Professional Documents

Culture Documents

Haccp

Haccp

Uploaded by

Doby Mezepekenia0 ratings0% found this document useful (0 votes)

12 views1 pageOriginal Title

haccp

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views1 pageHaccp

Haccp

Uploaded by

Doby MezepekeniaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

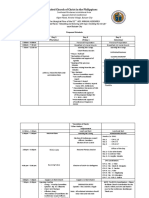

What is HACCP?

Hazard Analysis and Critical Control Points (HACCP) is a process control method designed to

find and eliminate microbiological and other dangers in the food manufacturing process.

What are the seven principles of HACCP?

Principle 1: Conducting a hazard analysis

Plants analyze the risks to food safety during this phase and identify preventive methods to

control these risks.

Principle 2: Identifying critical control points

A critical control point (CCP) is a stage in the manufacturing of food where measures are taken

to prevent, eliminate, or minimize the risk to a level that is acceptable for food safety.

Principle 3: Establish critical limits for each critical control point.

A physical, biological, or chemical hazard must be kept under control at a particular value

known as a critical limit. CCP distinguishes between safe and harmful food while also

preventing, eliminating, or reducing risk to a tolerable level. Notably, critical limits typically take

the form of numerical numbers based on scientific discoveries.

Principle 4: Establish critical control point monitoring requirements.

To ensure that the process is in control at each critical control point and that dangers are

likewise under control, the food manufacturing process must be monitored. The monitoring

process comprises measurements of temperature, visual inspection, timekeeping, etc. Each

process must be monitored, and the FSIS stipulates that the frequency of monitoring must be

specified in the HACCP plan.

Principle 5: Establish corrective actions.

Corrective measures must be performed to stop the hazard if deviations are found during the

monitoring phase. Corrective measures make sure that contaminated products that are harmful

to health do not reach the market.

Principle 6: Establish record keeping procedures

All plants must maintain records detailing hazard analysis, CCP monitoring, critical limits, and

process deviation checks in accordance with HACCP requirements.

Principle 7: Establish verification procedures.

The HACCP plan's validity and the system's compliance with the plan can both be ascertained

through verification.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Program ScriptDocument2 pagesProgram ScriptDoby MezepekeniaNo ratings yet

- Text Demo Edit 1Document1 pageText Demo Edit 1Doby MezepekeniaNo ratings yet

- 2018 SOF Calendar of TopicsDocument109 pages2018 SOF Calendar of TopicsDoby MezepekeniaNo ratings yet

- Approved Schedule For Annual Ass.Document3 pagesApproved Schedule For Annual Ass.Doby MezepekeniaNo ratings yet