Professional Documents

Culture Documents

Maintenance Schedule ACS800 2016 and Before

Maintenance Schedule ACS800 2016 and Before

Uploaded by

MostafaElrakhawyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maintenance Schedule ACS800 2016 and Before

Maintenance Schedule ACS800 2016 and Before

Uploaded by

MostafaElrakhawyCopyright:

Available Formats

—

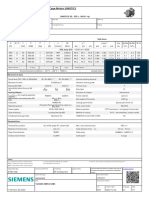

MOTION SERVICES

Maintenance schedule for ACS800

Applied to Industrial Single Drives, Multidrives and Liquid-

Cooled Drives, manufactured or maintained 2016 or before.

For drives manufactured or maintained 2017 and onward please refer to 4FPS10000573508.

Recommended maintenance

intervals and component

replacements are based on

specified operational and

environmental conditions. ABB

recommends annual drive

inspections to ensure the

highest reliability and optimum

performance.

Note See the below listed technical notes for

Long term operation near or over the maximum more details on component aging and

specified ratings or environmental conditions may possible effects on the drive.

require shorter maintenance intervals.

Check the device specific technical specifications in Electrolytic 4FPS10001015180

the relevant hardware manual and consult your local capacitors

ABB Service for maintenance recommendations at: Film capacitors 4FPS10001454838

/new.abb.com/channel-partners/search IGBTs 4FPS10001147623

Cooling fans 4FPS10001147616

More detailed maintenance information can be found

in maintenance instructions, product manuals and on PCBAs 4FPS10001147621

the Internet: Power supplies 4FPS10001454842

/new.abb.com/drives

DOCUMENT ID REV. DATE LANG. PAGE

4FPS10000223379 N 15.6.2022 EN 1/3

MA I NT ENA N CE S CHEDU LE FOR ACS8 00 , MA NU FACTUR ED OR MAI NTA INED 20 16 O R BEFOR E

Years from startup

COOLING

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

Air-cooled

Internal/additional cooling fan for

ACS800-01, -04, -11, -31, -104 (IP20, IP21 and R R R R R R R

IP55)

Cooling fan for ACS800-01, -02, -04, -07, -11,

I R I R I R I

-17, -31, -37, -38, -14, -104, DSU, ISU, ALCL

(1)

DOL Cooling fan for DSU+992, ALCL-1X,

R R R R R R R

0X-X (mains supply frequency 60Hz)

Cooling fan for DSU+V992

I I I I I I I I I I I I I I I I I I I

(mains supply frequency 50Hz)

Enclosure extension cooling fan (ACS800-

R R R R R R R

02)

Extra cooling fans inside cabinet (ACS800-

I R I R I R I

x7, ACS800 md)

Extra IP54 cooling fan on roof of cabinet

I R I R I R I

(ACS800-07, ACS800 md)

Liquid-cooled units

Cooling fans ACS800LC, 50Hz I R I R I R I

(1)

DOL Cooling fan for ACS800LC, DSU LC,

R R R R R R R

(mains supply frequency 60Hz)

Check pH of coolant P P P P P P P P P P

Add coolant corrosion inhibitor P P P P P P P P P P

Heat exchanger cleaning P P P P P P P P P P

Expansion tank air pressure P P P P P P P P P P

Cooling liquid pump assembly I R I R I R I

Change coolant in internal cooling circuit R R

Expansion tank R R

Cooling fans ACS800LC, 50Hz I I I I I I I I I I I I I I I I I I I I I

(1)

DOL Cooling fan = Direct online fan

__

Legend

I Inspection (visual inspection and maintenance action if needed)

P Performance of on/off-site work (commissioning, tests, measurements, or other work)

R Replacement

DOCUMENT ID REV. DATE SECURITY LEVEL LANG. PAGE

4FPS10000223379 N 15.6.2022 External EN 2/3

© Copyright 2022 ABB. All rights reserved.

MA I NT ENA N CE S CHEDU LE FOR ACS8 00 , MA NU FACTUR ED OR MAI NTA INED 20 16 O R BEFOR E

Years from startup

AGING

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

Common

Electrolytic capacitors (DC circuit) R R

Converter electronic boards: APOW, AFIN,

AFPS, AGPS, AINP, CMRB, CMIB, DSMB, R R

DSAB, DSCB

(2)

Cabinet Auxiliary Power Supplies R R

Memory backup battery replacement in

R R R

APBU-xx unit

(3)

ALCL filter capacitor 380 - 415V supply

network (ACS800-14, -17, -37, -38, -67, md, I I/R I I I/R I

LC)

(3)

ALCL filter capacitor 460V - 690V supply

network (ACS800-14, -17, -37, -38, -67, md, I/R I I/R I I/R I

LC)

Connections and environment

AINT+ flat cables, CINT, NRED, discharging

R R

resistors

Power cable connections and quick

connectors of the supply, inverter and

I I I I I I I

converter modules

(ACS800-x7/ and ACS800 md)

Air filters (IP20 to IP42) I I I I I I I I I I I I I I I I I I I I I

Air filters (IP54 and IP54R) R R R R R R R R R R R R R R R R R R R R R

Cleanliness check (dustiness, corrosion and

I I I I I I I I I I I I I I I I I I I I I

temperature) and/or heat sink cleaning

Main Contactor maintenance I I I I I I I I I I I I I I I I I I I I I

Improvements

Based on product notes I I I I I I I

Spare parts

DC circuit capacitors reforming P P P P P P P P P P P P P P P P P P P P P

Safety function

Safety function test interval P P P P P P P P P P P P P P P P P P P P P

(2)

Check amount of Auxiliary power supplies from cabinet or manufactured BOM.

(3)

If filter capacitor is not replaced, the filter capacitor shall be inspected/measured after 3 years from the last inspection.

__

Legend

I Inspection (visual inspection and maintenance action if needed)

P Performance of on/off-site work (commissioning, tests, measurements, or other work)

R Replacement

Note

Long term operation near or over the maximum

specified ratings or environmental conditions may

require shorter maintenance intervals. To minimize

the risk of failures in the frequency converter, ABB

recommends including IGBT modules as part of the

maintenance program. ABB suggests a module

reconditioning at the authorized Drives Service

Workshop in these cases. Reconditioning restores

all the drive’s aging components to the latest version

and revisions. That improves the drive’s reliability and

extends its lifetime.

More information about reconditioning.

Please consult your local ABB for more details on the

maintenance program and available services.

DOCUMENT ID REV. DATE SECURITY LEVEL LANG. PAGE

4FPS10000223379 N 15.6.2022 External EN 3/3

© Copyright 2022 ABB. All rights reserved.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- EC-C+MC 11.1 CommunicationDocument51 pagesEC-C+MC 11.1 CommunicationMostafaElrakhawyNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Motor data for 114222Document1 pageMotor data for 114222MostafaElrakhawyNo ratings yet

- mm4_online_starter_engDocument7 pagesmm4_online_starter_engMostafaElrakhawyNo ratings yet

- 6SL3710-1GE32-1AA3-Z D02+G60+L13+L26+L45+L55+L57+L83+L84 Datasheet enDocument1 page6SL3710-1GE32-1AA3-Z D02+G60+L13+L26+L45+L55+L57+L83+L84 Datasheet enMostafaElrakhawyNo ratings yet

- 1le5603 3BB53 4ab3Document2 pages1le5603 3BB53 4ab3MostafaElrakhawyNo ratings yet

- Iner View: Panel Yamamah Steel Layout CustomerDocument1 pageIner View: Panel Yamamah Steel Layout CustomerMostafaElrakhawyNo ratings yet

- Ach580 01 430a 4+J400Document3 pagesAch580 01 430a 4+J400MostafaElrakhawyNo ratings yet

- Acs880 01 12a6 3+e200+l502Document2 pagesAcs880 01 12a6 3+e200+l502MostafaElrakhawyNo ratings yet

- 00 Report SampleDocument4 pages00 Report SampleMostafaElrakhawyNo ratings yet

- Iner View: Panel Yamamah Steel Layout CustomerDocument1 pageIner View: Panel Yamamah Steel Layout CustomerMostafaElrakhawyNo ratings yet

- Sea Fgreg AdfadfDocument1 pageSea Fgreg AdfadfMostafaElrakhawyNo ratings yet

- Ach580 01 145a 4+J400Document2 pagesAch580 01 145a 4+J400MostafaElrakhawyNo ratings yet

- Ach550 2Document1 pageAch550 2MostafaElrakhawyNo ratings yet

- SDCS Ioe 21Document1 pageSDCS Ioe 21MostafaElrakhawyNo ratings yet

- Acs580 01 145a 4+J400Document2 pagesAcs580 01 145a 4+J400MostafaElrakhawyNo ratings yet

- 00 Time Sheet EmptyDocument2 pages00 Time Sheet EmptyMostafaElrakhawyNo ratings yet

- 3AUA0000036521 3aua0000036521Document3 pages3AUA0000036521 3aua0000036521MostafaElrakhawyNo ratings yet

- Danfoss FC 101p11kt4e20h4xxcxxxsxxxxaxbxcxxxxdx 131l9869Document2 pagesDanfoss FC 101p11kt4e20h4xxcxxxsxxxxaxbxcxxxxdx 131l9869MostafaElrakhawyNo ratings yet

- 1RQ1562-6JJ70-Z A65+D12+K09+K72+K97+L27+L54+Y55 2D Dimension Withframe enDocument1 page1RQ1562-6JJ70-Z A65+D12+K09+K72+K97+L27+L54+Y55 2D Dimension Withframe enMostafaElrakhawyNo ratings yet

- Motor Data For 1531Document1 pageMotor Data For 1531MostafaElrakhawyNo ratings yet

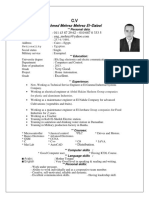

- C.V.Ahmed Mohrez EldaleelDocument1 pageC.V.Ahmed Mohrez EldaleelMostafaElrakhawyNo ratings yet

- EN - Lowvoltagedrives - For - Cement - REVEDocument24 pagesEN - Lowvoltagedrives - For - Cement - REVEMostafaElrakhawyNo ratings yet

- EC-C Resolver Configuration 11.1Document15 pagesEC-C Resolver Configuration 11.1MostafaElrakhawyNo ratings yet

- EC-C+DC 11.1 ApplicationDocument28 pagesEC-C+DC 11.1 ApplicationMostafaElrakhawyNo ratings yet

- Mohamed Abd El Baky-NyDocument2 pagesMohamed Abd El Baky-NyMostafaElrakhawyNo ratings yet

- EC-C+DC 11.1 CommunicationDocument48 pagesEC-C+DC 11.1 CommunicationMostafaElrakhawyNo ratings yet

- Vacon 100 Flow Application ManualDocument254 pagesVacon 100 Flow Application ManualMostafaElrakhawyNo ratings yet