Professional Documents

Culture Documents

Procedure Dye Penetration Testing Step-by-Step Guide

Uploaded by

Zuly AidaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Procedure Dye Penetration Testing Step-by-Step Guide

Uploaded by

Zuly AidaCopyright:

Available Formats

Procedure Dye Penetration

No. Explanation Photo

1. Surface Preparation

The surface must be thoroughly cleaned

from dirt, oil, paint, grease, water or other

inclusion by using dry cloth, solvents or rust

remover depends on the conditions of the

surface to be inspected.

2. Penetration Application

Penetrant which is the red-color liquid was

applied after the surface of the material

was cleaned. Step to spray the penetrant on

the surface are by spraying it most

commonly. This technique is most

important to make sure the penetration is

not too wet while the temperature of the

surface before penetration shall be

between 5 to 52 degree Celsius.

3. Dwell Time / Dwell Period

The penetration need to be leaved for a

minimum period of time or well period

varies until the penetrant seeps into the

flaws due to Capillary actions. Based on the

experiments, the dwell period may varies

15 to 60 minutes or even more depending

upon the material and its service condition

was considered.

4. Removal of Excess Penetrant

Next, after the surface was leaved as

recommended dwell period, the penetrant

was cleaned by using penetrant removal by

took care two things which is:

1. During cleaning excess penetrant,

the cleaning shall be done one

direction only.

2. Moreover, the penetrant remover

shall not be applied directly on the

surface rather applied it on the

cloth.

5. Application of Developer

After a thorough cleaning, a thin layer of

developer was applied. The steps were

applied the developer as followed:

1. Shake the bottle rigorously.

2. Maintain a distance of 10 to 12

inches from the surface, while

spraying the developer.

3. Then, the spray need to be wait for

10 minutes to 60 minutes or as

known as development time.

6. Inspection

Last but not least, the inspection was

performed after the development time has

done. The inspection has been done by

using Magnetic Particle Testing(MT).

Steps to applied a Magnetic Particle Testing

as follows:

1. Induce a magnetic field in the

specimen.

2. Apply magnetic particles to the

specimen’s surface.

3. View the surface, looking for the

particle grouping that are caused by

defects.

4. Demagnetize and clean the

specimen.

References

1. Anand, S. (n.d.). Sandeep Anand. welding & NDT. Retrieved November 19, 2022,

from

https://www.weldingandndt.com/dye-penetrant-test-dpt-lpi-pt-non-destructive-test/

2. S., W. (n.d.). Magnetic particle inspection. Non Destructive Testing - Magnetic

Particle Inspection (MPI). Retrieved November 19, 2022, from

https://www.wermac.org/others/ndt_mpi.html

You might also like

- Penetrant Testing: Principles, Techniques, Applications and Interview Q&AFrom EverandPenetrant Testing: Principles, Techniques, Applications and Interview Q&ANo ratings yet

- Liquid Penetrant Testing ModuleDocument59 pagesLiquid Penetrant Testing ModuleDITANo ratings yet

- Plays A Crucial Role in Everyday Life and Is Necessary To Assure Safety and ReliabilityDocument2 pagesPlays A Crucial Role in Everyday Life and Is Necessary To Assure Safety and ReliabilityAbuja sygNo ratings yet

- Optigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLEFrom EverandOptigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLENo ratings yet

- Department of Mechanical Engineering: Unit-2Document65 pagesDepartment of Mechanical Engineering: Unit-2aman jainNo ratings yet

- Liquid Penetrant Testing ExplainedDocument20 pagesLiquid Penetrant Testing Explainedajayghosh3140No ratings yet

- Handbook of Adhesive Bonded Structural RepairFrom EverandHandbook of Adhesive Bonded Structural RepairRating: 5 out of 5 stars5/5 (1)

- Liquid Penetrant TestingDocument20 pagesLiquid Penetrant TestingsanjibkrjanaNo ratings yet

- Towards A Unified Soil Mechanics Theory: The Use of Effective Stresses in Unsaturated Soils, Revised EditionFrom EverandTowards A Unified Soil Mechanics Theory: The Use of Effective Stresses in Unsaturated Soils, Revised EditionNo ratings yet

- Penetrant Testing ReportDocument8 pagesPenetrant Testing ReportBabar Ali BaigNo ratings yet

- Analisys and application of dry cleaning materials on unvarnished pain surfacesFrom EverandAnalisys and application of dry cleaning materials on unvarnished pain surfacesNo ratings yet

- Liquid Penetrant Testing PDFDocument20 pagesLiquid Penetrant Testing PDFgueridiNo ratings yet

- Quality Control in the Food Industry V1From EverandQuality Control in the Food Industry V1S HerschdoerferNo ratings yet

- DPTDocument10 pagesDPTShabbir HassanNo ratings yet

- PT quiz questions answersDocument11 pagesPT quiz questions answersReinaldo OrejuelaNo ratings yet

- Liquid Penetrant TestingDocument47 pagesLiquid Penetrant Testingbrotherhood1618No ratings yet

- Liquid Penetrant TestingDocument20 pagesLiquid Penetrant TestingReymond AbayonNo ratings yet

- Government Polytechnic Junagadh: Liquid Penerant TestingtDocument16 pagesGovernment Polytechnic Junagadh: Liquid Penerant TestingtArvind DedunNo ratings yet

- Liquid Penetrant Testing: A Nondestructive Method for Detecting Surface-Breaking DefectsDocument10 pagesLiquid Penetrant Testing: A Nondestructive Method for Detecting Surface-Breaking DefectsMastram HatheshNo ratings yet

- PTDocument217 pagesPTkhaled saadnehNo ratings yet

- LPTDocument19 pagesLPTananth.sankar123No ratings yet

- 2 2Document11 pages2 2RAJESH. RNo ratings yet

- Liquid Penetrant TestingDocument3 pagesLiquid Penetrant TestingRegina Lopez- BongcatoNo ratings yet

- NDT Panetrent OnlineDocument3 pagesNDT Panetrent OnlineZa HirNo ratings yet

- LPTDocument58 pagesLPTShrikant MojeNo ratings yet

- Penetrant Testing GuideDocument7 pagesPenetrant Testing Guidewasim7862280% (5)

- NDT of MaterialsDocument10 pagesNDT of MaterialsSuresh HaldipurNo ratings yet

- Material Science AlfathiDocument5 pagesMaterial Science AlfathiAnonymous UdOhqLMNo ratings yet

- LAB 1 - Colour Contrast Penetrant TestDocument9 pagesLAB 1 - Colour Contrast Penetrant TestRaiham EffendyNo ratings yet

- Dye Penetrant TestDocument4 pagesDye Penetrant TestRavi kumarNo ratings yet

- Written Instruction (WELD) PT Rev 2Document4 pagesWritten Instruction (WELD) PT Rev 2Anna PariniNo ratings yet

- 4012 WI58 DP Test Procedure - Rev.0Document4 pages4012 WI58 DP Test Procedure - Rev.0sachinpsawantNo ratings yet

- Dye Penetrant TestDocument4 pagesDye Penetrant Testarunkumarnoola100% (1)

- Quiz II PTDocument12 pagesQuiz II PTReinaldo OrejuelaNo ratings yet

- Liquid Penetrant Testing ExplainedDocument6 pagesLiquid Penetrant Testing ExplainedVandan GundaleNo ratings yet

- Module 2 Surface Gears MethodsDocument12 pagesModule 2 Surface Gears MethodsNAVEEN H V MENo ratings yet

- Dye Penetration Test: Fig. 1: Surface Cleanser, Developer and PenetrantDocument3 pagesDye Penetration Test: Fig. 1: Surface Cleanser, Developer and PenetrantAmeenNo ratings yet

- PT PRO FOR ExamDocument3 pagesPT PRO FOR ExamManivannanMudhaliarNo ratings yet

- Non-Destructive Inspection Practical: NAME:-Amol Rajhans Talekar Roll No.: - Name of DepartmentDocument40 pagesNon-Destructive Inspection Practical: NAME:-Amol Rajhans Talekar Roll No.: - Name of DepartmentAniket DhoneNo ratings yet

- Dye Penetration TestDocument3 pagesDye Penetration Testzhuxueyun55No ratings yet

- LIQUID PENETRANT SOLVENT REMOVABLE INSPECTIONDocument4 pagesLIQUID PENETRANT SOLVENT REMOVABLE INSPECTIONJoshnewfound50% (4)

- LPT Study Material LatestDocument33 pagesLPT Study Material Latestbeltranrommel100% (2)

- NDTM 2 LPT 200818082453 PDFDocument21 pagesNDTM 2 LPT 200818082453 PDFMECHANICAL SMCETNo ratings yet

- NDT Module 2Document21 pagesNDT Module 2Sajeesh Saji100% (1)

- 1303 Qemt Hand OutsDocument4 pages1303 Qemt Hand OutsAkash ShuklaNo ratings yet

- Lec7 MaintenancePlanningDocument25 pagesLec7 MaintenancePlanningtarekhadad99No ratings yet

- Basics of LPIDocument21 pagesBasics of LPISuresh RathodNo ratings yet

- 30 Question PT QuizDocument12 pages30 Question PT Quizmnaseemiqbal4200100% (1)

- New PTDocument5 pagesNew PTHossein SharifpourNo ratings yet

- Dye Penetration TestingDocument4 pagesDye Penetration TestingMahrukh JavedNo ratings yet

- LPT Method Guide for Surface Crack DetectionDocument29 pagesLPT Method Guide for Surface Crack DetectionSameer MohammadNo ratings yet

- Dye Penetrant TestDocument14 pagesDye Penetrant TestSaif FaridiNo ratings yet

- Liquid Dye Penetration Examination: 1.0 ScopeDocument3 pagesLiquid Dye Penetration Examination: 1.0 Scopesuria qaqc100% (1)

- Non Destructive Testing and Evaluation Course Module Topic - Dye Penetrant TestingDocument118 pagesNon Destructive Testing and Evaluation Course Module Topic - Dye Penetrant TestingV.Muthu KumarNo ratings yet

- Procedure For LPT TestDocument4 pagesProcedure For LPT Testdyke_enggNo ratings yet

- LPT SopDocument7 pagesLPT SopQUALITYNo ratings yet

- Dye Penetration Testing QuestionsDocument9 pagesDye Penetration Testing QuestionsMuhammad HannanNo ratings yet

- Dye Pentrant Test ProcedureDocument6 pagesDye Pentrant Test ProcedurePer DCNo ratings yet

- Reactions of Carboxylic Acids and Its DerivativesDocument40 pagesReactions of Carboxylic Acids and Its DerivativesRoger ReyesNo ratings yet

- Guide To Apparel and Textile Care Symbols - Canadian StandardsDocument6 pagesGuide To Apparel and Textile Care Symbols - Canadian StandardspraknithNo ratings yet

- Gamsat Chemistry Sample QuestionsDocument6 pagesGamsat Chemistry Sample QuestionsM S Rahman100% (1)

- Grade 9 2nd Quarter DLL-MOLEDocument49 pagesGrade 9 2nd Quarter DLL-MOLEleiziah xyrille maturan100% (1)

- International Standard: ISO 105-C08Document14 pagesInternational Standard: ISO 105-C08Om Prakash ShuklaNo ratings yet

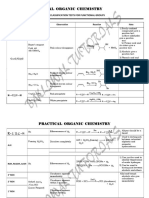

- Practical Organic Chemistry Classification TestsDocument19 pagesPractical Organic Chemistry Classification TestsJonathan ParkerNo ratings yet

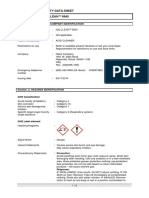

- SDS Acid CleanerDocument9 pagesSDS Acid CleanerMohamed AlamariNo ratings yet

- Rock Identification TablesDocument2 pagesRock Identification TablesFirdaus Dauz SNo ratings yet

- Life Cycle Assessment of Fertilizer Manufacturing and Impacts (39Document31 pagesLife Cycle Assessment of Fertilizer Manufacturing and Impacts (39Vijay SinghNo ratings yet

- Folio Chemistry Form 4 (Ceramics and Glass)Document12 pagesFolio Chemistry Form 4 (Ceramics and Glass)Izzat Munawwir Ismail86% (7)

- Faber Castell Polychromos - 2018 - Colour Chart - ShinebrightdesignDocument4 pagesFaber Castell Polychromos - 2018 - Colour Chart - ShinebrightdesignMagrizNo ratings yet

- Chemical Performance of PE: Chemical Formula Temp. Conc. Resistance (C) (%) Mdpe/Hdpe Ldpe AcetaldehydeDocument25 pagesChemical Performance of PE: Chemical Formula Temp. Conc. Resistance (C) (%) Mdpe/Hdpe Ldpe AcetaldehydeBobdNo ratings yet

- Shieldmaster Brochure by Manuli HydraulicsDocument12 pagesShieldmaster Brochure by Manuli HydraulicsPawan ChaturvediNo ratings yet

- Oregano Leaves As An Alternative Shoe Polish IngredientDocument9 pagesOregano Leaves As An Alternative Shoe Polish IngredientJen RealNo ratings yet

- Sampling and Sample PreparationDocument15 pagesSampling and Sample PreparationMuhdLuqman100% (1)

- 15.13 ThiolsDocument19 pages15.13 ThiolsSNo ratings yet

- Introduction To Different Types of Strainers PDFDocument7 pagesIntroduction To Different Types of Strainers PDFRalyn BasisNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetEduardo MazariegosNo ratings yet

- AIATS Practise PDFDocument44 pagesAIATS Practise PDFdeepNo ratings yet

- Tamirat Haile ComettedDocument48 pagesTamirat Haile ComettedWOndewosen AbelNo ratings yet

- MovidynDocument3 pagesMovidynJohnNo ratings yet

- Identify The Presence of Oxalate Ions in Guava and Sapota Fruits at Various StagesDocument4 pagesIdentify The Presence of Oxalate Ions in Guava and Sapota Fruits at Various StagesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Photosynthesis Iodine Test For StarchDocument5 pagesPhotosynthesis Iodine Test For StarchtaekookNo ratings yet

- R410a IceloongDocument6 pagesR410a IceloongMarco Ruales100% (1)

- Acid Value and Amine Value of Fatty Quaternary Ammonium ChloridesDocument3 pagesAcid Value and Amine Value of Fatty Quaternary Ammonium ChloridesShaker Qaidi100% (1)

- Manuscrito 3Document30 pagesManuscrito 3Sofia del CañoNo ratings yet

- 80005302enDocument134 pages80005302enUlfahanny RachsetyaNo ratings yet

- TDS 25740 Jotafloor EP SL Euk GBDocument5 pagesTDS 25740 Jotafloor EP SL Euk GBDavid TumboimbelaNo ratings yet

- TDS Byk-1780 enDocument2 pagesTDS Byk-1780 enabhijit.home2022No ratings yet

- Unit Four - PhagnosyExtraction TechniquesDocument74 pagesUnit Four - PhagnosyExtraction TechniquesMulugeta TesfayNo ratings yet

- Teach Yourself Electricity and Electronics, 6th EditionFrom EverandTeach Yourself Electricity and Electronics, 6th EditionRating: 3.5 out of 5 stars3.5/5 (15)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (543)

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)From EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Rating: 4.5 out of 5 stars4.5/5 (2)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialFrom EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialRating: 3.5 out of 5 stars3.5/5 (3)

- Practical Electronics for Inventors, Fourth EditionFrom EverandPractical Electronics for Inventors, Fourth EditionRating: 4 out of 5 stars4/5 (3)

- C++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingFrom EverandC++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingRating: 4 out of 5 stars4/5 (1)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 5 out of 5 stars5/5 (8)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersFrom Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersRating: 5 out of 5 stars5/5 (1)

- Off-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemFrom EverandOff-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemNo ratings yet

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- ARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)From EverandARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)No ratings yet

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesFrom EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesRating: 5 out of 5 stars5/5 (1)

- The Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026From EverandThe Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Rating: 5 out of 5 stars5/5 (1)

- Lithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsFrom EverandLithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsRating: 5 out of 5 stars5/5 (2)

- Open Radio Access Network (O-RAN) Systems Architecture and DesignFrom EverandOpen Radio Access Network (O-RAN) Systems Architecture and DesignNo ratings yet

- Power Quality in Power Systems and Electrical MachinesFrom EverandPower Quality in Power Systems and Electrical MachinesRating: 4.5 out of 5 stars4.5/5 (11)

- Digital Gold: The Beginner's Guide to Digital Product Success, Learn Useful Tips and Methods on How to Create Digital Products and Earn Massive ProfitsFrom EverandDigital Gold: The Beginner's Guide to Digital Product Success, Learn Useful Tips and Methods on How to Create Digital Products and Earn Massive ProfitsRating: 5 out of 5 stars5/5 (3)

- The Graphene Revolution: The Weird Science of the Ultra-thinFrom EverandThe Graphene Revolution: The Weird Science of the Ultra-thinRating: 4.5 out of 5 stars4.5/5 (4)