Professional Documents

Culture Documents

Annexure 2

Annexure 2

Uploaded by

Istaqrar Mehdi BaqriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Annexure 2

Annexure 2

Uploaded by

Istaqrar Mehdi BaqriCopyright:

Available Formats

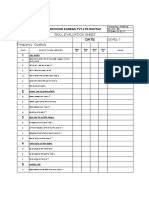

ANNEXURE – 2

( PERMIT TO WORK AND CHECKLISTS )

WORK AT HEIGHT PERMIT

( ऊंचाई पर काम का परगमट )

Area (क्षेत्र) : Exact Location (स्थान) : Permit No:

Permit required from Date: _______________ Time : _______ To Date: __________________ Time:_______

परमिट की आवश्यकता का मिनाांक से: सिय: मिनाां क तक: सिय:

Name of the Contractor/Agency: ________________________________________

ठे केिार/एजेंसी का नाि:

SL. Risk Control measures to prevent Fall of Person and Material Not

Done

NO. व्यक्ति तथा सामग्री के गिरने से रोकने के गिए जोक्तिम गनयंत्रण के उपाय

Required

Whether Safe access to workplace is provided

1. क्या कायय स्थल पर सुरमक्षत पहुँच प्रिान की गई है

Whether the edge protection provided adequate

2.

क्या मकनारे की सुरक्षा पयायप्त प्रिान की गई है

Is the work area away from the vicinity of moving equipment and vehicle.

3.

क्या कायय क्षेत्र चलती उपकरण और वाहन के आसपास के क्षेत्र से िू र है।

Whether work platform is adequate with respect to strength and dimension?

4.

क्या कार्य मंच, शक्ति और आर्ाम के संबंध में पर्ायप्त है?

Is the working platform fully boarded?

5.

क्या वमकिंग प्लेटफॉिय पूरी तरह से बोर्डे र्ड है?

Whether work platforms provided with guard rail?

6.

क्या कायय प्लेटफािय गार्डय रे ल के साथ प्रिान मकए गए हैं?

Whether the workmen screened for working at height?

7.

क्या कािगारोां की ऊांचाई पर काि करने के मलए स्क्रीमनांग की गई है?

Whether adequate fall protection arrangement made (Static line, Double Lanyard

8. harness, Fall Arrestor, Safety Net)?

क्या पयायप्त मगरने से सुरक्षा व्यवस्था की गई है (स्टे मटक लाइन, र्डबल र्डोरी हानेस, फॉल अरे स्टर, सेफ्टी नेट)?

Risk Control measures for avoiding Fall of Materials

सामग्री को गिरने से बचाने के गिए जोक्तिम गनयंत्रण उपाय

Work at more than one elevation at the same segment is restricted.

1.

एक ही सेगिेंट िें एक से अमिक स्तर पर काि करना प्रमतबांमित है।

Walkways, aisles & all overhead workplaces cleared of loose material.

2.

क्या पैिल िागय, गमलयारे और सभी ऊपरी काययस्थलोां को ढीली सािग्री से िुक्त मकया गया है।

Whether all tools & tackles inspected before use?

3.

क्या उपयोग करने से पहले सभी उपकरण और टै कल का मनरीक्षण मकया गया है?

STB-HSE-P-03 Page 1 of 2 Rev 00, Dated 07.11.2022

WORK AT HEIGHT PERMIT

( ऊांचाई पर काि का परमिट )

Whether hand tools & handling materials secured against accidental fall?

4.

क्या आकस्मिक रूप से मगरने से हैंर्डटू ल और हैंर्डमलांग सािग्री सुरमक्षत हैं?

Workmen provided with bag / box to carry bolt, nuts & hand tools?

5.

क्या कािगारोां को बोल्ट, नट और हाथ उपकरण ले जाने के मलए बैग/बॉक्स उपलब्ध कराया गया है?

Whether area below, where the height work being performed is cordoned off and

unauthorised entries are avoided?

6. क्या नीचे का क्षेत्र, जहाां ऊांचाई का कायय मकया जा रहा है, की घेराबांिी कर िी गई है और अनमिकृत प्रवेश प्रमतबांमित

कर मिया गया है?

Permit Requested By Issuing Authority

परमिट अनुरोिकताय परमिट जारीकताय

Name(नाि) Name(नाि)

Designation(पि) Designation(पि)

Signature(हस्ताक्षर)

Signature(हस्ताक्षर)

Closing of the Permit परगमट क्लोगजंि

Time सिय __________________________ & Date मिनाां क ___________________________

Name & Sign of Permit Requester: _________________________________

परमिट अनुरोिकताय का नाि और हस्ताक्षर:

Name & Sign of Permit Issuer: ___________________________________

परमिट जारीकताय का नाि और हस्ताक्षर:

Signature of HSEO: ____________

STB-HSE-P-03 Page 2 of 2 Rev 00, Dated 07.11.2022

PERMIT TO LIFT (लिफ्ट वर्क परलिट)

Identification/Reg. No: Permit No:

Make / Model: Contractor Name:

Load Details: Date: Time:

Area: Exact Location:

Sl. Remark

Check Points

No. YES NO NA

Whether the ground condition is levelled and well compacted?

1.

क्या जमीन की स्थिति को समिल और अच्छी िरह से ठोस तकया गया है?

Whether lifting equipment is stable on the ground?

2.

क्या उठाने वाले उपकरण जमीन पर स्थिर हैं?

Outriggers can be fully extendible and placed on firm footing, Steel base plates are available.

3.

आउटररगर को पूरी िरह से बढाया जा सकिा है और मजबूिी से रखा जा सकिा है, स्टील बेस प्लेट उपलब्ध हैं।

Whether the condition of lifting gears have been checked and valid TPI (third party certificates) are

4. available?

क्या तलस्टिं ग तगयसस की स्थिति की जािंच की गई है और वैध टीपीआई (िर्स पाटी सतटस तिकेट) उपलब्ध हैं?

Whether lifting hook and safety latch are visible in good working condition?

5.

क्या तलस्टिं ग हुक और सेटी लैच अच्छी काम करने की स्थिति में तिखाई िे रहे हैं?

Audible alarm / warning horns are in good working conditions.

6.

सुनाई िे ने योग्य अलामस/चेिावनी हॉनस अच्छी काम करने की स्थिति में हैं।

Safety/Warning Signs are in place.

7.

सुरक्षा/चेिावनी के सिंकेि मौजूि हैं।

ASLI is not bypassed and is in good working condition.

8.

ASLI को नजरअिंिाज नहीिं तकया गया है और यह अच्छी काम करने की स्थिति में है ।

Counterweights are available as per the load chart.

9.

लोर् चाटस के अनुसार काउिं टरवे ट उपलब्ध हैं ।

Whether appropriate illumination is provided for night work?

10.

क्या राि के काम के तलए उतचि रोशनी की व्यवथिा की गई है ?

Whether operator details pasted on the machines?

11.

क्या मशीनोिं पर ऑपरे टर तववरण तचपकाया गया है?

Operator competency checked and having valid driving license.

12.

ऑपरे टर की योग्यिा की जााँच की गई और उसके पास वैध र्र ाइतविंग लाइसेंस है ।

Rigger / Signalman is available with all required PPE.

13.

ररगर/तसग्नलमैन सभी आवश्यक पीपीई के साि उपलब्ध है ।

Site Engineer/Lifting supervisor available.

14.

साइट इिं जीतनयर/तलस्टिं ग सुपरवाइजर उपलब्ध।

Are there any OH lines present in the lifting & Swinging area?

15.

क्या तलस्टिं ग और स्विं तगिं ग क्षे त्र में कोई ओवरहेर् लाइनें मौजूि हैं?

If OH lines are present, whether shutdown has been taken?

16.

यति ओएच लाइनें मौजूि हैं, िो क्या शटर्ाउन तलया गया है?

Whether the lifting area is cordoned off to prevent the entry of people below the suspended load?

17.

क्या सस्पेंर्ेर् लोर् से नीचे के लोगोिं के प्रवेश को रोकने के तलए तलस्टिं ग क्षेत्र की घेराबिंिी की गई है?

A. THE PERSON RECEIVING PERMIT (RECEIVER) TO FILL UP:

The above points have been complied with and rendered safe / hazards innocuous to undertake the lifting work. This

permit is valid for one shift only.

उपरोक्त तबिंिुओिं का पालन तकया गया है और तलस्टिं ग कायस करने के तलए सुरतक्षि / जोस्खम रतहि प्रिान तकया गया है। यह परतमट केवल एक तशट के तलए

वैध है।

Name of permit requester____________ Signature____________ Designation _____________

STB-HSE-P-02 Page 1 of 2 Rev 00, Dated 07.11.2022

PERMIT TO LIFT (लिफ्ट वर्क परलिट)

B. THE PERSON GIVING PERMIT (ISSUER) TO FILL UP:

I have checked and the conditions mentioned above are compiled and the lifting can be carried out in the above area.

मैंने जााँच की है और ऊपर उस्िस्खि शिों को सिंकतलि तकया गया है और उपरोक्त क्षेत्र में तलस्टिं ग की जा सकिी है।

Name of permit Issuer_______________ Signature_____________ Designation _____________

C. CANCELLATION OF PERMIT (परलिट रद्द र्रना)

This permit to work is cancelled and the relevant staff I have been notified. No more work under this permit shall be

carried out. This permit stands invalid.

Date: ____ /___ /______ Time_________ Name__________________ Signature__________________

(Issuer/HSE Engineer/Client)

D. CLOSURE OF PERMIT (परलिट र्ी सिाप्ति)

The lifting was carried out safely and the location cleared off with all materials.

Date: ___ /___ /______ Time_________ at which the permit closed & filed.

Name & Sign of Permit Requester ___________________ Name & Sign of Permit Issuer_____________________

LIFTING PLAN

Boom angle °

S. No Description UOM Qty Remarks

1. Capacity of crane MT

2. Boom Length Mtr.

3. Radius Mtr.

4. Boom Angle Deg.

Cap. Of crane @ above boom &

5. MT

radius

6. Sling Nos.

7. D- Shackles Nos.

8. Wt. of Material MT

9. Length of Material Mtr.

Name & Signature:

Site engineer/ In- charge

STB-HSE-P-02 Page 2 of 2 Rev 00, Dated 07.11.2022

HOT WORK PERMIT

(हॉट वर्क परमिट)

Permit No: ______________________

A) The person taking permit (Receiver) to fill up

परमिट लेने वाला व्यक्ति (परमिटी) भरने के मलए: उप-ठे केदार प्रमिमनमि

Name & Signature: _____________________ Contractor Name: ___________________

a) Area & Exact location where hot work is being planned _____________________

क्षेत्र एवं सटीक स्थान जहां हॉट कार्य की र्ोजना बनाई जा रही है।

b) Approximate duration of work.

From: Date मिन ांर् : ___________________ Time सिय : ____________

To : Date मिन ांर् : ___________________ Time सिय : ____________

Points to be checked ज ाँच मर्ए ज ने व ले म ांिु

Sl. Remark

Check Points

No YES NO NA

Has the area immediately around the work spot, been cleared / removed of oil, grease &

waste cotton and other combustibles etc.?

1.

क्या कार्य स्थल के आसपास के क्षेत्र से िेल, ग्रीस और अपमिष्ट कपास और अन्य ज्वलनिील पदाथों आमद को िुरंि हटा

मदर्ा गर्ा है?

Have flash back arresters mounted on both gas cylinder end and cutting torch ends? &

Hose condition is inspected and satisfactory?

2.

क्या फ्लैिबैक अरे स्टर गैस मसलेंडर के मसरे और कमटं ग टार्य दोनों मसरों पर लगा है? और नली की क्तस्थमि का मनरीक्षण मकर्ा

गर्ा िथा संिोषजनक है?

Have suitable fire extinguishers been kept in the vicinity at site?

3.

क्या स्थल के आसपास उपर्ुि अमििािक र्ंत्र रखे गए हैं?

whether to control sparks in work area tin shed/ gunny bag/ fire retardant cloth/sheet

4. been provided?

क्या कार्य क्षेत्र िें मर्ंगाररर्ों को मनर्ंमत्रि करने के मलए मटन िीट/गीले बोरी/अमिरोिी कपडा/िीट प्रदान की गई है?

Whether a sand bucket and water source available near the Gas Cutting area?

5.

क्या गैस कमटं ग क्षेत्र के पास बालू की बाल्टी और पानी का स्रोि उपलब्ध है?

Is the area cordoned off and warning sign ensured?

6.

क्या क्षेत्र की घेराबंदी कर दी गई है और र्ेिावनी संकेि सुमनमिि मकर्ा गर्ा है?

Has the double body earthing done for welding machines?

7.

क्या वेक्तडंग ििीन के मलए डबल बॉडी अमथिंग की गई है?

STB--HSE-P-04 Page 1 of 2 Rev 00, Dated 07.11.2022

HOT WORK PERMIT

(हॉट मलफ्ट वर्क परमिट)

All the electrical connections are taken care and cables are without any defects and joints

are with IP 44 sockets, lug is in good condition?

8.

क्या सभी मवद् र्ुि कनेक्शनों का ध्यान रखा गर्ा है और केबल मबना मकसी त्रुमट के हैं और जोड IP44 सॉकेट के साथ हैं, लग्स

अच्छी क्तस्थमि िें हैं?

Has sufficient Illumination & ventilation been ensured prior to starting the work?

9.

क्या काि िुरू करने से पहले पर्ायप्त रोिनी और वेंमटलेिन सुमनमिि मकर्ा गर्ा है?

All the mandatory & activity-specific PPEs (Safety Shoes, Leather hand gloves, welding

face shield, hard hat, aprons, leg & handguards) are available?

10.

सभी अमनवार्य और गमिमवमि-मवमिष्ट पीपीई (सुरक्षा जूिे, र्िडे के हाथ के दस्ताने, वेक्तडंग फेस िीड, हाडय हैट, एप्रन, लेग

और हैंडगाडय ) उपलब्ध हैं?

Whether fire watch person/supervisor has been deployed to closely monitor the activity

and in case of any deviation?

11.

क्या गमिमवमि की बारीकी से मनगरानी करने और मकसी भी मवर्लन के िािले िें फार्र वॉर् व्यक्ति/पर्यवेक्षक को िैनाि

मकर्ा गर्ा है?

Any other precautions taken (specify): _____________________

12.

कोई अन्य साविामनर्ां बरिी गई हैं (मनमदय ष्ट करें )

The above points have been complied with and rendered safe / hazards innocuous to undertake the hot work. This

permit is valid for one shift only.

उपरोि मबंदुओं का पालन मकर्ा गर्ा है और िप्त किय करने के मलए सुरमक्षि/जोक्तखि रमहि बना मदर्ा गर्ा है। र्ह परमिट केवल एक मिफ्ट के मलए वैि है।

B) The person-giving permit (Issuer) to fill up:

परमिट ज रीर्र् क (परमिट िे ने व ल व्यक्ति) द्व र भर ज न है:

After checking all the above precautions, the hot work can be carried out.

उपरोि सभी साविामनर्ों की जााँ र् करने के बाद, उपरोि क्षेत्र िें हॉट वकय मकर्ा जा सकिा है ।

Name & Signature of _______________________ _______________

Issuing authority Name Signature

C) Closure of Permit:

I have inspected the work location and declare that now the work location is safe and without any possibility of a

fire mishap.

िैंने र् यक स्थल र् मनरीक्षण मर्य है और घोषण र्ी है मर् अ र् यक स्थल सुरमक्षर् है और आग लगने र्ी र्ोई सांभ वन नही ां है।

Close Time ____________ Date____________________ at which the permit closed & filed.

Name & Signature of Permit Reciever: ____________________ _______________

Name & Signature of Permit Issuer: _______________________ _______________

__________________________________________________________

Signature of HSEO

STB--HSE-P-04 Page 2 of 2 Rev 00, Dated 07.11.2022

General Work Permit

Contractor Name: Permit No:

Section A: Identification of Job Scope (To be completed by Permit requestor)

Area Locations (Specific) Equipment’s Used

Detailed Job Description: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_____________________________________________________________________

Section B: Hazard Analysis (To be completed by Permit Issuer & Permit Receiver)

Identify Potential Hazards:

Soil Collapse/ Cave-In Contact with Heat / Cold Moving Machinery Slips / Trips

Chemical/Toxic Exposure Poor Visibility / Illumination Access/Ingress/Egress Fall Potential

Stored Energy / Pressure Radiation Entrapment Noise

Electricity Material Handling Poor Ventilation Fire / Spark

Hazardous Atmosphere Flying Objects Confined Space Hazard Marine Hazard

Vibration Ergonomics Hazard Adverse Weather condition Other ______

Identify Required Precautions:

Documents / Permits Equipment Personal Protective Section C: Corequisite

Equipment Clearance (To be signed before

TBT Scaffold Goggles permit issued/obtained)

HIRA /JSA Barricades Face Shield Excavation Clearance

(Checklist should be

Lifting Plan Manlift Rubber/Gum Boots

attached)

Excavation Clearance Additional Lighting Full Body Harness

MSDS Review Dewatering Pump Hearing Protection

Electrical Isolation

Work Method Statement Shoring / Banking Dust Mask

Clearance

LOTO Spill Containment Rain Suit (Isolation done/not

Others_______________ Multi-gas Detector Apron / Shin Pad required)

Crane Disposable Coveralls

Confined Space

DG Set Hand Protection Clearance

Communication Heavy Construction Leather Gloves (Ambient gas test done

Supervisor Presence Equipment _________ Rubber Gloves and recorded before

Radio Communication Any other Equipment Cut Resistant Gloves entry inside C.S.)

Other Affected Parties __________________ High Voltage Gloves

Other PPEs__________

Section D: Authorization, Validity and Acceptance (To be completed by Permit Issuer & Permit Receiver)

Worksite has been inspected and all permit conditions are satisfied.

Valid Time Permit Receiver Permit Issuer

Date

From Up-to Name Designation Sign Name Designation Sign

Safety officer Name & Sign:

Section E: Extension of Authorization, Validity and Acceptance (To be completed by Permit Issuer & Permit Receiver)

Worksite has been inspected and all permit conditions are satisfied.

Valid Time Permit Receiver Permit Issuer

Date

From Up-to Name Designation Sign Name Designation Sign

Safety officer Name & Sign:

Section F: Permit Close Out (To be completed by Permit Receiver and Permit Issuer)

Work is complete Work is incomplete Area is safe and clean

Name Designation Signature Mobile No.

Permit Receiver

Permit Issuer

Note: For Hi-po risk activities PTW should be attached with specific job safety checklist.

Field copies of the permits must be display at job location/available with permit receiver at location.

HSE-F-04 Rev 01, Dated 13.09.2022

Inspection Checklist- Scaffolding

Contractor Name: Inspection Date:

Area: Exact Location:

Sr. No. Check Points Yes /No / NA Remarks

1 Are the scaffoldings erected as per the load duty requested?

Is every work platform fitted with handrail (top rail 1000 mm and mid rail at 500 mm high)

2

and a toe board (150 mm) secured to the platform sides?

3 Are the scaffolding in plumb and level?

4 Are the planks/gratings placed in order without undue gaps and anchored?

Are the footing / anchorage for scaffolds sound and the bay lengths maintained as per the

5

maximum Intended load (duty)?

Are the poles, legs or uprights of scaffolding are securely braced to prevent swaying /

6

displacement?

7 Are the base plates (100 x 100 x 3 mm) provided for scaffolding posts?

8 Are the base plates are supported by sole plate (300 x 300 x 6 mm) at unpaved area?

Is kicker lift (at distance 150 mm from ground/base) provided for scaffold of height more

9

than 6.0 meter?

If the scaffolding is erected above walkways or work areas, are the space between toe

10

boards and railings screened?

If work is done over men who are working on scaffolding, is overhead protection

11

provided?

Has the scaffolding area suitably barricaded during erection / usage / dismantling? As far

12 as practicable, barricades shall be provided by keeping a clear distance of 1.0 meter from

scaffold structure.

13 Is free standing scaffolding tower protected from tipping by guying or other means?

Is there a safe and convenient means of access? If a ladder is used, is it rising at least 1000

14

mm above the platform?

Are relevant Green tag / Red Tag attached to the scaffolding completed / under erection

15

as applicable?

16 Is safe access to equipment or emergency Egress are restricted by scaffolds?

17 Are wall scaffolding anchored every 10 meters of length and 8 meters of Height ?

18 Are landing platforms provided for access ladders more than 9 meters height?

Have all scaffolding components been inspected for defects such as broken welds,

19

corroded members, and missing locks, bent or dented tubes?

Has the erection site been evaluated for hazards such as earth fills, ditches, debris,

20

underground electric wires, unguarded openings, or conditions created by other trades?

21 Is the scaffold being erected under the direction of a competent person?

22 Are all braces, bearer, and clamps secured all sections pinned or appropriately secured?

If two pipes are connected, are they overlapped at least 600 mm and at least two clamps

23

used?

Checked by (Authorize Supervisor):

Sign:

Name:

STB-HSE-CL-08 Rev 00, Dated 25.10.2022

Construction Equipment/Vehicle Inspection Checklist

Contractor Name: Inspection Date:

Vehicle/Equipment Name:

Make & Model: Registration No:

Legends- Mark "✓"=compliant, "X"=Non-compliant, "NA"=Not-applicable

Status

Check points

Sl.No. Remarks

(Check for Availability and Functionality) Compliant

Not Not

compliant applicable

License and authorization note of driver/operator

1 Name:

Valid till:

2 Medical examination(incl. Eye Test) of operator

3 Driver trained in defensive driving

4 Registration Certificate(RC)

5 Fitness Certificate

6 PUC Certificate

7 Insurance Certificate

8 Seat Belts(Three points,elastic & lock type)

9 Glass (Broken and/or Vision Limiting)

10 Windshield & Wipers

11 Levers & Control

12 Instruments(guages/meters)

13 Battery & Ignition System

14 Fire Extinguisher(Charged & Inspected)

15 ABC (Accelerator,Brakes,Clutch)

16 Registration number plates displayed

17 Audible Horn

18 Reverse Horn/Swing Alarm audible

19 Lights (Headlights and Taillights)

20 Indicators

21 Rear view convex Mirrors on both side

22 Bucket connected with standard pin(for excavator)

23 Tires & Pressure conditions

24 Guards on moving parts

25 Hydraulic System (Leaks or Damage)

26 Exhaust System

27 Outriggers fully extendable & free movement

28 Flashing Light (If Equipped)

29 Any other point…...................................................

Post Site Inspection Remarks(If any):

Result Post Site Inspection:

FIT UNFIT

for deployement for deployement

Sign of Site Engineer/Supervisor: Varified by EHSO Sign:

Name: Name:

HSE-F-CHL-03 Rev 00, Dated 05.09.2022

You might also like

- Work at Height in HindiDocument2 pagesWork at Height in HindiShailendra100% (2)

- Excavation Do's & Don'tsDocument2 pagesExcavation Do's & Don'tsAmit kumar thakur100% (1)

- Inspection Hand ToolsDocument5 pagesInspection Hand ToolsbhartiNo ratings yet

- Tower Crane SopDocument3 pagesTower Crane SopRajesh DhakeNo ratings yet

- APAR Format For GP B Non Gazetted OfficersDocument13 pagesAPAR Format For GP B Non Gazetted OfficersGARUAV RAHI100% (1)

- Flange Opening Work Permit...Document8 pagesFlange Opening Work Permit...bajayNo ratings yet

- Manlifter Permit (Hindi)Document1 pageManlifter Permit (Hindi)Biswaranjan SahooNo ratings yet

- Critical Work Permit...Document6 pagesCritical Work Permit...bajayNo ratings yet

- Confined Space Work Permit...Document6 pagesConfined Space Work Permit...bajayNo ratings yet

- Annual Performance Appraisal Report: Khurda Road Khurda RoadDocument6 pagesAnnual Performance Appraisal Report: Khurda Road Khurda Roadsumeetpadhi1No ratings yet

- Common Work Permit....Document12 pagesCommon Work Permit....bajayNo ratings yet

- Contractor Safety Guidelines - BilingualDocument14 pagesContractor Safety Guidelines - BilingualPrem Shanker RawatNo ratings yet

- GeM Bidding 5957279Document6 pagesGeM Bidding 5957279Trilok ChanduNo ratings yet

- Annual Performance Appraisal Report: Khurda Road Khurda RoadDocument6 pagesAnnual Performance Appraisal Report: Khurda Road Khurda Roadsumeetpadhi1No ratings yet

- Wjetgq A3 2021-2022 051Document7 pagesWjetgq A3 2021-2022 051sujeshbhakthanbhakthanNo ratings yet

- HUGRS Daily Inspection Checklist For Fork LiftDocument1 pageHUGRS Daily Inspection Checklist For Fork LiftRabbanNo ratings yet

- Scaffold Inspection Checklist (HSE-CTN-HPP-CHK-001)Document5 pagesScaffold Inspection Checklist (HSE-CTN-HPP-CHK-001)Radha BuildtechNo ratings yet

- Apar PerformaDocument5 pagesApar PerformaManager NSH100% (1)

- Form IiiDocument11 pagesForm IiiPankaj PattanaikNo ratings yet

- Cable Laying Work HindiDocument4 pagesCable Laying Work Hindimani sharmaNo ratings yet

- SOP-005-painting, Tiles, Aluminium, False Ceiling - En.hiDocument9 pagesSOP-005-painting, Tiles, Aluminium, False Ceiling - En.hisambit sarat satpathyNo ratings yet

- GeM Bidding 5984074Document5 pagesGeM Bidding 5984074rajivsharmadrishNo ratings yet

- F.MR.28 Traub Operator Skill Evaluation Check SheetDocument7 pagesF.MR.28 Traub Operator Skill Evaluation Check SheetMohit KaushikNo ratings yet

- 23 Housekeeping JodhpurDocument6 pages23 Housekeeping JodhpurshyamNo ratings yet

- GeM Bidding 5452706Document6 pagesGeM Bidding 5452706swagatachatterjee01No ratings yet

- Form IvDocument11 pagesForm IvPankaj PattanaikNo ratings yet

- NIT 228ocrDocument5 pagesNIT 228ocrvarun.vsconstructionNo ratings yet

- GeM Bidding 5469015Document7 pagesGeM Bidding 5469015Trilok ChanduNo ratings yet

- Level 2Document3 pagesLevel 2DinakaranNo ratings yet

- GeM Bidding 4806908Document5 pagesGeM Bidding 4806908Ecologics IndiaNo ratings yet

- GeM Bidding 5384915Document5 pagesGeM Bidding 5384915srashmiiiscNo ratings yet

- GeM Bidding 4541167Document10 pagesGeM Bidding 4541167Sachendra ChaudharyNo ratings yet

- Form IiDocument11 pagesForm IiPankaj PattanaikNo ratings yet

- 5 Apar-Sms As RaDocument10 pages5 Apar-Sms As Rasndppm7878No ratings yet

- SEBI Circular SEBIHOITDITD VAPTPCIR2023033Document53 pagesSEBI Circular SEBIHOITDITD VAPTPCIR2023033regina.phalangeNo ratings yet

- (New) HINDI-JUPC Daily Inspection Checklist For GeneratorDocument2 pages(New) HINDI-JUPC Daily Inspection Checklist For GeneratorFarooq MohammadNo ratings yet

- Earthing & Surge Protection For S&T InstallationsDocument56 pagesEarthing & Surge Protection For S&T Installationsacharya010No ratings yet

- GeM Bidding 5063334Document9 pagesGeM Bidding 5063334Awadh GroupNo ratings yet

- Bid DocumentDocument5 pagesBid DocumentPiyush YadavNo ratings yet

- 07 Daily Equipment Inspection Checklist For Mobile Crane English HindiDocument3 pages07 Daily Equipment Inspection Checklist For Mobile Crane English Hindimunna yadavNo ratings yet

- GeM Bidding 5219458Document9 pagesGeM Bidding 5219458Kartik RajputNo ratings yet

- Flipkart MHDocument13 pagesFlipkart MHPenuel PeterNo ratings yet

- (SOP-CM-PI-017) Fire Fighting Air Water Pressure TestDocument6 pages(SOP-CM-PI-017) Fire Fighting Air Water Pressure TestHMN YDVNo ratings yet

- Bid DocumentDocument6 pagesBid Documentabhay 247No ratings yet

- Moo-Spccc-Hse-F-29 Daily Crane Operator ChecklistDocument1 pageMoo-Spccc-Hse-F-29 Daily Crane Operator ChecklistRejan LawrenceNo ratings yet

- GeM Bidding 4857187Document9 pagesGeM Bidding 4857187Awadh GroupNo ratings yet

- Inspection Note FormatDocument5 pagesInspection Note FormatMOHAN SANGANINo ratings yet

- GeM Bidding 5962507Document5 pagesGeM Bidding 5962507srashmiiiscNo ratings yet

- GeM Bidding 6242039Document9 pagesGeM Bidding 6242039Hetal PatelNo ratings yet

- GeM Bidding 5583594Document7 pagesGeM Bidding 5583594NE-II Circle Electrical Division - DimapurNo ratings yet

- GeM Bidding 5849905Document11 pagesGeM Bidding 5849905Bhavik PanchalNo ratings yet

- GeM Bidding 6215876 2Document5 pagesGeM Bidding 6215876 2Anand PatelNo ratings yet

- GeM Bidding4Document7 pagesGeM Bidding4Sandeep TiwariNo ratings yet

- GeM Bidding 5886180Document5 pagesGeM Bidding 5886180Kundan PrasadNo ratings yet

- GeM Bidding 5651480Document6 pagesGeM Bidding 5651480srashmiiiscNo ratings yet

- GeM Bidding 4611324Document6 pagesGeM Bidding 4611324Sachendra ChaudharyNo ratings yet

- GeM Bidding 4867160Document7 pagesGeM Bidding 4867160gangaNo ratings yet

- GeM Bidding 5692904Document10 pagesGeM Bidding 5692904Mohd FaizNo ratings yet