Professional Documents

Culture Documents

Types of CHP Systems

Types of CHP Systems

Uploaded by

Peter iruna0 ratings0% found this document useful (0 votes)

11 views1 pageThere are five principal types of combined heat and power (CHP) systems: back pressure steam turbine systems, pass-out condensing steam turbine systems, gas turbine systems, reciprocating engine systems, and combined cycle systems. Back pressure and pass-out condensing steam turbine systems use steam generated in a boiler and exhausted from a turbine. Gas turbine systems combust fuel in a gas turbine and use the exhaust gases to produce heat. Reciprocating engine systems produce high and low grade heat from the engine exhaust and cooling circuits. Combined cycle systems use exhaust gases from engines like gas turbines to generate steam for steam turbines.

Original Description:

Original Title

Types of CHP systems

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThere are five principal types of combined heat and power (CHP) systems: back pressure steam turbine systems, pass-out condensing steam turbine systems, gas turbine systems, reciprocating engine systems, and combined cycle systems. Back pressure and pass-out condensing steam turbine systems use steam generated in a boiler and exhausted from a turbine. Gas turbine systems combust fuel in a gas turbine and use the exhaust gases to produce heat. Reciprocating engine systems produce high and low grade heat from the engine exhaust and cooling circuits. Combined cycle systems use exhaust gases from engines like gas turbines to generate steam for steam turbines.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views1 pageTypes of CHP Systems

Types of CHP Systems

Uploaded by

Peter irunaThere are five principal types of combined heat and power (CHP) systems: back pressure steam turbine systems, pass-out condensing steam turbine systems, gas turbine systems, reciprocating engine systems, and combined cycle systems. Back pressure and pass-out condensing steam turbine systems use steam generated in a boiler and exhausted from a turbine. Gas turbine systems combust fuel in a gas turbine and use the exhaust gases to produce heat. Reciprocating engine systems produce high and low grade heat from the engine exhaust and cooling circuits. Combined cycle systems use exhaust gases from engines like gas turbines to generate steam for steam turbines.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

Types of CHP systems

There are five principal types of CHP system :

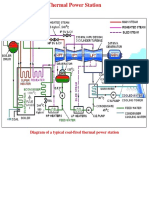

Back pressure steam turbine systems, where steam at high pressure is generated

in a boiler and is wholly or partly used in a turbine being exhausted from the

turbine at the required pressure for the site. A proportion of the steam used by the

turbine may also be extracted at an intermediate pressure from the turbine (a pass-

out/back pressure steam turbine).

Pass-out condensing steam turbine systems, where a proportion of the steam

used by the turbine is extracted at an intermediate pressure from the turbine with

the remainder being fully condensed before it is exhausted at the exit

(pass-out/condensing steam turbine).

Gas turbine systems, where fuel is combusted in the gas turbine and the exhaust

gases are normally used in a waste heat boiler to produce usable heat, though the

exhaust gases may be used directly in some process applications.

Reciprocating engine systems, producing two grades of waste heat: high grade

heat from the engine exhaust and low grade heat from the engine cooling circuits.

Two principal types of engine exist: compression ignition and spark ignition,

dependent on their firing method.

Combined cycle systems, where the plant comprises one or more engines

(usually gas turbines but in some cases reciprocating engines) whose exhaust gases

are utilised in a steam generator, the steam of which is used wholly or in part in

one or more steam turbines.

You might also like

- Theory For FinalDocument2 pagesTheory For FinalKhalid RasheedNo ratings yet

- Introduction To Gas Turbine:: Land Based Gas Turbines Are of Two TypesDocument9 pagesIntroduction To Gas Turbine:: Land Based Gas Turbines Are of Two TypesTahir MuneebNo ratings yet

- Chapter Five Gas Turbine Power PlantDocument21 pagesChapter Five Gas Turbine Power PlantBiniam Nega100% (1)

- Co GenerationDocument47 pagesCo GenerationDeshdeepak Sharma D DNo ratings yet

- Gas Turbine DescriptionDocument8 pagesGas Turbine DescriptionSIVAPATHASEKARANNo ratings yet

- 4 رضاDocument9 pages4 رضااحمد تاشهاويNo ratings yet

- Gas Turbine Power PlantDocument15 pagesGas Turbine Power Plantrahul100% (1)

- Gas Turbine ReportDocument13 pagesGas Turbine Reportwaleed100% (1)

- Chapter Five Gas Turbine Power PlantDocument23 pagesChapter Five Gas Turbine Power PlantBese Mat100% (1)

- Minor Project Report On Combined Cycle Power Plant: Submitted ByDocument23 pagesMinor Project Report On Combined Cycle Power Plant: Submitted ByAyush JainNo ratings yet

- Co-Generation SystemDocument5 pagesCo-Generation SystemPavan AherNo ratings yet

- Combined Gas (Turbine) and Steam (Turbine) : (COGAS)Document28 pagesCombined Gas (Turbine) and Steam (Turbine) : (COGAS)scribdhas2006100% (1)

- Open, Combined and Combined Heat and Power Cycle: Muzzamil Shahzad Process Engineering Inter Engro Powerge Thar LimitedDocument12 pagesOpen, Combined and Combined Heat and Power Cycle: Muzzamil Shahzad Process Engineering Inter Engro Powerge Thar LimitedMuzzamilNo ratings yet

- How Gas Turbine Power Plants WorkDocument6 pagesHow Gas Turbine Power Plants Workchella2705100% (1)

- Working Principle Gas Turbine and Combined Cycles, Auxiliary SystemsDocument27 pagesWorking Principle Gas Turbine and Combined Cycles, Auxiliary SystemsRey Danielle Navea100% (2)

- GT1Document91 pagesGT1Irfan Ullah100% (1)

- Cogeneration - Combined Heat and Power (CHP)Document23 pagesCogeneration - Combined Heat and Power (CHP)Reyes SanchezNo ratings yet

- Gas Turbine Power PlantDocument13 pagesGas Turbine Power PlantGreesh MaheshwariNo ratings yet

- Cogeneration by Naresh Meena 10EMBME036 Mechnical 8 SemDocument20 pagesCogeneration by Naresh Meena 10EMBME036 Mechnical 8 SemMultiverseIitNo ratings yet

- Gas Turbine Power Plant PresentationDocument126 pagesGas Turbine Power Plant Presentationjehadyam100% (2)

- RA Templates - Tank CleaningDocument32 pagesRA Templates - Tank CleaningBharath KumarNo ratings yet

- GALGALLA - Working Assignment 3 - Gas TurbineDocument5 pagesGALGALLA - Working Assignment 3 - Gas TurbineGodfrey Jr Jr.No ratings yet

- TurbineDocument9 pagesTurbineKabir Bashir ShariffNo ratings yet

- An Overview of Combined Cycle Power Plant - EEPDocument12 pagesAn Overview of Combined Cycle Power Plant - EEPrereilham100% (1)

- Unit-3: Diesel Power Plant LayoutDocument12 pagesUnit-3: Diesel Power Plant LayoutPavankumar PavankumarpvNo ratings yet

- Combined Cycle Power PlantDocument11 pagesCombined Cycle Power PlantPGPalomaNo ratings yet

- Combined Gas and Steam: (COGAS) Plant. Multiple Stage Turbine or Steam Cycles Are AlsoDocument12 pagesCombined Gas and Steam: (COGAS) Plant. Multiple Stage Turbine or Steam Cycles Are AlsoRobinsyahNo ratings yet

- Thermal Power Plant PDFDocument16 pagesThermal Power Plant PDFMoustafa MahmoudNo ratings yet

- Combined CycleDocument8 pagesCombined CycleAnonymous mNQq7oj100% (1)

- CogenerationDocument39 pagesCogenerationSandeep SharmaNo ratings yet

- Lec 05Document21 pagesLec 05Shamsuzzaman SharifNo ratings yet

- AES Thermal Power Plant, Lalpir, District Muzaffargarh: Prepared byDocument25 pagesAES Thermal Power Plant, Lalpir, District Muzaffargarh: Prepared byIrfan UllahNo ratings yet

- Gas Turbine PPDocument49 pagesGas Turbine PPChersey DoctorNo ratings yet

- CCTP AdstractDocument10 pagesCCTP Adstractmkarthikeyan023No ratings yet

- Gas Turbine Power Plant PresentationDocument49 pagesGas Turbine Power Plant PresentationZizou Junior75% (4)

- Gas Turbine Power Plant PresentationDocument49 pagesGas Turbine Power Plant PresentationMehmet TuncarNo ratings yet

- Thermodynamics Lecture 6Document32 pagesThermodynamics Lecture 6MarkJude Morla100% (1)

- Pertemuan 4 - Turbin Gas (2016)Document53 pagesPertemuan 4 - Turbin Gas (2016)Prabowo WicaksonoNo ratings yet

- Gas Turbine 1Document21 pagesGas Turbine 1Md. Adnan NabibNo ratings yet

- Gas Turbine Power Plant PresentationDocument49 pagesGas Turbine Power Plant PresentationAmlan Saha100% (1)

- Gas Turbine Power Plant PresentationDocument49 pagesGas Turbine Power Plant PresentationM Hamza Nadeem100% (1)

- Gas Turbine Power PlantDocument49 pagesGas Turbine Power PlantamrutnerlikarNo ratings yet

- Combined Cycle Power PlantDocument17 pagesCombined Cycle Power PlantJennifer L. Madronio100% (2)

- Gas Turbines - Hassan ElBanhawiDocument3 pagesGas Turbines - Hassan ElBanhawijesus_manrique2753No ratings yet

- How Does A Gas Turbine Power Plant Work?: 1. CompressorDocument8 pagesHow Does A Gas Turbine Power Plant Work?: 1. CompressorSuresh Ram R100% (2)

- Combined Gas and Steam Power PlantDocument8 pagesCombined Gas and Steam Power Planttushar1128100% (1)

- Combined Cycle Power PlantDocument7 pagesCombined Cycle Power Plantchella2705100% (1)

- CHAPTER III IV and VDocument84 pagesCHAPTER III IV and VJohn Louie Pimentel0% (1)

- Unit Iv Cogeneration and Residual Heat RecoveryDocument16 pagesUnit Iv Cogeneration and Residual Heat RecoveryShanmuga SundharamNo ratings yet

- Assignment - 2 (Waste Heat Recovery)Document4 pagesAssignment - 2 (Waste Heat Recovery)Akmal Hafeez Muhammad HafeezNo ratings yet

- Gas Turbine Power PlantDocument16 pagesGas Turbine Power PlantSathya Raj SimiNo ratings yet

- Ee3b9Experiment No.6 To Study The Working Principle of Simple Gas Turbine Engine. ObjectiveDocument3 pagesEe3b9Experiment No.6 To Study The Working Principle of Simple Gas Turbine Engine. Objectivefarah nazNo ratings yet

- Gas TurbineDocument53 pagesGas TurbinedipakbagNo ratings yet

- Comparison of Diesel and Petrol EnginesFrom EverandComparison of Diesel and Petrol EnginesRating: 2.5 out of 5 stars2.5/5 (3)

- Ways of Cogeneration: Bottoming Cycle: in This Cycle, The Generation of Heat Is Given The Priority To Supply ProcessDocument1 pageWays of Cogeneration: Bottoming Cycle: in This Cycle, The Generation of Heat Is Given The Priority To Supply ProcessPeter irunaNo ratings yet

- Synchronization PREPARATIONDocument1 pageSynchronization PREPARATIONPeter irunaNo ratings yet

- Ways of CogenerationDocument1 pageWays of CogenerationPeter irunaNo ratings yet

- Impacts of Net Energy Metering On Feeder PerformanceDocument16 pagesImpacts of Net Energy Metering On Feeder PerformancePeter irunaNo ratings yet

- FDocument93 pagesFPeter irunaNo ratings yet

- External Job Advert - HME Mechanic - Oct 2022Document1 pageExternal Job Advert - HME Mechanic - Oct 2022Peter irunaNo ratings yet

- EEE 2517 Exam Dec 2016Document4 pagesEEE 2517 Exam Dec 2016Peter irunaNo ratings yet

- Accounts Assignment - 041915Document5 pagesAccounts Assignment - 041915Peter irunaNo ratings yet

- Advantages of CogenerationDocument2 pagesAdvantages of CogenerationPeter irunaNo ratings yet