Professional Documents

Culture Documents

What Is Recirculation & Separation - Kelair Pump Clinic

Uploaded by

rosliyuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

What Is Recirculation & Separation - Kelair Pump Clinic

Uploaded by

rosliyuCopyright:

Available Formats

Kelair Pumps Australia Pty Ltd ABN 28 001 308 381 215 Walters Road Arndell Park NSW

2148

Ph: 1300 789 466 Fax: 02 9678 9455 Email: kelair@kelairpumps.com.au www.kelairpumps.com.au

QLD Fax: 07 3808 8758 VIC Fax: 03 9569 7866 TAS Fax: 03 6331 9102 WA Fax: 08 9248 2255

PUMPS STEAM TURBINES BUILDING & FIRE WASTEWATER SERVICE

PUMP CLINIC 3

What is Recirculation and Separation?

There is a small flow from impeller discharge to suction through the wearing rings and

any hydraulic balance device present. This takes place at all capacities but does not

usually contribute to raising the liquid temperature very much unless operation is near

shut-off.

When the capacity has been reduced by throttling (or as a result of an increase in

system head), a secondary flow called recirculation begins. Recirculation is a flow

reversal at the suction and/or at the discharge tips of the impeller vanes. All impellers

have a critical capacity at which recirculation occurs. The capacities at which suction

and discharge recirculation begin can be controlled to some extent by design, but

recirculation cannot be eliminated.

Suction recirculation is the reversal of flow at the impeller eye. A portion of the flow is

directed out of the eye at the eye diameter, as shown in Figure 1 Page 1 and travels

upstream with a rotational velocity approaching the peripheral velocity of the diameter.

A rotating annulus of liquid is produced upstream from the impeller inlet and through

the core of this annulus passes an axial flow corresponding to the output capacity of

the pump. The high shear rate between the rotating annulus and the axial flow through

the core produces vortices that form and collapse, producing noise and cavitation in the

suction of the pump.

Discharge recirculation is the reversal of flow at the discharge tips of the impeller

vanes, as shown in Figure 2 Page 1. The shear rate between the inward and outward

relative velocities produces vortices that cavitate and usually attack the pressure side

of the vanes.

Pump Clinic 3 What is Recirculation & Separation 24/05/06 Page 1 of 4

Kelair Pumps Australia Pty Ltd ABN 28 001 308 381 215 Walters Road Arndell Park NSW 2148

Ph: 1300 789 466 Fax: 02 9678 9455 Email: kelair@kelairpumps.com.au www.kelairpumps.com.au

QLD Fax: 07 3808 8758 VIC Fax: 03 9569 7866 TAS Fax: 03 6331 9102 WA Fax: 08 9248 2255

PUMPS STEAM TURBINES BUILDING & FIRE WASTEWATER SERVICE

The capacity at which suction recirculation occurs is directly related to the design

suction-specific speed S of the pump. The higher the suction-specific speed, the closer

will be the beginning of recirculation to the capacity at best efficiency. Figure 3 Page 2

shows the relation between the suction-specific speed and suction recirculation for

pumps up to 2500 (1530) specific speed and Figure 4 Page 2 shows the same relation

for pumps up to 10,000 (6123) specific speed.

For water pumps, the minimum operating flows can be as low as 50% of the suction

recirculation values shown for continuous operation and as low as 25% for intermittent

operation. For hydrocarbons, the minimum operating flows can be as low as 60% of

the suction recirculation values shown for continuous operation and as low as 25% for

intermittent operation.

Figure 3: Suction-specific speed S at best efficiency flow, single suction or one

side of double suction (to obtain S in SI units, multiply by 0.6123)

Figure 4: Suction-specific speed S at best efficiency flow, single suction or one

side of double suction (to obtain S in SI units, multiply by 0.6123)

Pump Clinic 3 What is Recirculation & Separation 24/05/06 Page 2 of 4

Kelair Pumps Australia Pty Ltd ABN 28 001 308 381 215 Walters Road Arndell Park NSW 2148

Ph: 1300 789 466 Fax: 02 9678 9455 Email: kelair@kelairpumps.com.au www.kelairpumps.com.au

QLD Fax: 07 3808 8758 VIC Fax: 03 9569 7866 TAS Fax: 03 6331 9102 WA Fax: 08 9248 2255

PUMPS STEAM TURBINES BUILDING & FIRE WASTEWATER SERVICE

The high turbulence produced by recirculation and separation accounts for most of the

high power consumed at shut-off. This may vary from about 30% of the normal power

for pumps of very low-specific speed to nearly three times the normal power for

propeller pumps. Separation and, possibly, cavitation may take place on the casing

tongue or diffusion vanes at very low capacities. Operation near shut-off causes not

only excessive heating, but also vibration and cavitation, which may cause serious

mechanical damage.

Diagnosis of Suction and Discharge Recirculation

Cause and Effect: Recirculation occurs at reduced flows and is the reversal of a

portion of the flow-back through the impeller. Recirculation at the inlet of the impeller is

known as suction recirculation. Recirculation at the outlet of the impeller is discharge

recirculation. Suction and discharge recirculation can be very damaging to pump

operation and should be avoided for continuous operation.

Diagnosis From Pump Operation: Suction recirculation will produce a loud crackling

noise in and around the suction of the pump. Recirculation noise is of greater intensity

than the noise from low NPSH cavitation and is a random knocking sound. Discharge

recirculation will produce the same characteristic sound as suction recirculation except

that the highest intensity is in the discharge volute or diffuser.

Diagnosis From Visual Examination: Suction and discharge recirculation produce

cavitation damage to the pressure side of the impeller vanes. Viewed from the suction

of the impeller, the pressure side would be the invisible, or underside, of the vane.

Figure 5 Page 3 shows how a mirror can be used to examine the pressure side of the

inlet vane for cavitation damage from suction recirculation. Damage to the pressure

side of the vane from discharge recirculation is shown in Figure 6 Page 3. Guide

vanes in the suction may show cavitation damage from impingement of the back-flow

from the impeller eye during suction recirculation. Similarly, the tongue or diffuser

vanes may show cavitation damage on the impeller side from operation in discharge

recirculation.

Figure 5: Examining the pressure side of the inlet vanes for Figure 6: Damage to the pressure side

suction recirculation. of the vane from discharge recirculation.

Pump Clinic 3 What is Recirculation & Separation 24/05/06 Page 3 of 4

Kelair Pumps Australia Pty Ltd ABN 28 001 308 381 215 Walters Road Arndell Park NSW 2148

Ph: 1300 789 466 Fax: 02 9678 9455 Email: kelair@kelairpumps.com.au www.kelairpumps.com.au

QLD Fax: 07 3808 8758 VIC Fax: 03 9569 7866 TAS Fax: 03 6331 9102 WA Fax: 08 9248 2255

PUMPS STEAM TURBINES BUILDING & FIRE WASTEWATER SERVICE

Corrective Procedures: Every impeller design has specific recirculation

characteristics. These characteristics are inherent in the design and cannot be

changed without modifying the design. An analysis of the symptoms associated with

recirculation should consider the following as possible corrective procedures.

1. Increase the output capacity of the pump.

2. Install a bypass between the discharge and the suction of the pump.

3. Bleed air into the suction of the pump to reduce the intensity of the noise,

vibration and cavitation damage.

4. Substitute a harder material for the impeller to reduce the rate of cavitation

damage.

Pump Clinic 3 What is Recirculation & Separation 24/05/06 Page 4 of 4

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Pipe Vibration Testing and AnalysisDocument34 pagesPipe Vibration Testing and AnalysisenjoygurujiNo ratings yet

- Wabco GuideDocument16 pagesWabco GuideMohd FairusNo ratings yet

- Motor TestingDocument26 pagesMotor TestingGas Gas DucatiNo ratings yet

- Unit 1 Vehicle Components - BackDocument20 pagesUnit 1 Vehicle Components - BackCarlos CabreraNo ratings yet

- Thrust in Vertical Turbine PumpsDocument5 pagesThrust in Vertical Turbine PumpsKamal Arab100% (1)

- Lab-Java Programming Intro IDocument83 pagesLab-Java Programming Intro IHeavenlyPlanetEarth80% (5)

- Difference Between Forging and CastingDocument2 pagesDifference Between Forging and CastingMOHAMMAD ALINo ratings yet

- Dresser Rand - TMTTV - Trip & Throttle ValveDocument2 pagesDresser Rand - TMTTV - Trip & Throttle Valverosliyu50% (2)

- NPSH and Pump Cavitation - E Shashi Menon - ScienceDirectDocument17 pagesNPSH and Pump Cavitation - E Shashi Menon - ScienceDirectrosliyu100% (1)

- JSA Basket TransferDocument3 pagesJSA Basket TransferCristina Rican100% (1)

- Application of Neutralization TitrationsDocument21 pagesApplication of Neutralization TitrationsAsuncion Thea50% (2)

- Air Lift PumpDocument4 pagesAir Lift PumpFoxty67% (3)

- NPSHR Changes With Impeller Diameter - JM CampbellDocument6 pagesNPSHR Changes With Impeller Diameter - JM CampbellrosliyuNo ratings yet

- Cavitation in PumpDocument11 pagesCavitation in Pumpshafeeqm3086No ratings yet

- A Definition and An Introduction To Net Positive Suction Head - NPSHDocument6 pagesA Definition and An Introduction To Net Positive Suction Head - NPSHbekaen bekaenNo ratings yet

- Troubleshooting Piping Vibration - Pipeline & Gas TechnoDocument3 pagesTroubleshooting Piping Vibration - Pipeline & Gas TechnorosliyuNo ratings yet

- Troubleshooting Piping Vibration - Pipeline & Gas TechnoDocument3 pagesTroubleshooting Piping Vibration - Pipeline & Gas TechnorosliyuNo ratings yet

- AESSEAL DualDam DGS - Catalog BrochureDocument12 pagesAESSEAL DualDam DGS - Catalog BrochurerosliyuNo ratings yet

- Application of Dry Gas SealDocument3 pagesApplication of Dry Gas Sealotokar2No ratings yet

- Electrical Energy Equipment: Pumps and Pumping SystemsDocument19 pagesElectrical Energy Equipment: Pumps and Pumping SystemsvsajvNo ratings yet

- Surtec 680: Protection UpgradedDocument7 pagesSurtec 680: Protection Upgradedyudhien4443No ratings yet

- AXE400P User Manual With Centos6.0 Dahdi V2.0 D130603 enDocument12 pagesAXE400P User Manual With Centos6.0 Dahdi V2.0 D130603 enCartimex S.A.No ratings yet

- Project Management Dashboard TemplateDocument10 pagesProject Management Dashboard Templateindra prasetyaNo ratings yet

- Security For VPNs With IPsec Configuration Guide - 15.2MTDocument166 pagesSecurity For VPNs With IPsec Configuration Guide - 15.2MTAnonymous fIXhrYSmNo ratings yet

- Microsoft SQL Server 2005 Express Edition &Document95 pagesMicrosoft SQL Server 2005 Express Edition &lgmep350No ratings yet

- Erpi Admin 11123510Document416 pagesErpi Admin 11123510prakash9565No ratings yet

- 03 Vetotouch Europa - Group 170821Document2 pages03 Vetotouch Europa - Group 170821HalaNo ratings yet

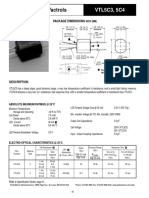

- Low Cost Axial Vactrols: VTL5C3, 5C4Document2 pagesLow Cost Axial Vactrols: VTL5C3, 5C4sillyNo ratings yet

- Saskatchewan Drivers HandbookDocument175 pagesSaskatchewan Drivers HandbookdrivershandbooksNo ratings yet

- ADPDocument165 pagesADPmohhizbarNo ratings yet

- Lennox - G40UH - Service ManualDocument46 pagesLennox - G40UH - Service ManualKen Christoffersen0% (1)

- Google Gender Pay LawsuitDocument31 pagesGoogle Gender Pay LawsuitUSA TODAYNo ratings yet

- Repair ListDocument36 pagesRepair ListRizky SkrillexNo ratings yet

- IR2200 - IR2800 - IR3300 Error CodeDocument7 pagesIR2200 - IR2800 - IR3300 Error CodeTiger DineshNo ratings yet

- VAV CablingDocument2 pagesVAV Cablingsripriya01No ratings yet

- Parts Catalog: MF9280Cdn/9220Cdn/9170/ 9150/9130/8450 SeriesDocument94 pagesParts Catalog: MF9280Cdn/9220Cdn/9170/ 9150/9130/8450 SeriesAdorjan Sandor ZoltanNo ratings yet

- Liquid Ring Vacuum Pump: LPH 55312, LPH 55316, LPH 55320Document12 pagesLiquid Ring Vacuum Pump: LPH 55312, LPH 55316, LPH 55320Edu CordonNo ratings yet

- Maxwell v16 2DDocument10 pagesMaxwell v16 2Ddesi_parisNo ratings yet

- Aluminium Aluminum 6070 Alloy (UNS A96070)Document2 pagesAluminium Aluminum 6070 Alloy (UNS A96070)HARIPRASATH PNo ratings yet

- Road Geometry & Transition CurveDocument8 pagesRoad Geometry & Transition CurveNann Kay Thari KyawNo ratings yet

- IRFP240Document8 pagesIRFP240Hugo JimenezNo ratings yet

- Delphi Heavy Duty Emissions Brochure 2011 2012Document100 pagesDelphi Heavy Duty Emissions Brochure 2011 2012Younwoo NamNo ratings yet