Professional Documents

Culture Documents

E1345 A040 Ommm Maintenance A

Uploaded by

Phong leOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E1345 A040 Ommm Maintenance A

Uploaded by

Phong leCopyright:

Available Formats

GE Power & Water

Rev : A

Page : 1/9

OPERATION AND MAINTENANCE MANUAL

MAINTENANCE

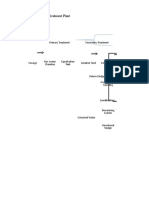

1. SYSTEM MAINTENANCE

1.1. PREVENTIVE MAINTENANCE LIST

Refer to appendix 1 : E1345_A040_OMMM1_Preventive_maintenance

1.2. DESCRIPTION OF THE EQUIPMENTS

1.2.1. Bulkhead light

100 W bulkhead metal and glass

Class I, IP 55, LEGRAND ref. 60573

CM 10 (PG 11) cable gland

Permissible lamps : maxi 70 W

1.2.2. Amerkool GT filter cell

by a disposable coalescer filter : « Amerkool GT ».

This is a coalescer filter cell.

These pad filters are placed in a Ve filter bank.

1.2.3. Dripak GT20

by a disposable pre-filter : « Dripak GT20 ».

This is an air pre-filter cell.

These pocket filters are placed in Matrix filter bank in the same cell as the HE filters

1.2.4. Duravee cell

DuraVee is a heavy dirty high efficiency filter developed specially for the rotating

machinery industry. DuraVee media is water resistant and can with stand exposure

to free moisture in the air stream. The header and cell sides provide a sturdy and

handling. DuraVee utilizes material which are incinerable and do not emit

hazardous chlorine gases.

1.3. HEALTH AND SAFETY

Replace the filter cells (pre-filter or coalescer or HE) (assembly and disassembly) :

a) Preferably wear a dust mask

b) Wear light and very flexible gloves

c) If very steep and narrow steps or a mobile platform is being used to access the upper row

of cells, ensure that they are stable and/or fixed, and use chains or hand rails if possible.

Work with a companion to pass him the cells from the circulation floor or for him to pass

them to you.

d) If locker with 2 or 3 levels of maintenance ensure that during passage to an upper level

the access hatch (including that for passing the filters) is/are replaced or secured by a

guard device.

e) In downstream housing (upper and lower) use removable platforms to access to HE filter

upper back zone.

1.4. LUBRICATION SCHEDULE

Not applicable

All right reserved copyright

E1345_A040_OMMM_Maintenance_A_en Rev : A Date: 28/11/2014

GE Power & Water

Rev : A

Page : 2/9

OPERATION AND MAINTENANCE MANUAL

MAINTENANCE

1.5. PREVENTIVE MAINTENANCE INSTRUCTIONS

1.5.1. Housing general inspection

During every important inspection of the gas turbine, check with a special attention the

following items:

x Tightness of polyurethane sealant on prefilter and filter banks inside the filter housing and

on junction of modules inside and outside the filter housing. If some parts are damaged

or missing, take out the damaged sealant part, clean the support and apply a new strand

of polyurethane sealant.

x The good fixation of mechanical parts.

x The good condition and air tightness of gaskets on access doors.

x The good draining water (not obstructed pipes). Clean the draining boxes under floors.

x Once a year, check the good aspect of anti-corrosion protection.

Make touches-up where necessary.

Take care especially to the good aspect of paint inside clean air module.

1.5.2 Electrical parts

Regular inspections :

x Check that all lighting are working and replace them if necessary.

x Check that all wiring are in good condition (parts of cables out of cables ways, no mark of

cutting or abnormal overheating on the sheath,…).

During every important inspection of the gas turbine, every 10 to 12 years, check with a

special attention :

x The condition of power supply cables, connections and electrical equipment (heater, Plug,

light, switches,…).

x The condition of electrical cabinet and the equipment it contain (gaskets for tightness,

cables connection, heater,…).

1.5.3 Instrumentation parts

Regular inspections :

x Check of the good working of instrumentation (when the gas turbine is stopped for

instrumentation located inside clean air plenum).

During every important inspection of the gas turbine, every 10 to 12 years, check with a

special attention :

x The condition of connection and wiring of instrumentation connected to the gas turbine

control system.

All right reserved copyright

E1345_A040_OMMM_Maintenance_A_en Rev : A Date: 28/11/2014

GE Power & Water

Rev : A

Page : 3/9

OPERATION AND MAINTENANCE MANUAL

MAINTENANCE

1.6. CORRECTIVE MAINTENANCE INSTRUCTIONS

1.6.1. General

CAUTION : After every maintenance period inside the clean air plenum of the filter,

It’s important to respect cleanliness procedures.

1.6.1.1. Mechanical parts

The damage or the breakdown of mechanical parts of the gas turbine’s filter can have

effects of various gravity for the gas turbine.

For the security of the turbine, maintenance operations on the following parts of the air filter

should implicate the stop of the turbine :

x Maintenance operation on “Dripak GT20”, “Duravee” and “Amerkool GT” filters, or on their

frames.

x Maintenance operation on any part of the clean air plenum.

1.6.1.2. Electrical parts

The breakdown of any electrical part of the gas turbine air filter is not a critical break down

for the operating of the gas turbine itself.

Most of electrical parts located outside the clean air plenum can be replaced while the gas

turbine is working.

For electrical parts out of order located inside the clean air plenum, wait until the gas turbine

is stopped to repair or replace them.

1.6.1.3. Instrumentation parts

The breakdown of any instrumentation part of the gas turbine air filter is not a critical break

down for the operating of the gas turbine itself.

Most of instrumentation parts located outside the clean air plenum can be replaced while the

gas turbine is working.

For instrumentation parts out of order located inside the clean air plenum, wait until the gas

turbine is stopped to repair or replace them.

All right reserved copyright

E1345_A040_OMMM_Maintenance_A_en Rev : A Date: 28/11/2014

GE Power & Water

Rev : A

Page : 4/9

OPERATION AND MAINTENANCE MANUAL

MAINTENANCE

1.6.2 “Amerkool GT” cells cleaning

Frequency

Following the cleaning chart.

Initial conditions

During a stop of the turbine

Operate in team of 2 or 3 operators

Replacement instructions :

A) Remove the 4 latches

B) Put down the “Amerkool GT” cell without shaking it and shut it up in a hermetic plastic bag

to avoid discharging of dust

C) Clean correctly the frame with a damp drag

D) Put in place the AmerKool GT cell inside the frame and lock it by using for latches (see

photos here under). Take care of right sense of prefilter installation, green face must be

installed on clean air side or air leaving side (see arrow on frame).

Filter bank (sample)

Amerkool GT filter

cell

Quantity = 180

! SECURITY INSTRUCTIONS !

BEFORE FILTER MAINTENANCE OPERATIONS, YOU MUST USE PROTECTION GLOVES.

WITHOUT GLOVES, YOU EXPOSE YOURSELF TO DEEP INJURIES. (CUTTINGS)

All right reserved copyright

E1345_A040_OMMM_Maintenance_A_en Rev : A Date: 28/11/2014

GE Power & Water

Rev : A

Page : 5/9

OPERATION AND MAINTENANCE MANUAL

MAINTENANCE

1.6.3 «Duravee » and « Dripak » cells replacement

IMPORTANT : For this part of replacement cells Please refer to document 049169-1071

Frequency

Following the replacement chart given item 1.4

Initial conditions

During a stop of the turbine

Operate in team of 2 or 3 operators.

Replacement instructions :

the frame M206 or M207 HE filter frame latchs

Place first the Duravee filter Take care that the filter frame is in contact with filter bank cell.

All right reserved copyright

E1345_A040_OMMM_Maintenance_A_en Rev : A Date: 28/11/2014

GE Power & Water

Rev : A

Page : 6/9

OPERATION AND MAINTENANCE MANUAL

MAINTENANCE

Lock the four latches the Duravee filter is fasten

Prepare the Dripak filter by adding the filter basket The filter pockets must be in horizontal position

Introduce the filter basket in the Dripak cell Place the Dripak filter in the filter bank cell, the bottom part first

All right reserved copyright

E1345_A040_OMMM_Maintenance_A_en Rev : A Date: 28/11/2014

GE Power & Water

Rev : A

Page : 7/9

OPERATION AND MAINTENANCE MANUAL

MAINTENANCE

Take care that the Dripak frame is on the latches support - Control that the Dripak frame is in contact with the

Duravee

Place the fastening rods (two per cells) The first one is placed on the upper side Dripak frame

Detail of the fastening rod position opposite side

Note 1 : The bottom fastening rods is placed between the two bottom Dripak filter pockets.

All right reserved copyright

E1345_A040_OMMM_Maintenance_A_en Rev : A Date: 28/11/2014

GE Power & Water

Rev : A

Page : 8/9

OPERATION AND MAINTENANCE MANUAL

MAINTENANCE

Note 2 : For the next filter bank cell, the position of the fastening rods is offset of one pocket :

Upper fastening rod, between the two upper filter pockets

Lower fastening rod, on the lower side filter frame

1.6.3.1 - Special advice for fastening rods mounting

After engage the first extremity (opposite side) … Push on the rod till the opening

Push in the external direction … till the fastening rods is engage in the frame opening

1.6.3.2 - Special advice for fastening on “pressure tips” cells :

Some Matrix filter cells (3x3) are specialized for pressure tips to allow the independent measurement of the

prefilter and of the HE filter cells pressure drop.

In these cells, it is needed to install, between the Duravee and the Dripak a stainless steel frame to create a

space. The Dripak fastening bars are then different on this assembly.

All right reserved copyright

E1345_A040_OMMM_Maintenance_A_en Rev : A Date: 28/11/2014

GE Power & Water

Rev : A

Page : 9/9

OPERATION AND MAINTENANCE MANUAL

MAINTENANCE

1.7. STORAGE INSTRUCTIONS

If spare parts (instrumentation, lights) or replacement air filter cells are in storage meet the

storage requirements :

- Maximum ambient temperature during storage is + 50°C and mini -20°C.

- Protect the air filters from exposure to sun and rain, snow or other forms of free moisture

and store them in closed buildings or weather proof containers.

The cardboard boxes can be stacked on pallets with a maximum of 4 cardboard boxes on

the top of one another (generally, 16 cardboard boxes per standard pallet : 1,2 x 1,2 m).

Palettes SHOULD NOT be stacked.

It is recommended to strap the pallet with strong tape or iron-straps in order to prevent

falling-off of the cardboard boxes when handled with forklift.

Persons must not walk on the cardboard boxes or on the palettes.

1.8. PRESERVATION INSTRUCTIONS

If the gas turbine is shut down because peak use or for maintenance period any length of

time :

A) Close the maintenance doors

B) Cut off the internal lighting

C) Cut off the power supply on electrical cabinet

1.9. SPECIFIC INSTRUCTIONS

Not applicable

2. APPENDIX DOCUMENTS

x Appendix 1: Preventive_maintenance: E1345_A040_OMMM1_Preventive_Maintenance

x Appendix 2: Instrumentation and control valves list:

E1345_A040_OMMM2_ instrumentation_and_control_valves_list

All right reserved copyright

E1345_A040_OMMM_Maintenance_A_en Rev : A Date: 28/11/2014

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Root Canal Cover UpDocument248 pagesRoot Canal Cover UpVictor Mendes97% (36)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- MD Totco Series 2000 Instruments Installation, Calibration, & OperationDocument160 pagesMD Totco Series 2000 Instruments Installation, Calibration, & OperationDenzil Stephenson100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Gei 41040MDocument28 pagesGei 41040MPhong leNo ratings yet

- Design Sheet STPDocument17 pagesDesign Sheet STPBhagyashree Rath0% (1)

- Attachment 2 - Aux-System Maintenance Procedure Rev4Document26 pagesAttachment 2 - Aux-System Maintenance Procedure Rev4Phong leNo ratings yet

- Dura Vee XLIN0507Document2 pagesDura Vee XLIN0507Phong leNo ratings yet

- Scope of WorkDocument75 pagesScope of WorkPhong leNo ratings yet

- Combustion InspectionsDocument81 pagesCombustion InspectionsPhong leNo ratings yet

- Totally Scope of WorkDocument75 pagesTotally Scope of WorkPhong le100% (1)

- Boroscope Inspection CriteriaDocument6 pagesBoroscope Inspection CriteriaPhong leNo ratings yet

- Scope of Work Gas TurbineDocument13 pagesScope of Work Gas TurbinePhong le100% (2)

- Scope of Work For Gas TurbineDocument47 pagesScope of Work For Gas TurbinePhong le100% (1)

- POTS - 27022021 - CI and MI Scope of WorkDocument10 pagesPOTS - 27022021 - CI and MI Scope of WorkPhong leNo ratings yet

- Omml 0495 06 Loadgear ADocument532 pagesOmml 0495 06 Loadgear APhong leNo ratings yet

- IGV AssamblyDocument31 pagesIGV AssamblyPhong le100% (1)

- Onkyo TX Sr501Document2 pagesOnkyo TX Sr501Phong leNo ratings yet

- M24-Plate Heat ExcahngerDocument16 pagesM24-Plate Heat ExcahngerAlexNo ratings yet

- AIC Plans - All Key Characters and Responsibility Apr. 23Document26 pagesAIC Plans - All Key Characters and Responsibility Apr. 23Tiran AsawrusNo ratings yet

- De Asis, John Rey V. Take Action Activity 1. Making An Inventory of Curriculum Approach As A Content, Content, Process and ProductDocument2 pagesDe Asis, John Rey V. Take Action Activity 1. Making An Inventory of Curriculum Approach As A Content, Content, Process and ProductDexter Malonzo Tuazon100% (1)

- GEETHICS Lesson 1 and 2 PDFDocument2 pagesGEETHICS Lesson 1 and 2 PDFMargarita Lucis Manalo-AlcantaraNo ratings yet

- Free PRM Handbook PDFDocument2 pagesFree PRM Handbook PDFRichard0% (1)

- Self-Learning Home Task (SLHT) : KG Given To HelperDocument4 pagesSelf-Learning Home Task (SLHT) : KG Given To HelperCatherine AbabonNo ratings yet

- 2400 Cau Trac Nghiem Tieng Anh On Thi Vao Lop 10 ChuyenDocument101 pages2400 Cau Trac Nghiem Tieng Anh On Thi Vao Lop 10 ChuyennhgtrNo ratings yet

- Santosh BharatiDocument2 pagesSantosh Bharatisan_bharNo ratings yet

- 27 August To 02 SeptemberDocument16 pages27 August To 02 SeptemberpratidinNo ratings yet

- Harmonising Border Procedures - Position PaperDocument10 pagesHarmonising Border Procedures - Position PaperPeter SsempebwaNo ratings yet

- C and CAP PracticalDocument2 pagesC and CAP PracticalDurga SampathNo ratings yet

- Review of LiteratureDocument18 pagesReview of LiteratureVimal VickyNo ratings yet

- Fluid and Electrolyte Therapy, Calculation of Fluids and Its AdministrationDocument11 pagesFluid and Electrolyte Therapy, Calculation of Fluids and Its AdministrationAnusha Verghese100% (2)

- SEO Case StudyDocument6 pagesSEO Case StudyAmrita JaiswalNo ratings yet

- POST Newspaper For 16th of May, 2015Document88 pagesPOST Newspaper For 16th of May, 2015POST NewspapersNo ratings yet

- Redox (Multiple Choice) QPDocument8 pagesRedox (Multiple Choice) QPShafaq RamzanNo ratings yet

- TABLE 135 - Mood Stabilizing MedicationsDocument1 pageTABLE 135 - Mood Stabilizing MedicationsDragutin PetrićNo ratings yet

- State Wise List of Trees Species Free From Felling and Transit Regulations GrowDocument9 pagesState Wise List of Trees Species Free From Felling and Transit Regulations GrowPriyanka ShindeNo ratings yet

- Supply Chain Management - Master Carbon ManagementDocument16 pagesSupply Chain Management - Master Carbon ManagementIBMElectronicsNo ratings yet

- OCSPDocument3 pagesOCSPgayathrisanNo ratings yet

- Building Materials Lab ManualDocument21 pagesBuilding Materials Lab Manualapi-348488925100% (3)

- ArulesDocument106 pagesArulesFadhilah Amin FathoniNo ratings yet

- January 2017 MS - Paper 1 Edexcel (B) Maths IGCSEDocument22 pagesJanuary 2017 MS - Paper 1 Edexcel (B) Maths IGCSEAhmed ArefinNo ratings yet

- Agency Theory EssayDocument2 pagesAgency Theory EssayAnggi KartikaNo ratings yet

- Preboring Works To DWall With Air-Lift & RCD Core Barrer - 17.6.14 PDFDocument18 pagesPreboring Works To DWall With Air-Lift & RCD Core Barrer - 17.6.14 PDFErick SmithNo ratings yet

- Final Exam Study Guide: Content Will Focus On Post-Midterm Material. However, Pre-Midterm Material Is Fair GameDocument8 pagesFinal Exam Study Guide: Content Will Focus On Post-Midterm Material. However, Pre-Midterm Material Is Fair GameJake Fowler0% (1)

- Ending The Houthi Threat To Red Sea ShippingDocument7 pagesEnding The Houthi Threat To Red Sea ShippingKevin ParkerNo ratings yet