Professional Documents

Culture Documents

Impact of Fecal Waste Management On The Profitability of Poultry Farmers in Nigeria

Uploaded by

Mamta AgarwalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Impact of Fecal Waste Management On The Profitability of Poultry Farmers in Nigeria

Uploaded by

Mamta AgarwalCopyright:

Available Formats

International Journal of Environment, Agriculture and Biotechnology

Vol-7, Issue-6; Nov-Dec, 2022

Journal Home Page Available: https://ijeab.com/

Journal DOI: 10.22161/ijeab

Peer Reviewed

Impact of Fecal Waste Management on the Profitability of

Poultry Farmers in Nigeria

Eric Okomado1, Christopher Osamudiamen Emokaro2, Peace Chukwuyem Ugbekile3

1Department of Agricultural Economics and Extension Services, Faculty of Agriculture, University of Benin, Benin City, Edo State,

Nigeria.

2 Department of Agricultural Economics and Extension Services, Faculty of Agriculture, University of Benin, Benin City, Edo State,

Nigeria.

3 Department of Agricultural Economics and Farm Management, College of Agricultural Management and Rural Development, Federal

University of Agriculture, Abeokuta, Ogun State, Nigeria.

Received: 11 Nov 2022; Received in revised form: 02 Dec 2022; Accepted: 06 Dec 2022; Available online: 11 Dec 2022

©2022 The Author(s). Published by Infogain Publication. This is an open access article under the CC BY license

(https://creativecommons.org/licenses/by/4.0/).

Abstract— The observation that there is far more quantity of poultry waste than can be managed by land

disposal being produced yearly suggests the obvious problem of poultry waste management. This scenario

offers great opportunities for organic farming and bio-energy generation in Nigeria. Hence, this study

examined the economic contribution of fecal waste to the profitability of poultry farmers in Delta State,

Nigeria. A multi-stage sampling process was used to select the 123 poultry farmers for this study. The data

collected were analyzed using descriptive statistics, profitability ratios and the Stochastic Frontier Profit

Function model. The Gross Margin analysis gave a value of ₦5,771,437.10 and a Net Farm Income of

₦1,960.18 per bird. The profitability ratios showed a Profitability Index of 0.86, a Rate of Return on

Investment of about 19.25%, and a Return per Naira Invested (RNI) of ₦0.23. From the Stochastic Frontier

Profit Function analysis, veterinary cost and cost of labor for fecal waste management had a significant

positive effect on profit efficiency. The cost of birds and depreciation on fixed input had a significant negative

effect on profit efficiency. Age and cooperative membership of layer farmers were significant socioeconomic

factors positively influencing profit inefficiency. While education and household size were shown to

negatively influence profit inefficiency. It was therefore concluded that farmers should focus on improved

quality feed either self-compounded or purchased and better emolument for their workers as these positively

influenced their profit. They should also be enlightened on the huge benefit of fecal wastes-to-biogas-

electricity technology.

Keywords— Delta State, Gross Margin, Profit Efficiency, Profitability Index, Stochastic Frontier

Analysis.

I. INTRODUCTION and protein as they are good converters of feed into usable

1.1 Background of the Study protein (Farrell, 2013; Qaid and Al-Garadi, 2021) and some

Poultry production is one of the most developed aspects of researchers have associated this expansion potential with

the Nigerian livestock industry (Miebi, 2020), and with the various factors including relatively low production cost per

increase in population, there is pressure on local poultry unit, short incubation period, high returns on investment and

farmers and the potential to expand the sector (The the absence of geographical, cultural, and religious

Commonwealth Scientific and Industrial Research restrictions (Achoja, 2013; Akanni and Benson 2014; Heise

Organisation, CSIRO, 2021). This expansion is not et al., 2015). This implies that fecal waste generated from

unrelated to the fact that they have a high level of energy the industry contributes significantly to the total waste

generated in agriculture.

ISSN: 2456-1878 (Int. J. Environ. Agric. Biotech.)

https://dx.doi.org/10.22161/ijeab.76.14 123

Oyekale et al. International Journal of Environment, Agriculture and Biotechnology, 7(6)-2022

While there is difficulty in getting the true figures of northern part of Nigeria have besieged the South (Delta

waste produced from the Nigerian livestock industry, there State inclusive) with a request for poultry droppings. This is

are obvious indications that the volume is massive, and the obviously in recognition of its long-term benefit of helping

environmental consequences are enormous. In the wake of to improve the soil's physical properties. However, since

the 20th Century, Itodo et al., (2001) estimated 1.4 million, there is a dearth of information on the profitability of fecal

6.40 million and 5.2 million kilograms of cattle, poultry, and waste or its contribution to the profitability or otherwise of

piggery manure per day respectively. Another estimate layers enterprises in Delta State, this work is designed to

shows that about 932.5 tonnes of manure are produced answer the following research questions:

annually from the well-established poultry industries alone, • What is the contribution of revenue from fecal

which keeps expanding at 8% every year (Adewumi et al., waste to the profitability of layer farms in the

2011). Delta State livestock industry is known to have study area?

poultry production as the predominant enterprise with layer

• What is the profit efficiency of layer farms

production taking the central stage as it is a double-barreled

generating income from fecal wastes?

approach serving both the egg and meat production

purposes of poultry production. Generally, there is a The broad objective of the study was to investigate the

tendency for farmers to focus on the main production output impact of fecal waste management on the profitability of

than the waste of any production system. However, since poultry farmers in Nigeria and the specific objectives of this

poultry fecal wastes generate a lot of environmental study were to:

concerns and possess some economic value, there is a need • estimate the contribution of revenue from

to reconsider such waste viz-a-viz the economic impact on fecal waste to the profitability of layer farms

layer production. in the study area.

1.2 Problem Statement • determine the profit efficiency of layer farms

generating income from fecal wastes in the

Nigerian poultry farmers faced with the need to intensify

study area.

production have the problems of waste management and

inflated input prices to grapple with. This is particularly true The above objectives were used to explain the

in terms of the long-term growth and sustainability of hypothesis below:

poultry production in larger bird facilities located near • H0: There is no significant contribution of fecal

urban and peri-urban areas, as well as for smaller waste to the profitability of poultry farmers in the

commercial systems associated with live bird markets, and study area

for village and backyard flocks located in rural areas 1.3 Justification and Novelty

(Williams, 2013). It has been estimated that a layer bird

Numerous research efforts bordering on the economics and

produces about 63–70 kg of waste in a year and 1,000 layers

the profitability of poultry production in different parts of

can produce 1 tonne of manure weekly while in deep litters

Nigeria exist. Adewunmi (2008) researched the economics

(Oluyemi and Roberts, 2000). There is far more quantity of

of poultry production in Egba Division of Ogun State.

waste than can be managed by land disposal being produced

Hassan et al., (2016) did work on the economic analysis of

yearly (Gerber et al., 2008). While on the one hand, this

poultry egg enterprise in Kaduna State, while Nmadu et al.,

shows the obvious problem of poultry waste management,

(2014) looked at the profitability and resource use

on the other hand, it offers great opportunities for organic

efficiency of poultry egg production in Abuja. Emokaro and

farming and bio-energy generation in Nigeria.

Erhabor (2014) did a comparative analysis of the

The sales of fecal waste from poultry farms increase profitability of layers production in Esan North East and

revenue and ensure environmental stewardship at the same Ovia North-East local government areas of Edo State.

time as these wastes are recycled as organic manure for crop Joining this array of research, Achoja (2013) researched the

cultivation. Generating bioenergy from these wastes or allocative efficiency of feeds among poultry farmers in

developing other eco-innovative strategies to manage these Delta State. Also, there have been several studies on the

wastes of environmental concern, is expected to reduce the environmental effects of poultry production and the

cost of waste management and money spent on fossil fuel potential of poultry waste (Gerber et al, 2008; Williams,

and electricity bills in the long run. Both approaches to 2013; Alabi et al., 2014). It is also worth noting that outside

managing waste ensure a cleaner environment and the Nigeria, there have been studies on the use and profitability

generation of more revenue through the reduction of cost of poultry manure in electricity generation. Works of

which is consistent with the objective function of profit Murphy et al., 2004; Gebrezgabher et al., 2010 and Lassner,

maximization. In recent times, arable crop farmers from the 2011 looked at various aspects of this eco-innovative way

ISSN: 2456-1878 (Int. J. Environ. Agric. Biotech.)

https://dx.doi.org/10.22161/ijeab.76.14 124

Oyekale et al. International Journal of Environment, Agriculture and Biotechnology, 7(6)-2022

of waste management. More specifically, bothered that the saved through this process and from selling manure to crop

use of wastes for biogas production has been restricted to a farmers become an additional source of income from the

few feedstocks like cattle manure and food waste, Ajieh et poultry enterprise. Making money from fecal waste is also

al., (2021), reasoned that increasing the feedstock base for a way of waste management, thus this double-barreled

biogas production can increase the sustainability of model is what any farm can adopt. Researchers (Akanni and

feedstock availability. Thus, the sociocultural and Benson, 2014; Alabi et al., 2014; Onu et al., 2014) have

acceptability issues associated with the use of fecal waste as shown that one of the ways of managing poultry waste,

a source of energy in Benin City, Edo State, Nigeria were especially fecal waste is through selling these wastes,

assessed. Ihoeghian et al., (2022), also looked at anaerobic especially for those involved in urban agriculture. In fact, in

co-digestion of cattle rumen content and food waste for the research on poultry litter/manure management practices

biogas production as an alternative energy source. This was in intensively managed poultry farms in Port Harcourt

against the backdrop that Nigeria generates approximately (South-South Nigeria), it was shown that 53.3% of the

42 million tonnes of solid waste, with attendant poor waste respondents sell their bags of fecal waste immediately,

management practices that have made it impossible to 43.3% store and sell later, and 3.3% apply manure directly

properly collect and harness these waste materials. to their farmlands (Kalu, 2015). This shows that there is an

However, while the plethora of research around profitability available market, not just for poultry products but also for

gives great insight to all stakeholders in the solid waste the by-products, specifically, fecal waste.

management and poultry subsector of the livestock industry, Beyond the sales of fecal waste for soil fertility

there is hardly any work on the economics of the fecal waste supplementation, poultry and other types of animal wastes

generated from poultry production in terms of their could be used as energy feedstock to generate biogas. The

contribution to the profitability of the poultry enterprise and production of methane from biomass e.g., human excreta,

meeting the objective of environmental stewardship in line animal manure, sewage sludge, and vegetable crop residues

with the trend of eco-innovation. This identified gap is what can be used in families, farms and industrial units for

this current research effort is designed to fill. cooking, heating, and lighting, and in larger institutions for

1.4 Review of Previous Studies power generation (Simeon, 2009). Although this option has

A major challenge in Nigeria in terms of poultry waste been adequately explored in many developed countries

management is the fact that reliable data on the volume of (Mehta, 2002; Murphy et al., 2004; Singh et al., 2008;

waste generated from poultry farms annually are not readily Gebrezgabher et al, 2010; Jensen et al., 2010; Lassner,

available. In Nigeria, about 932.5 metric tonnes (MT) of 2011), there are only a few farms or institutions currently

manure are produced annually from the well-established employing this technology of environmentally-friendly

poultry/livestock industries which keep expanding at 8% waste management in Nigeria. This may be due to

every year (Adewumi et al., 2011). It is obvious that with ignorance, unavailability of technical know-how,

the increased intensification of poultry production over the unavailability of adequate poultry wastes to feed biogas

past 15 years, the figures have soared. In Minna, North- digester to produce desired energy demand, lack of policy

Central Nigeria, Adeoye et al., (2014) reported an estimate attention and government support, and lack of research on

of 100.97 tonnes of dead birds over a brooding cycle and the feasibility and profitability amongst others.

about 159,430 metric tonnes of poultry manure being However, whenever poultry farmers are ready to look

generated annually from the 117 poultry farms in that State. toward methods to decrease farm energy costs, use energy

The case in the other States of the country may not be for their operations in a sustainable manner, and sustainably

different. To better overcome the monumental task of dispose of litter, their interest would always increase in

poultry waste management, different waste management using poultry litter as a potential energy feedstock (Jensen

practices like sanitary landfills rendering faculties, et al., 2010). The use of poultry wastes as energy feedstock

extrusion machinery, compost plants, lagoons, or holding for biogas generation is not only an efficient and

tanks and land application have been used (Pope, 1991). environmentally friendly way of managing waste but also

Apart from being a by-product of poultry production, helps to save money or a part of the cost that would have

fecal waste has economic value and potential thus the been spent on electricity.

potential for income in the farm. This is because they could

be applied as manure for soil nutrient augmentation, thus

saving or reducing the money that would have been spent

on inorganic fertilizers for the case of poultry farms

integrated with crop production. The value of the money II. METHODS

2.1. Sampling and Sampling Procedure

ISSN: 2456-1878 (Int. J. Environ. Agric. Biotech.)

https://dx.doi.org/10.22161/ijeab.76.14 125

Oyekale et al. International Journal of Environment, Agriculture and Biotechnology, 7(6)-2022

The study was conducted in Delta State, Nigeria. The State

lies approximately between Latitudes 5°00' and 6°30' North 𝐺𝑀 = 𝑇𝑅 − 𝑇𝑉𝐶

and Longitudes 5°00' and 6°45' East. It is bounded in the

( 1)

North by Edo State, the East by Anambra State, South-East

by Bayelsa State, and on the Southern flank is the Bight of Where;

Benin (Delta State Ministry of Agriculture and Natural GM = Gross Margin (N),

Resources, 2010). It is situated in the tropics and therefore

TR = Total Revenue (N),

experiences a fluctuating climate, ranging from the humid

tropical in the South, and the sub-humid in the Northeast. TVC = Total Variable Cost (N).

A three-stage sampling procedure was employed in Net Farm Income: This was another index for profitability

drawing the sample. In the first stage, the stratification of determination, and it represents the total profit and was

the State into three zones following the ADP-Agricultural determined using the:

zones delineation namely, Delta North Agricultural Zone 𝑁𝐹𝐼 = 𝑇𝑅 − 𝑇𝐶

(DNAZ), Delta Central Agricultural Zone (DCAZ) and

( 2)

Delta South Agricultural Zone (DSAZ) was maintained.

The second stage involved the simple random sampling of Where;

five blocks (LGAs) from DNAZ, five blocks from DCAZ NR = Net Farm Income; TR = Total Revenue and TC=

and three blocks from the DSAZ. Since, poultry farms were Total Cost.

randomly distributed in communities (cells) within these 𝑇𝑅 = 𝑃𝑉 𝑉 + 𝑃𝑊 𝑊 + 𝑃𝑋 𝑋 + 𝑃𝑌 𝑌 + 𝑃𝑍 𝑍

blocks, with some towns having several farms and others

having no poultry farm at all, the third stage involved the ( 3)

use of a simple random sampling to select 12 poultry farms But:

from each of the earlier selected blocks in DNAZ and 𝑇𝐶 = 𝑇𝑉𝐶 + 𝑇𝐹𝐶

DCAZ while eight poultry farms each were selected from = 𝑇𝑉𝐶

the blocks of DSAZ. The ratio of farmers selected from the + 𝐷𝑒𝑝𝑟𝑒𝑐𝑖𝑎𝑡𝑖𝑜𝑛 𝑜𝑛 𝐹𝑖𝑥𝑒𝑑 𝐼𝑛𝑝𝑢𝑡

three zones was done in proportion to the total number of

farms in the sampling frame. This selection was drawn from ( 4)

the sampling frame containing the lists of active layer Pv = Price of eggs; v = quantity of eggs (in crates); Pw =

farmers across the State as provided by the Delta State Price of cracked eggs; w = quantity of cracked eggs (in

Ministry of Agriculture, Asaba and the Delta State crates); Px = Price of spent bird x = quantity of spent birds

Agricultural Development Programme, Ibusa. The (in kg); Py = Price of fecal waste; y = quantity of fecal

sampling frame contained 224 active layer farmers and the waste (in bags of kg); Pz = Price of feed bags/sack; z =

sampling goal was to sample 130 layer farmers (58% of the quantity of feed bags/sack (in dozens).

sampling frame) satisfying the Central Limit Theorem and 𝑁𝐹𝐼

Profitability Index (PI) =

inclusion of a 10% buffer (i.e. 13 extra respondents) to give 𝐺𝑀

allowance for non-response and invalid responses. Thus 60 ( 5)

respondents each were obtained from DNAZ and DCAZ 𝑁𝐹𝐼

Rate of Return to Investment (RRI) = ∗ 100

while 24 respondents came from DSAZ giving a total of 144 𝑇𝐶

respondents in all. A total number of 144 copies of the ( 6)

research questionnaire were administered. However, upon 𝐺𝑀

Return Per Naira Invested on Variable Cost =

collation, only 123 copies were found useful for further 𝑇𝑉𝐶

analysis, thus giving a response rate of 85.41%. ( 7)

2.2. Analytical Techniques The depreciation of all fixed assets (cost) was calculated

Gross Margin Analysis: This was used to determine the using the Straight-Line Method as shown below:

profitability or otherwise of the poultry farmers. Gross 𝑆

𝐷=𝐶−

Margin is the difference between gross income (revenue) 𝑁

and total variable cost (TVC) of production (Olukosi and ( 8)

Erhabor, 2005). This was one of the indices used in

Where;

determining the costs, returns as well as the profitability of

the poultry farmers in the study area. It was determined as D = Depreciated amount; C = Initial cost of the assets; S =

follows: Scrap value (which in this case is assumed to be zero); and

N = Expected number of useful life spans.

ISSN: 2456-1878 (Int. J. Environ. Agric. Biotech.)

https://dx.doi.org/10.22161/ijeab.76.14 126

Oyekale et al. International Journal of Environment, Agriculture and Biotechnology, 7(6)-2022

Furthermore, the Student’s t-test was used to find out if of jth variable input prices faced by the ith farm divided by

there is a significant contribution of fecal waste to the output price (in this case, the price of fecal waste); Zik is the

profitability measures of poultry farmers. The formula for level of the kth of fixed factors on the ith farm; i is an error

the T-test is given below: term; here i =1,., n, is the number of poultry farms in the

𝑡 = (𝑋1 − 𝑋2 )/𝑆𝑑 sample. The assumption here is that the error term i behave

in a manner consistent with the frontier concept, that is;

( 9)

𝜀𝑖 = 𝑣𝑖 − 𝜇𝑖

Where;

( 13)

√𝑆12 √𝑆22

𝑆𝑑 = + The symmetric two-sided error term (v) accounts for

𝑛1 𝑛2

random variation in profit attributed to factors outside the

( 10) farmer’s control (white noise). The one-sided component

Where; (µ) is a non-negative error term accounting for the

X1 = Mean of the first set of values (those who make inefficiency of the farm. Therefore, it represents the profit

money from fecal waste), X2 = Mean of the second set of shortfall from its maximum possible value on the stochastic

values (those who do not make money from fecal waste), profit frontier.

s1 = Standard deviation of the first set of values, s2 = A multiple regression model based on the stochastic

Standard deviation of the second set of values, n1 = Total frontier profit function which assumes a translog functional

number of values in the first set, n2 = Total number of form was employed to determine the profit efficiency of

values in the second set. farmers generating revenue from wastes in the study area.

While the formula for standard deviation is given: This is in line with Ifeanyi and Onyenweaku (2007). It was

chosen due to its inherent advantage as well as suitability in

2 estimating sole enterprises and analyzing interactions

𝑆 = √∑(𝑥 − 𝜇) /(𝑛 − 1) among input variables and the output. This is specified

below:

( 11)

ln*i = a0 + a1lnX1 + a2lnX2 + a3lnX3 + a4lnX4 + a5lnX5 +

Where; a6lnX6 + a7lnX7 + 0.5a11 ln(X1)2 + 0.5a22ln(X2)2 +

x = profit of a given layer farmer, μ = Mean profit of layer 0.5a33ln(X3)2 + 0.5a44ln(X4)2 + 0.5a55ln(X5)2 + 0.5a66 ln(X6)2

farmers, n = Total number of layer farmers. +0.5a77 ln(X7)2 + a12 lnX1*lnX2 + a13 lnX1*lnX3 + a14

The profit function was used to determine the profit lnX1*lnX4 + a15lnX1*lnX5 + a16lnX1*lnX6 + a17lnX1*lnX7

efficiencies of farms generating income from fecal wastes + a23 lnX2*lnX3 + a24lnX2*lnX4 + a25lnX2*lnX5 +

in the study area by employing the stochastic profit frontier a26lnX2*lnX6 + a27lnX2*lnX7 + a34lnX3*lnX4 +

model. This followed Battese and Coelli (1995) who a35lnX3*lnX5 + a36lnX3*lnX6 + a37lnX3*lnX7 + a45

extended the stochastic production frontier model by lnX4*lnX5 + a46lnX4*lnX6 + a47lnX4*lnX7 + a56 lnX5*lnX6

suggesting that inefficiency effects can be expressed as a + a57 lnX5*lnX7 + a67 lnX6*lnX7 vi - µi

linear function of explanatory variables, reflecting farm- ( 14)

specific characteristics. The advantage of the model is that Where:

it makes it possible to estimate the specific efficiency *i = restricted profit (total revenue less total cost of variable

scores and the factors explaining the efficiency inputs) profit normalized by the price of the output

differentials among farmers in a single-stage estimation computed for the ith farmer; ln = natural log; X1 =

procedure. normalized cost of layer feed (in Naira); X 2 = normalized

The profit function which is assumed to behave in a cost of labor (in Naira); X3 = cost of stock/birds (in Naira);

manner consistent with the stochastic frontier concept is X4 = normalized veterinary cost (in naira); X5 = normalized

defined as: cost of labor for fecal waste management (in Naira); X6 =

𝜋𝑖 = 𝑓(𝑃𝑖𝑗 , 𝑍𝑖𝑘 ). exp (𝜀𝑖 ) normalized cost of bags for waste; X7 = depreciation on

fixed assets; a0 and a1- 7 are parameters to be estimated, vi

( 12) represents statistical disturbance term and µi = represents

Where; profit inefficiency effects of ith poultry farmer generating

i is the normalized profit of the ith farm defined as gross income from fecal waste.

revenue less variable

cost, divided by farm-specific output price P; Pij is a vector

ISSN: 2456-1878 (Int. J. Environ. Agric. Biotech.)

https://dx.doi.org/10.22161/ijeab.76.14 127

Oyekale et al. International Journal of Environment, Agriculture and Biotechnology, 7(6)-2022

The determinants of profit inefficiency of layer/egg and 25-54 years of age, respectively. The mean ages were

production in line with Bamiro et al. (2013) were modeled 46 years, 45 years, 45 years, and 46 years, respectively. This

following specific characteristics of farmers in the study implies that the majority of the farmers were young, agile

area. From equation (13) component is specified as and within their active age, this may positively influence

follows: their productivity. This finding resonates with the findings

5 of Yusuf and Malomo (2007) who reported an average age

𝜇𝑖 = 𝑙0 + ∑ 𝑙𝑑 𝑊𝑑 + 𝑘 of 44 years.

𝑑=1

The greater proportion (57.41%, 69.39%, 65% and

( 15) 63.41%) of the farmers in DNAZ, DCAZ, DSAZ and

pooled sample had tertiary education. This implies that the

Where: majority of them were well-educated. Generally, educated

µi = Profit inefficiency of ith farmer; l0 and ld are parameters farmers are more receptive and apt to adopt new

to be estimated; Wd = variables representing socioeconomic technologies that would enhance productivity, better

variables (d =1,2,3...., n,); W1 = ages (in years); W2 = manage waste, and increase profit, and profit efficiency

education (yearsj); W3 = years farming experience; W4 = (Paltasingh and Goyari, 2018). The greater proportion

Household size (head count); W5 = Cooperative (46.3%, 46.94%, 55% and 47.97%) of the respondents in

membership (Member = 0, Nonmember =1); k is truncated DNAZ, DCAZ, DSAZ and pooled sample respectively had

random variable. 6 -10 years of poultry farming experience. The mean

farming experience for DNAZ, DCAZ, DSAZ and the

pooled sample was seven years, six years, eight years, and

III. RESULTS AND DISCUSSION

seven years, respectively. Since the continuous practice of

3.1. Socioeconomics Characteristics of Poultry Farmers in

an occupation for a long time has the potential of making a

the Study area

person more experienced and productive in the practice, it

Results presented in Table 1 show that the majority could imply that they have good experience in poultry

(66.67%, 73.47%, 65% and 69.11%) of the poultry farmers production, a development that can influence their

in Delta North Agricultural Zone (DNAZ), Delta Central efficiency and productivity positively. Concerning

Agricultural Zone (DCAZ), Delta South Agricultural Zone household size, a greater proportion (61.11%, 61.22%, 55%

(DSAZ) and pooled sample respectively were males, and 60.16%) of the farmers in DNAZ, DCAZ, DSAZ and

indicating that only a few females were actively involved. pooled sample had a household size of 4 - 6 persons. The

Thus, the industry is male-dominated. Age distribution mean household size was five persons. This implies that the

among the majority (85.19%, 83.67%, 90% and 85.17%) of majority of the farmers had a fairly large size of household

the poultry farmers in DNAZ, DCAZ, DSAZ and pooled members, thus increasing their employment of family labor.

sample were within 25-54 years, 55-64 years, 25-54 years,

Table 1: Frequency and Percentage Distribution of Farmers according to their Socio-economic Characteristics

Variable Description DNAZ DCAZ DSAZ Pooled

Freq. Percent Freq. Percent Freq. Percent Freq. Percent

Sex Male 36 66.67 36 73.47 13 65.00 85 69.11

Female 18 33.33 13 26.53 7 35.00 38 30.89

Age (years) ≤30 1 2.04 1 0.81

31-40 16 29.63 18 36.74 5 25.00 37 30.08

41-50 22 40.74 14 28.57 11 55.00 49 39.84

51-60 12 22.22 13 26.53 4 20.00 29 23.58

Above 60 4 7.41 3 6.12 7 5.69

Mean 46 45 45 46

Standard 8.48 9.06 6.32 8.36

deviation

ISSN: 2456-1878 (Int. J. Environ. Agric. Biotech.)

https://dx.doi.org/10.22161/ijeab.76.14 128

Oyekale et al. International Journal of Environment, Agriculture and Biotechnology, 7(6)-2022

Level of Primary 3 5.56 2 4.08 5 4.07

education Secondary 20 37.04 13 26.53 7 35.00 40 32.52

Tertiary 31 57.41 34 69.39 13 65.00 78 63.41

Farming 1-5 20 37.04 26 53.06 4 20.00 50 40.65

experience 6-10 25 46.30 23 46.94 11 55.00 59 47.97

(years)

11-15 8 14.81 5 25.00 13 10.57

16-20 1 1.85 1 0.81

Mean 7 6 8 7

Standard 3.33 2.10 3.15 2.97

deviation

Household 1-3 10 18.52 12 24.49 3 15.00 25 20.33

size (persons) 4-6 33 61.11 30 61.22 11 55.00 74 60.16

7-9 11 20.37 7 14.29 6 30.00 24 19.51

Mean 5 5 5 5

Standard 1.64 1.95 1.56 1.78

deviation

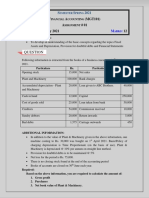

3.2. Profitability of Poultry Production net farm income were ₦5,771,437.10 and ₦4,966,761.94,

The mean result of the profitability accruable from poultry respectively. The positive gross margin and net farm income

farming is presented in Table 2. The result showed that the imply that this is a profitable enterprise in the area. The

average revenue realized by the farmers in the study area profitability measures (Profitability Index, Rate of Return

was ₦30,773,161.91. Revenue from egg production was on investment and Return on Variable Cost) showed that

₦27,489,426.19, the revenue realized from cracked eggs poultry production in the area is profitable. The Profitability

was ₦287,336.37, and revenue realized from culled layers Index showed that for every naira earned as revenue, ₦0.86

was ₦2,923,621.89 while revenue realized from fecal waste returned to the producers as net income. In other words,

was ₦72,777.45. The total cost of production incurred by 86% of the total revenue earned constituted the net income.

the farmers was ₦25,806,399.9, and the variable cost This implies that an appreciable profit level can be made

incurred was ₦25,001,724.81 which represented most from the enterprise. The rate of return on investment (RRI)

(96.88%) of the total production cost. The cost of feed in this study was estimated to be 19.25%, implying that for

contributed 88.51% to the total production cost. The fixed every one naira spent or invested in layer production by

cost of production was ₦804,675.15 and this contributed farmers in the study area, the farmers earned on average

3.12% to the total cost of production. The gross margin and 19.25% profit.

Table 2: Mean Cost and Return Structure of Layer Production

Variable Quantity Cost/unit Value (₦) % Total

Cost

Revenue

Eggs produced/season 30,216.26 909.76 27,489,426.19

Cracked eggs sold/season 803.24 357.72 287,336.37

Layers disposed 2,336.62 1,251.22 2,923,621.89

Fecal waste per season 209.93 346.67 72,777.45

ISSN: 2456-1878 (Int. J. Environ. Agric. Biotech.)

https://dx.doi.org/10.22161/ijeab.76.14 129

Oyekale et al. International Journal of Environment, Agriculture and Biotechnology, 7(6)-2022

Total Revenue 30,773,161.91

Variable Cost

Labor cost 82 10,645.19 873,944.21 3.39

Cost of feed 7,922.26 2,883.05 22,840,257.25 88.51

Electricity cost 38.02 3,769.51 143,327.09 0.56

Fuel 37.11 9,397.45 348,781.73 1.35

Stock/DOC 2,533.83 178.83 453,115.52 1.76

Veterinary cost 2,533.83 130.70 331,159.16 1.28

Labor for waste management 11,139.85 0.04

Total variable cost 25,001,724.81 96.88

Fixed cost

Depreciation on Fixed inputs 636,770.51 2.47

Feeding bag 660.63 247.24 163,332.16 0.63

Cost of waste sacks 4,572.48 0.02

Total fixed cost 804,675.15 3.12

Total cost 25,806,399.96 100.00

GM 5,771,437.10

NFI 4,966,761.94

PI 0.86

RRI 19.25

Return on Variable Cost 0.23

3.3. Contribution of Fecal Waste to Profitability critical probability value of 0.05, leading to a non-rejection

The result for testing the hypothesis of whether fecal waste of the null hypothesis. This result implies that fecal waste

contributes significantly to profitability or not is shown in generation has no significant contribution to the

Table 3. The null hypothesis was tested using a paired profitability index and rate of return on investment of the

student t-test. The result of the hypothesis test showed that farmers. This might be because the amount of revenue

the probability of the test statistics of the profitability generated from layer waste is small compared to that

measures (0.314, 0.157 and 0.843) was higher than the generated from eggs, cracked eggs, and culled layers.

Table 3: Result of Test of Hypothesis

Null hypothesis Profitability Fecal Non-fecal Mean p-value decision

measures difference

There is no significant PI 0.86 0.86 0.00 0.314 Fail to reject

contribution of fecal waste null

to profitability RRI 19.25 18.96 0.29 0.157 Fail to reject

null

3.4. Profit Efficiency of Layer Farmers

ISSN: 2456-1878 (Int. J. Environ. Agric. Biotech.)

https://dx.doi.org/10.22161/ijeab.76.14 130

Oyekale et al. International Journal of Environment, Agriculture and Biotechnology, 7(6)-2022

The result of the Maximum Likelihood Estimates (MLE) of because feed is a vital input in poultry production and about

the parameters of the Translog profit efficiency and 70-80% of the production cost was expended on feed, any

inefficiency model of the layer farmers is presented in attempt to raise the cost of feed will result in to decrease in

Tables 4 and 5, respectively. The variance parameters, the profit of the farmers. The coefficient of stock showed

sigma-square and gamma were estimated at 0.142 (p< 0.01) that a 1% increase in the cost of birds would reduce the

and 0.928 (p<0.01), respectively. The sigma-square attests profit by 9.44%. Increasing the cost of layer birds will

to the goodness of fit and correctness of the distributional reduce the profit of the farmers. The coefficient of

form assumed for the composite error term while the gamma veterinary cost showed that a 1% increase in the cost of

indicates the systematic influences that are unexplained by veterinary services would increase the profit by 8%. This is

the profit function and the dominant sources of random so because as veterinary cost increases so do the layer birds

errors. This implies that about 92.8% of the variation in become healthier thereby resulting in higher output which

profit is due to the differences in their inefficiency. The will invariably increase the profit level of the farmers. The

parameter estimates of the translog functional form of the coefficient of cost of labor for fecal waste management

stochastic frontier suggest that cost of feed (p<0.01), cost of showed that a 1% increase in the cost of fecal waste

bird/stock (p<0.05) and depreciation on fixed assets management would increase the profit of the farmers by

(p<0.01) negatively influenced the profit of the farmers 1.17%. The coefficient of depreciation on fixed assets

while veterinary cost (p<0.01) and labor cost for fecal waste showed that a 1% increase in the cost of depreciation of

management (p<0.01) had a positive influence on profit of fixed assets would reduce the profit by 9.36%. This is so

layer farmers. because fixed assets like cages, pens, and buildings are vital

The coefficient of feed showed that a 1% increase in the in poultry production and any attempt to increase their cost

cost of feed would reduce the profit by 18.25%. This is so will have a negative impact on the profit level of the

farmers.

Table 4: Maximum Likelihood Estimates of Profit Efficiency Model

Variable Coefficient Standard Error z-value P-value

Feed -18.251*** 4.516 -4.040 0.000

Stock -9.435** 4.402 -2.140 0.032

Labor 3.307 3.295 1.000 0.316

Veterinary 8.002*** 2.582 3.100 0.002

Labor*Waste 1.174*** 0.372 3.150 0.002

Bag*Waste -0.571 1.791 -0.320 0.750

Depreciation on Fixed Assets -9.362*** 1.456 -6.430 0.000

Feed*Feed -1.953*** 0.128 -15.280 0.000

Stock*Stock -1.800 5.563 -0.320 0.746

Labor*Labor -0.210 0.614 -0.340 0.732

Veterinary*Veterinary 0.987 0.700 1.410 0.159

2

(Labor*Waste) -0.202 0.168 -1.200 0.231

(Bag*Waste)2 0.058 0.198 0.290 0.771

2

(Depreciation on Fixed Assets) -1.802* 0.992 -1.820 0.069

Feed*Stock 6.892*** 1.731 3.980 0.000

Feed*Labor -1.316 1.339 -0.980 0.326

Feed*Veterinary 5.545 . . .

Feed*Labor*Waste 0.072 0.767 0.090 0.925

Feed*Bag*Waste 0.483 1.067 0.450 0.651

Feed*Depreciation on Fixed Assets 13.536*** 1.069 12.660 0.000

ISSN: 2456-1878 (Int. J. Environ. Agric. Biotech.)

https://dx.doi.org/10.22161/ijeab.76.14 131

Oyekale et al. International Journal of Environment, Agriculture and Biotechnology, 7(6)-2022

Stock*Labor -0.116 1.009 -0.110 0.909

Stock*Veterinary -13.123*** 1.954 -6.720 0.000

Stock*Labor*Waste -1.076 1.318 -0.820 0.414

Stock*Bag*Waste 0.001 0.001 0.790 0.428

Stock*Depreciation on Fixed Assets -13.491 . . .

Labor*Veterinary 2.144 1.749 1.230 0.220

Labor2*waste 0.433** 0.218 1.990 0.046

Labor*Bag*Waste -0.482 0.501 -0.960 0.335

Labor*Depreciation on Fixed Assets -0.836 0.522 -1.600 0.109

Veterinary*Labor*Waste 0.055 0.574 0.100 0.923

Veterinary*Bag*Waste -0.095 1.159 -0.080 0.934

Veterinary* Dep. on Fixed Assets 2.155*** 0.803 2.680 0.007

Labor*Waste*Bag*Waste 0.011 0.101 0.110 0.910

Labor*Waste*Dep. On Fixed Asset 0.434 0.306 1.420 0.156

2

Sigma 0.142 0.018

Gamma 0.928 0.024

Log likelihood 30.816

***, ** and * means significant at 1%, 5% and 10% respectively.

3.5. Determinants of Profit Inefficiency of Poultry Farmers education exposes the farmers to innovative ways of raising

The result of the determinants of profit inefficiency is their birds at reduced cost thereby reducing their profit

presented in Table 5. The result showed that age (p<0.1) and inefficiency. The coefficient of household size showed that

cooperative membership (p<0.01) positively influence an increase in the size of the household reduces the profit

profit inefficiency while education (p<0.01) and household inefficiency of the farmers. This might be because most of

size (p<0.05) negatively influence profit inefficiency. The the layer farmers engaged their household members on their

coefficient of age revealed that an increase in age increases farms to save costs expended on labor, this will invariably

profit inefficiency. This implies that older farmers are more increase their profit level. The coefficient of cooperative

profit inefficient compared to their younger counterparts. membership suggests that the profit inefficiency of the

This may be because as age increases so does the ability to farmers that are members of cooperative society increases

be more productive reduces thereby making farmers less than their counterparts that are non-members of cooperative

profit efficient. The coefficient of education showed that as society. This might be because those that belonged to

the number of years spent in school increases the profit cooperative societies did not receive adequate training and

inefficiency of the farmers reduces. This is so because financial support from their association.

Table 5: Estimates of Determinants of Profit Inefficiency

Variable Coefficient Standard Error z-value P-value

Constant 0.377*** 0.104 3.630 0.000

Age 0.003* 0.002 1.680 0.096

Education -0.088*** 0.022 -3.910 0.000

Farming experience -0.005 0.005 -1.050 0.294

Household size -0.019** 0.008 -2.450 0.016

Cooperative membership 0.149*** 0.035 4.210 0.000

ISSN: 2456-1878 (Int. J. Environ. Agric. Biotech.)

https://dx.doi.org/10.22161/ijeab.76.14 132

Oyekale et al. International Journal of Environment, Agriculture and Biotechnology, 7(6)-2022

IV. CONCLUSION AND RECOMMENDATION [8] Bamiro, O. M., Otunaiya, A. O., & Adejumo, I. (2013). Profit

efficiency in poultry production in Peri-Urban Lagos,

From the analysis, poultry production is profitable with a

Nigeria. International Journal of Applied Agriculture and

high potential for farmers to make more profit than the Apiculture Research, 9(1-2), 120-130.

current average farmers if inputs are more efficiently used. [9] Battese, G. E., & Coelli, T. J. (1995). A model for technical

The following recommendations are suggested: inefficiency effects in a stochastic frontier production

• Farmers are advised to invest in their function for panel data. Empirical economics, 20(2), 325-

332.

education as this is shown to have a significant

[10] CSIRO, (2021). Poultry production in Nigeria. Available at:

negative effect on their profit inefficiency. https://research.csiro.au/livegaps/findings/livestock-

• Poultry farmers are advised to creatively production/poultry-production-in-nigeria/ [Assessed

manage the factors of production that October 18, 2022]

significantly affect their profitability such as [11] Delta State Ministry of Agriculture and Natural resources

veterinary costs, cost of birds, cost of labor for (MANR) (2010) Official bulletin.

fecal waste management and depreciation to [12] Emokaro, C. O., and Erhabor, P. O. (2014). Comparative

improve the performance of their farm. Analysis of Profitability of Layers Production in Esan North

East and Ovia North East Local Government Areas of Edo

If these recommendations are adequately followed, there State, Nigeria. Journal of Applied Sciences and

will be a boost to poultry production in the study area as Environmental Management, 18(1), 121-126.

well as an increase in the income of layer farmers. In [13] Farrell, D. (2013). The role of poultry in human

addition, a sub-enterprise will be created from fecal waste nutrition. Poultry Development Review. Rome: Food and

which has great untapped potential, while production goes Agriculture Organization, pp.2-9.

on in an environmentally sustainable manner. [14] Gebrezgabher, S. A., Meuwissen, M. P., Prins, B. A., and

Lansink, A. G. O. (2010). Economic analysis of anaerobic

digestion—A case of Green power biogas plant in The

REFERENCES Netherlands. NJAS: Wageningen Journal of Life

Sciences, 57(2), 109-115.

[1] Achoja F. O. (2013). Allocative efficiency of feeds among

[15] Gerber, P., Opio, C., and Steinfeld H. (2008). Poultry

poultry farmers in Delta state, Nigeria. Russian Journal of

production and the environment – A review. Rome, Italy:

Agricultural and Socio-Economic Sciences, 14(2), 26-33.

Food and Agriculture Organization of the United Nations.

[2] Adeoye, P. A., Hasfalina, C. M., Amin, M. S. M., Thamer, A.

[16] Hassan, A. A., Ahmadu, H. J., Oseni, Y., Dawang, N. C.,

M., and Akinbile, C. O. (2014). Environmental implication of

Rahman, S. A., and AbdulSalam, Z. (2016). Economic

poultry waste generation and management techniques in

Analysis of Poultry Egg Enterprise in Kaduna State, Nigeria.

Minna, semi-arid region of Nigeria. Annual Research &

[17] Heise, H., Crisan, A., and Theuvsen, L. (2015). The poultry

Review in Biology, 1669-1681.

market in Nigeria: Market structures and potential for

[3] Adewumi, A. A., Adewumi, I. K., and Olaleye, V. F. (2011).

investment in the market. International Food and

Livestock waste-menace: Fish wealth-solution. African

Agribusiness Management Review, 18(1030-2016-83098),

Journal of Environmental Science and Technology, 5(3),

197-222.

149-154.

[18] Ihoeghian, N.A., Amenaghawon, A.N., Ajieh, M.U.,

[4] Adewunmi, O. I. (2008). Economics of poultry production in

Oshoma, C.E., Ogofure, A., Erhunmwunse, N. O., Edosa,

Egba division of Ogun State. Medwell Online Agricultural

V.I.O., Tongo, I., Obuekwe, I.S., Isagba, E.S., Emokaro,

Journal, 3(1), 9-12.

C.O., Ezemonye, L.I.N., Lag-Brotons, A.J., Semple, K.T.,

[5] Ajieh, M.U., Isagba, E.S., Ihoeghian, N., Edosa, V.I.O.,

Martin, A.D., (2022). Anaerobic co-digestion of cattle rumen

Amenaghawon, A., Oshoma, C.E., Erhunmwunse, N.,

content and food waste for biogas production: establishment

Obuekwe, I. S., Tongo, I., Emokaro, C.O., and Ezemonye,

of co-digestion ratios and kinetic studies. Bioresource

L.I.N. (2021). Assessment of socio-cultural acceptability of

Technology Reports 18 (2022) 101033.

biogas from faecal waste as an alternative energy source in

www.sciencedirect.com/journal/bioresource-technology-

Benin City, Edo State, Nigeria. Environ Dev

reports

Sustain 23, 13182–13199 (2021).

[19] Itodo, I. N., Awulu, J. O., and Philip, T. (2001). A

https://doi.org/10.1007/s10668-020-01205-y

comparative analysis of biogas yield from poultry, cattle and

[6] Akanni, K. A., and Benson, O. (2014). Poultry wastes

piggery wastes. In Livestock Environment VI, Proceedings of

management strategies and environmental implications on

the 6th International Symposium 2001 (p. 402). American

human health in Ogun state of Nigeria. Adv. Econ. Bus, 2,

Society of Agricultural and Biological Engineers.

164-171.

[20] Jensen, K. L., Roberts, R. K., Bazen, E., Menard, R. J., and

[7] Alabi, R. A., Aghimien, C. I., Osasogie, D. I., and Otasowie,

English, B. C. (2010). Farmer willingness to supply poultry

G. E. (2014). Environmental Effects of Poultry Production in

litter for energy conversion and to invest in an energy

Edo State, Nigeria. American Journal of Experimental

conversion cooperative. Journal of Agricultural and Applied

Agriculture, 4(12), 1773.

Economics, 42(1), 105-119.

ISSN: 2456-1878 (Int. J. Environ. Agric. Biotech.)

https://dx.doi.org/10.22161/ijeab.76.14 133

Oyekale et al. International Journal of Environment, Agriculture and Biotechnology, 7(6)-2022

[21] Kalu, E. (2015). Poultry litter/manure management practices [38] Yusuf, S. A., and Malomo, O. (2007). Technical efficiency of

in intensively managed poultry farms in portharcourt. IOSR poultry egg production in Ogun state: a data envelopment

J. Agric. Vet. Sci, 8(3), 53-58. analysis (DEA) approach. International journal of poultry

[22] Lassner, K. (2011). Financial and Economic Analyses of science, 6(9), 622-629.

Biogas-to-Energy Projects in Brazil.

[23] Mehta, A. (2002). The economics and feasibility of electricity

generation using manure digesters on small and mid-size

dairy farms. Available at SSRN 2638078.

[24] Miebi, G.T. (2020). Contributing Factors of the Choice of

Poultry Waste Management Practices: Evidence from

Nigeria. International Journal of Environment, Agriculture

and Biotechnology, 5(3).

[25] Murphy, J. D., McKeogh, E., and Kiely, G. (2004).

Technical/economic/environmental analysis of biogas

utilisation. Applied Energy, 77(4), 407-427.

[26] Nmadu, J. N., Ogidan, I. O., and Omolehin, R. A. (2014).

Profitability and resource use efficiency of poultry egg

production in Abuja, Nigeria. Kasetsart Journal of Social

Sciences, 35(1), 134-146.

[27] Nwachukwu, I. N., & Onyenweaku, C. (2007). Economic

efficiency of Fadama Telfairia production in Imo State

Nigeria: A translog profit function approach.

[28] Odemero, A. F. (2013). Allocative efficiency of feeds among

poultry farmers in Delta state, Nigeria. Russian Journal of

Agricultural and Socio-Economic Sciences, 14(2), 26-33.

[29] Olukosi, J. O. and Erhabor, P. O. (2005). Introduction to farm

management economics, principles and application, Agitab

publishers Limited, Zaria p.23.

[30] Oluyemi, J. A., and Roberts, F. A. (2000). Poultry production

in warm wet climates. Ibadan. Spectrum Book Limited, 2(2),

57-62.

[31] Onu, D. O., Offor, E. I., & Okpara, B. O. (2015). Poultry

wastes management strategies and environmental

implications in Abia State. International Research Journal of

Agricultural Science and Soil Science.

[32] Paltasingh, K. R., & Goyari, P. (2018). Impact of farmer

education on farm productivity under varying technologies:

case of paddy growers in India. Agricultural and Food

Economics, 6(1), 1-19.

[33] Pope, C. W. (1991). Poultry production's environmental

impact on water quality. Poultry Science, 70(5), 1123-1125.

[34] Qaid, M. M. and Al-Garadi, M. A. (2021). Protein and amino

acid metabolism in poultry during and after heat stress: A

review. Animals, 11(4), p.1167.

[35] Simeon, T. O. (2009). Techno-economic analysis of a model

biogas plant for agricultural applications: A case study of the

Concordia Farms Limited, Nonwa, Tai, Rivers State.

Published M. Eng. Project work of the Department of

Mechanical Engineering University of Nigeria, Nsukka.

Retrieved on April, 25, 2017 from

http://www.unn.edu.ng/publications/files/images/M.ENG__

0.pdf.

[36] Singh, R., Karki, A. B., and Shrestha, J. N. (2008). Production

of biogas from poultry waste. Journal of Renewable Energy

and Smart Grid Technology, 3(1), 11-20.

[37] Williams, C. M. (2013). Poultry waste management in

developing countries. the role of poultry in human

nutrition, 46.

ISSN: 2456-1878 (Int. J. Environ. Agric. Biotech.)

https://dx.doi.org/10.22161/ijeab.76.14 134

You might also like

- Renewable Energy for Agriculture: Insights from Southeast AsiaFrom EverandRenewable Energy for Agriculture: Insights from Southeast AsiaNo ratings yet

- Renewable Energy for Agri-food SystemsFrom EverandRenewable Energy for Agri-food SystemsNo ratings yet

- 179848-Article Text-459072-1-10-20181119Document9 pages179848-Article Text-459072-1-10-20181119Oyebola Akin-DeluNo ratings yet

- Sustainable Futures: Mawuli Yevu, Edward Ebo OnumahDocument10 pagesSustainable Futures: Mawuli Yevu, Edward Ebo OnumahLoan ÁnhNo ratings yet

- 21 Analysis of Profitability and Constraints PDFDocument8 pages21 Analysis of Profitability and Constraints PDFIJEAB Journal100% (1)

- Manuscript For NOUN Journal of Life and Physical Sciences (2) For PublishingDocument86 pagesManuscript For NOUN Journal of Life and Physical Sciences (2) For Publishingadamugambo006No ratings yet

- Analysis of Feed Palatability and Consumption Rate Between Self Formulated Feed and Commercial Feed by Gaiya EmmanuelDocument37 pagesAnalysis of Feed Palatability and Consumption Rate Between Self Formulated Feed and Commercial Feed by Gaiya EmmanuelAugustine MathiasNo ratings yet

- The Impact of Beekeeping On Household Income: Evidence From North-Western EthiopiaDocument8 pagesThe Impact of Beekeeping On Household Income: Evidence From North-Western EthiopiaClaudiu 10134No ratings yet

- White 2020Document14 pagesWhite 2020carlosNo ratings yet

- Aboaba (EE)Document8 pagesAboaba (EE)Tuấn NgôNo ratings yet

- A Wog Boro Etal 44320171Document12 pagesA Wog Boro Etal 44320171damititus014No ratings yet

- Economic Efficiency of Small Scale Food Crop Production in Nigeria: A Stochastic Frontier ApproachDocument10 pagesEconomic Efficiency of Small Scale Food Crop Production in Nigeria: A Stochastic Frontier ApproachadeNo ratings yet

- Pig Farmers Socioeconomic CharacteristicDocument12 pagesPig Farmers Socioeconomic CharacteristicPeter MukunzaNo ratings yet

- Analysis of Maize Value Addition Among Entrepreneurs in Taraba State, NigeriaDocument9 pagesAnalysis of Maize Value Addition Among Entrepreneurs in Taraba State, NigeriaIJEAB JournalNo ratings yet

- Economic Analysis of Cassava (Manihot Esculenta Crantz) Production in Akinyele Local Government Area of Oyo State, NigeriaDocument15 pagesEconomic Analysis of Cassava (Manihot Esculenta Crantz) Production in Akinyele Local Government Area of Oyo State, Nigeriadayo jattoNo ratings yet

- Market 1330765187 - Oyeyinka Et AlDocument8 pagesMarket 1330765187 - Oyeyinka Et AlMoiemen AhmedNo ratings yet

- Analysis of Resource Use Efficiency in Yam Production in Yakurr Local Government Area of Cross River State, NigeriaDocument7 pagesAnalysis of Resource Use Efficiency in Yam Production in Yakurr Local Government Area of Cross River State, NigeriaESTHER OGODONo ratings yet

- Eggs in Nigeria PDFDocument21 pagesEggs in Nigeria PDFCoco LumberNo ratings yet

- Efficiency Analysis of Crop Production in Gurage Zone: The Case of Abeshige Woreda, SNNPR EthiopiaDocument13 pagesEfficiency Analysis of Crop Production in Gurage Zone: The Case of Abeshige Woreda, SNNPR EthiopiaIJEAB Journal100% (1)

- Sorunke Kafaci PaperDocument9 pagesSorunke Kafaci PaperSorunke Adekunle OlubukunNo ratings yet

- 10 11648 J Ijae 20220705 14Document5 pages10 11648 J Ijae 20220705 14Hussen AbdulmenanNo ratings yet

- Awogboro Et Al 44 3 2017Document11 pagesAwogboro Et Al 44 3 2017YUSUF WASIU AKINTUNDENo ratings yet

- 7IJAERS 09202060 Economic PDFDocument14 pages7IJAERS 09202060 Economic PDFIJAERS JOURNALNo ratings yet

- Economics of Medium Scale On Station Broiler ProductionDocument8 pagesEconomics of Medium Scale On Station Broiler ProductionAldonny NurdiansyahNo ratings yet

- Economics of Organic Vegetables1 s2.0 S1877042817300241 MainDocument14 pagesEconomics of Organic Vegetables1 s2.0 S1877042817300241 MainVilma D. ConradoNo ratings yet

- Akhtaruzzaman Profit Efficiency2021Document9 pagesAkhtaruzzaman Profit Efficiency2021Stoic GeneralissimoNo ratings yet

- Effect of Machine Replacement Cost on Feed Mill ProfitabilityDocument9 pagesEffect of Machine Replacement Cost on Feed Mill ProfitabilityJoram MutuaNo ratings yet

- 2013JE AnietalDocument8 pages2013JE AnietalEDWARDNo ratings yet

- Assessment of The Perception of Farming Households On Off Farm Activities As A Livelihood Coping Strategy in Wudil Lga of Kano State, NigeriaDocument7 pagesAssessment of The Perception of Farming Households On Off Farm Activities As A Livelihood Coping Strategy in Wudil Lga of Kano State, NigeriaEditor IJTSRDNo ratings yet

- 200623-Article Text-503408-1-10-20201016Document5 pages200623-Article Text-503408-1-10-20201016Eugene Salem AbulocNo ratings yet

- Jurin 1 VianDocument8 pagesJurin 1 VianMoh AliffianNo ratings yet

- Agro-Science: Obike, K.C. Amusa, T.A. and Olowolafe, H.BDocument8 pagesAgro-Science: Obike, K.C. Amusa, T.A. and Olowolafe, H.BJoseph AbalosNo ratings yet

- Cucumber Farming Profitability and EfficiencyDocument13 pagesCucumber Farming Profitability and EfficiencyJoergen Bing SlametNo ratings yet

- Sustainability of Smallholder Quinoa Production in The Peruvian AndesDocument12 pagesSustainability of Smallholder Quinoa Production in The Peruvian AndesJAZMIN DLCNo ratings yet

- Profitability and Resource Use Efficiency of Poultry Egg Production in Kuje Area Council Federal Capital Territory NigeriaDocument8 pagesProfitability and Resource Use Efficiency of Poultry Egg Production in Kuje Area Council Federal Capital Territory NigeriaOlateju OmoleNo ratings yet

- Artigo ACVDocument13 pagesArtigo ACVLuciana Virginia Mario BernardoNo ratings yet

- Socio-Economic Determinants of Cassava Production in Benue State, Nigeria.Document8 pagesSocio-Economic Determinants of Cassava Production in Benue State, Nigeria.IJEAB JournalNo ratings yet

- Technical Efficiency in Agriculture in Ghana Analyses of Determining FactorsDocument10 pagesTechnical Efficiency in Agriculture in Ghana Analyses of Determining FactorsAlexander DeckerNo ratings yet

- Factors Affecting Adoption of Value Addition Practices Among Smallholder Irish Potato Farmers in Bomet County, KenyaDocument8 pagesFactors Affecting Adoption of Value Addition Practices Among Smallholder Irish Potato Farmers in Bomet County, KenyaPremier PublishersNo ratings yet

- Poultry Production in Uganda: Challenges and Opportunities: December 2019Document4 pagesPoultry Production in Uganda: Challenges and Opportunities: December 2019Brian TaylorNo ratings yet

- Agricultural Systems: ArticleinfoDocument12 pagesAgricultural Systems: ArticleinfoClaudioNo ratings yet

- Agricultura Tropica Et Subtropica Profitability and TechnicalDocument9 pagesAgricultura Tropica Et Subtropica Profitability and TechnicalWella ChristafariNo ratings yet

- Feasibility Analysis of White Oyster Mushroom CultDocument10 pagesFeasibility Analysis of White Oyster Mushroom CultFareed NaufalNo ratings yet

- Akinbode (EE)Document9 pagesAkinbode (EE)Tuấn NgôNo ratings yet

- Effects of Value Addition On The Profitability of Irish Potato Production in Bomet County, KenyaDocument6 pagesEffects of Value Addition On The Profitability of Irish Potato Production in Bomet County, KenyaPremier PublishersNo ratings yet

- EkonometDocument7 pagesEkonometmayalfianNo ratings yet

- Economic Analysis of Cassava Production: Prospects and Challenges in Irepodun Local Government Area, Kwara State, NigeriaDocument5 pagesEconomic Analysis of Cassava Production: Prospects and Challenges in Irepodun Local Government Area, Kwara State, Nigerianicholas ajodoNo ratings yet

- Awotide-Impact of Access To Credit On Agricultural Productivity-71-2 PDFDocument35 pagesAwotide-Impact of Access To Credit On Agricultural Productivity-71-2 PDFMunazza WardagNo ratings yet

- Profitability and Constraints of Pig Production in Southern Kebbi State, NigeriaDocument8 pagesProfitability and Constraints of Pig Production in Southern Kebbi State, NigeriaPremier PublishersNo ratings yet

- Ecological Economics: Adeline Ofori-Bah, John Asafu-AdjayeDocument11 pagesEcological Economics: Adeline Ofori-Bah, John Asafu-AdjayeNo NameNo ratings yet

- 115727-Article Text-321968-1-10-20150415Document12 pages115727-Article Text-321968-1-10-20150415Suliyaa MantawNo ratings yet

- Impact of Improved Rice Variety On Productivity Among Smallholder Farmers in GhanaDocument6 pagesImpact of Improved Rice Variety On Productivity Among Smallholder Farmers in GhanaEdward TsinigoNo ratings yet

- Semi-Organic Rice Farming As A Transition Period TDocument9 pagesSemi-Organic Rice Farming As A Transition Period TThuan DuongNo ratings yet

- Determinants of Smallholder Farmers' Participation in ImprovedDocument17 pagesDeterminants of Smallholder Farmers' Participation in ImprovedBishawNo ratings yet

- Economic Analysis of Watermelon Production in Ibarapa Central Local Government Area of Oyo State, NigeriaDocument10 pagesEconomic Analysis of Watermelon Production in Ibarapa Central Local Government Area of Oyo State, Nigeriadayo jattoNo ratings yet

- Organic Agriculture and The Multi-Dimensional Challenges of Future Food and Farming SystemsDocument26 pagesOrganic Agriculture and The Multi-Dimensional Challenges of Future Food and Farming Systemshanif_abi0410No ratings yet

- Stochastic Frontier Analysis PaperDocument8 pagesStochastic Frontier Analysis PaperzainurihanifNo ratings yet

- Economy Analysis of Broiler ProductionDocument6 pagesEconomy Analysis of Broiler Productioncklim123No ratings yet

- Assessment of Adoption of Improved Maize Varieties in Ayamelum LGA, Anambra State-NWANKWO COLUMBUS CHINEDUMDocument28 pagesAssessment of Adoption of Improved Maize Varieties in Ayamelum LGA, Anambra State-NWANKWO COLUMBUS CHINEDUMcc.nwankwoNo ratings yet

- 1 s2.0 S0308521X21003036 MainDocument11 pages1 s2.0 S0308521X21003036 MainDidier tovarNo ratings yet

- Trichoderma-Fortified Compost in Controlling Diseases and Increasing Yield of TomatoDocument10 pagesTrichoderma-Fortified Compost in Controlling Diseases and Increasing Yield of TomatoMamta AgarwalNo ratings yet

- Effect of Gibberellin and Nitrogen Fertilizer On Growth and Zucchini (Cucurbita Pepo L.) Yield in Tropical RegionsDocument7 pagesEffect of Gibberellin and Nitrogen Fertilizer On Growth and Zucchini (Cucurbita Pepo L.) Yield in Tropical RegionsMamta AgarwalNo ratings yet

- Comparative Performance of The Developed Mini Tractor Operated Sprayer Cum Weeder With The Various Types of Existing Spraying and Weeding MethodsDocument12 pagesComparative Performance of The Developed Mini Tractor Operated Sprayer Cum Weeder With The Various Types of Existing Spraying and Weeding MethodsMamta AgarwalNo ratings yet

- Evaluating The Effects of Different Sowing Dates and Tillage Practices On Faba Bean Yield Based On DSSAT ModelDocument11 pagesEvaluating The Effects of Different Sowing Dates and Tillage Practices On Faba Bean Yield Based On DSSAT ModelMamta AgarwalNo ratings yet

- Remodeling in Microbial Fuel Cell (MFC) Design and Parameters For The Sustained Production of ElectricityDocument14 pagesRemodeling in Microbial Fuel Cell (MFC) Design and Parameters For The Sustained Production of ElectricityMamta AgarwalNo ratings yet

- In Vitro Efficacy of Entomopathogenic Nematodes (EPNS) Against Economically Important Insect-Pests of CauliflowerDocument9 pagesIn Vitro Efficacy of Entomopathogenic Nematodes (EPNS) Against Economically Important Insect-Pests of CauliflowerMamta AgarwalNo ratings yet

- Land Use Dynamics and Socio-Economic Impacts of Wetlands in The Oti Plain in The Face of Climate ChangeDocument18 pagesLand Use Dynamics and Socio-Economic Impacts of Wetlands in The Oti Plain in The Face of Climate ChangeMamta AgarwalNo ratings yet

- Innovative Complex Coacervates of Gelatin and Sodium Carboxymethyl Cellulose For Cinnamaldehyde Delivery: Impact of Processing Conditions On Characteristics and BioactivityDocument10 pagesInnovative Complex Coacervates of Gelatin and Sodium Carboxymethyl Cellulose For Cinnamaldehyde Delivery: Impact of Processing Conditions On Characteristics and BioactivityMamta AgarwalNo ratings yet

- Benni Satria, Rachmad Hersi Martinsyah, Armansyah, Meisilva Erona, WarnitaDocument12 pagesBenni Satria, Rachmad Hersi Martinsyah, Armansyah, Meisilva Erona, WarnitaMamta AgarwalNo ratings yet

- Laying and Growth Performance of Local Chicken (Gallus Gallus Domesticus) Ecotype Konde in Burkina FasoDocument14 pagesLaying and Growth Performance of Local Chicken (Gallus Gallus Domesticus) Ecotype Konde in Burkina FasoMamta AgarwalNo ratings yet

- Research On Soil Erosion Intensity and Spatial Distribution Characteristics in Zhaoyang District of Zhaotong City Based On RS and GISDocument14 pagesResearch On Soil Erosion Intensity and Spatial Distribution Characteristics in Zhaoyang District of Zhaotong City Based On RS and GISMamta AgarwalNo ratings yet

- The Economic and Environmental Effects of Gold Panning in A Zone of Armed Conflict in The Circle of GaoDocument9 pagesThe Economic and Environmental Effects of Gold Panning in A Zone of Armed Conflict in The Circle of GaoMamta AgarwalNo ratings yet

- Effect of Priming Treatment and Storage Containers To Enhance The Seed Quality of Tomato SeedsDocument8 pagesEffect of Priming Treatment and Storage Containers To Enhance The Seed Quality of Tomato SeedsMamta AgarwalNo ratings yet

- Pseudouridine in RNA: Enzymatic Synthesis Mechanisms and Functional Roles in Molecular BiologyDocument17 pagesPseudouridine in RNA: Enzymatic Synthesis Mechanisms and Functional Roles in Molecular BiologyMamta AgarwalNo ratings yet

- Statistical Analysis of Recent Rainfall Variability and Trend Using A Merged Gauge and Satellite Time Series Data For The Cotton Zone of MaliDocument8 pagesStatistical Analysis of Recent Rainfall Variability and Trend Using A Merged Gauge and Satellite Time Series Data For The Cotton Zone of MaliMamta AgarwalNo ratings yet

- Proximate Composition, Energy and Nutritional Value of Local Malt (Asaana) Prepared From Maize in GhanaDocument4 pagesProximate Composition, Energy and Nutritional Value of Local Malt (Asaana) Prepared From Maize in GhanaMamta AgarwalNo ratings yet

- Search For A Suitable Substrate For Mass Propagation of A Local Strain of Trichoderma Harzianum (ThTab) Isolated in Burkina FasoDocument11 pagesSearch For A Suitable Substrate For Mass Propagation of A Local Strain of Trichoderma Harzianum (ThTab) Isolated in Burkina FasoMamta AgarwalNo ratings yet

- Arsenic Content in Rice in Ghana: A Potential Health HazardDocument4 pagesArsenic Content in Rice in Ghana: A Potential Health HazardMamta AgarwalNo ratings yet

- Analysis of Dynamic Changes of Winter Wheat in Xinye County, Henan Province Based On SVM MethodDocument9 pagesAnalysis of Dynamic Changes of Winter Wheat in Xinye County, Henan Province Based On SVM MethodMamta AgarwalNo ratings yet

- Adulteration of Honey On The Cape Coast Market in The Central Region of GhanaDocument7 pagesAdulteration of Honey On The Cape Coast Market in The Central Region of GhanaMamta AgarwalNo ratings yet

- Analysis of Technical Efficiency and The Influence of Socioeconomic Factors On Oil Palm Farming in Muaro Jambi District - IndonesiaDocument7 pagesAnalysis of Technical Efficiency and The Influence of Socioeconomic Factors On Oil Palm Farming in Muaro Jambi District - IndonesiaMamta AgarwalNo ratings yet

- The Effect of Organic Fertilizers On Growth Quality of Sweat Corn (Zea Mays Saccharata L)Document8 pagesThe Effect of Organic Fertilizers On Growth Quality of Sweat Corn (Zea Mays Saccharata L)Mamta AgarwalNo ratings yet

- Effects of Water Stress and Nutrient Management On The Performance of TomatoDocument10 pagesEffects of Water Stress and Nutrient Management On The Performance of TomatoMamta AgarwalNo ratings yet

- A Change Analysis of Land Use and Carbon Storage in Maoming Based On The InVEST Model and GISDocument17 pagesA Change Analysis of Land Use and Carbon Storage in Maoming Based On The InVEST Model and GISMamta AgarwalNo ratings yet

- Effect of Using Different Levels of Ginger (Zingiber Officinale Roscoe) Extract On The Quality Characteristics of Camel's SausageDocument9 pagesEffect of Using Different Levels of Ginger (Zingiber Officinale Roscoe) Extract On The Quality Characteristics of Camel's SausageMamta AgarwalNo ratings yet

- Analysis of Urban Thermal Environment Effect by TIRS and GIS: A Case Study of Zhuhai, GuangdongDocument14 pagesAnalysis of Urban Thermal Environment Effect by TIRS and GIS: A Case Study of Zhuhai, GuangdongMamta AgarwalNo ratings yet

- South African Legislation Pertinent To Building Practice: A Review in The Context of Inherent Dolomite Land HazardDocument9 pagesSouth African Legislation Pertinent To Building Practice: A Review in The Context of Inherent Dolomite Land HazardMamta AgarwalNo ratings yet

- Effect of Shade and Thinning On Yield and Chemical Content of Tomato (Lycopersicum Esculentum Mill.)Document6 pagesEffect of Shade and Thinning On Yield and Chemical Content of Tomato (Lycopersicum Esculentum Mill.)Mamta AgarwalNo ratings yet

- Impact of Maize Seed Moisture Content Reduction On Germination Parameters As Influenced by Sun DryingDocument5 pagesImpact of Maize Seed Moisture Content Reduction On Germination Parameters As Influenced by Sun DryingMamta AgarwalNo ratings yet

- Spatial-Temporal Evolution Characteristics of Vegetation Coverage and Urbanization Expansion in Dongguan Based On Remote SensingDocument12 pagesSpatial-Temporal Evolution Characteristics of Vegetation Coverage and Urbanization Expansion in Dongguan Based On Remote SensingMamta AgarwalNo ratings yet

- IAM Anatomy V3 Dec 2015 Esp PDFDocument166 pagesIAM Anatomy V3 Dec 2015 Esp PDFCamilo Andres Cardozo FajardoNo ratings yet

- Pay For Performance and Financial Incentives: T TwelveDocument14 pagesPay For Performance and Financial Incentives: T TwelveNouman AhmadNo ratings yet

- Full Download Management Accounting Information For Decision Making and Strategy Execution Atkinson 6th Edition Test Bank PDF Full ChapterDocument36 pagesFull Download Management Accounting Information For Decision Making and Strategy Execution Atkinson 6th Edition Test Bank PDF Full Chaptersloppy.obsidian.v8ovu100% (18)

- Abstracti ON: (Using Our Illustrative Problem, The Labahan Laundry Services, The FollowingDocument11 pagesAbstracti ON: (Using Our Illustrative Problem, The Labahan Laundry Services, The FollowingAkosi NoynoypiNo ratings yet

- Oz8660ln PDFDocument1 pageOz8660ln PDFAngel Ignacio Correa SerranoNo ratings yet

- IQ OQ PQ Validation Guideline DocumentsDocument2 pagesIQ OQ PQ Validation Guideline DocumentsBIMO KUKUHNo ratings yet

- Maven Silicon - BPD Training Agreement 2023Document4 pagesMaven Silicon - BPD Training Agreement 2023kothapalli naveenNo ratings yet

- Zalando Returns ArticleDocument29 pagesZalando Returns ArticleMushiraNo ratings yet

- Major Activities of NabardDocument13 pagesMajor Activities of NabardAbhishek .SNo ratings yet

- University of The GambiaDocument53 pagesUniversity of The GambiasoninkeNo ratings yet

- Narrative Report of Principle of MarketingDocument7 pagesNarrative Report of Principle of MarketingErick MeguisoNo ratings yet

- Multiple Nuclei TheoryDocument16 pagesMultiple Nuclei TheoryAura Puteri PelangiNo ratings yet

- Project Report Ritesh SonawaneDocument66 pagesProject Report Ritesh SonawaneRitesh SonawaneNo ratings yet

- Env Audit - TimetableDocument1 pageEnv Audit - Timetablerobby damanikNo ratings yet

- Indian Labour Market Outline: Regional Dimension and Employment StatusDocument11 pagesIndian Labour Market Outline: Regional Dimension and Employment StatusAnurag JayswalNo ratings yet

- Fast TrackDocument45 pagesFast TrackSAUMYA MNo ratings yet

- DECENA Case Digest Estate of Encarnacion V DizonDocument1 pageDECENA Case Digest Estate of Encarnacion V DizonElias Rafael DecenaNo ratings yet

- Lectures On Financial Economics (PDFDrive)Document900 pagesLectures On Financial Economics (PDFDrive)Emalu BonifaceNo ratings yet

- David OgilvyDocument9 pagesDavid OgilvyDan DsouzaNo ratings yet

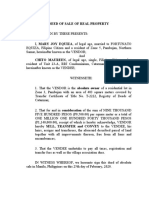

- Deed of Sale Real PropertyDocument2 pagesDeed of Sale Real PropertyAndrew M. AcederaNo ratings yet

- Ipr Unit 2 Part 2Document42 pagesIpr Unit 2 Part 2Tanay SHAHNo ratings yet

- Exercise Accounting Changes and Error PDFDocument2 pagesExercise Accounting Changes and Error PDFStefanNo ratings yet

- Fire Insurance Claim - HomeworkDocument18 pagesFire Insurance Claim - Homeworknikhilcoke7No ratings yet

- MGT211 Assignment 1 Solution Spring 2021Document5 pagesMGT211 Assignment 1 Solution Spring 2021Beaming Kids Model schoolNo ratings yet

- 095 Priyanka TejwaniDocument19 pages095 Priyanka TejwaniNitin BasoyaNo ratings yet

- Indian Textile Industry: Opportunities, Challenges and SuggestionsDocument16 pagesIndian Textile Industry: Opportunities, Challenges and SuggestionsGadha GopalNo ratings yet

- Tilahun EsmaelDocument46 pagesTilahun EsmaelFasika WorkuNo ratings yet

- Retail TelDocument70 pagesRetail TelSairam RaghunathanNo ratings yet

- Case Study ProcessDocument15 pagesCase Study ProcessKhandelwal CyclesNo ratings yet

- DIACARE AbhilashDocument7 pagesDIACARE AbhilashKumaraguru ManickavasagamNo ratings yet