Professional Documents

Culture Documents

A Review On Catalytic Biodiesel Producti

Uploaded by

Ahmad InterestaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Review On Catalytic Biodiesel Producti

Uploaded by

Ahmad InterestaCopyright:

Available Formats

J. Bio. & Env. Sci.

2014

Journal of Biodiversity and Environmental Sciences (JBES)

ISSN: 2220-6663 (Print) 2222-3045 (Online)

Vol. 5, No. 4, p. 48-59, 2014

http://www.innspub.net

RESEARCH PAPER OPEN ACCESS

A review on catalytic biodiesel production

A. Gorji, R. Ghanei1*

Department of Chemical Engineering, Farahan Branch, Islamic Azad University, Farahan, Iran

Article published on October 12, 2014

Key words: Biodiesel, Catalyst, Transesterification, Vegetable oil, Animal fat.

Abstract

The industrialization of societies and as the result, the increase of demand for fuel in the world and speculations

on the reduction of fossil fuels and on the other hand, the issue of world health emphasizes on the necessity of

substituting renewable and clean energy, so biodiesel as the best substitute for diesel fuels is common. In general,

three ways are used to produce biodiesel including pyrolysis, micro-emulsification and transesterification among

which transesterification is known as the most usual and common way. The catalysts used in transesterification

are divided into three groups of acidic, alkaline and enzymatic catalysts in which the acidic and alkaline catalysts

in turn divide into two groups of heterogeneous and homogeneous. The Transesterification reaction using acidic

catalysts involves more time for the reaction and high cost. The alkaline catalysts produce an appropriate amount

of product in moderate operational conditions and show a better performance in comparison with the other

catalysts. These catalysts have a limitation in use for raw material containing high free fatty acids. The way of

using Lipase catalysts is the most viable method that can be applied, however it requires high costs. Given today's

high total cost as the main obstacle for producing biodiesel, using animal fats and waste oils as raw material and

using the heterogeneous catalysts and preferably renewable ones is suggested so as to reduce the total cost.

*Corresponding Author: R. Ghanei rghaneie@iau-Farahan.ac.ir

48 | Gorji and Ghanei

J. Bio. & Env. Sci. 2014

Introduction green fuel (Caynak et al., 2009) that can be used in a

The invention of Internal combustion engines and the variety of cases either as a fuel directly or in

progresses made over the past years in the field of combination with so-called diesel in cars (Guan et al.,

technology of making engines, has led to the great use 2009), fuel for heating (Mushrush et al., 2001),

of oil sources and quick evacuation of these sources. aviation fuels and machines (Dunn, 2001), surfactants

One type of such engines are the Compression-ignition (Doll et al., 2008), lubricants (Willing, 1999) and also

engines or as they are commonly called the "diesel as a good solvent (Pereira and Mudge, 2004).

engine" which have a variety of uses in road and rail

transportation, agriculture and other industries. The According to the definition American Society for

industrialization of societies and as the result, the Testing and Materials (ASTM), biodiesel is "mono-

increase of demand for fuel in the world and alkyl esters of long chain fatty acids derived from

speculations on the reduction of fossil fuels from one renewable fatty raw material such as vegetable oils or

side, and on the other hand, the issue of global hygiene animals fats". The term "Bio" is the symbol of its

and health, made the researchers concentrate their renewability and biological origin and the term "diesel"

research on substituting renewable and clean energy is the symbol of its similarity to diesel fuel and its

for common fuels (Balat and Balat, 2010; Gerpen, application in diesel engine (Guan et al., 2009;

2005; Leung et al., 2010). Among these energies we Graboaki and McComick, 1998; Demirbas, 2009).

can refer to solar energy and biofuels of which biodiesel

is known as the most prevalent Biofuel (Balat and Biodiesel production resources

Balat, 2010; Basha, 2009; Leung et al., 2010). Biodiesel can be produced from vegetable oils such as

Biodiesel due to its advantages such as better palm kernel oil, soybean oil, hazelnut oil, castor oil,

lubrication, complete combustion for having 10-12 corn oil, tobacco seed oil, Jatropha oil, mustard oil,

percent oxygen weight and dissemination of fewer sunflower oil and animal fats such as waste tallow,

pollutants such as Carbon monoxide and Sulfur mutton tallow, fish oil, lard, chicken fat, as well as

dioxides and also because of its biodegradability and its waste edible oils such as waste frying oils. Using

role in the reduction of global hygiene and health animal fats and waste edible oils leads to the total

problems, has drawn the attention of researchers and cost reduction for producing biodiesel (Balat and

nations (Dias et al., 2008; Ramus et al., 2004). In Balat, 2010; Sbihi et al., 2014). Table 1 demonstrates

comparison to conventional fossil fuels, biodiesel lacks some of the properties of produced biodiesel from

sulfur, aromatic hydrocarbons, metals and tiny various oil sources.

particles of solid, hence biodiesel is called the clean or

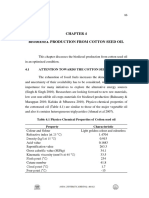

Table 1. Some of the properties for produced biodiesel from various oil sources (Sbihi et al., 2014; Ghobadian et

al., 2005; Bhatti et al., 2008).

Heating

Viscosity Specific Cloud Flash Cetane

Methyl ester value Ref

cSt gravity point ˚C point ˚C number

MJ/l

Camelus 3.39 0.871 15.5 158 58.7 39.52 Sbihi et al (2014)

dromedaries fat

Peanut 4.9 0.883 5 176 54 33.6 Ghobadian et al (2005)

Soybean oil 4 0.880 - - 45.7-56 32.7

Palm oil 4.3-4.5 0.872-0.877 - - 64.3-70 32.4

Sunflower 4.6 0.860 1 183 49 33.5

Canola oil 4.2 0.882 - - 53 32.8

Waste canola oil 9.48 0.895 - 192 63.9 36.7

Waste corn oil 6.23 0.884 - 166 51 42.3

Chicken fat 6.25 - -5 - 61 - Bhatti et al (2008)

Sheep fat 5.98 - -4 - 59 -

Waste frying oil 4.36 - -3 - 53 -

49 | Gorji and Ghanei

J. Bio. & Env. Sci. 2014

Vegetable oils have the highest proportion in the field of vegetable fuels have been published

biodiesel production. Vegetable oils contain more (Ebrahimi and Rahmani, 2012). The diversity and the

unsaturated fatty acids than saturated ones and extent of vegetable oils has created a potential for

hence, they usually possess appropriate cold flow biodiesel production in different countries regarding

properties. Table 2 demonstrates the amount of fatty various climate conditions. Table 3 demonstrates the

acids in a number of vegetable oils (Marchetti JM, amount of oil and main producers of some of

2012). According to the statistics by Sciencedirect vegetable oil seeds (Marchetti JM, 2012).

institute, in 2012 more than 5000 academic papers in

Table 2. Percentage of fatty acids in a number of vegetable oils (Marchetti JM, 2012).

Fatty acid composition (% by weight)

Vegetable oil

16:1 18:0 20:0 22:0 24:0 18:1 22:1 18:2 18:3

Corn 11.67 1.85 0.24 0.00 0.00 25.16 0.00 60.60 0.48

Cottonseed 28.33 0.89 0.00 0.00 0.00 13.27 0.00 57.51 0.00

Crambe 20.7 0.70 2.09 0.80 1.12 18.86 58.51 9.00 6.85

Peanut 11.38 2.39 1.32 2.52 1.23 48.28 0.00 31.95 0.93

Rapeseed 3.49 0.85 0.00 0.00 0.00 64.4 0.00 22.30 8.23

Soybean 11.75 3.15 0.00 0.00 0.00 23.26 0.00 55.53 6.31

Sunflower 6.08 3.26 0.00 0.00 0.00 16.93 0.00 73.73 0.00

Table 3. Main producers of some of vegetable oil seeds (Marchetti JM, 2012).

Amount of

Seed Productive areas

oil (%)

Canola 40-45 Canada, China, India, France, Austria, United Kingdom, Germany, Poland,

Denmark, Chech, Republic.

Corn 3.1-5.7 USA, Mexico, Russia, Belgium, France, Italy, Germany, Spain, United Kingdom.

Cotton 18-20 China, Russia, USA, India, Pakistan, BBrazil, Egypt, Turkey.

Peanut 45-50 China, India, Nigeria, USA, Senegal, South Africa, Argentina.

Crocus 30-35 China, USA, Spain, Portugal.

Soybean 18-20 USA, Brazil, Argentina, China, India, Paraguay, Bolivia.

Sunflower 35-45 Russia, Argentina, Austria, France, Italia, Germany, Spain, United Kingdom.

Coconut 65-68 Filipinas, Indonesia, India, Mexico Sri Lan Ka, Thailand, Malaysia, Vietnam,

Mozambique, New Guinea, Republic of Cote d´Ivoire.

Olive 15-35 Spain, Italy, Italia, Greece, Tunes, Turkey, Morocco, Portugal, Syria, Algeria,

Yugoslavia, Egypt, Israel, Libya, Jordan, Lebanon, Argentina, Chile, Mexico,

Peru, USA, Australia.

Palm 45-50 Malaysia, Indonesia, China, Filipinas, Pakistan, Mexico, Bangladesh, Colombia,

Nigeria, Republic of Cote d´Ivoire

Palm 44-53 Malaysia, Indonesia, China, Filipinas, Pakistan, Mexico, Bangladesh, Colombia,

Kernel Nigeria, Republic of Cote d´Ivoire

Due to the lack of the process of planting, conserving which requires researchers' more attention is the

and harvesting in animal fats and also extraction of amount of animal fats which is not that low compared

vegetable oils which leads to the total cost reduction with vegetable oils and can help to provide energy in

for providing oil for biodiesel production, top the world (Canakci, 2007). On the other hand,

photoobjectives and proper parameters, animal fats producing biodiesel from waste edible oils is a

can be a more appropriate alternative than vegetable promising alternative, since this type of oils can be

oils. On the other hand, Methyl ester from the provided in lower cost compared with fresh oils.

transesterification of animal fats, because of having Furthermore, using waste edible oils helps to protect

high unsaturated fatty acids possesses inappropriate the environment because these oils are discharged

cold flow properties. Statistics show that using merely into the environment without any processing (Balat

animal fats does not have the potential of providing and Balat, 2010). From the other side, due to the

the world required fuel (Balat and Balat, 2010; Sbihi exposure to high temperature, waste edible oils

et al., 2014; Jeong et al., 2009). The important point possess high levels of free fatty acids from which one-

50 | Gorji and Ghanei

J. Bio. & Env. Sci. 2014

stage biodiesel production causes a reduction in (Srivastava and Prasad, 2000; Fukuda et al., 2001).

product level and two-stage biodiesel production In this method low viscosity is obtained for the fuel,

applying such methods as pre-esterification causes an but from the other side, this fuel has a low cetane

increase in production total cost (Nicheran, 2012). number and little energy and the combustion would

be done incompletely and much carbon deposits will

Biodiesel production methods come out (Boro et al., 2012).

So far, a lot of efforts have been made to produce

biodiesel. There are three main and common methods Transesterification

to use vegetable oils and animal fats as diesel fuel Transesterification is the most common method for

which include: pyrolysis, micro-emulsification and producing biodiesel. Transesterification is done

transesterification. through vegetable oil or animal fat reaction with

alcohol in presence of appropriate catalyst (Alkali,

Pyrolysis acid, enzyme) to produce alkyl ester and glycerin as a

In the method of pyrolysis, chemical changes are valuable by-product. In this method, the resulting

taken place through the use of heat in the presence of biodiesel has high cetane number, low emission of

air or nitrogen. Thermal decomposition of pollutants, and high combustion efficiency and

triglycerides leads to the creation of several groups of besides, this method leads to conserve oxygen atoms

material such as alkanes and alkenes, alkadyns, the in biodiesel molecule. Fig. 1 shows the above-

aromatics and carboxylic acid. The resulting fuel from mentioned reaction (Ghanei et al., 2011):

this method has low viscosity and high cetane number

compared with pure vegetable oils. In this method

appropriate amounts of sulfur, water, deposits and

corrosion rate of copper and inappropriate amounts

of ash, carbon residue and cloudy spot are produced Fig. 1. Transesterification reaction scheme.

(Ghobadian et al., 2005; Ranganathan et al., 2008;

Srivastava and Prasad, 2000). Alcohols in transesterification reaction

Appropriate alcohols in transesterification method for

The process of chemical preparation in this method is producing biodiesel are methanol, ethanol, propanol

similar to the process of preparing diesel fuel derived and butanol among (Vicente et al., 2004) which

from petroleum and with the egression of oxygen methanol is used more than ethanol and other

during the thermal process, the eco-friendly alcohols due to its low price and availability. For this

advantages of loving the environment for using reason biodiesel is also called fatty acid methyl esters

Oxygenated oils vanish (Ghobadian et al., 2005; or "FAME" (Guan et al., 2009; Demirbas, 2009).

Ranganathan et al., 2008). Although alcohol's stoichiometric ratio to oil is 3:1,

this ratio is more considered to facilitate the

Micro-emulsification dissolution and the collision of alcohol and oil

Applying micro-emulsification by using the solvents molecules. Furthermore, extra amounts of alcohol

methanol, ethanol, and butanol to improve the cause the reaction to transfer toward products and

physical properties such as high viscosity of vegetable increase the conversion rate of methyl ester which is

oils and blended material is immiscible. extremely depended on the kind of used catalyst

Microemulsions are isotropic, transparent and (Guan et al., 2009; Ghanei et al., 2011). According to

thermodynamically stable and consist of oil particles, the investigation made by some researchers it has

water and surfactant and often small amounts of been defined that the kind of alcohol used in the

amphiphilic molecules which are called co-surfactant reaction affects the reaction conversion rate and

51 | Gorji and Ghanei

J. Bio. & Env. Sci. 2014

biodiesel physical properties. Canakei et al (2007) two groups: Heterogeneous and homogeneous

examined the effect of the kind of alcohol on the catalysts (Leung et al., 2010; McNeff et al., 2008).

transesterification reaction, the result of which has Fig. 2 demonstrates catalyst classification and table 5

been presented in Table 4. The conducted surveys presents a comparison of catalyst types which can be

show that using ethanol instead of methanol causes used for producing biodiesel (Leung et al., 2010;

the resulted fuel to have high biodegradation level. It Graboaki and McComick, 1998; Li et al., 2009;

has also been shown that using alcohols with longer Chouhan and Sarma, 2011).

chain produces fuels with better cold flow properties

(McNeff et al., 2008). Table 4. Effect of the type of alcohol on the conversion

rate and biodiesel density (Canakci, 2007).

Catalysts in transesterification reaction Boiling Reaction Conver

kind of Specific

In general the catalysts that can be used for producing Point Temperat sion

Alcohol gravity

(K) ure (K) (%)

biodiesel are divided into three groups: alkaline,

Methanol 338 333 87.8 0.8876

acidic and enzymatic. Compared with other catalysts Ethanol 351.5 348 95.8 0.8814

alkaline catalysts show a better performance. 2-Propanol 355.4 348 92.9 0.8786

Alkaline and acidic catalysts are also classified into 1-Butanol 390 383 92.1 0.8782

Table 5. Comparison of various types of catalysts in the transesterification of oils ((Leung et al., 2010; Graboaki

and McComick, 1998; Li et al., 2009).

Catalyst example Advantages Disadvantages

Homogeneous NaOH High catalytic activity, Need to feed without FFA

alkaline KOH Low cost, Favorable and water, Saponify, Forming

kinetics and mild emulsions, High effluent for

operating conditions washing, Catalyst Loss

Heterogeneous CaO, CaTiO3,CaZrO3, CaO- Non-corrosive, Need to feed without FFA

alkaline CeO2, Environmentally and water, Need to a high

CaMnO3, Ca2Fe2O5, friendly, Recyclable, ratio of methanol to oil, High

KOH/Al2O3, Easy segregation, Less pressure and temperature,

excretion, Penetration limits and high

KOH/NaY, KI/Al2O3, ETS-10 Appropriate selectivity prices

Zeolite, K2CO3/Alumina-silica and long life

Homogeneous Strong sulfuric acid Simultaneous Device Corrosion, High

acid advancing of the effluent,

esterification process Catalyst loss, High

along with temperature, Long time and

transesterification and low catalytic activity

preventing the

formation of soap

Heterogeneous carbon based solid acid, Simultaneous Low density of acid sites, Low

acid carbohydrate drived catalyst advancing of the porosity, Penetration limits

esterification process and high prices

Vanadyl phosphate, Niobic along with

acid, transesterification,

Sulphated zirconia, Amberlyst- Environmentally

15, friendly and recyclables

Nafion-Nr50

Enzymes Candida Antarctica fraction B Preventing the Costly and transmutation

lipase, Rhizomucor mieher formation of soap, Non-

lipase polluting,

Easy purification of the

product

52 | Gorji and Ghanei

J. Bio. & Env. Sci. 2014

Fig. 2. Catalyst classification (Chouhan and Sarma, 2011).

Acidic catalysts to reach a higher efficiency, greater amount of

Organic and mineral acids as catalysts are active in methanol close to the ratio of 30:1 is needed. Of the

transesterification, such as sulfuric acid, hydrochloric most popular catalysts we can refer to sulfuric acid,

acid (Jeong et al., 2009), phosphoric acid of mineral hydrochloric acid and phosphoric acid (Canakci,

types and toluene and benzene sulfonic acid 2007). Chemical mechanism of acidic catalyst is

derivatives as organic acids (Balat and Balat, 2010), demonstrated in Fig. 3 (Chouhan and Sarma, 2011).

acetate, and calcium stearate, barium, magnesium,

cadmium, titanium, lead and nickel, which acetates Alkaline catalysts

generally showed less activity than stearate (Serio et Types of alkaline catalysts such as Alkoxides,

al., 2005), Even though, at times the process of hydroxides, carbonates and oxides of alkali and

transesterification of acids is up to 4000 times slower alkaline earth metals are highly active in

than Alkaline types (Georgogianni et al., 2009; Wen transesterification reaction to produce biodiesel so

et al., 2010), when the feed possesses water that in lower amounts of catalyst and alcohol the

impurities and a great amount of free fatty acids, this reaction can take place in low temperature (Balat and

kind of catalysts is preferable (Soriano et al., 2009). Balat, 2010; Shu et al., 2007).

This kind of catalyst produces a lot of products but its

reaction is done quite slowly.

Fig. 4. The transesterification mechanism in the

presence of heterogeneous base catalyst (Chouhan

and Sarma, 2011).

Fig. 3. The transesterification mechanism in the

presence of acid catalyst (Chouhan and Sarma, 2011). The used catalyst has an important role in defining

the time of reaction. The reason for high tendency to

On the basis of Helwani et al. (2009) report this kind use base reactions is more impact and less corrosion

of reactions generally require temperatures higher compared with acid reactions.Of the most popular

than 100ºC and between 3 to 50 hours time. Besides, and applicable base catalysts we can refer to sodium

53 | Gorji and Ghanei

J. Bio. & Env. Sci. 2014

and potassium hydroxide and methoxide (Canakci, cost including effluent costs, product purification and

2007). The limitation for the use of these catalysts is catalyst neutralization (Leung et al., 2010; Guan et

related to the purity level of food and raw materials so al., 2009). By substituting solid catalysts for

they should be without water because water generates homogeneous catalysts, various processes of

soap and using the raw material, emulsion is formed separation, corrosion and hazardous effluents would

and this makes purification difficult and costly be omitted (Leung et al., 2010; Borges and Dias,

(Chouhan and Sarma, 2011; Semwal et al., 2011). 2012). In processes in which homogeneous catalysts

Transesterification mechanism in the presence of are used, the catalyst should be ultimately

heterogeneous base catalyst has been demonstrated neutralized and cannot be reused (Borges and Dias,

in Fig. 4. (Chouhan and Sarma, 2011). 2012) whereas heterogeneous catalysts are applicable

in the process easily, they can be retrieved and

Enzymatic catalysts reused. Using solid catalysts in fixed bed reactors are

Although acid and base chemical Transesterification also quite easier in constant processes (Guan et al.,

is successful in producing biodiesel, the energy 2009; Graboaki and McComick, 1998; Li et al.,

consumption is high and acid or base should be 2009). Among the most important features of

separated from the product and this causes hazardous heterogeneous catalysts, we can refer to the lack of

effluents. Lipases are enzymes that can be applied as soap formation which causes the water used for

catalyst in the transesterification reaction. This washing to reduce and so there would not be a

process is quite optional and neat however it requires probability for making an emulsion while washing

a long time (Balat, 2009). In general the advantages (Serio et al., 2005). Besides, the resulted products

and disadvantages for using lipases are as follows: including biodiesel and glycerin are clean and they

don’t need purification any more (Georgogianni et al.,

Advantages for using lipases (Demirbas, 2007): 2009; Li et al., 2014). Compared with homogeneous

1. The remnant of these materials is renewable and catalysts, heterogeneous catalysts show less

decomposes in the life cycle. sensitivity to the presence of FFA (Wen et al., 2010).

2. They are approximately sustainable to changes in There are also some disadvantages for heterogeneous

temperature. catalysts including low activity, high reaction

temperature, needing auxiliary solvent, long reaction

3. Non-moving property of lipase causes it not to be

time and moisture sensitivity (Soriano et al., 2009).

dissolved in reactive substances and as a result the

Sakai et al. (2009) made a comparison between 4

whole lipase acts as an enzyme.

homogeneous and heterogeneous catalyst processes,

4. Applying catalysts in reaction, the product

respectively on the basis of KOH and CaO. In this

separation would be facilitated.

research it was defined that heterogeneous processes

were relatively cheaper and their products had the

Disadvantages for using lipases (Balat, 2009;

potential of competition in the current market. One of

Demirbas, 2007):

the most important features of solid catalysts is lack

1. Prolongation of reaction time

of dissolution in reaction mixture in the condition of

2. High cost

reaction process (Serio et al., 2005). Zabeti et al.

3. Enzyme does not support reactive substances

(2009) have mentioned the most effective parameters

steadily.

in heterogeneous catalyst activity as specific area,

cavity volume and the density of active sites on the

Comparison of heterogeneous and homogeneous

surface. The use of a support for the reduction of

catalysts

mass transfer resistance and the catalyst increased

Using multistage homogeneous processes causes the

longevity and efficiency has also been considered

process to extend and is followed by production high

54 | Gorji and Ghanei

J. Bio. & Env. Sci. 2014

quite effective (Graboaki and McComick, 1998). Table through heterogeneous catalysts over the past years.

6 shows the reviewed article about transesterification

Table 6. Reviewed articles on transesterification by heterogeneous catalysts.

Research

No Research subject period Comments Ref

(year)

Solid heterogeneous catalysts 1984-2007 This review focuses on the use of Helwani et al

1 for transesterification of different methods for producing (2009)

triglycerides with methanol: a biodiesel and catalysts for

review transesterification reaction

Activity of solid catalysts for 1993-2007 Description of Catalyst activities Zabeti et al

biodiesel production: a (2009)

2 review

Recent inventions in 1974-2007 This review focuses on recent Sarma et al

3 biodiesel production and technologies in the field of (2008)

processing – a biodiesel

review

Biodiesel production by 1987-2010 This review focuses on different Lee and Saka

heterogeneous catalysts and new technologies of solid (2010)

4 Supercritical technologies catalysts and non-catalytic

supercritical process

Parametric sensitivity in 2002-2006 This review focuses on advances Banerjee et al

transesterification of waste in esterification and (2009)

5 cooking oil for biodiesel transesterification reaction to

production-a review facilitate biodiesel production

Latest developments on 2005-2010 This review focuses on alkaline Sharma et al

application of heterogeneous heterogeneous catalysts such as (2011)

basic catalysts for an efficient oxides of magnesium, calcium,

6 and eco friendly synthesis of alumina and zeolites

biodiesel: a review

Homogeneous, 1998-2007 This review focuses on the Lam et al (2010)

heterogeneous and enzymatic advantages and limitations of

7 catalysis for using heterogeneous,

transesterification of high homogeneous and enzymatic

free fatty acid oil (waste catalysts in transesterification

cooking oil) to biodiesel: a reaction

review

Technologies for biodiesel 2002-2009 This review focuses on the Math et al

production from used production and description of (2010)

8 cooking Oil-a review biodiesel fuel and its comparison

with diesel fuel

Biodiesel production using 2003-2009 This review focuses on the Semwal et al

heterogeneous catalysts production of biodiesel using (2011)

appropriate heterogeneous

9 catalysts to produce biodiesel.

This research will help to select a

catalyst and suitable operating

conditions.

Upstream and downstream 1999-2009 This review focuses on the Hasheminejad

strategies to economize various methods for biodiesel et al (2011)

10 biodiesel production production and their advantages

and disadvantages

Modern heterogeneous 2001-2010 This review focuses on the alkali, Chouhan and

catalysts for biodiesel acid, alkali – acid catalysts and Sarma (2011)

11 production: A comprehensive biocatalysts to produce bio-

review diesel.

Recent developments on 2001-2011 This review focuses on the Borges and Dias

heterogeneous catalysts for studies of the effect of recent (2012)

12 biodiesel production by oil catalysts used to produce

esterification and biodiesel at low temperatures

Transesterification reactions:

A review

55 | Gorji and Ghanei

J. Bio. & Env. Sci. 2014

Summary Recovery Utilization & Environmental Effects 31,

Due to their diversity and extent, vegetable oils have a 1300–1314.

high potential in biodiesel production which of

course, because of having the stages of Planting, Balat M, Balat H. 2010. Progress in biodiesel

conserving and harvesting and also the stage of oil processing. Applied Energy 87, 1815-1835.

extraction causes the biodiesel total price to increase.

Therefore, using animal fats and waste oils can help Banerjee A, Chakraborty R. 2009. Parametric

the total cost for producing biodiesel to decrease. sensitivity in transesterification of waste cooking oil

Among the used alcohols for transesterification for biodiesel production: A review. Conservation and

reaction, methanol draws more attention for its low Recycling 53, 490–497.

cost and availability. In general the used catalysts in

the transesterification reaction of triglyceridesare are Basha SA, Gopal KR, Jebaraj S. 2009. A review

divided into three groups: acidic, alkaline and on biodiesel production, combustion emissions and

enzymatic. Using alkaline catalysts, the appropriate performance. Renewable and Sustainable Energy

product with favorable conversion rate is produced Reviews 13, 1628-1634.

which has a more suitable performance compared

with other catalysts. The limitation for the use of Bhatti HN, Hanif MA, Qasim M, Rehman A.

alkaline catalysts is the existence of water in raw 2008. Biodiesel production from waste tallow. Fuel

material, high free fatty acids in the oil. By using 87, 2961–2966.

acidic catalysts, a good conversion rate is acquired but

its requisite is spending a long time and as the result, Borges ME, Diaz L. 2012. Recent developments on

increased cost for reaction. Using these catalysts is heterogeneous catalysts for biodiesel production by

preferable when the feed has an amount of high free oil esterification and transesterification reactions: A

fatty acids. Over the past years, favorable results have review. Renewable and Sustainable Energy Reviews

been presented about the application of lipase in 16, 2839– 2849.

transesterification reaction but similarly, high cost

and the reaction long time were among the obstacles Boro J, Deka D, Thakur AJ. 2012. A review on

to prevent us from using these catalysts in biodiesel solid oxide derived from waste shells as catalyst for

industrial production. Given that today high total cost biodiesel production. Renewable and Sustainable

is the main obstacle for producing biodiesel, using Energy Reviews 16, 904-910.

animal fats and waste oils as the raw material and

using renewable heterogeneous catalysts like CaO Canakci M. 2007. The potential of restaurant waste

from eggshell, oyster, crab shell, etc is suggested to lipids as biodiesel feedstocks. Bioresource Technology

reduce the total cost for producing biodiesel. 98, 183-190.

References Çaynak S, Gürü M, Biçer A, Keskin A, Içingür

Ebrahimi B, Rahmani M. 2012. A review on the Y. 2009. Biodiesel production from pomace oil and

outcomes of the technology development of improvement of its properties with synthetic

production and use of vegetable fuels in comparison manganese additive. Fuel 88, 534–538.

with fossil fuels. Quarterly Journal of Industrial

Technology Development 19, 27-38. Chouhan APS, Sarma AK. 2011. Modern

heterogeneous catalysts for biodiesel production: A

Balat M. 2009. Biodiesel fuel from triglycerides via comprehensive review. Renewable and Sustainable

transesterification: A review. Energy Sources Part A: Energy Reviews 15, 4378-4399.

56 | Gorji and Ghanei

J. Bio. & Env. Sci. 2014

Demirbas A. 2007. Importance of biodiesel as Ghobadian B, Khatamifar M, Rahimi H. 2005.

transportation fuel. Journal of Energy Policy 35, Biodiesel Fuel production using Transesterification of

4661-4670. Waste Vegetable oils. The Forth Intenational

Conference on Internal Combustion Engines, Tehran,

Demirbas A. 2009. Progress and recent trends in Iran.

biodiesel fuels. Energy Conversion and Management

50, 14-34. Graboski MS, McCormick RL. 1998. Combustion

of fat and vegetable oil drived fuels in diesel engines.

Dias JM, Alvim-Ferraz MCM, Almeida MF. Progress in Energy and Combustion Science 24,125-

2008. Comparison of the performance of different 164.

homogeneous alkali catalysts during

transesterification of waste and virgin oils and Guan G, Kusakabe K, Sakurai N, Moriyama K.

evaluation of biodiesel quality. Fuel 87, 3572-3578. 2009. Transesterification of vegetable oil to biodiesel

fuel using acid catalysts in the presence of dimethyl

Doll KM, Sharma BK, Suarez PAZ, Erhan SZ. ether. Fuel 88, 81-86.

2008. Comparing biofuels obtained from pyrolysis, of

soybean oil or soapstock, with traditional soybean Guan G, Sakurai N, Kusakabe K. 2009. Synthesis

biodiesel: density, kinematic viscosity, and surface of biodiesel from sunflower oil at room temperature

tensions. Energy Fuels 22, 2061–2066. in the presence of various cosolvents. Chemical

Engineering Journal 146, 302-306.

Dunn RO. 2001. Alternative jet fuels from vegetable

oils. American Society of Agricultural and Biological Hasheminejad M, Tabatabaei M,

Engineers 44,1751–1757. Mansourpanah Y, Khatamifar M, Javani A.

2011. Upstream and downstream strategies to

Fukuda H, Kondo A, Noda H. 2001. Biodiesel fuel economize biodiesel production. Bioresour

production by transesterification of oil. Bioscience Technology 102, 461–468.

and Bioengineering 92, 405-416.

Helwani Z, Othman MR, Aziz N, Kim J,

Georgogianni KG, Katsoulidis AK, Pomonis Fernando WJN. 2009. Solid heterogeneous

PJ, Manos G, Kontominas MG. 2009. catalysts for transesterification of triglycerides with

Transesterification of rapeseed oil for the production methanol: A review. Applied Catalysis A: General

of biodiesel using homogeneous and heterogeneous 363, 1-10.

catalysis. Fuel Processing Technology 90, 1016-1022.

Jeong GT, Yang HS, Park DH. 2009.

Gerpen JV.2005. Biodiesel processing and Optimization of transesterification of animal fat ester

production. Fuel Processing Technology 86, 1097- using response surface methodology. Bioresource

1107. Technology 100, 25-30.

Ghanei R, Moradi GR, Taherpourkalantari R, Lam MK, Lee KT, Mohamed AR. 2010.

Arjmandzadeh E. 2011. Variation of physical Homogeneous, heterogeneous and enzymatic

properties during transesterification of sunflower oil catalysis for transesterification of high free fatty acid

to biodiesel as an approach to predict reaction oil (waste cooking oil) to biodiesel: A review.

progress. Fuel Processing Technology 92, 1593-1598. Biotechnology Advances 28, 500–518.

57 | Gorji and Ghanei

J. Bio. & Env. Sci. 2014

Lee JS, Saka S. 2010. Biodiesel production by Nicheran MS. 2012. Production methods of

heterogeneous catalysts and supercritical biodiesel fuel from vegetable oils. Iranian Combustion

technologies: review. Bioresource Technology 101, Institute Newsletter 43, 10-14.

7191–7200.

Park YM, Lee JY, Chung SH, Park IS, Lee SY,

Leung DYC, Wu X, Leung MKH. 2010. A review Kim DK, Lee JS, Lee KY. 2008. Esterification of

on biodiesel production using catalyzed used of soybean oil to biodiesel with methanol. Fuel

transesterification. Applied Energy 87, 1083-1095. 87, 1076-1982.

Li E, Xu ZP, Rudolph V. 2009. MgCoAl-LDH Pereira MG, Mudge SM. 2004. Cleaning oiled

derived heterogeneous catalysts for the ethanol shores: laboratory experiments testing the potential use

transesterification of canola oil to biodiesel. Applied of vegetable oil biodiesels. Chemosphere 54, 297–304.

Catalysis B: Environmental 88, 42-49.

Ramus S, Lingaiaha N, Devi BLAP, Prasadb

Li M, Zheng Y, Chen Y, Zhu X. 2014. Biodiesel RBN, Suryanarayana I, Prasad PSS. 2004.

production from waste cooking oil using a Esterification of palmitic acid with methanol over

heterogeneous catalyst from pyrolyzed rice husk. tungsten oxide supporyed on zirconia solid acid

Bioresource Technology 154, 345-348. catalysts: effect of method of preparation of the

catalyst on its structural stability and reactivity.

Marchetti JM. 2012. A summary of the available Applied Catalysis A:General 276, 163-168.

technologies for biodiesel production based on a

comparison of different feedstock’s properties. Ranganathan SV, Narasimham SL,

Process Safety and Environmental Protection 90, Muthukumar K. 2008. An overview of enzymatic

157–163. production of biodiesel. Bioresource Technology 99,

3975-3981.

Math MC, Kumar SP, Soma V, Chetty SV. 2010.

Technologies for biodiesel production from used Sakai T, Kawashima A, Koshikawa T. 2009.

cooking oil. A review. Energy for Sustainable Economic assessment of batch biodiesel production

Development 14, 339–345. processes using homogeneous and heterogeneous

alkali catalysts. Bioresource Technology 100 (13),

McNeff CV, McNeff LC, Yan B, Nowlan DT, 3268-3276.

Rasmussen M, Gyberg AE, Krohn BJ, Fedie

RL, Hoye TR. 2008. A continuous catalytic system Sarma AK, Sarmah JK, Barbora L, Kalita P,

for biodiesel production. Applied Catalysis A: General Chatterjee S, Mahanta P. 2008. Recent inventions

343, 39-48. in biodiesel production and processing: A review.

Recent Patents on Engineering 2, 47–58.

Mushrush G, Beal EJ, Spencer G, Wynne JH,

Lloyd CL, Hughes JM, Walls CL, Hardy DR. Sbihi HM, Nehdi IA, Tan CP, Al-Resayes SI.

2001. An environmentally benign soybean derived 2014. Production and characterization of biodiesel

fuel as a blending stock or replacement for home from Camelus dromedarius (Hachi) fat. Energy

heating oil. Journal Environmental Science and Conversion and Management 78, 50-57.

Health A 36, 613–622.

58 | Gorji and Ghanei

J. Bio. & Env. Sci. 2014

Semwal S , Arora AK , Badoni RP , Tuli DK. Srivastava A, Prasad R. 2000. Triglycerides-based

2011. Biodiesel production using heterogeneous diesel fuels. Renewable and Sustainable Energy

catalysts. Bioresource Technology 102, 2151-2161. Reviews 4, 111-133.

Serio MD, Tesser R, Dimiccoli M, Cammarota Vicente G, Martinez M, Aracil J. 2004.

F, Nastasi M, Santacesaria E. 2005. Synthesis of Integrated Biodiesel production: A comparison of

biodiesel via homogeneous Lewis acid catalyst. Journal different homogeneous catalysts systems.

of Molecular Catalysis A: Chemical 239, 111-115. Bioresource Technology 92, 297-305.

Sharma YC, Singh B, Korstad J. 2011. Latest Wen Z, Yu X, Tu ST, Yan J, Dahlquist E. 2010.

developments on application of heterogeneous basic Synthesis of biodiesel from vegetable oil with

catalysts for an efficient and eco friendly synthesis of methanol catalyzed by Li-doped magnesium oxide

biodiesel: A review. Fuel 90, 1309–1324. catalysts. Applied Energy 87, 743-748.

Shu Q, Yang B, Yuan H, Qing S, Zhu G. 2007. Willing A. 1999. Oleochemical esters-

Synthesis of biodiesel from soybean oil and methanol environmentally compatible raw materials for oils and

catalyzed by zeolite beta modified with La3+. lubricants from renewable resources. European

Catalysts Communication 8, 2159-2165. Journal of Lipid Science and Technology 101, 192–198.

Soriano NU, Venditti R, Argyropoulos DS. Zabeti M, Wan Daud WMA, Aroua MK. 2009.

2009. Biodiesel synthesis via homogeneous Lewis Activity of solid catalysts for biodiesel production: A

acid-catalyzed transesterification. Fuel 88, 560-565. review. Fuel Processing Technology 90, 770–777.

59 | Gorji and Ghanei

You might also like

- Soybeans Processing For Biodiesel ProductionDocument18 pagesSoybeans Processing For Biodiesel ProductionJovan GrujićNo ratings yet

- Biodiesel Production From Non Edible Plant OilsDocument29 pagesBiodiesel Production From Non Edible Plant OilsTeshome DengisoNo ratings yet

- Biodiesel Fuel Production by Enzymatic TDocument26 pagesBiodiesel Fuel Production by Enzymatic TFeras SwaidNo ratings yet

- The Synthesis of Biodiesel From Vegetable OilDocument6 pagesThe Synthesis of Biodiesel From Vegetable OilAlex FaudoaNo ratings yet

- Taravus, Temur, Yartasi - 2009 - Alkali-Catalyzed Biodiesel Production From Mixtures of Sunflower Oil and Beef TallowDocument4 pagesTaravus, Temur, Yartasi - 2009 - Alkali-Catalyzed Biodiesel Production From Mixtures of Sunflower Oil and Beef TallowTatiana VargasNo ratings yet

- Chapter I III Group 4Document37 pagesChapter I III Group 4Andrea Gienel MontallanaNo ratings yet

- IJTech - CE 4804 - Multifeedstock Biodiesel Production From A Blend oDocument13 pagesIJTech - CE 4804 - Multifeedstock Biodiesel Production From A Blend oArif SusantoNo ratings yet

- Matecconf Rsce2018 06007Document7 pagesMatecconf Rsce2018 06007Widayat DayatNo ratings yet

- Chowdhury DKK., 2021 1,4-1-4Document4 pagesChowdhury DKK., 2021 1,4-1-4claudiaNo ratings yet

- PROCEEDINGAPTECS2011ITS TheBio FuelPressureStoveFueledbyWasteCookingOil SjaffriadiNugrohoAdiSasongkoDocument36 pagesPROCEEDINGAPTECS2011ITS TheBio FuelPressureStoveFueledbyWasteCookingOil SjaffriadiNugrohoAdiSasongkoJoanna Marie SimonNo ratings yet

- PROCEEDINGAPTECS2011ITS TheBio FuelPressureStoveFueledbyWasteCookingOil SjaffriadiNugrohoAdiSasongkoDocument36 pagesPROCEEDINGAPTECS2011ITS TheBio FuelPressureStoveFueledbyWasteCookingOil SjaffriadiNugrohoAdiSasongkoVmthreek SecNo ratings yet

- Anwaretal The Efficacy 2019Document15 pagesAnwaretal The Efficacy 2019banstalaNo ratings yet

- Biodiesel Production PaperDocument30 pagesBiodiesel Production PaperCarlosNo ratings yet

- Chapter One IntrtoductionDocument4 pagesChapter One IntrtoductionifiokNo ratings yet

- Dash 2018 IOP Conf. Ser. Mater. Sci. Eng. 377 012006Document9 pagesDash 2018 IOP Conf. Ser. Mater. Sci. Eng. 377 012006Aincard ZeldrisNo ratings yet

- Ijost PaperDocument15 pagesIjost PaperRusmansyahNo ratings yet

- Effect of Blending Various Biodiesels With Diesel On Performance and Emissions of Diesel Engine: A ReviewDocument11 pagesEffect of Blending Various Biodiesels With Diesel On Performance and Emissions of Diesel Engine: A ReviewResearch ShareNo ratings yet

- CottonOilGCMS PDFDocument12 pagesCottonOilGCMS PDFakshit patidarNo ratings yet

- Admin,+38268 211-218Document8 pagesAdmin,+38268 211-218Denilton GarciaNo ratings yet

- Producion de BiodieselDocument7 pagesProducion de BiodieselRoger Tolosa AyalaNo ratings yet

- Article1379952416 - Bello Et Al PDFDocument6 pagesArticle1379952416 - Bello Et Al PDFSetiyo WibisonoNo ratings yet

- Optimization and Production of Biodiesel From Cottonseed Oil and Neem OilDocument7 pagesOptimization and Production of Biodiesel From Cottonseed Oil and Neem OilMauricio PiñeresNo ratings yet

- Edit ThesisDocument22 pagesEdit ThesisCj MoLanoNo ratings yet

- 8.transesterification of Waste Edible Oils To Biodiesel Using Calcium OxideDocument11 pages8.transesterification of Waste Edible Oils To Biodiesel Using Calcium Oxideshamirah98No ratings yet

- Izah and OhimainDocument13 pagesIzah and Ohimaina_minisoft2005No ratings yet

- Biodiesel As An Alternative Fuel A StateDocument24 pagesBiodiesel As An Alternative Fuel A Statepadam0088No ratings yet

- Production of Biodiesel Using Rubber (He 6ea Brasiliensis (Kunth. Muell.) ) Seed OilDocument6 pagesProduction of Biodiesel Using Rubber (He 6ea Brasiliensis (Kunth. Muell.) ) Seed OilTwushsfNo ratings yet

- Suitability of Some Fruit Seeds Oil For Use As Biodiesel FuelDocument4 pagesSuitability of Some Fruit Seeds Oil For Use As Biodiesel FuelyohannesNo ratings yet

- Clean BiofuelDocument29 pagesClean BiofuelYunardiNo ratings yet

- Hakun W. Aparamarta, Setiyo Gunawan, Husni Husin, Badril Azhar, Hanggoro Tri AdityaDocument9 pagesHakun W. Aparamarta, Setiyo Gunawan, Husni Husin, Badril Azhar, Hanggoro Tri Adityaridho febriNo ratings yet

- Bioresource Technology: María Jesús Ramos, Carmen María Fernández, Abraham Casas, Lourdes Rodríguez, Ángel PérezDocument8 pagesBioresource Technology: María Jesús Ramos, Carmen María Fernández, Abraham Casas, Lourdes Rodríguez, Ángel PérezJames VeraNo ratings yet

- 453-463V9N6CT 2Document11 pages453-463V9N6CT 2Rizwan NasirNo ratings yet

- Mathematical ModellingDocument72 pagesMathematical ModellingNicodemus RafealNo ratings yet

- Rapeseed Oil As Renewable Resource For Polyol SynthesisDocument7 pagesRapeseed Oil As Renewable Resource For Polyol SynthesisMohamed AlhayaniNo ratings yet

- Determination of Oil and Biodiesel Content, Physicochemical Properties of The Oil Extracted From Avocado Seed (Persea Americana) Grown in Wonago and Dilla (Gedeo Zone), Southern EthiopiaDocument9 pagesDetermination of Oil and Biodiesel Content, Physicochemical Properties of The Oil Extracted From Avocado Seed (Persea Americana) Grown in Wonago and Dilla (Gedeo Zone), Southern EthiopiayohannesNo ratings yet

- Soybean Oil Composition For BiodieselDocument4 pagesSoybean Oil Composition For BiodieselIAMANDU COSTANo ratings yet

- Dissertation Fan2010 (204-253)Document50 pagesDissertation Fan2010 (204-253)ابوايمن العمراني ايمنNo ratings yet

- Production of Biodiesel From Used Cooking OilDocument7 pagesProduction of Biodiesel From Used Cooking OilDennis OrlandoNo ratings yet

- Biolubricants From Natural Waste Oils and FatsDocument8 pagesBiolubricants From Natural Waste Oils and FatsZak YanNo ratings yet

- Different Techniques For The Production of Biodiesel From Waste Vegetable OilDocument31 pagesDifferent Techniques For The Production of Biodiesel From Waste Vegetable OilShreyank Deepali GoelNo ratings yet

- E 6 Biodeisel 2022Document26 pagesE 6 Biodeisel 2022ณัฐนันท์ ปรีเปรมNo ratings yet

- IJETR021268Document5 pagesIJETR021268erpublicationNo ratings yet

- Kostic Et Al., 2018 Reciklaza Biodizel Iz Ulja KukuruzaDocument10 pagesKostic Et Al., 2018 Reciklaza Biodizel Iz Ulja KukuruzaOlivera StamenkovicNo ratings yet

- Negm2016 Castor BaberDocument6 pagesNegm2016 Castor Babermohamed aliNo ratings yet

- A Comprehensive Review On Palm Oil and The Challenges Using Vegetable Oil As Lubricant Base-StockDocument16 pagesA Comprehensive Review On Palm Oil and The Challenges Using Vegetable Oil As Lubricant Base-StockSpenda RangupNo ratings yet

- Geospatial Visualization For Second-Generation Renewable Diesel Feedstock From Palm Oil Value Chain in Indonesia-RevisionDocument60 pagesGeospatial Visualization For Second-Generation Renewable Diesel Feedstock From Palm Oil Value Chain in Indonesia-RevisionYori Timotius BangunNo ratings yet

- Production of Biodiesel From Waste Cooking OilDocument5 pagesProduction of Biodiesel From Waste Cooking OilIJMERNo ratings yet

- 1623 1629 PDFDocument7 pages1623 1629 PDFnitin birajdarNo ratings yet

- Biodiesel Production From Euphorbia Tirucalli L.: Full Length Research PaperDocument6 pagesBiodiesel Production From Euphorbia Tirucalli L.: Full Length Research PaperMáximo Décimo MeridioNo ratings yet

- Renewable Energy: Jerekias Gandure, Clever Ketlogetswe, Abraham TemuDocument7 pagesRenewable Energy: Jerekias Gandure, Clever Ketlogetswe, Abraham TemuLacramioara Iuliana VladulescuNo ratings yet

- Renewable Energy: Hu Seyin Aydin, Hasan BayindirDocument5 pagesRenewable Energy: Hu Seyin Aydin, Hasan BayindirAkshay SundarNo ratings yet

- 01 - Review Suresh2018Document12 pages01 - Review Suresh2018Chirag PatidarNo ratings yet

- Effectofpre Treatmentonsolventsextractionandphysico ChemicalpropertiesDocument18 pagesEffectofpre Treatmentonsolventsextractionandphysico ChemicalpropertiesAlifia RisaNo ratings yet

- 2003 - Biodiesel Production From Waste Cooking Oil - ProcessDocument16 pages2003 - Biodiesel Production From Waste Cooking Oil - ProcessKaoutar SefriouiNo ratings yet

- Performance Analysis of Ci Engine Fueled With Diesel and Used Vegetable Oil BlendDocument8 pagesPerformance Analysis of Ci Engine Fueled With Diesel and Used Vegetable Oil BlendYohannes AlemuNo ratings yet

- Catalytic Production of Biodiesel From Shea ButterDocument19 pagesCatalytic Production of Biodiesel From Shea Butterebenezer sarkodie100% (1)

- BiodieselDocument8 pagesBiodieselKaviya SNo ratings yet

- 2010 - Biodiesel Production From Waste Frying Oils and Its Quality ControlDocument5 pages2010 - Biodiesel Production From Waste Frying Oils and Its Quality ControlDeodata Leela AndiavitriNo ratings yet

- Mathematical modeling of biofuel synthesis and storageFrom EverandMathematical modeling of biofuel synthesis and storageNo ratings yet

- Trait-Modified Oils in FoodsFrom EverandTrait-Modified Oils in FoodsFrank T. OrthoeferNo ratings yet

- Production of Biodiesel From Corn Oil and Ethanol by Homogeneous Alkali Catalyzed TransesterificationDocument47 pagesProduction of Biodiesel From Corn Oil and Ethanol by Homogeneous Alkali Catalyzed TransesterificationAhmad InterestaNo ratings yet

- Transport Phenomena-W13Document12 pagesTransport Phenomena-W13Ahmad InterestaNo ratings yet

- Lect 13Document56 pagesLect 13Ahmad InterestaNo ratings yet

- Lect 7Document80 pagesLect 7Ahmad InterestaNo ratings yet

- Badal C. Saha, Jonathan Woodward - Fuels and Chemicals From Biomass (Acs Symposium Series) - An American Chemical Society Publication (1997)Document359 pagesBadal C. Saha, Jonathan Woodward - Fuels and Chemicals From Biomass (Acs Symposium Series) - An American Chemical Society Publication (1997)Ahmad InterestaNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument29 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsAhmad InterestaNo ratings yet

- Renewable and Sustainable Energy Reviews: R. Sakthivel, K. Ramesh, R. Purnachandran, P. Mohamed ShameerDocument23 pagesRenewable and Sustainable Energy Reviews: R. Sakthivel, K. Ramesh, R. Purnachandran, P. Mohamed ShameerAhmad InterestaNo ratings yet

- English - SixthDocument2 pagesEnglish - SixthAhmad InterestaNo ratings yet

- Anders+T +Madsenم1Document172 pagesAnders+T +Madsenم1Ahmad InterestaNo ratings yet

- مصادرDocument1 pageمصادرAhmad InterestaNo ratings yet

- English - SixthDocument2 pagesEnglish - SixthAhmad InterestaNo ratings yet

- Chemical PreparationsDocument12 pagesChemical PreparationsAhmad Interesta100% (1)

- مستند جديد 7Document18 pagesمستند جديد 7Ahmad InterestaNo ratings yet

- United States Patent (10) Patent No.: US 9,096,564 B2Document6 pagesUnited States Patent (10) Patent No.: US 9,096,564 B2Ahmad InterestaNo ratings yet

- Us4645656 PDFDocument9 pagesUs4645656 PDFHasan Djadid AssegaffNo ratings yet

- Prediction of Higher Heating Value of Biochars UsiDocument1 pagePrediction of Higher Heating Value of Biochars UsiAhmad InterestaNo ratings yet

- Kirova Yordanovafinal196 1087 2 DRaccT3Document13 pagesKirova Yordanovafinal196 1087 2 DRaccT3Ahmad InterestaNo ratings yet

- Astm d86 PDFDocument28 pagesAstm d86 PDFNaty Silva100% (1)

- 231 F 08 e 1 BDocument5 pages231 F 08 e 1 BReshmiRaiNo ratings yet

- ChemistryDocument4 pagesChemistryMalik Ameer Hamza BalochNo ratings yet

- 0625 PHYSICS: MARK SCHEME For The March 2016 SeriesDocument7 pages0625 PHYSICS: MARK SCHEME For The March 2016 Serieskhalil rehmanNo ratings yet

- Impact of Heterogeneous Cavities On The Electrical Constraints in The Insulation of High-Voltage CablesDocument9 pagesImpact of Heterogeneous Cavities On The Electrical Constraints in The Insulation of High-Voltage CablesOlga OliveiraNo ratings yet

- PhysicsDocument63 pagesPhysicsmsrsg25% (4)

- B.SC - Agricuture 4 Year Code A PCBDocument16 pagesB.SC - Agricuture 4 Year Code A PCBsachin sharmaNo ratings yet

- N4 Electrotechnics November 2016 MemorandumDocument7 pagesN4 Electrotechnics November 2016 MemorandumPetro Susan BarnardNo ratings yet

- Lecture 1Document23 pagesLecture 1meku44No ratings yet

- Colorimeter NewDocument22 pagesColorimeter NewKarthik RajaNo ratings yet

- Yag ManualDocument43 pagesYag ManualMi Sinziana100% (1)

- Sensors Evaluation 2019 Oct 19 (19) - DOC#NDL:NDA:DGA:ON:072002 PDFDocument1 pageSensors Evaluation 2019 Oct 19 (19) - DOC#NDL:NDA:DGA:ON:072002 PDFDivyansh KohliNo ratings yet

- BoQ-Beam Retrofitting Works LandTDocument2 pagesBoQ-Beam Retrofitting Works LandTAbhijit KarpeNo ratings yet

- 108 Chapter 3 StoichiometryDocument29 pages108 Chapter 3 Stoichiometryzabdullahstud1No ratings yet

- PDF DocumentDocument14 pagesPDF DocumentmaxNo ratings yet

- Heat Exchangers ReportDocument15 pagesHeat Exchangers ReportBigNo ratings yet

- 94 Jurnal Rekayasa Proses, Vol. 11, No. 2, 2017, Hal. 94-100Document8 pages94 Jurnal Rekayasa Proses, Vol. 11, No. 2, 2017, Hal. 94-100AbdulNo ratings yet

- Topic 8 Acids and Bases SLDocument11 pagesTopic 8 Acids and Bases SLoscarbec0% (1)

- 81098046EN Leaflet LL ElectrodeDocument2 pages81098046EN Leaflet LL ElectrodefernandoNo ratings yet

- Revision SPM 2018 Paper 2Document70 pagesRevision SPM 2018 Paper 2Azie Nurul Akhtar75% (4)

- Carbon Nanotubes, Inorganic Nanowires and FunctionalizationDocument68 pagesCarbon Nanotubes, Inorganic Nanowires and FunctionalizationFrancisco Javier Delgado MartínezNo ratings yet

- Epoxi Resins Reactive Diluyents EPOSIR EPONACDocument8 pagesEpoxi Resins Reactive Diluyents EPOSIR EPONACfatemeh.ahmadkhaniNo ratings yet

- Module - 3 and 4Document72 pagesModule - 3 and 4Karthik A KulalNo ratings yet

- Dynamic Model For Nutrient Uptake by Tomato Plant in HydroponicsDocument46 pagesDynamic Model For Nutrient Uptake by Tomato Plant in HydroponicsAmmarsalNo ratings yet

- Kukatpally, Hyderabad - 500072.: Narayana Junior College - Hyd - KPBG - 1580 Junior Intermediate Cbse DATE - 11/04/2023Document2 pagesKukatpally, Hyderabad - 500072.: Narayana Junior College - Hyd - KPBG - 1580 Junior Intermediate Cbse DATE - 11/04/2023StandbyNo ratings yet

- Paul DiracDocument6 pagesPaul DiracLeonNo ratings yet

- UhhghghhgjDocument2 pagesUhhghghhgjDivyansh SinghNo ratings yet

- Assay of Magnesium HydroxideDocument8 pagesAssay of Magnesium HydroxiderahulNo ratings yet

- Lab ReportDocument6 pagesLab ReportShashaNo ratings yet

- Safety Data Sheet Isopropanol: Revision Date 13-MAR-2013 Revision Rev 02: 0717Document7 pagesSafety Data Sheet Isopropanol: Revision Date 13-MAR-2013 Revision Rev 02: 0717Mutiara AdzaniNo ratings yet

- Gen Chem Module Q2Week 7 8Document23 pagesGen Chem Module Q2Week 7 8Dan MacabingilNo ratings yet

- Dielectric Coatings For High Voltage Gas Insulated Switchgear - Dennis Van Der Born PDFDocument306 pagesDielectric Coatings For High Voltage Gas Insulated Switchgear - Dennis Van Der Born PDFAmila FritzgeraldNo ratings yet