Professional Documents

Culture Documents

An5346 Stm32g4 Adc Use Tips and Recommendations Stmicroelectronics

Uploaded by

Paulo PecegueiroCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

An5346 Stm32g4 Adc Use Tips and Recommendations Stmicroelectronics

Uploaded by

Paulo PecegueiroCopyright:

Available Formats

AN5346

Application note

STM32G4 ADC use tips and recommendations

Introduction

The STM32G4 Series microcontrollers are designed to support high-end analog applications. These MCUs embed high-

performance analog peripherals (ADCs, DACs, COMPs, OPAMPs, reference voltage) and high-performance digital components

such as their Arm® Cortex®-M4 CPU, mathematical accelerators, DMA, and high-resolution timer among others.

This application note presents specific properties of the embedded ADCs in the STM32G4 Series and an introduction on how to

properly design an application using those specific ADC properties.

This document introduces the specific ADC properties that influence the ADC accuracy of a final application and explains how to

correctly design application hardware and software to improve the ADC accuracy for various application cases.

AN5346 - Rev 2 - October 2019 www.st.com

For further information contact your local STMicroelectronics sales office.

AN5346

STM32G4 ADC features

1 STM32G4 ADC features

This document uses as reference the specific STM32G4 ADC features listed in Table 1. This table presents the

basic numeric values used as reference in the following sections.

Table 1. ADC features on STM32G4 Series

Features Values for STM32G4 Series

Number of ADCs Up to 5

Resolution 12 bits (or 10, 8, 6 bits), 16 bits with oversampling

Number of input channels Up to 42

ADC principle Successive approximation register (SAR)

ADC clock frequency Up to 60 MHz (up to 52 MHz in multiple-ADC operation case)

Sampling rate Up to 4 Msps (up to 3.46 Msps in multiple-ADC operation case)

Sampling time 2.5 to 640.5 [ADC clock periods]

Supply voltage VDDA = 1.62 V to 3.6 V

On dedicated VREF+ pin(1) (internal or external), VREF+ = 1.62 V to VDDA (see

Reference voltage

datasheet)

Triggers From external pins or internal peripherals (timers)

Conversion modes Single, continuous, scan-selected channels, discontinuous mode

Offset calibration, analog watchdog, hardware oversampling, offset compensation, gain

Others compensation, interleaved mode (two ADCs coupled), sampling time controlled by

trigger edges, bulb mode sampling

1. In the LQFP128-pin packages, two VREF+ pins are available.

For more detailed information on ADC features and characteristics on STM32G4 Series, refer to the

corresponding products datasheet and reference manual (RM0440) available at www.st.com.

The STM32G4 Series microcontrollers are based on the Arm® Cortex®-M4 processor.

Note: Arm is a registered trademark of Arm Limited (or its subsidiaries) in the US and/or elsewhere.

AN5346 - Rev 2 page 2/15

AN5346

Maximum ADC speed

2 Maximum ADC speed

2.1 Successive approximation principle

The ADC in STM32G4 Series is based on the successive approximation register principle. This principle is

depicted in the figure below:

Figure 1. ADC operation based on successive approximation principle

Clock SAR EOC

D N-1 D N-2 D2 D1 D0

VREF

DAC

Comparator

-

V IN +

S/H

The input voltage (VIN) is sampled by the sample-and-hold block (S/H) (as voltage on sampling capacitor) to have

stable voltage during conversion time. This sampled voltage is then compared by the comparator with a known

voltage. This known voltage is provided by the DAC that is supplied by the reference voltage VREF.

The DAC digital input is generated by the successive approximation register (SAR) as a digital word. This digital

word is generated according to the result from the comparator and is based on the successive approximation

principle. The SAR initially generates a word corresponding to a half-voltage range. If the result from the

comparator is zero (meaning that input voltage is less than ½ VREF), then, in the second step, the word

corresponding ¼ VREF is generated by the SAR . In each approximation step, the SAR adds or subtracts 2n

weight according to the current step result from the comparator. After N steps, the SAR generates a final word

that is the ADC digital result. The generated analog voltage is close to the measured voltage (with maximum

½ LSB difference).

2.2 Maximum ADC speed in successive approximation

The maximum ADC speed is given for the successive approximation principle by the DAC speed and the

comparator speed (see Figure 1). In each successive approximation clock cycle, the DAC must set the correct

stable analog voltage on its output (with ½ LSB accuracy) and the comparator must provide the result at the end

of each cycle.

For example: If the ADC clock is 60 MHz, then each ADC clock cycle takes 1 / 60 MHz = 16 ns. This 16 ns time

represents the DAC output stabilization time plus the propagation delay of the comparator.

2.3 Switched capacitors

The ADC principle in STM32 MCUs is based on successive approximation where the DAC is based on switched-

capacitor network. The capacitor network implementation is technologically acceptable and precise. The

advantage of this solution is that the capacitive network works also as sampling capacitor. So there is no need to

have one more additional sampling capacitor.

The principle of this implementation is explained in section 1. ADC internal principle of the application note How to

get the best ADC accuracy in STM32 microcontrollers (AN2834).

AN5346 - Rev 2 page 3/15

AN5346

Parasitic components

The figure below shows the basic principle of switched-capacitor SAR ADC principle (for a 10-bit ADC).

Figure 2. Basic schematic of SAR switched-capacitor ADC (10-bit ADC example)

VREF

VIN

Sa

S1 S2 S3 S4 S5 S6 S7 S8 S9 S10 S11

C C/2 C/4 C/8 C/16 C/32 C/64 C/128 C/256 C/512 C/512

Sb A D PRQ ADC data

CLK

CLR

ADC clk

Note: This is a schematic of an ADC with digital output.

In this figure, the input voltage (VIN) is connected through sampling switch (Sa) to the whole capacitive network

that works as sampling capacitor (its charging duration defines the sampling time, Sb is closed). The whole

capacitive network is charged to VIN voltage. Then the Sa switches from VIN to VREF and Sb is open. Then the

successive approximation is performed: in each clock cycle, the switches S1 to S11 are rearranged and the

comparator compares the final voltage. During each S1 to S11 switches rearrangement, there is a charge

redistribution between capacitors.

2.4 Parasitic components

In each approximation step, the charge redistribution between capacitors is performed. This charge redistribution

causes current peaks between capacitors and also from VREF voltage (see Figure 2). Those current peaks are

limited by the parasitic components: resistance and inductance between capacitors and VREF/VSSA voltage.

At the end of each approximation cycle (ADC clock frequency), all currents must be close to zero because the

voltage must be stable for comparator comparison. The speed to reach this stable state during charge

redistribution is given by all RLC components. The dominant capacity fraction is the capacity of the capacitors

network, respectively rearranged sampling capacitor into serial-parallel combination during the approximation

(given by configuration of S1 to S11 switches).

The R and L components are parasitic:

• R represents the resistance: dominant is the resistivity of switches S1 to S11 (and on-chip metal paths).

• L represents the inductance of all conductive paths: dominant is the longest conductive path from VREF/

VSSA pads to VREF/VSSA pins (bonding wires and on-chip metal paths).

In practice there are attenuated voltage and current oscillations in each approximation step. For correct operation,

the amplitude of voltage oscillations (on comparator, respectively on the capacitor network) must decrease below

1 LSB.

The frequency of oscillations is given by LC components and the attenuation is given by RL components. For

rapid attenuation, the inductance must be kept at a low value: exponential decrease of oscillations is given by the

following formula:

e - R / (2 L) . t (envelope of attenuated oscillations at frequency (2πf)2 = 1 / (LC))

The ADC maximum operating frequency is given by those parasitic RL components.

Note: A large decoupling capacitor must be connected directly between pins VREF+ and VSSA. This capacitor creates

an ideal VREF voltage source (fixed DC voltage without oscillations on this decoupling capacitor).

AN5346 - Rev 2 page 4/15

AN5346

Application design to reach ADC maximum conversion speed

2.5 Application design to reach ADC maximum conversion speed

2.5.1 Decoupling capacitor and PCB design

As mentioned in the previous section, the VREF+ pin must be correctly decoupled.

An appropriate decoupling capacitor must be connected between VREF+ and VSSA pins with a minimum added

inductance. Each 1cm of metal path on PCB adds approximately from 6 to 10 nH of inductance. The decoupling

capacitor must be placed as close as possible to VREF+ and VSSA pins without through hole connections that

may create a loop increasing the inductance.

The placement of the decoupling capacitor must be made on the same layer as VREF+ and VSSA pins. The

decoupling capacitor must have a low ESR and a low inductance (for example: ceramic capacitor).

2.5.2 Package selection

The internal parasitic inductance depends on the chip layout and also on the distance between the VREF+/VSSA

pads on chip and the VREF+/VSSA pins on the package (bonding wire length).

This distance is given by the bonding wires and the pins. The pinout of STM32G4 Series MCUs is designed to

have a minimum internal inductance: VREF+ and VSSA pins are adjacent, creating then a minimum current loop

and minimizing the internal inductance (see the figure below).

Figure 3. Example of VREF+ and VSSA pins location on STM32G4 LQFP48 package

PB8-BOOT0

PA15

PA14

PA13

VDD

VSS

PB9

PB7

PB6

PB5

PB4

PB3

48

47

46

45

44

43

42

41

40

39

38

37

VBAT 1 36 VDD

PC13 2 35 VSS

PC14 - OSC32_IN 3 34 PA12

PC15 - OSC32_OUT 4 33 PA11

PF0 - OSC_IN 5 32 PA10

PF1 - OSC_OUT 6 31 PA9

PG10 - NRST 7

LQFP48 30 PA8

PA0 8 29 PB15

PA1 9 28 PB14

PA2 10 27 PB13

PA3 11 26 PB12

PA4 12 25 PB11

13

14

15

16

17

18

19

20

21

22

23

24

PB0

PB1

PB2

VREF+

VSS

VSSA

VDDA

PB10

VDD

PA5

PA6

PA7

Even though, some packages offer lower distance between chip pads and package pins. For example, the

internal inductance is larger on LQFP packages than on UFBGA, UFQFPN or WLCSP packages, due to longer

wires from pads to pins.

To decrease even more the inductance on large packages (such as the high-pin count LQFP128) has a VREF+

signal connected by two wires to the two VREF+ pins.

2.5.3 Decrease of ADC clock frequency

If the PCB design is not good enough and if there is an additional external inductance, the oscillations are not

attenuated below 1 LSB at the end of the approximation cycle (equal to ADC clock cycle). In this case the ADC

may produce DNL errors at high ADC clock frequency.

The solution is to decrease the ADC clock frequency with keeping, if possible, the required final data sampling

rate.: slow down each approximation cycle and wait more time for attenuation.

Application example

In this example:

• The ADC is triggered by a timer at a 2 MHz trigger frequency ( ADC conversion triggered every 500 ns).

AN5346 - Rev 2 page 5/15

AN5346

STM32G4 multiple ADCs and parallel operations

• The ADC clock is 60 MHz.

• The sampling time is 2.5 ADC clock cycle.

• The conversion time is 15 ADC clock cycles (250 ns).

• The sampling rate is 1 / 250 ns = 4 Msps.

The ADC frequency can be decreased down to 30 MHz (each approximation cycle is then two times longer), while

keeping the timer trigger frequency at 2 MHz.

Figure 4. Example ADC frequency decrease while keeping the final data rate

Sampling

Sampling

Sampling

ADC clock Conversion Conversion Conversion

60 MHz

Timer trigger Timer trigger Timer trigger

Sampling

Sampling

Sampling

ADC clock Conversion Conversion Conversion

30 MHz

Timer trigger Timer trigger Timer trigger

2.6 STM32G4 multiple ADCs and parallel operations

2.6.1 Parasitic oscillations influences

Up to five ADC instances are implemented in the STM32G4 Series MCUs. More than one ADC is used at one

time in the applications, means various ADCs conversions happen at the same time. This ADCs parallel operation

may influence the final ADCs results.

The effect of parasitic RLC components to conversion speed is explained in Section 2.4 . In case of parallel

ADCs operation, all the ADCs use the same VREF voltage. The schematic diagram in Figure 2 is therefore

multiplied but the VREF voltage remains common for all ADCs. There are more capacitors networks connected in

parallel to VREF. More capacity change in each approximation step causes higher current peaks from VREF and

the internal oscillations have then higher amplitude. The frequency of oscillations decreases due to larger

capacity connected to VREF.

Due to all those effects, the attenuation reaches 1 LSB level later and the maximum ADC frequency of all parallel

operating ADCs is lower than in case of only one ADC. If the ADCs clock is kept high, the attenuation does not

decrease below 1 LSB level and the ADCs produce DNL errors. There is also an interference between the ADCs:

one ADC influences another ADC result. This influence depends on the synchronization between the ADCs: when

a given ADC starts an approximation regarding to another ADC. The ADC frequency must be decreased to keep

the ADCs results accurate (each approximation cycle is extended).

2.6.2 Optimizations for multiple-ADC operation

The suggestions for the design of an application using multiple-ADC operation are the same as for a single ADC

(refer to Section 2.5 ): good VREF+/VSSA pins decoupling, correct VSSA grounding.

For multiple-ADC operation, all the effects of the internal oscillations and charging currents from VREF are

cumulated (from all used ADCs). A correct PCB design is therefore very important: take care of the decoupling of

VREF+ pin and the correct grounding layout, because there are relatively high current peaks on the VREF+ pin.

Note: Unstable voltage on pin VREF+ can influence the DAC performance because the VREF+ pin provides reference

voltage for the DAC.

AN5346 - Rev 2 page 6/15

AN5346

ADC limitation: input channel switch disturbs ongoing conversions

3 ADC limitation: input channel switch disturbs ongoing conversions

3.1 Limitation description

This limitation is described in the errata sheets of the STM32G4 Series MCUs. More details and possible

workarounds are detailed below.

Each ADC has an input multiplexer that performs the selection of a given channel: there are sets of analog

switches between the ADC input and a given pin on the package. The Sa sampling switch (see Figure 2) is

implemented behind the multiplexer. Sa is switched on during sampling time (initiated by the trigger). During the

successive approximation, Sa is open to isolate the capacitors network from the analog input. The multiplexer is

switched to the next programmed channel in the middle of the successive approximation (in case of scan mode).

If the ADC is used in single mode or at the end of the scan sequence, the multiplexer is switched to the internal

channel (Channel 31).

The multiplexer switching from the current channel to the following channel generates some noise that may

influence the successive approximation currently in progress (especially the bit under evaluation in the successive

approximation sequence). This may also impact the DNL error of any ADC currently converting.

The worst case is when various ADCs operates synchronously and their input multiplexers switch to the next

channel at the same clock cycle (usually the case as all ADCs are programmed with the same parameters and

triggered by the same trigger). In this case, the noise is cumulated and the DNL error of the ADC results is

maximal.

3.2 Workaround

This workaround is based on disabling the input multiplexer switch during the successive approximation.

The input multiplexer switch is not performed in the following cases:

• in continuous conversions for the same channel

Continuous conversions are performed on the same channel and the input multiplexer is kept switched on

the given selected channel (except for the final conversion).

• in bulb mode for the same channel

The input multiplexer is kept switched on the selected channel (and does not switch to internal channel)

because the sampling phase starts immediately after finishing conversion from the same selected channel.

• in scan sequence if the next channel number is the same as current channel number

The multiplexer switches to the following channel in the middle of the conversion, but no switch is performed

if the following channel number is the same as current channel .

The above cases can be used as workaround to solve switching problem. In single channel applications (only one

channel per ADC is used), the 'bulb mode for the same channel' use-case is appropriate. In multiple channels

applications (various channels per ADC are used), the last use-case is better.

In the last use-case, the original channel scan sequence must be modified that each channel is doubled into pairs

in the scan sequence. The correct results are taken only from the first sample of the pair. This solution leads to

decrease the effective sampling data rate to one half (each second conversion is thrown). This case offers also a

solution if various ADCs are operating together in synchronous operation. In asynchronous ADCs operation, the

channel switching noise may influence another ADC as the channel switching is not synchronized among ADCs.

3.3 Optimized channels sequence

For some applications, the proposed workarounds are not suitable. For example, a high data rate is required and

doubling each channel in scan sequence impacts too much data rate. In this case the scanned channel sequence

can be optimized regarding the channel numbers order.

The noise level generated by the multiplexer channel switch depends on the channel numbers used, especially on

the change between current channel number and the following channel number. The generated noise level is

proportional to the number of bits changed in the channel number (in case of channel change).

Each number (for example Channel 6) has a binary representation (0110 in the example). If there is a change to

the next number (for example to Channel 15 with binary representation 1111), the generated noise is proportional

to the number of changed bits in this number (2 bits changed from Ch 6 to Ch 15: 0110 to 1111). Those changed

bits represents the Hamming distance. An optimum channels sequence represents a Gray code sequence. In a

Gray code sequence, only one bit is changed between each number change.

AN5346 - Rev 2 page 7/15

AN5346

Optimized channels sequence

Example

For numbers 0-15, the Gray code sequence in binary representation is the following: 0000 to 0001 to 0011 to

0010 to 0110 to 0111 to 0101 to 0100 to 1100 to 1101 to 1111 to 1110 to 1010 to 1011 to 1001 to 1000.

The ADC channels numbers must be carefully selected for the scan sequence, to minimize the impact of this ADC

limitation.

When no scan mode is used (channel selected by software before each conversion), the channel switching is

performed to the internal channel (in the middle of the conversion). The internal channel is Channel 31 in the

ADCs of the STM32G4 Series MCUs. In this case, the workaround with bulb mode only is recommended:

optimization with Gray code to number 31 is possible only from number 15: 01111 to 11111). The workaround with

bulb mode completely removes this ADC limitation.

AN5346 - Rev 2 page 8/15

AN5346

Minimize the ADC errors

4 Minimize the ADC errors

4.1 General rules

The application note How to get the best ADC accuracy in STM32 microcontrollers (AN2834) describes the

general rules, methods and recommendations for correct design of applications using ADCs. Refer to this

document to design properly any application with STM32G4 Series MCU ADCs.

4.2 Specific recommendations

The ADCs in STM32G4 Series devices have some specific properties for which the following additional

recommendations are defined:

• Reference voltage on VREF+ pin can be also driven from VREFBUFF (internal reference voltage used on

VREF+ pin):

– Use recommended decoupling capacitor on VREF+ pin: 1 μF + 100 nF. Place this capacitor directly

between VREF+ and VSSA pins.

– Take care of the external load connected to VREF+ pin. Driving capability of VREFBUFF is 6.5 mA, that

covers also the internal ADCs and DACs consumptions from VREF+ pin. If the application uses more

ADCs and DACs, the external driving capability from VREF+ pin decreases proportionally (see the

STM32G4 Series datasheets for ADC and DAC current consumptions from VREF+).

• VSSA and VSS grounding:

– The VSSA pin must be connected as close as possible to the VSS pin. The VSSA pin is used as

analog supply (together with VDDA pin) and also as ground reference for VREF+ voltage (VSSA pad is

internally double bonded with VREF- pad).

– The PCB design must use a large ground plate for VSS ground and connect VSSA pin directly to this

VSS ground plate. If a specific voltage source is used for VREF+ (or VDDA), connect this voltage source

directly to VREF+/VSSA or VDDA/VSSA pins.

AN5346 - Rev 2 page 9/15

AN5346

Specific recommendations

• Filtering of analog supply voltages:

– Avoid to use of larger inductors as filters for VSSA or VREF+ pins. The inductor together with the

decoupling capacitor create an LC filter that operates correctly only if its load is stable (like some

resistance on the LC filter output). It filters correctly the input voltage fluctuations. If the LC filter load

generates current peaks (like current peaks from VREF+ or VDDA pin), this fast transient current peak

can lead to attenuated oscillations of this LC filter at its resonant frequency. In fact, the current peak

decreases the voltage on the decoupling capacitor and, because the inductor inhibits large current

changes, the capacitor is charged back slowly and the LC circuit may oscillate. These voltage

oscillations are present on the decoupling capacitor and therefore, the VREF+ or VDDA voltage is

influenced. The oscillations on VREF+ or VDDA pin are attenuated after a relative long time (when the

current peak disappears) and may influence the VREF+ and VDDA voltages in later critical times.

– In some designs, the high frequency inductor (or better say choke) must be used to filter very high

noise from the power supply (if really present). In parallel to this choke footprint, it is recommended to

design the solder bridge that can short the choke in case of problems with VREF+ or VDDA voltage

stability (see the example in the figure below). The ferrite choke must be properly selected to filter very

high frequencies (relative to current supply peaks frequency) and their impedance character at high

frequencies must be more resistive than inductive (high-frequency losses in the ferrite core).

Figure 5. Example of designing solder bridges (SB8, SB10) in parallel to chokes (L1, L2) on

analog supply voltages

VREF+

SB10

JP8 shunt fitted 1-2

C48 1 μF

VREF 1

L2

2

3 600 R @100 MHz

VDD C47 C49 100 nF

100 nF

AGND

SB8 STM32G474RET6

AVDD

VREF+ 27

L1 VSSA

VDD 29 VDDA

600 R @100 MHz

1

VDD VBAT AGND

SB38

16 VSS 15

VBAT VDD

C53 1 μF 32 31

VDD VSS

48 VSS 47

VDD

64 63

VDD VDD VSS

C55 C45 C54 C42 C52

4.7 μF 100 nF 100 nF 100 nF 100 nF

AN5346 - Rev 2 page 10/15

AN5346

Specific recommendations

• Signal source driving properties knowledge regarding to ADC input properties:

– The signal source impedance value must be known to correctly design the ADC sampling time. If the

signal source has higher impedance, longer sampling times must be used to charge properly the

sampling capacitor (see STM32G4 Series devices datasheets for recommended ADC sampling times

for various external source impedance). The use of longer sampling time leads to decrease the

maximum ADC data rate. For very fast data rate, the use of signal source with low impedance is

recommended.

– To decrease the signal source impedance, an analog buffer can be used as ADC signal source (for

example OPAMP in the follower mode). The speed of this analog buffer (slew rate and frequency

bandwidth) must be known to correctly program the ADC sampling time. At the beginning of the ADC

sampling phase, the discharged sampling capacitor is connected to the analog buffer (OPAMP) output.

The voltage on the OPAMP output is zero at this moment (discharged sampling capacitor at OPAMP

output). Then the OPAMP (thanks to its feedback) starts compensating this unbalance by increasing

the output driving and charging the sampling capacitor. The speed of this OPAMP driving increase

depends on the OPAMP speed (propagation of the OPAMP input change to the OPAMP output

change). In the example of the OPAMP embedded in STM32G4 Series devices: The OPAMP has a

frequency bandwidth of 13 MHz. A first estimation of the propagation delay is 1 / 13 MHz = around 77

ns. The sampling capacitor must then be charged by the OPAMP to 1 LSB accuracy. The

recommended ADC sampling time to read the embedded OPAMP output by ADC is 200 ns (see the

datasheet). If the ADC clock is for example 60 MHz, the sampling time must be programmed to more

than 200 ns x 60 MHz = 12 clock cycles (leading to program sampling time to 12.5 ADC clock cycles,

bits SMP[2:0] = 010). The final data rate is then 60 MHz / (12.5 + 12.5) = 2.4 Msps (maximum data rate

while using the embedded OPAMP as buffer for ADC).

– For measurement of signal sources with very high impedance, refer to section 3.4 High impedance

source measurement of the application note How to get the best ADC accuracy in STM32

microcontrollers (AN2834), where some methods for high-impedance source measurement and design

calculation for practical implementation are detailed.

AN5346 - Rev 2 page 11/15

AN5346

Revision history

Table 2. Document revision history

Date Version Changes

14-Jun-2019 1 Initial release.

15-Oct-2019 2 Updated Table 1. ADC features on STM32G4 Series.

AN5346 - Rev 2 page 12/15

AN5346

Contents

Contents

1 STM32G4 ADC features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Maximum ADC speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Successive approximation principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Maximum ADC speed in successive approximation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Switched capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.4 Parasitic components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.5 Application design to reach ADC maximum conversion speed . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5.1 Decoupling capacitor and PCB design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5.2 Package selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5.3 Decrease of ADC clock frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.6 STM32G4 multiple ADCs and parallel operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.6.1 Parasitic oscillations influences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.6.2 Optimizations for multiple-ADC operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 ADC limitation: input channel switch disturbs ongoing conversions . . . . . . . . . . . . . . . . 7

3.1 Limitation description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Workaround . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Optimized channels sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Minimize the ADC errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 General rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Specific recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

List of figures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

AN5346 - Rev 2 page 13/15

AN5346

List of figures

List of figures

Figure 1. ADC operation based on successive approximation principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Figure 2. Basic schematic of SAR switched-capacitor ADC (10-bit ADC example) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 3. Example of VREF+ and VSSA pins location on STM32G4 LQFP48 package . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 4. Example ADC frequency decrease while keeping the final data rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 5. Example of designing solder bridges (SB8, SB10) in parallel to chokes (L1, L2) on analog supply voltages . . . 10

AN5346 - Rev 2 page 14/15

AN5346

IMPORTANT NOTICE – PLEASE READ CAREFULLY

STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, enhancements, modifications, and improvements to ST

products and/or to this document at any time without notice. Purchasers should obtain the latest relevant information on ST products before placing orders. ST

products are sold pursuant to ST’s terms and conditions of sale in place at the time of order acknowledgement.

Purchasers are solely responsible for the choice, selection, and use of ST products and ST assumes no liability for application assistance or the design of

Purchasers’ products.

No license, express or implied, to any intellectual property right is granted by ST herein.

Resale of ST products with provisions different from the information set forth herein shall void any warranty granted by ST for such product.

ST and the ST logo are trademarks of ST. For additional information about ST trademarks, please refer to www.st.com/trademarks. All other product or service

names are the property of their respective owners.

Information in this document supersedes and replaces information previously supplied in any prior versions of this document.

© 2019 STMicroelectronics – All rights reserved

AN5346 - Rev 2 page 15/15

You might also like

- Ads 131 M 08Document117 pagesAds 131 M 08Paulo PecegueiroNo ratings yet

- Ads 131 M 02Document94 pagesAds 131 M 02Paulo PecegueiroNo ratings yet

- Ads 1285Document7 pagesAds 1285Paulo PecegueiroNo ratings yet

- Ads131b02 q1Document69 pagesAds131b02 q1Paulo PecegueiroNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Aspire Es1-432 - Quanta ZQF - Da0zqfmb6f0Document32 pagesAspire Es1-432 - Quanta ZQF - Da0zqfmb6f0Nico Saibort JuniorNo ratings yet

- An11425 Lna DesignDocument25 pagesAn11425 Lna DesignRaul LunaNo ratings yet

- Mc78l00a D 94916 PDFDocument16 pagesMc78l00a D 94916 PDFAndres Emilio Veloso RamirezNo ratings yet

- Codigo de FallaDocument5 pagesCodigo de FallaMarco Yarasca RomeroNo ratings yet

- Trip Circuit Supervision Relay 7PJ13Document1 pageTrip Circuit Supervision Relay 7PJ13Kuenley TiNy OndeNo ratings yet

- Catalog IDSI TYCODocument226 pagesCatalog IDSI TYCOAdrian OprisanNo ratings yet

- Access Control SystemDocument39 pagesAccess Control Systemscribd99190100% (3)

- VSAT Inspection ChecklistDocument4 pagesVSAT Inspection ChecklistMwai JannaNo ratings yet

- What Circuit For Computer Audio Out To Key Rig?: Search QRQCWDocument11 pagesWhat Circuit For Computer Audio Out To Key Rig?: Search QRQCWKostyantyn SushchykNo ratings yet

- Omni FlowDocument592 pagesOmni FlowJose Luis Mtz Llanos100% (4)

- Current Status and Future Applications For DMD - Based Projection DisplaysDocument4 pagesCurrent Status and Future Applications For DMD - Based Projection Displaysgangwar_neeteshNo ratings yet

- Vostro-3450 Setup Guide En-UsDocument16 pagesVostro-3450 Setup Guide En-UsViết Lãm NguyễnNo ratings yet

- Zain Kuwait PPT - Executive Report - v3Document21 pagesZain Kuwait PPT - Executive Report - v3Manuel CardenasNo ratings yet

- Craig - 4353 TX CobraDocument3 pagesCraig - 4353 TX CobraJorge ContrerasNo ratings yet

- Wireless Microphone SystemsDocument62 pagesWireless Microphone SystemsKamran KhanNo ratings yet

- EVK 7 8 M8 PCBVC D - UserGuide - (UBX 14002502)Document25 pagesEVK 7 8 M8 PCBVC D - UserGuide - (UBX 14002502)Rizwan AhmedNo ratings yet

- Confidential Power Electronics TestDocument9 pagesConfidential Power Electronics TestMuhammad NabilNo ratings yet

- Line Code DecoderDocument34 pagesLine Code DecoderDuncan KingNo ratings yet

- Simulation Study of A Three Phase Transmission LineDocument21 pagesSimulation Study of A Three Phase Transmission LineAsith SavindaNo ratings yet

- Yarns v0.3: SMT PartsDocument3 pagesYarns v0.3: SMT PartsjbwiltsNo ratings yet

- Texecom Premier 24 Installation ManualDocument88 pagesTexecom Premier 24 Installation ManualJenna Beard0% (1)

- N173hge L11Document29 pagesN173hge L11范揚鑫No ratings yet

- Examen 3Document14 pagesExamen 3cameraman01No ratings yet

- QC H/G Drive: Qty Order No. Product DescriptionDocument2 pagesQC H/G Drive: Qty Order No. Product DescriptionSalim82 LKNo ratings yet

- Computer Science Project 1Document22 pagesComputer Science Project 1sanjanaNo ratings yet

- Computer Organization and Architecture Micro-OperationsDocument9 pagesComputer Organization and Architecture Micro-OperationsArvinder SinghNo ratings yet

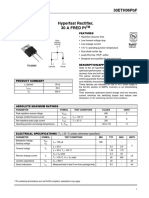

- 30ETH06P DiodoDocument6 pages30ETH06P DiodorepelindNo ratings yet

- EE2155 Set 3Document4 pagesEE2155 Set 3rkumarlingam1988No ratings yet

- Arvin: 3 CH Power Amp PA800, PA1200Document1 pageArvin: 3 CH Power Amp PA800, PA1200Francisco Sanabria NajeraNo ratings yet

- 3 to 8 Decoder Verilog designDocument59 pages3 to 8 Decoder Verilog designvaishnaviNo ratings yet