Professional Documents

Culture Documents

QM 03 - Mechanical-General (01-04,13,31,32) - A

Uploaded by

mohamed elmasry0 ratings0% found this document useful (0 votes)

22 views45 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views45 pagesQM 03 - Mechanical-General (01-04,13,31,32) - A

Uploaded by

mohamed elmasryCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 45

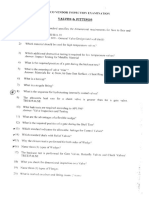

1. Which Mechanical test minimum required for WPQ.

a) Grided bending test.

b) Face bend test.

c) Root bend test.

2. Which electrodes are used for all positions.

a) 6010

b) 7014

c) 6020

d) All of the above.

3. What is the temperature for successive welds.

Ans: Inter pass temperature.

4. What is the difference between Defect & Discontinuity?

5. Compare to E6010, E7014 most suitable for overhead welding.

True or False.

6. What are the precautions before welding a clad material?

7. What is NACE MR0175?

8. What is WPS?

9. What is PQR?

10. What is WPQ?

11. What is the factors effecting Tensile strength?

12. One arc means how much minutes?

Ans: 60

13. True or false- 0.1%of carbon steel is harden than 0.5% of carbon steel.

14. What are toughness testing required in welding alloy steel.

a) Charpy test

b) Dead weight test

c) Izod test

d) All of the above

15. What is the defect if hydrogen is present in Alloy steel.

a) Rust

b) Oil

c) Cracking

d) All of the above

e)

16. To repair weld defects, the visual inspection should perform

a) During welding

b) During repair time

17. Inspector should process:

a) Integrity

b) Honesty

c) Both a & b

d) None of the above

You might also like

- Bsen10056 1Document12 pagesBsen10056 1mohamed elmasryNo ratings yet

- Bsen1043 2Document14 pagesBsen1043 2mohamed elmasryNo ratings yet

- Valve Test Pressures ASME B16.34API598 API6DDocument2 pagesValve Test Pressures ASME B16.34API598 API6Dmohamed elmasryNo ratings yet

- BearingDocument15 pagesBearingmohamed elmasryNo ratings yet

- Bsen1011 3Document32 pagesBsen1011 3mohamed elmasryNo ratings yet

- Exam Aramco ExcelDocument32 pagesExam Aramco Excelmohamed elmasry100% (3)

- Valves & Fittings Question - 02Document3 pagesValves & Fittings Question - 02mohamed elmasry100% (1)

- QM 07 - QM 08 - Valves and Fittings QuestionsDocument3 pagesQM 07 - QM 08 - Valves and Fittings Questionsmohamed elmasryNo ratings yet

- QM 05. Line PipesDocument2 pagesQM 05. Line Pipesmohamed elmasryNo ratings yet

- QM 34 - TanksDocument10 pagesQM 34 - Tanksmohamed elmasryNo ratings yet

- QM 30 - Pressure Vessels Questions (JGM Comments Incorp)Document3 pagesQM 30 - Pressure Vessels Questions (JGM Comments Incorp)mohamed elmasry100% (1)

- QM 07 - ValvesDocument6 pagesQM 07 - Valvesmohamed elmasryNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)