Professional Documents

Culture Documents

B 575 Hydra Liner Installation Instructions Rev 2.26.2019

Uploaded by

ccorp0089Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B 575 Hydra Liner Installation Instructions Rev 2.26.2019

Uploaded by

ccorp0089Copyright:

Available Formats

INSTALLATION Hydra Liner

INSTRUCTIONS

READ INSTRUCTIONS COMPLETELY BEFORE BEGINNING INSTALLATION

HYDRA LINER RESERVOIR REINFORCEMENT CRITERIA

Depending on application and the existing reservoir wall thickness, a reinforcement may be suggested surrounding the 2 inch NPT

opening for the Hydra Liner. When required, a reinforcement ring 8 inches (203mm) minimum outside diameter and with an inside

diameter just large enough to fit over the 2 inch NPT coupling is suggested. The ring should have a minimum thickness of 0.250

inch (6mm) for steel or stainless steel reservoirs and 0.313 inch (8mm) for aluminum reservoirs. The reinforcement ring should be

welded to the 2 inch NPT coupling and to the reservoir wall using recommended welding practices.

Contact Arctic Fox Applications Engineering (800) 654-5382 or (763) 972-2758 before attempting to use the Hydra Liner in

reservoirs with a wall thickness less than 0.118 inch ( 3mm). If wall thickness is 0.118 inch (3mm) or thicker, then refer to the

following chart for installation of a reinforcement as suggested.

IT IS THE INSTALLERS RESPONSIBILITY TO ADEQUATELY REINFORCE THE RESERVOIR WALL

CONTACT ARCTIC FOX APPLICATIONS ENGINEERING FOR ASSISTANCE IF NECESSARY

(800) 654-5382 OR (763) 972-2758

Due to local fabrication and welding practices beyond our control, Arctic Fox, LLC will not be responsible for repair or replacement

of damaged reservoirs.

ON-OFF HIGHWAY

TANK

OR ON HIGHWAY

MATERIAL

OFF HIGHWAY

Steel

Reinforcement suggested if wall thickness is less Reinforcement suggested if wall thickness is less than

or

than 0.250 inch ( 6mm) 0.187 inch ( 5mm)

Stainless Steel

Reinforcement suggested if wall thickness is less Reinforcement suggested if wall thickness is less than

Aluminum

than 0.313 inch ( 8mm) 0.250 inch ( 6mm)

TYPICAL

TYPICAL

“A” DIMENSION “B” DIMENSION SURFACE AREA BTU/hr APPLICATION

PART NUMBER APPLICATION

NOMINAL NOMINAL NOMINAL NOMINAL(1) (AMBIENT AIR TEMP)

TO –20°F / -29°C (2)

TO –40°F / -40°C (2) **

H-4000-8 7 Inches 10 Inches 105 In² Water 4,200 Up to 20 US gallons Up to 8 US gallons

H-4000-8-STOR 178mm 254mm 8 dm² Oil 2,100 76 Liters 30 Liters

H-4000-12 11 Inches 14 Inches 180 In² Water 7,200 Up to 35 US Gallons Up to 14 US gallons

H-4000-12-STOR 280mm 356mm 12 dm² Oil 3,600 133 Liters 53 Liters

H-4000-16 15 Inches 18 Inches 250 In² Water 10,000 Up to 50 US Gallons Up to 19 US gallons

H-4000-16-STOR 381mm 457mm 16 dm² Oil 5,000 190 Liters 72 Liters

H-4000-20 19 Inches 22 Inches 315 In² Water 13,000 Up to 63 US Gallons Up to 25 US gallons

H-4000-20-STOR 483mm 559mm 20 dm² Oil 6,500 239 Liters 90 Liters

H-4000-24 23 Inches 26 Inches 385 In² Water 16,000 Up to 77 US Gallons Up to 30 US gallons

H-4000-24-STOR 584mm 660mm 24 dm² Oil 8,000 292 Liters 113 Liters

(1) Nominal BTU/hr based upon 180°F / 82°C Coolant flowing at 5 US Gallons / 19 Liters per minute.

Water—beginning temperature at +35°F / +2°C

Oil—ISO 32 Hydraulic Oil beginning temperature –20°F / -29°C.

(2) Actual temperature rise will be affected by factors such as coolant temperature and flow rate, specific heat capacity of fluids and air

movement around reservoir.

** Contact Arctic Fox Application Engineering for estimated temperature rise for your specific application.

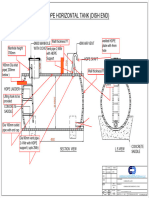

2” NPT H-4000-XX-STOR 2-1/2X12 UN

H-4000-XX Coolant Coolant

Ports Ports

ARCTIC FOX ARCTIC FOX

HYDRALINE HYDRALINE

“A” Dimension “A” Dimension

“B” Dimension “B” Dimension

Part No. B-575 2/26/2019 © 2019 Phillips & Temro Industries

H-4000 SERIES HYDRA LINER RESERVOIR MOUNTING CRITERIA

BEST ACCEPTABLE NOT ACCEPTABLE

FLUID LEVEL FLUID LEVEL FLUID LEVEL

1.50 Inches

(38mm)

Approximate

H-4000 SERIES HYDRA LINER COOLANT CONNECTIONS

Coolant Supply:

Obtain hot coolant from a pipe plug or other available opening on the engine coolant pressure side.

Route coolant via minimum 3/4” (19mm) ID hose to “IN” port on Hydra Liner.

Coolant Return:

Route coolant from Hydra Liner “OUT” port back to suction side of engine water pump via minimum

3/4” (19mm) ID hose.

Suggestion:

If uncertain as to which pipe plug ports on engine are coolant supply and return, locate hose

connections for cab heater and plumb into ports located in same cavities.

Contact Arctic Fox Applications Engineering in USA (800) 654-5382 or (763) 972-2758 for further

information on specific installations

WELD ON TANK ADAPTERS

PART NUMBER DESCRIPTION APPLICATION

A-3228HD Steel—Schedule 80 2” NPT Female Coupling Preferred for most installations on steel tanks

A-3228AHD Aluminum T-6061—Schedule 80 2” NPT Female Coupling Preferred for most installations on aluminum tanks

A-3228HD-STOR Steel—Combination 32 STOR & 1/2” NPT May be used to install either design Hydra Liner

V6216 Steel—Half Coupling—32 STOR Used when external tank clearance is limited

A-5878SSHD Stainless Steel—Half Coupling—32 STOR Used when external tank clearance is limited

IS43THCK Stainless Steel—2” NPT Half Coupling 300# Preferred for most installations on Stainless Steel Tanks

TWF-32 Steel—Flange 32 STOR Used when external clearance is limited

TWF-32N Steel—Flange 2” NPT Used when external clearance is limited

WARRANTY

The Phillips & Temro Industries and Arctic Fox warranty statements are located on the website at phillipsandtemro.com/terms

Part No. B-575 2/26/2019 © 2019 Phillips & Temro Industries

You might also like

- Hydraulic Fluid Warmers: Hydra Liner SeriesDocument2 pagesHydraulic Fluid Warmers: Hydra Liner Seriesfrancis_15inNo ratings yet

- Arctic-Fox Europe Datasheet Hydra Liner SeriesDocument2 pagesArctic-Fox Europe Datasheet Hydra Liner Seriesfrancis_15inNo ratings yet

- High-Pressure Ball Valves for 20,000 Psi ApplicationsDocument8 pagesHigh-Pressure Ball Valves for 20,000 Psi Applicationshisaj4uNo ratings yet

- Newco Cast Steel Valves Tech DataDocument86 pagesNewco Cast Steel Valves Tech Dataeduardo goveaNo ratings yet

- 7800 Spec PDFDocument2 pages7800 Spec PDFxnbsxNo ratings yet

- HL160M Dri-Prime Pump: Features SpecificationsDocument2 pagesHL160M Dri-Prime Pump: Features SpecificationsMohamed Badian TraoreNo ratings yet

- DTH Hammers and Bits: Quarry - Construction - MiningDocument2 pagesDTH Hammers and Bits: Quarry - Construction - Miningds5aqdnaver.comNo ratings yet

- 3ME - Technical CatalogueDocument24 pages3ME - Technical CatalogueRamonNo ratings yet

- Ball Valves: 3-Way SeriesDocument8 pagesBall Valves: 3-Way SerieslorenzoNo ratings yet

- A Mefi MC001 E1Document16 pagesA Mefi MC001 E1aptureincNo ratings yet

- Calculation Sheet For Tank - API 620 12th EdDocument48 pagesCalculation Sheet For Tank - API 620 12th EdHamid Mansouri71% (17)

- API 620 DesignDocument27 pagesAPI 620 Designrsubramani100% (2)

- ShinmaywaDocument20 pagesShinmaywaYuswadi 3vkNo ratings yet

- Venturi Gas ScrubberDocument3 pagesVenturi Gas ScrubberKevin VargasNo ratings yet

- Venturi Gas Scrubber WorkingDocument3 pagesVenturi Gas Scrubber WorkingDonNo ratings yet

- CRS-V: Versatile sonic rig for sampling and drillingDocument4 pagesCRS-V: Versatile sonic rig for sampling and drillingAnonymous nZcViIP0hNo ratings yet

- Catalogue Seal Oil CoolerDocument28 pagesCatalogue Seal Oil CoolerSharad KokateNo ratings yet

- HD 242 Flexible HoseDocument4 pagesHD 242 Flexible HoseSelvakumar EkambaramNo ratings yet

- 4000 m3 Storage Tank - Data SheetDocument3 pages4000 m3 Storage Tank - Data SheetSakthi Vel100% (1)

- ACAF Fire Fighting BrochureDocument4 pagesACAF Fire Fighting Brochure1029384765qazwsxNo ratings yet

- 40RBX - Catalog EvaporadorDocument12 pages40RBX - Catalog EvaporadorLuis RojasNo ratings yet

- FlexiROC T20R Brochure English WEB Tcm835-3507342Document5 pagesFlexiROC T20R Brochure English WEB Tcm835-3507342Cristian Andres Araya CisternasNo ratings yet

- Datasheet TankDocument1 pageDatasheet TankAnonymous lQiANQusxiNo ratings yet

- Bermad Combination Air Valve C70 - Product-Page - English - 9-2018Document4 pagesBermad Combination Air Valve C70 - Product-Page - English - 9-2018M MNo ratings yet

- O Rings CatalogueDocument87 pagesO Rings CatalogueVictor A. Claure ManzoniNo ratings yet

- Top Guide Control ValveDocument32 pagesTop Guide Control Valveachari_swapnilNo ratings yet

- CD300M Dri-Prime Pump: Features SpecificationsDocument2 pagesCD300M Dri-Prime Pump: Features SpecificationsMohamed Badian TraoreNo ratings yet

- Sulfuric Acid Tank - APIDocument4 pagesSulfuric Acid Tank - APISakthi VelNo ratings yet

- Series Description: Universal Product Line: Steel Externals - Jacketed PumpsDocument9 pagesSeries Description: Universal Product Line: Steel Externals - Jacketed PumpsAnonymous uCYIu1No ratings yet

- 2ME - Technical CatalogueDocument30 pages2ME - Technical Catalogueluis felipe rojas huamaniNo ratings yet

- Data Sheet: 25 Frame Plunger PumpsDocument4 pagesData Sheet: 25 Frame Plunger PumpsGioNo ratings yet

- 2520 - H Cat PumpDocument5 pages2520 - H Cat PumpRicardo RosasNo ratings yet

- Hisense Corporation: AS-09UR4SVNVG1 AS-12UR4SVNVG1 As-12Ur4Svgvg As-18Ur4Stvvg As-24Ur4SqjvgDocument34 pagesHisense Corporation: AS-09UR4SVNVG1 AS-12UR4SVNVG1 As-12Ur4Svgvg As-18Ur4Stvvg As-24Ur4SqjvgRajesh SoniNo ratings yet

- Vacuum CondensersDocument12 pagesVacuum CondensersErick EspinosaNo ratings yet

- High Efficient Industrial WashersDocument2 pagesHigh Efficient Industrial WashersfebryNo ratings yet

- 1800DIA. HORIZONTAL TANK - ModelDocument1 page1800DIA. HORIZONTAL TANK - Modelsavanth jayaramNo ratings yet

- Flexitallic Spiralwound CgiDocument1 pageFlexitallic Spiralwound CgiDiego Martínez FernándezNo ratings yet

- Jamesbury 7000 Series Ball ValveDocument34 pagesJamesbury 7000 Series Ball ValveHamed FarajpourNo ratings yet

- Forum Fluid End Pump PartsDocument18 pagesForum Fluid End Pump PartsriskvisionNo ratings yet

- JC Gasket CranfoilDocument2 pagesJC Gasket CranfoilMachineryengNo ratings yet

- Terradrain Soil Strip: DrainDocument8 pagesTerradrain Soil Strip: DrainSky MoonNo ratings yet

- Trencher - Bigfoot Heavy Duty - 2" Pitch: New Barrel & Spoil AugerDocument2 pagesTrencher - Bigfoot Heavy Duty - 2" Pitch: New Barrel & Spoil Augerilyas wahidNo ratings yet

- Portfolio 2.4 DuctingDocument69 pagesPortfolio 2.4 Ductingjitendrashukla10836No ratings yet

- 85,000 Barrels Every Day!: 8L-912Y Series Standard Product SpecificationsDocument6 pages85,000 Barrels Every Day!: 8L-912Y Series Standard Product SpecificationsManuel GimenezNo ratings yet

- Coppus Catalog 2019Document24 pagesCoppus Catalog 2019ananthkhNo ratings yet

- Product Brochure: Manufacturers and Stockists of High Pressure Pipeline and Drilling EquipmentDocument30 pagesProduct Brochure: Manufacturers and Stockists of High Pressure Pipeline and Drilling EquipmentSaravanan NatesanNo ratings yet

- 7203-6311-MDC-030KL TankDocument34 pages7203-6311-MDC-030KL TankDarshJhaNo ratings yet

- BWT 9000 SCDocument1 pageBWT 9000 SCMehdi AcilNo ratings yet

- Atmospheric Foam TankDocument5 pagesAtmospheric Foam TankAndro SidhomNo ratings yet

- FIBA's Finnco Vaporizers Provide Safety, Economy and EfficiencyDocument3 pagesFIBA's Finnco Vaporizers Provide Safety, Economy and EfficiencysalvgranNo ratings yet

- 17E10.5 Na enDocument2 pages17E10.5 Na enRasoolKhadibiNo ratings yet

- 2014 10 09 13 55 Caldonhydro-TransducersDocument2 pages2014 10 09 13 55 Caldonhydro-TransducersmukramaliNo ratings yet

- COPPUS Portable VentilatorsDocument24 pagesCOPPUS Portable Ventilatorsebrahimbatul2No ratings yet

- COPPUS-Catalog-2020-(Digital)Document24 pagesCOPPUS-Catalog-2020-(Digital)elliotmoralesNo ratings yet

- Series LFII Residential Flush Pendent Sprinklers 4.2 K-FactorDocument8 pagesSeries LFII Residential Flush Pendent Sprinklers 4.2 K-FactorAchraf BoudayaNo ratings yet

- High Pressure FiltersDocument108 pagesHigh Pressure FiltersKristine ReyesNo ratings yet

- Caterpillar Fluid Systems SRL: Hydraulic Hose & CouplingsDocument28 pagesCaterpillar Fluid Systems SRL: Hydraulic Hose & CouplingsNelson PeraltaNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- B 463 Hot Fox Adapter Kits Rev 2.26.2019Document4 pagesB 463 Hot Fox Adapter Kits Rev 2.26.2019ccorp0089No ratings yet

- 1/2" NPT Thread: Special Characteristics Tube Elbow W/Pipe FTG BDocument1 page1/2" NPT Thread: Special Characteristics Tube Elbow W/Pipe FTG Bccorp0089No ratings yet

- Zerust Approval Letter Liquids 10-10-2017Document3 pagesZerust Approval Letter Liquids 10-10-2017ccorp0089No ratings yet

- Zerust AxxaCoat90 TechnicalDataSheet RevD2Document3 pagesZerust AxxaCoat90 TechnicalDataSheet RevD2ccorp0089No ratings yet

- b521 bh3100 Series Battery Heaters Rev 0714Document2 pagesb521 bh3100 Series Battery Heaters Rev 0714ccorp0089No ratings yet

- Roughness Numbers micrometers (μm) microinches (μin) ISO Roughness Number Nominal Value of RaDocument4 pagesRoughness Numbers micrometers (μm) microinches (μin) ISO Roughness Number Nominal Value of Raccorp0089No ratings yet

- Design Clearances For Standard Wrenches and SocketsDocument2 pagesDesign Clearances For Standard Wrenches and SocketsAnonymous aOXD9Juqd100% (3)

- Tap Drill SizesDocument2 pagesTap Drill SizeswhitehawkNo ratings yet

- BH 3110Document1 pageBH 3110ccorp0089No ratings yet

- Tap Drill ChartDocument1 pageTap Drill Chartccorp0089No ratings yet

- Eriks Oring ChartDocument1 pageEriks Oring Chartccorp0089No ratings yet

- Surface FinishesDocument2 pagesSurface Finishesccorp0089No ratings yet

- Electrical Wire Sizes AWG To Mm2Document1 pageElectrical Wire Sizes AWG To Mm2ccorp0089No ratings yet

- Expanded Metal (AMICO)Document12 pagesExpanded Metal (AMICO)ccorp0089No ratings yet

- Electrical Wire Sizes AWG Diameter Cross-Sectional Area Mils Inches MM Cmils MMDocument1 pageElectrical Wire Sizes AWG Diameter Cross-Sectional Area Mils Inches MM Cmils MMccorp0089No ratings yet

- Regular Drill Bits 118 Inserted Spade Drills 135 Chamfer Tools (Used As Drills) 90Document1 pageRegular Drill Bits 118 Inserted Spade Drills 135 Chamfer Tools (Used As Drills) 90ccorp0089No ratings yet

- External Mounted Magnetostrictive Level TransmitterDocument6 pagesExternal Mounted Magnetostrictive Level Transmitterjuan vazquezNo ratings yet

- Electronics Foundations - Basic CircuitsDocument20 pagesElectronics Foundations - Basic Circuitsccorp0089No ratings yet

- Nucor Fastener Shear Strength TDSDocument2 pagesNucor Fastener Shear Strength TDSmnaziria6612No ratings yet

- Chapter 3. Bolted Connection 3.1 Introductory ConceptsDocument15 pagesChapter 3. Bolted Connection 3.1 Introductory ConceptsJIBEESH01No ratings yet

- Power Triangle DefinitionsDocument2 pagesPower Triangle Definitionsccorp00890% (1)

- EMD Catalog 2013 02 Wire ConnectorsDocument22 pagesEMD Catalog 2013 02 Wire ConnectorsJose Alejandro Mansutti GNo ratings yet

- Are You Properly Specifying MaterialsDocument7 pagesAre You Properly Specifying Materialsrslama_lecturesNo ratings yet

- KM26 Operation and Installation ManualDocument36 pagesKM26 Operation and Installation Manualccorp0089No ratings yet

- Barniz Aislante 1601-1602-1603Document2 pagesBarniz Aislante 1601-1602-1603ralvaradoarayaNo ratings yet

- EMD Catalog 2013 01 Vinyl Electrical TapesDocument56 pagesEMD Catalog 2013 01 Vinyl Electrical Tapesherysyam1980No ratings yet

- American Fastener TablesDocument7 pagesAmerican Fastener TablesAhmed BdairNo ratings yet

- FB Sealant CP 25WB Plus PDS Cg1Document2 pagesFB Sealant CP 25WB Plus PDS Cg1Miguel SordoNo ratings yet

- Catalog, Aerosols Coating (2013)Document6 pagesCatalog, Aerosols Coating (2013)ccorp0089No ratings yet

- JWS-400 Triplex Well Service Pump: SpecificationsDocument2 pagesJWS-400 Triplex Well Service Pump: SpecificationsgfwtNo ratings yet

- Power Inverter: Model BI800T and BI800FDocument18 pagesPower Inverter: Model BI800T and BI800FG NAIRNo ratings yet

- Cutting Edge HACO CNC MachinesDocument9 pagesCutting Edge HACO CNC MachinesJaja SumarjaNo ratings yet

- CBM Plus DoD Guidebook (May 08)Document116 pagesCBM Plus DoD Guidebook (May 08)Iwan VitryawanNo ratings yet

- The VLSI Ruby II Advanced Communication ProcessorDocument1 pageThe VLSI Ruby II Advanced Communication ProcessorvlkumashankardeekshithNo ratings yet

- Digital B2B Marketing Strategies of Kuehne + NagelDocument5 pagesDigital B2B Marketing Strategies of Kuehne + NagelRahul GuptaNo ratings yet

- Low Cost Arduino Based Smart Energy Monitoring System Using Internet of ThingsDocument9 pagesLow Cost Arduino Based Smart Energy Monitoring System Using Internet of ThingsabdullahNo ratings yet

- ProfileDocument2 pagesProfileJunaid AsrarNo ratings yet

- Introduction to Process Equipment Failure Rate DataDocument6 pagesIntroduction to Process Equipment Failure Rate Datadaimon_pNo ratings yet

- Description Features: LTC3861 Dual, Multiphase Step-Down Voltage Mode DC/DC Controller With Accurate Current SharingDocument36 pagesDescription Features: LTC3861 Dual, Multiphase Step-Down Voltage Mode DC/DC Controller With Accurate Current SharingrotenolabsNo ratings yet

- TutorialDocument91 pagesTutorialmongi6limNo ratings yet

- DBB1104-Unit 15 Recent Trends in MarketingDocument16 pagesDBB1104-Unit 15 Recent Trends in Marketingamarnath15416277No ratings yet

- F Series - CatalogDocument2 pagesF Series - CatalogJeghiNo ratings yet

- Case Study 1Document3 pagesCase Study 1ramtwinsmeNo ratings yet

- SkyAir R410 Inv Cooling EDMT281537 PDFDocument524 pagesSkyAir R410 Inv Cooling EDMT281537 PDFAnh Thu Mai100% (2)

- Broshure EE-120A 500V ColorDocument4 pagesBroshure EE-120A 500V ColorITQAN TASYRIQANNo ratings yet

- OM Chapter 03 DR B DayalDocument44 pagesOM Chapter 03 DR B DayalMebre WelduNo ratings yet

- Project Report: Topic:-Portable Mobile ChargerDocument15 pagesProject Report: Topic:-Portable Mobile ChargerrohitkgangotiaNo ratings yet

- ERAC Inst EnglishDocument26 pagesERAC Inst EnglishlilWolfy100% (1)

- Meco Ah AP FTL Seal TechnologyDocument2 pagesMeco Ah AP FTL Seal Technologycristobal_tl2277No ratings yet

- Curtain WallDocument36 pagesCurtain Wallhayat49000100% (1)

- Fuse Box Diagram Fiat Strada (2007-2017) PDFDocument5 pagesFuse Box Diagram Fiat Strada (2007-2017) PDFAlbert BriceñoNo ratings yet

- 355 FT0 Santosh Shetty ResumeDocument5 pages355 FT0 Santosh Shetty ResumeIndresh Pratap SinghNo ratings yet

- Google Map - DartDocument9 pagesGoogle Map - Dartİlter Engin KIZILGÜNNo ratings yet

- AMP - Triggers PDFDocument8 pagesAMP - Triggers PDFTồChủTịchNo ratings yet

- QSG0009 PS Selection Guide For AC BackupDocument8 pagesQSG0009 PS Selection Guide For AC BackupRoberto MontoyaNo ratings yet

- ANSI-IEEE Device Numbers PDFDocument12 pagesANSI-IEEE Device Numbers PDFMario SamudioNo ratings yet

- Tnms SNMP Nbi - Operation GuideDocument90 pagesTnms SNMP Nbi - Operation GuideAdrian FlorensaNo ratings yet

- ABB Spec MCB SH200Document2 pagesABB Spec MCB SH200Jirayu KhumwanichNo ratings yet

- Lebw4982 02Document52 pagesLebw4982 02alexanderponomarevNo ratings yet