded TendonsAnonymous ELujOV3No ratings yet

- Pages From UBC 1997 - Uniform Building Code 12Document1 pagePages From UBC 1997 - Uniform Building Code 12danieldumapitNo ratings yet

- Fema 450 2 Commentary Part 2Document110 pagesFema 450 2 Commentary Part 2Tariq AbdulsalamNo ratings yet

- Electrical Heating of Bars PDFDocument15 pagesElectrical Heating of Bars PDFsotos raptopoulosNo ratings yet

- 11.1 GENERAL: Building Code Requirements For Masonry Structures (ACI 530Document10 pages11.1 GENERAL: Building Code Requirements For Masonry Structures (ACI 530Ahmed Ben HmidaNo ratings yet

- Technical Column: Fretting (Inner Ply) PotentialDocument1 pageTechnical Column: Fretting (Inner Ply) PotentialRose Mary ChackoNo ratings yet

- Serviceability of Beams and One Way SlabsDocument20 pagesServiceability of Beams and One Way Slabsjust meNo ratings yet

- TES-T-111-19 R0 Design Criteria For Communication TowersDocument10 pagesTES-T-111-19 R0 Design Criteria For Communication TowersNauman Habib KhanNo ratings yet

- Two Mark QuestionsDocument9 pagesTwo Mark QuestionsNitin SureshNo ratings yet

- Compliance SheetDocument4 pagesCompliance Sheetمحمد عبدالرحيمNo ratings yet

- IRS Seismic Code 2017 PDFDocument39 pagesIRS Seismic Code 2017 PDFvigneshrajamanickamNo ratings yet

- Uniform Building Code - Div2Document25 pagesUniform Building Code - Div2minedataNo ratings yet

- March-2020 CDRDocument4 pagesMarch-2020 CDRShivam SharmaNo ratings yet

- RC 2Document5 pagesRC 2Adea SafraNo ratings yet

- Asme B31.4 - Allow Stress Sa - Factor FDocument1 pageAsme B31.4 - Allow Stress Sa - Factor Fjoaquin torrano veraNo ratings yet

- County of Los Angeles - Department of Public Works - Building and Safety Division - Concrete Shear Wall Correction ListDocument3 pagesCounty of Los Angeles - Department of Public Works - Building and Safety Division - Concrete Shear Wall Correction ListQuang Hoành LêNo ratings yet

- Chapter 26-Prestressed Concrete: 2602-ScopeDocument15 pagesChapter 26-Prestressed Concrete: 2602-ScopeSantiago CiroNo ratings yet

- EC2-Shear and TorsionDocument9 pagesEC2-Shear and TorsionDonald HamiltonNo ratings yet

- Indian Standard: High Strength Bolts Structures - Code of in Steel PracticeDocument15 pagesIndian Standard: High Strength Bolts Structures - Code of in Steel Practice4geniecivilNo ratings yet

- PDF - Change Ibc 2003 To Ibc 2006Document3 pagesPDF - Change Ibc 2003 To Ibc 2006MIKHA2014No ratings yet

- 5.14.1.4 Simple Spans Made ContinuousDocument2 pages5.14.1.4 Simple Spans Made ContinuousHermann PankowNo ratings yet

- Lecture 1 PDFDocument24 pagesLecture 1 PDFhira maqsood100% (1)

- Moisture and Air: Householder's GuideDocument32 pagesMoisture and Air: Householder's GuideMichael BodnarNo ratings yet

- Rebar GBDocument18 pagesRebar GBkevinrr98No ratings yet

- Concrete Nominal Cover For Reinforcement and Prestressing SteelDocument4 pagesConcrete Nominal Cover For Reinforcement and Prestressing SteelselinaNo ratings yet

- Cat 1300-2Document42 pagesCat 1300-2Sasan SasaNo ratings yet

- Benefits of Inverted T BeamsDocument2 pagesBenefits of Inverted T BeamsUhGuanHongNo ratings yet

- Proposed Studio: 11 Reno RD, Sandringham, Vic 3191Document11 pagesProposed Studio: 11 Reno RD, Sandringham, Vic 3191Engineer 1122No ratings yet

- CP Assignment 1Document57 pagesCP Assignment 1mrunmayee pandeNo ratings yet

- R.A 3Document54 pagesR.A 3veer developersNo ratings yet

- Concrete - Draft - Manual DrawingDocument3 pagesConcrete - Draft - Manual DrawingSiska LieNo ratings yet

- Panel Exterior # Panels Area 600 X 1800 - 900 X 1800 - 1200 X 1800 - TotalDocument8 pagesPanel Exterior # Panels Area 600 X 1800 - 900 X 1800 - 1200 X 1800 - TotalMariella PascualNo ratings yet

- 32 12 16 - Asphalt PavingDocument4 pages32 12 16 - Asphalt PavingSteve LezamaNo ratings yet

- Velox Slab FormworkDocument15 pagesVelox Slab FormworkahmadsawalmahNo ratings yet

- TC Rungta 02Document1 pageTC Rungta 02pmmahobaNo ratings yet

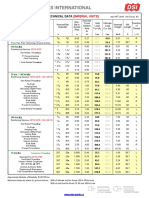

- Threadbars (Imperial Units) : Dywidag - Technical DataDocument1 pageThreadbars (Imperial Units) : Dywidag - Technical Dataradi_ashrafNo ratings yet

- Piles DesignDocument12 pagesPiles Designn_sasanNo ratings yet

- Evanmar O. Pinoliad BSCE-5B July 13, 2020 Bridge Engineering - Assignment #3 Engr. Marvin O. Madera Design of Abutment On Spread FootingDocument10 pagesEvanmar O. Pinoliad BSCE-5B July 13, 2020 Bridge Engineering - Assignment #3 Engr. Marvin O. Madera Design of Abutment On Spread FootingBUGTOK TVNo ratings yet

- Stainless Steel For Bolts UseDocument4 pagesStainless Steel For Bolts UseLEONARDONo ratings yet

- Lenocean Plant DetailsDocument2 pagesLenocean Plant DetailsYahyaNo ratings yet

- Round Cassette Catalogue - A4Document4 pagesRound Cassette Catalogue - A4Pongalfest byaravNo ratings yet

- Form WorksDocument13 pagesForm Worksmaryeonee12No ratings yet

- Table 2 - HVAC Design Check FiguresDocument3 pagesTable 2 - HVAC Design Check FiguresEsteban De Vargas CueterNo ratings yet

- Behaivour of Earthquake Resisting Masonry Building As Per Is 4326:1993Document40 pagesBehaivour of Earthquake Resisting Masonry Building As Per Is 4326:1993SaHil ShaRmaNo ratings yet

- Group No 18 Page BorderDocument12 pagesGroup No 18 Page BorderAmey KadulkarNo ratings yet

- Brosur Handal Heatpump NewDocument23 pagesBrosur Handal Heatpump Newewina90No ratings yet

- Quadwall: Product Data SheetDocument2 pagesQuadwall: Product Data SheetAndrei TeacăNo ratings yet

- Dca 7000t PerformancesDocument2 pagesDca 7000t PerformancesAlejandro CastilloNo ratings yet

- Mechanical Properties of MaterialsDocument4 pagesMechanical Properties of MaterialsBoykeNo ratings yet