Professional Documents

Culture Documents

SPM

SPM

Uploaded by

SetyohdW0 ratings0% found this document useful (0 votes)

25 views12 pagesSPM

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSPM

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views12 pagesSPM

SPM

Uploaded by

SetyohdWSPM

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

SWIVEL JOINTS

| SPM long radius swivel joints are

engineered and manufactured for high

pressure well service applications. SPM

‘swivel joints are machined from forged alloy

steel, and heat-treated for extended product

life, They are manufactured by SPM in

numerous styles for 360° rotation in one,

two or three planes. Available in standard

service and sour gas models.

2" and 3° swivel joints are

‘esigned or high-pressure

‘applications such as,

fracturing, aiding,

‘cementing and ereulating

hoses, and test ines

TE

ada

eM

Design features include:

+ Three rows of bearings in hardened and.

«ground races to provide better flow and

longer product ife. 4” models utilize a

dual race design

+ Long radius configuration to minimize

cavitation,

+ Uniform wall thickness throughout for a

including slurries and abrasives.

+ Elastomeric packing for service to 225°F;

instream packing

designed not to enter

stream regardless

of velocity.

SPM 4 swivel ints

aro rated at 6,000 pst.

‘SPM SWIVEL JOINT

WITH CONSISTENT

WALL THICKNESS,

OTHER LEADING

‘BRAND OF STYLE 10MXM

‘SWIVEL JOINTS _

‘Wit (

INCONSISTENT | r

WALL THICKNESS. &

“These un-etouched an un-enhanced ~

Cutaway photographs of suv fins show SI

the content wall thickness of the SPM a

| gillemssandincaaitoney tthe oer | STYLE 10F XM STYLE 100FXM STYLE 100MXM

| feaaing bran

STEEL HOSE LOOPS

| spttastetnos op are sed

| tora varity of high pressure well

|

|

service applications including

discharge lines, water lines,

‘cementing and circulating lines, well

test lines and temporary flow lines.

SPM all-stee! hoses utilize field-

proven SPM Swivel Joints for

greater flexibility, shock and

vibration resistance, and more

uniform flow. Also utilized are SPM

wing union end connections for fast

pressure-tight make-up and break-

out.

‘These rugged hoses handle a full

range of fluids to cold working

pressures up to 15,000 psi and

come in sizes and configurations to

meet any need. Hoses for sour gas

service are available at cold working

pressure up to 10,000 psi.

SPM hoses are designed to easily

and conveniently fold up for storage

and transportation.

FLOW LINE

SPM all-steel, one-piece flow line

piping with wing union end

connections eliminate the need for

welds or threads for an uninterrupted

bore and greater flow.

This light-weight piping is available

in lengths to 10 feet to handle fluids

at cold working pressures to 15,000

psi. They are used on high-pressure

discharge lines, auxiliary flow lines,

cchoke-and-kill ines and for abrasive

applications. 3" (one-piece) piping

feature a capture nut.

SPM also manufactures flow line

piping in non-pressure seal thread

styles as well as butt weld styles in

sizes up to 4” in pressure ranges

from 6,000 to 20,000 psi, up to 20

feet in length.

Ah roy

Q. gsssarmnn 3 Seu Ls Long Roan Hooe

7

‘SPM LR-15 Long Radius Hose,

SPM LR-15 Long Radius Hose,

Oremeneianaem 5)

O — J

SPM LR-10 Long Radius Hose,

SPM LR-10 Long Radius Hose

sou | Come tthod OF Constction | cog verning |___280)

| Hts | Coit veel WS ier wee Foie S| 2 | a |

ge fom |. | =

Sever | ¥

dus | Green viejy | woo [vie

Sanet 1

sms! | Red vile lel som | vl’

= |v | oj ¥

Bales | om | | 1000 | |

PIPING

secon

STYLE

FORGED-END ONE-PIECE CONSTRUCTION

1" Tera] — cay ca

[63 [Ses [SSRIS | commtn

[2 [see [iso | Fa nn

3 | Standara 15.000 Fig. 1502 Union|

vs ‘Sour Gas. 10,000 Fig. 1502 Union

[3 ‘Standard 20,000 Fig. 2002 Union |

[a ‘Standard 15,000 Fig. 1502 Union

soupncseuneseac rena

[sme | wwowe | oe [om |e |

Fig 602 | 6,000 PS! viv v v

Fig 1002 | woors | v | wv» |w | wv

rats | wore |e ¥ |»

Fate | sso at eee,

Fig. 2002 ooo Psi | ai v |

Fig 2200 [15,000 PSI HS] v v

PLUG VALVES

1", 1" 2", 1%", and 2" PLUG VALVES

SPM high pressure plug valves are

tough, field-proven units that provide

dependable service for applications

‘such as cementing, fracturing and

acidizing, coiled tubing and sand

control. Available in 1", 1° x2", 1%"

| and 2" sizes and in pressure ratings to

15,000 psi NSCWP". SPM plug valves

| feature quality components throughout

{or greater dependability, minimum

weight and maximum strength.

Available in standard service and sour

gas service models. Also, special

models are available to 20,000 psi

3" and 4" PLUG VALVES

SPM three-inch plug valves are

available in pressure ratings to 20,000

psi NSCWP*. Features include a

flanged body for easier maintenance,

integral inlets and outlets, hand crank,

locked-open and shut gear drive

standard, and multiple lubricating

inlets. Standard service and sour gas

service models are available.

REMOTE OPERATION

Hydraulic and pneumatic actuators are

available for all sizes of plug valves

which enhances SAFETY in the field

REPAIR and SEAL KITS

‘SPM repair kits and seal kits contain all

the parts necessary to rebuild valves in

the field or in the shop. SPM seal kits

contain all items in the standard repair

kit, except the plug. Individual

components and elastomer kits are

Gea U aren

and PNEUMATIC

as

ACTUATORS

AVAILABLE

also avaiable

Valve Rated End sizes]

Model | NSCwP* Connections =| 1" x 2" 4 2 ca a

SPSOTF 5000 Trreaded ¥ ¥

‘SP1O0TF 10,000 Threaded a ¥

SPIGOTF 16.000 Threaded v v

| ‘SP150TM 15,000 ‘Threaded v

‘SPISOTMF_ 15.000 | Threaded a v

SP1sONU 15,000 Fig 1502 ia |S | v vl

‘SP200WU 20,000 Fig. 2002 v v Z

‘Special models are availabe to 20,000 psi

FLOW LINE SAFETY EQUIPMENT a

Safety Restraint System “%; FSR Field Transporter

SPM Flow Line Salety Restraint f er2'tongx6' wide.

System for use with energized .

fluids is designed to help provide gg

a safer environment in case of 7 + Specially designed

rupture or disengagement of the j racks for hanging

flow line while under pressure. , SPM's Ribs and

Spines.

PATENTED

‘ | + Specially designed

“Shackle ‘Spine | sail system for easy

loading ané

| Anchor Assembly _ loading and

unloading of SPM's

‘Anchor Assemblies.

Applications can * Standard ball hitch for easy hookup to most trucks. |

vary. Contact SPM |

for application ig critical that, since most SPM products generate, contro! |

guidelines. or direct pressurized fluids, those who work with these |

producte be throughly trained in their proper application and safe

hhandling. iieuse, side loading, Improper maintenance, or disassembly |

lunder pressure can cause serious injury or death! |

‘SPM emergency relief valves provide over-pressure protection for

reciprocating pumps, treating lines, pressure vessels and other equipment

operating under a variety of pressure and flow conditions. The valves are

compact, simple to operate and rely on the system's pressure to open

when a preset pressure is exceeded, and automatically snap shut when

the pressure drops.

The valves are externally adjustable, and unlike shear relief

valves which use common nails to trigger the valve, SPM's

emergency relief valves utilize an internal spring, nitrogen

or rig air to activate opening and closing. Valves are

available in 2", 3° and 4" models. Operating pressures,

range from 5,000 psi to 20,000 psi. Standard service

and sour gas models are available.

"WELL SERVICE

sx comer | erro] SR

% [502M niet Line Pipe Outt || ONS

1502 M inlet, 1502 F Oust v =

seine er Owe [vv

‘et in 2 val

et We 12 Fu vow

7 [een Fost vw

i oF Cue voto

CHECK VALVES

| SPM check valves are made of | applications such as acidizing, cementing, fracturing and

high strength steel and are energized fluids.

precision manufactured to exact

| tolerances in clapper styles in | SPM carries the most complete line of

2" through 4” sizes, dart styles | check valves available to the well service

in 1" through 3" sizes and industry. Various configurations are offered,

CO2Initrogen styles in 2” and 3"| including wing-ahead

styles. Clapper designs include | (standard flow) or

the standard coating or the —_| thread-ahead

superior abrasion and acid _| (reverse flow) models.

resistant coating to give longer | Each check valve

operating life in corrosive is color-coded

applications, for safety and

convenience.

These rugged valves operate at

working pressures from 6,000 | SPs cape, sive, dart sive

dra CODhtapen sy cece aos aro

t0 20,000 psi in well service fad proven for upped wel service applications.

CLAPPER STYLE .

D

REVERSE FLOW STANDARD FLOW

‘an eave wscwr

Sn ae omer aa eccrerass ror car | ww |

a a Pas a

[ce | ona | wae | Sts ew [1800 me

ees wae | _sandostew | 20000 ra st

[acess | NN | eos | Tos oa

eso | Male pe bee ‘000 = ronal

1002 Female 7 ‘Male ‘Standard Flow: 10,000 Blue EE 1120 |

31502 Male Female ReverseFiow | __ 15.000 Purple 1148

iste | _Fenol ao Sena Fw ‘noo | red i

32002 Female Male Standard Row 20.000 | white 245

eon ae Fomaie | Revere Few 2000 | nee 8

re ve Sanaa Fw e900 ek a

ea a m7 fae Fon row Bue 7]

| [sme [sme Fora | Reese Fw 6000 ‘aon =| |

a cs ihe coneerd Fw 15000 fee sr

*Non-Shock Cold Working Pressure

Clapper siyle check valves avaiable in standard service ony, Abrasion resistant clappers avalable fr 3" valves,

CHECK VALVES

DART STYLE

REVERSE FLOW

Valve | Upstream

Size Inlet | Outlet | downstream es" Color Weight Service

171502 | Female | Male Standard Fow “15000 Red om Standaré

1502 | Female | Male "Standard Fow 15,000 Red 628 Standard

z 1502 | Mate | Female Reverse Flow 15000 | Purple ean Standard

21502 | Female | Male Standard Flow 15.000 Red em | Standard

sr1s02 | Male | Female Reverse Fow 15000 | Pune | 1108 | Standard

[sr1sc2_| Femaie | Male ‘Standard Flow 15,000 Res | 1108 Standard

1502 | Male | Female Reverse Flow H2S 10.000 Gro | out Hes

1802 | Female | Male ‘Standard Fow #25, 10,000 Green| 64 Hes

1502 | Male | Female Reverse Flow H2s 10.000 Green 1108 Hes

1802 | Female | Male Standard Flow H2 10,000 Green 1108 Hes

“Non Shack Cold Working Pressure

CO2/NITROGEN STYLE

(WLLL ee

STANDARD FLOW

va) | Upstream NscwP

Sze | inlet | Outlet Downstream sy Color | Weight | Service

| zrs02 | mae | Female | Reverse riowtowTemp | 15000 Pupie za | Standard

z1502 | Femae | mae | standardFiowtowtemp | 15,000 ea rae | Standard

| sttsa2 | Male | Female | Reverse Flow Low Temp. 15,000 Purple 1438 ‘Standard

1502 | Female | Male | Standard ow Low temp | 15,000 Red ase | Standars

Nex Shock Cold Working Pressure

HAMMER UNIONS

Fig. 100

eb NUT

YeLLow sues

cy

Es

Sain

Fig. 200

BLUE NUT

Gray sues

‘etal sein

Stace between

irate anaterale

‘hte, Fora wae,

Steams

Nsowe,

Fig. 206

ee wor

Say Ses

oe

aaa

Erste

ee

Fig. 207

aLUe CAP

Gray sua

nerchargea

Fp on: wh

Hsing cap

fg seit msnure

roteaccoaue ct

tran anes

zones

Fig. 400

BLACK NUT

RED SUBS

prodison tal ana

(5 and mod

SPM hammer unions are available in a wide range of sizes and in

‘working pressures to 20,000 psi. Pressure seal, non-pressure seal

and welded styles are offered in various sizes and pressures. All SPM

hammer unions provide pressure-tight, postive sealing, Available for

standard service and sour gas models. SPM hammer unions for sour

{gas service are specially heat-treated for controlled hardness and

utlze fluorocarbon elastomer seal rings,

1] 2 [2%

sisi

S

sivisisis|&

sisis

S

Fig. 402

BLACK NUT

BLACK SUBS

ester ipsype

to4.00per

Nscwe"

Fig, 602

aubknur

Geant ues

ieocoes

cae

Fig. 1002

RED NUT

BLUE SUBS

tert ope

‘acco seal

‘ans abrasion a

‘3 wae, gas

10000 pst

sisisisisic/<

(Po. 1502 aso abi for

aur gas sorace)

Fig. 1502

BLUE NUT

RED SUBS

for anid and

tcourtnng gh

presures ncn

Sat oh

‘S00 pa

Fig. 2002

WE NOT

viare Sos

a

—

Fig. 2202

GREEN NUT

GREEN SUBS

Especial fo sour

(as sre hoa.

‘ated comeenents

sng. For sorce a

sce

SPM manufactures a quality line of high pressure integral union connections in a broad range of

configurations and sizes from 1” through 4” and in pressure ratings to 20,000 psi NSCWP". Manufactured

from high strength alloy steel forgings, SPM integrals are ofa lightweight design not found in competitive

products. All SPM integral union connections are subjected to controlled heat-treat processes,

CG

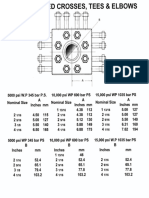

crosses GAUGE CROSSES (Sha andLong Rais)

Pressure

ratings to Soe h sid

20,000 psi

NSCWP*

conve suis wees

ey

fg. soe | fg ta | Fg ne | ig an0a | ig 2a [al Fen Ale |_conbiation

10,000 ps | 15,000 ps | 10,000 ps" Hs | 20.00 psi|15000 ps H2s| {Tivead) | (Wing) Sys and Sizes

| v_ | - viv

|e [+ vw v

¥ v v | v v v yl

= v v v_ |” vi 7 a cama

«pv p+ | fo I vp v

UNION ADAPTER FLANGES UNION CHANGEOVER and CROSSOVER ADAPTERS

In flange sizes from 2-1/16'tru | Availabe in a variety of cilferent sizes and thread types in female-to-

7-4/16" and integral union male, female-to-lemale and male-to-male configurations from 1 thru 4°

end sizes from in pressure ratings from 6,000 to 20,000 psi NSCWP” in standard service

We thru 4 | and up to 15,000 psi in sour gas service

UNION BULL, GAUGE and

LIFTING BULL PLUGS —

Available in 1", 1'%", 2", 3" and 4" | UNION MALE and FEMALE TO PIPE AND TUBING THREAD.

sizes in male and female models in. | swaGES |

pressure ratings to 20,000 psi

NSCWP in standard service Available in numerous different sizes and threaded configurations from 1°

and up to 20,000 psi in thru 4" in pressure ratings from 6,000 to 10,000 psi NSCWP*

sour gas service. Also

available with special ports a =

for high pressure testing

MANIFOLDS

PUMP DISCHARGE, FLOW-THRU,

TEST and CIRCULATION

MANIFOLDS

Pump discharge manifolds are

available in single or multiple discharge

outlets in a variety of integral union

connections up to 20,000 psi NSCWP*.

Features include full bore, thick-wall

tubing and pump discharge flanges to

fit most major brands of pumps.

Flow-thru, test and circulation

‘manifolds are available in both 5,000

and 10,000 psi NSCWP* for threaded

and to 20,000 psi NSCWP* for all-

integral connection sizes. All styles

utilize proven SPM plug valves of all

sizes, 1" through 3", Available

variations include gauge ports, fixed

choke and adjustable choke models.

ip d

INTEGRAL UNION and

FABRICATED MANIFOLDS

Fabricated manifolds are available in 3*

and 4” sizes with various end branch

Connections in pressure ratings of 6,000

and 15,000 psi, NSCWP". Integral union

‘manifolds come in many configurations

using SPM integral laterals, crosses,

tees and ells. Stands and lifting eyes are

available on request.

“Non Shook Cold Working Prossure

CHOKE TEES

Adjustable and positive choke tees are primarily used in choke

manifolds, flow thru manifolds and test manifolds. Various forged-body

configurations are available in 2-inch and 3-inch sizes, each rated at

15,000 psi NSCWP*. Also available in sour gas configuration.

BUTTERFLY VALVES

SPM butterlly valves are manufactured with features that make them the

most up-to-date products of their kind in today’s market.

‘The valve's specially designed disc allows for a noticeably smoother

mediaflow, reducing or eliminating turbulence commonly found in other

valves. Another superior design feature is the split stem, which allows,

the disc to automatically center in the media flow path, thus assuring

an even seal around the disc. The upper stem also incorporates a

positive hex drive located out of the media flow; this feature

eliminates the often troublesome bolt-and-screw attachments inf

other designs. SPM triple stem seal eliminates premature leakage |

into the stem area, avoiding stem seizure. A two-piece phenolic

back-up ring allows internal pressure to anchor the seat within

the valve body and prevents seat walking.

WELL SERVICE PRODUCTS

HIGH PRESSURE FILTER UNIT |SUR-DROP™ BALL INJECTOR — JET MIXERS and

Cus

Pe ie

sr

oh Weel

ENINW Tn

it eliminates bacterial con- MUD MIXERS

The unit eiminates bacterial con- | the SPM Sur-Drop high pressure

tamination of brine solutions or

ball injector has

other types of completion tuids

features that make it

during gravel packing obs. Standard | atures that make

fiters are offered in 1, 3, 5 and 10 Ps

Pie reliable than conven-

es tional units. Its unique

Flowyate fe “positive feed system |

iwatanels eliminates the need for

per minute multiple units to handle

through each different size balls. One

side at §,000 Sur-Drop unit handles as

psi or four barrels per minute many as six ifer- 4

through both sides. ent ball sizes by :

simply changing the e

internal cartridge. The unit

PIPEVISES _____ } __. | teatures a man-

SPM jet mixers feature quick

disconnect hoppers with

accessories including goose:

neck assembly and mixing

bowls with single and

ual hand crank,

remote control

or combination |

manual/remote_ :

control system.

SPM Sur-Grip™ screw-

type vises feature heavy J Le

alloy steel bodies and

screws, reinforced anvils

and optional rotating

base, Available with a Tare Car multet nozzles, allowing for

S.98"jew opening ho FE mvemasnete| single, dual or tr-jet selection while

eee eres S mixing is taking place.

valves, fitings a

| and many other 12

iter. 109

100

WELL SERVICE PUMPS

‘SPM manufactures the most

‘comprehensive range of high pressure

plunger pumps in the industry. SPM's

pump designs incorporate the ultimate

Jn weight and space savings while

‘having a reputation for dependable

service even in today's hybrid

continuous duty applications, such as

under-balanced coiled tubing driling

‘SPM offers 13 intermittent service

pump madels forthe fll range of well,

service applications; six extended duty

plunger pump models for those oilfield

and industrial applications requiring a

‘small footprint, lightweight pump; and

two mud service pumps that are both

‘compact and lightweight,

'SPM's DNV Type Approved intermittent

Service plunger pumps range from 250

BHP to 2500 BHP with pressure

Capabilities up to 20,000 psi. Premium

plungers, valves, seats, packing, ete

can be configured to a variety of well

service needs fram mud based coiled

tubing support services to hot oi

cementing, acidizing, fracturing, gravel

packing, etc

‘SPMs small footprint, yet heavy duty

extended service plunger pumps range

from 175 BHP to 1575 BHP. These

‘extended duty plunger pumps are

specially designed to provide durable

service in extended applications one

day and provide exceptional high

pressure / high rate intermittent service

the next. These pumps’ unique

versatility in duty cycle adaptability

greatly increases the range of work

that can be performed and the amount

of revenue that can be generated with

‘a single pump. These pumps are

designed so that the expendable parts

(packing, etc:) can easily be

reconfigured for mud, water, drill

cuttings, acid, cement, ete.

‘SPM pumps are available with life cycle

‘enhancing ‘auto-frettage" processing

ofthe fluid cylinder. This very

‘economical process adjusts for the

harmful effects of cyclic stress and the

stress corrosion cracking which can

‘occur in high pressure fluid cylinders,

‘SPM state-of-the-art auto-rettage

process results in a fui cylinder with

several mes the fatigue life

cxpecancy ata fractonal erase in|

cost

1SO recognized classroom and shop

training are availabe to better

familiarize the customer with the |

design parameters, tachnical

specifications and operating

characteristics of each pump model.

SPM provides a wealth of technical

data, assembly drawings and

‘maintenance information on i's plunger

pumps (and flow control products as

Wel) through an interactive home page

(on the Internet at www. spmitlo.com.

at of SPM lew control and pump

seminars icluae hands-on

‘emonstratonsin the company’s

manufacturing maintenance facies.

WORLDWIDE SERVICES

IRON RECERTIFICATION

‘SPM's Iron Management Program for refurbishment and/or recertification is designed to provide customers

with products on an ongoing basis that maximize reliability and safety.

* Insures customers of the most comprehensive refurbishment and recertification procedures in the industry,

performed by skilled technicians with significant experience.

Provides the customer's client with third party certifiable safety on the job site.

Provides the customer with complete certification packages.

Reduces downtime.

Insures that treating iron is ready to go when the customer needs it

Maximizes the useful lfe of the product which reduces the customer's inventory requirements.

Global database tracking system allows customer to monitor and analyze flow control iron worldwide

Via the Internet.

PUMP REPAIR

‘You can count on the experts at our repair facilites to handle all your pump repair and rebuild needs.

* All makes and models of well service pumps repaired and rebuilt

* Detailed diagnostic analysis and evaluation of required repairs.

* Itemized cost estimates provided.

‘+ Repairing and rebuilding done by professional SPM technicians.

+ On-site, off-the-shelf availability of most replacement parts.

+ Certified testing to verify quality.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AMPCODocument5 pagesAMPCOSetyohdWNo ratings yet

- Guard Air 022802Document24 pagesGuard Air 022802SetyohdWNo ratings yet

- RidgidDocument62 pagesRidgidSetyohdWNo ratings yet

- Gear EnchDocument18 pagesGear EnchSetyohdWNo ratings yet

- GoldenrodDocument5 pagesGoldenrodSetyohdWNo ratings yet

- Thompson ValvesDocument8 pagesThompson ValvesSetyohdWNo ratings yet

- Sand VikDocument5 pagesSand VikSetyohdWNo ratings yet

- Tech DrillDocument4 pagesTech DrillSetyohdWNo ratings yet

- Jet LubeDocument20 pagesJet LubeSetyohdWNo ratings yet

- James Walker MoorflexDocument19 pagesJames Walker MoorflexSetyohdWNo ratings yet

- Greenlee BendingDocument22 pagesGreenlee BendingSetyohdWNo ratings yet

- Parker InstrumentationDocument87 pagesParker InstrumentationSetyohdWNo ratings yet

- AquaFlex Offshore and Industrial HosesDocument28 pagesAquaFlex Offshore and Industrial HosesSetyohdWNo ratings yet

- MACDEMIDDocument55 pagesMACDEMIDSetyohdWNo ratings yet

- SamsonDocument3 pagesSamsonSetyohdWNo ratings yet

- Kero TestDocument19 pagesKero TestSetyohdWNo ratings yet

- Varco Drilling Handling Equip CatelogDocument34 pagesVarco Drilling Handling Equip CatelogSetyohdW100% (2)

- Sara Gasket BrochureDocument4 pagesSara Gasket BrochureSetyohdWNo ratings yet

- MissionDocument4 pagesMissionSetyohdWNo ratings yet

- Varco BJ Catalog - Rotary & Hoisting Tools - Parts & AssembliesDocument109 pagesVarco BJ Catalog - Rotary & Hoisting Tools - Parts & AssembliesSetyohdWNo ratings yet

- SC-400.10AQR1 Supplement 1 0Document3 pagesSC-400.10AQR1 Supplement 1 0SetyohdWNo ratings yet

- Varco Catelog MiscDocument44 pagesVarco Catelog MiscSetyohdWNo ratings yet

- Mobile Type Air Cylinders SC-1000Document38 pagesMobile Type Air Cylinders SC-1000SetyohdWNo ratings yet

- Varco BJ Catalog - Bushings Slips & ClampsDocument41 pagesVarco BJ Catalog - Bushings Slips & ClampsSetyohdWNo ratings yet

- S Pressure RegulatorsDocument5 pagesS Pressure RegulatorsSetyohdWNo ratings yet

- SC 300 35 - CL03Document27 pagesSC 300 35 - CL03SetyohdWNo ratings yet

- SC 600 Electro Pneumatic DevicesDocument60 pagesSC 600 Electro Pneumatic DevicesSetyohdWNo ratings yet