Professional Documents

Culture Documents

High-Strength Low-Alloy Steel Shapes of Structural Quality, Produced by Quenching and Self-Tempering Process (QST)

Uploaded by

indityoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High-Strength Low-Alloy Steel Shapes of Structural Quality, Produced by Quenching and Self-Tempering Process (QST)

Uploaded by

indityoCopyright:

Available Formats

Designation: A913/A913M – 11

Standard Specification for

High-Strength Low-Alloy Steel Shapes of Structural Quality,

Produced by Quenching and Self-Tempering Process (QST)1

This standard is issued under the fixed designation A913/A913M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

--``,`,`,,,,`,,`,`,,```,``,,`-`-`,,`,,`,`,,`---

1. Scope* 2. Referenced Documents

1.1 This specification covers high-strength low-alloy struc- 2.1 ASTM Standards:3

tural steel shapes in Grades 50 [345], 60 [415], 65 [450] and 70 A6/A6M Specification for General Requirements for Rolled

[485], produced by the quenching and self-tempering process Structural Steel Bars, Plates, Shapes, and Sheet Piling

(QST).2 The shapes are intended for riveted, bolted or welded A673/A673M Specification for Sampling Procedure for

construction of bridges, buildings and other structures. Impact Testing of Structural Steel

1.2 The QST process consists of in line heat treatment and A898/A898M Specification for Straight Beam Ultrasonic

cooling rate controls which result in mechanical properties in Examination of Rolled Steel Structural Shapes

the finished condition that are equivalent to those attained

using heat treating processes which entail reheating after 3. General Requirements for Delivery

rolling. A description of the QST process is given in Appendix 3.1 Material furnished under this specification shall con-

X1. form to the applicable requirements of the current edition of

1.3 Due to the inherent characteristics of the QST process, Specification A6/A6M.

the shapes shall not be formed and post weld heat treated at

temperatures exceeding 1100°F [600°C]. 4. Materials and Manufacture

1.4 When the steel is to be welded, it is presupposed that a 4.1 The shapes shall be produced by the quenching and

welding procedure suitable for the grade of steel and intended self-tempering process (QST). Self-tempering temperature

use or service will be utilized. See Appendix X3 of Specifica- shall be a minimum of 1100°F [600°C] and the self-tempering

tion A6/A6M for information on weldability. temperature for the material represented shall be reported on

1.5 The values stated in either inch-pound units or SI units the mill test report. See Appendix X1 for Process Description.

are to be regarded separately as standard. Within the text, the 4.2 For grades 60 [415], 65 [450], and 70 [485], the

SI units are shown in brackets. The values stated in each requirements for fine austenitic grain size in Specification

system are not exact equivalents; therefore, each system must A6/A6M shall be met.

be used independently of the other. Combining values from the

two systems may result in nonconformance with this specifi- 5. Chemical Composition

cation. 5.1 The chemical analysis of the heat shall conform to the

requirements prescribed in Table 1.

5.2 The steel shall conform on product analysis to the

1

requirements prescribed in Table 1 subject to the product

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

analysis tolerances in Specification A6/A6M.

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.02 on Structural Steel for Bridges, Buildings, Rolling Stock and Ships.

Current edition approved Nov. 1, 2011. Published November 2011. Originally 6. Mechanical Properties

approved in 1993. Last previous edition approved in 2007 as A913/A913M – 07. 6.1 Tensile Properties—The material as represented by the

DOI: 10.1520/A0913_A0913M-11.

2

The quenching and self-tempering process (QST) and the used apparatus are

test specimens shall conform to the tensile properties given in

covered by patents held by the Centre de Recherches Métallurgiques (CRM)—Rue Table 2.

Ernest Solvay, 11, B 4000, Liège (Belgium). Interested parties are invited to submit

information regarding the identification of acceptable alternatives to these patented

3

items to the Committee on Standards, ASTM Headquarters, 100 Barr Harbor Drive, For referenced ASTM standards, visit the ASTM website, www.astm.org, or

West Conshohocken, PA 19428–2959. Comments will receive careful consideration contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

at the meeting of the responsible technical committee, which any interested party Standards volume information, refer to the standard’s Document Summary page on

may attend. the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International

Provided by IHS under license with ASTM

1Licensee=Committee on Institutional Cooperation/5967164001

No reproduction or networking permitted without license from IHS Not for Resale, 02/12/2012 22:37:36 MST

A913/A913M – 11

TABLE 1 Chemical Requirements (Heat Analysis) 6.2.1 The test results of full-size specimens shall meet an

Maximum content in % average value of 40 ft-lbf [54 J] at 70°F [21°C].

Element Grade 50 Grade 60 Grade 65 Grade 70 6.2.1.1 Test reports for every heat supplied are required.

[345] [415] [450] [485]

6.2.2 Charpy V-notch test requirements exceeding the value

Carbon 0.12 0.14 0.16 0.16 specified in 6.2.1 or lower test temperatures are subject to

Manganese 1.60 1.60 1.60 1.60

Phosphorus 0.040 0.030 0.030 0.040 agreement between the purchaser and the producer.

Sulfur 0.030 0.030 0.030 0.030

Silicon 0.40 0.40 0.40 0.40

Copper 0.45 0.35 0.35 0.45

7. Maximum Carbon Equivalent Requirement

Nickel 0.25 0.25 0.25 0.25 7.1 The carbon equivalent on heat analysis shall not exceed

Chromium 0.25 0.25 0.25 0.25

Molybdenum 0.07 0.07 0.07 0.07 the limits listed in this section. The chemical analysis (heat

Columbium 0.05 0.04 0.05 0.05 analysis) of the elements that appear in the carbon equivalent

Vanadium 0.06 0.06 0.08 0.09 formula and the actual carbon equivalent shall be reported.

Carbon equivalent limits

Grade 50 [345]: 0.38 %

TABLE 2 Tensile Requirements Grade 60 [415]: 0.40 %

Grade 65 [450]: 0.43 %

Yield Point, Tensile

Elongation, min Grade 70 [485]: 0.45 %

min. Strength, min.

Grade

--``,`,`,,,,`,,`,`,,```,``,,`-`-`,,`,,`,`,,`---

ksi [MPa] ksi [MPa]

8 in. 2 in. 7.2 Calculate the carbon equivalent using the following

[200 mm], % [50 mm], % equation:

50 [345] 50 [345] 65 [450] 18 21

60 [415] 60 [415] 75 [520] 16 18

CE 5 C 1 Mn/6 1 ~Cr 1 Mo 1 V!/5 1 ~Cu 1 Ni!/15

65 [450] 65 [450] 80 [550] 15 17

70 [485] 70 [485] 90 [620] 14 16 8. Keywords

8.1 high-strength low-alloy steel; QST; quenching and self-

6.2 Charpy V-notch tests shall be made in accordance with tempering process; steel shapes; structural shapes; structural

Specification A673/A673M, Frequency H: steel

SUPPLEMENTARY REQUIREMENTS

Supplementary requirements shall not apply unless specified in the purchase order or contract.

Standardized supplementary requirements for use at the option of the purchaser are listed in

Specification A6/A6M. Those that are considered suitable for use with this specification are listed by

title:

S1. Vacuum Treatment. S5. Charpy V-Notch Impact Test.

S2. Product Analysis. S18. Maximum Tensile Strength.

S3. Simulated Post-Weld Heat Treatment of Mechanical S30. Charpy V-Notch Impact Test for Structural Shapes:

Test Coupons. Alternate Core Location.

ADDITIONAL SUPPLEMENTARY REQUIREMENTS

In addition, the following special supplementary requirements are also suitable for use with this

specification:

S4. Additional Tension Test: S75. Maximum Yield Point to Tensile Strength Ratio—

S4.1 One tension test shall be made per ingot or per bloom. Grade 50 [345]:

The results obtained and the actual self-tempering temperature S75.1 The maximum yield point shall be 65 ksi. [450].

for the ingot or bloom represented shall be reported on the mill

S75.2 The maximum yield to tensile strength ratio shall be

test report when such tests are required by the order.

0.85.

S8. Ultrasonic Examination:

S8.1 Ultrasonic Examination in accordance with Specifica- S77. Reduced Sulfur—Grade 65 [450]:

tion A898/A898M. S77.1 The Grade 65 [450] shall be furnished with a maxi-

S32. Single Heat Bundles: mum sulfur of 0.010 %. This may be desirable in material

S32.1 Bundles containing shapes or bars shall be from a subjected to high through-thickness stresses.

single heat of steel.

Copyright ASTM International

Provided by IHS under license with ASTM

2Licensee=Committee on Institutional Cooperation/5967164001

No reproduction or networking permitted without license from IHS Not for Resale, 02/12/2012 22:37:36 MST

A913/A913M – 11

APPENDIX

(Nonmandatory Information)

X1. QUENCHING AND SELF-TEMPERING PROCESS (QST)

X1.1 Introduction—The quenching and self-tempering pro- and varying the pearlite or bainite, or both, volume fraction

cess, commonly referred to as “QST,” has evolved from the through time quenching (interrupted quenching in which the

“thermo-mechanical control processes” (TMCP) that have duration of holding in the quenching medium (water) is

been known and used for a number of years. QST, which is a controlled) in the temperature region above Ar3 (the tempera-

variation of TMCP, produces fine-grained steel by a combina- ture at which austenite begins to transform to ferrite during

tion of chemical composition and integrated controls of manu- cooling) to a minimum self-tempering temperature (STT, that

facturing processes from ingot or bloom reheating to in-line is, the maximum surface temperature after quenching) of

interrupted quenching and self-tempering, thereby achieving 1100°F [600°C] in order to meet the specified requirements.

the specified mechanical properties in the required product Time quenching can be performed after conventional rolling

thicknesses. processes (AR) and (CR) or after thermomechanical controlled

rolling (TMCR).

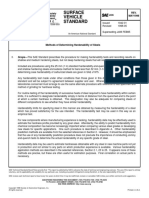

X1.2 Outline of QST—Given in Fig. X1.1. X1.2.2 The selection of the rolling process to be used is

X1.2.1 Quenching and self-tempering (QST)-steels of fine made by the producer depending upon the chemical composi-

grain size are manufactured by producing tempered martensite tion, the product thickness, and the required properties.

--``,`,`,,,,`,,`,`,,```,``,,`-`-`,,`,,`,`,,`---

FIG. X1.1 Schematic Diagrams of Thermo-Mechanical Control and Conventional Process

Copyright ASTM International

Provided by IHS under license with ASTM

3Licensee=Committee on Institutional Cooperation/5967164001

No reproduction or networking permitted without license from IHS Not for Resale, 02/12/2012 22:37:36 MST

A913/A913M – 11

SUMMARY OF CHANGES

Committee A01 has identified the location of selected changes to this standard since the last issue

(A913/A913M – 07) that may impact the use of this standard. (Approved Nov. 1, 2011.)

(1) Revised Table 1.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

--``,`,`,,,,`,,`,`,,```,``,,`-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

4Licensee=Committee on Institutional Cooperation/5967164001

No reproduction or networking permitted without license from IHS Not for Resale, 02/12/2012 22:37:36 MST

You might also like

- Astm A376 A376m 2012Document7 pagesAstm A376 A376m 2012prabuharan89No ratings yet

- A1018Document5 pagesA1018Aleksei AvilaNo ratings yet

- Steel, Strip, Carbon and High-Strength, Low-Alloy, Hot-Rolled, General Requirements ForDocument9 pagesSteel, Strip, Carbon and High-Strength, Low-Alloy, Hot-Rolled, General Requirements FormuhammadNo ratings yet

- Pressure Vessel Plates, Alloy Steel, Chromium-Molybdenum: Standard Specification ForDocument6 pagesPressure Vessel Plates, Alloy Steel, Chromium-Molybdenum: Standard Specification Foralucard375No ratings yet

- Specifying Harmonized Standard Grade Compositions For Wrought Carbon, Low-Alloy, and Alloy SteelsDocument13 pagesSpecifying Harmonized Standard Grade Compositions For Wrought Carbon, Low-Alloy, and Alloy SteelsTamil funNo ratings yet

- A 1018 - A 1018M - 16aDocument8 pagesA 1018 - A 1018M - 16aJose Anisio Silva0% (1)

- Higher-Strength Martensitic Stainless Steel Plate, Sheet, and StripDocument3 pagesHigher-Strength Martensitic Stainless Steel Plate, Sheet, and StripshamrajjNo ratings yet

- A 635Document10 pagesA 635Gustavo Suarez100% (1)

- High-Strength Low-Alloy Structural Steel Plate With Low Carbon and Restricted Sulfur For Improved Weldability, Formability, and ToughnessDocument3 pagesHigh-Strength Low-Alloy Structural Steel Plate With Low Carbon and Restricted Sulfur For Improved Weldability, Formability, and ToughnessMarcelo BarretosNo ratings yet

- Astm A554 10Document6 pagesAstm A554 10Lisandro ClaverolNo ratings yet

- A 958 - A 958M - 17Document5 pagesA 958 - A 958M - 17Eddie Michael67% (3)

- Astm A194Document3 pagesAstm A194Lulu_123No ratings yet

- High-Strength Low-Alloy Structural Steel With 50 Ksi (345 Mpa) Minimum Yield Point To 4 In. (100 MM) ThickDocument2 pagesHigh-Strength Low-Alloy Structural Steel With 50 Ksi (345 Mpa) Minimum Yield Point To 4 In. (100 MM) ThickGustavo SuarezNo ratings yet

- Astm A690Document2 pagesAstm A690Genesis Lissette Loyola Ortiz100% (1)

- Astm A 307Document6 pagesAstm A 307jeigocNo ratings yet

- Astm A 1011M PDFDocument8 pagesAstm A 1011M PDFJuan CarlosNo ratings yet

- Astm F 2329Document5 pagesAstm F 2329haharameshNo ratings yet

- A108 13Document7 pagesA108 13solrac4371100% (1)

- Astm A 307-2014 (Latest) PDFDocument6 pagesAstm A 307-2014 (Latest) PDFakashdruva892No ratings yet

- A 879Document2 pagesA 879Gustavo SuarezNo ratings yet

- Astm b85 1984Document7 pagesAstm b85 1984Siddhi Sharma100% (1)

- Measuring Flatness Characteristics of Steel Sheet Products: Standard Practice ForDocument9 pagesMeasuring Flatness Characteristics of Steel Sheet Products: Standard Practice Forguillermo aponte100% (1)

- Hardox 500 Sheet: General Product DescriptionDocument2 pagesHardox 500 Sheet: General Product DescriptionDylkanWingsNo ratings yet

- En 10268-2006 - Cold Rolled High Strength - Dual Phase SteelsDocument16 pagesEn 10268-2006 - Cold Rolled High Strength - Dual Phase SteelsSuvro ChakrabortyNo ratings yet

- ASTM A563 - 07 Standard Specification For Carbon and Alloy Steel NutsDocument8 pagesASTM A563 - 07 Standard Specification For Carbon and Alloy Steel NutsDagoberto AguilarNo ratings yet

- Astm A 227 A227m 2006Document4 pagesAstm A 227 A227m 2006Aadhya engineering ServicesNo ratings yet

- Steel, Sheet, Carbon, Structural, and High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, General Requirements ForDocument31 pagesSteel, Sheet, Carbon, Structural, and High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, General Requirements Foralucard375No ratings yet

- Astm A 240 2019Document12 pagesAstm A 240 2019geraldo leoncioNo ratings yet

- 15-5 PHDocument2 pages15-5 PHfedaquiNo ratings yet

- Astm A500 A500m-21Document6 pagesAstm A500 A500m-21alvin duey100% (1)

- ANSI H35-2 - ERRATA Pages - Dec 19 2017 - 0 PDFDocument3 pagesANSI H35-2 - ERRATA Pages - Dec 19 2017 - 0 PDFAhmad SyafiqNo ratings yet

- Astm B209 B209M (2001)Document26 pagesAstm B209 B209M (2001)Asif ChougleNo ratings yet

- Astm b169Document4 pagesAstm b169ANIL100% (1)

- Sae J429Document8 pagesSae J429David Lay IINo ratings yet

- Astm A 108 (2007)Document7 pagesAstm A 108 (2007)IMSQANo ratings yet

- Steel Castings, Welding, Qualifications of Procedures and PersonnelDocument19 pagesSteel Castings, Welding, Qualifications of Procedures and PersonnelDavidNo ratings yet

- A709a 709M-17 PDFDocument8 pagesA709a 709M-17 PDFandresNo ratings yet

- The Thin Section Bearing of Today: An SKF Group BrandDocument8 pagesThe Thin Section Bearing of Today: An SKF Group BrandSrinandh Aeron SriNo ratings yet

- A1003Document6 pagesA1003hamidharvardNo ratings yet

- Saej406v002 - Methods of Determining Hardenability of SteelsDocument47 pagesSaej406v002 - Methods of Determining Hardenability of Steelswilian_coelho3309No ratings yet

- Astm A582 - A582m-22Document4 pagesAstm A582 - A582m-221965karanfil6No ratings yet

- A493 00 PDFDocument3 pagesA493 00 PDFJohano AraújoNo ratings yet

- Jis G 3131-2010Document16 pagesJis G 3131-2010christian210789No ratings yet

- Astm F788MDocument6 pagesAstm F788MDaniel Velázquez100% (1)

- Ionic Technologies Aerospace Heat Treatment and Nitriding ServicesDocument3 pagesIonic Technologies Aerospace Heat Treatment and Nitriding ServicesSinan YıldızNo ratings yet

- ASTM-A449: Licensed by Information Handling Services Licensed by Information Handling ServicesDocument7 pagesASTM-A449: Licensed by Information Handling Services Licensed by Information Handling ServicesRoland CepedaNo ratings yet

- Tool Steel, Carbon: Standard Specification ForDocument12 pagesTool Steel, Carbon: Standard Specification ForVivi VargasNo ratings yet

- Wing Nuts (Inch Series) : ASME B18.6.9-2010Document24 pagesWing Nuts (Inch Series) : ASME B18.6.9-2010amine bouizarNo ratings yet

- Astm A 322 - 07Document4 pagesAstm A 322 - 07Luis MendozaNo ratings yet

- A449-14 Standard Specification For Hex Cap Screws, Bolts and Studs, Steel, Heat Treated, 120 - 105 - 90 Ksi Minimum Tensile Strength, General UseDocument7 pagesA449-14 Standard Specification For Hex Cap Screws, Bolts and Studs, Steel, Heat Treated, 120 - 105 - 90 Ksi Minimum Tensile Strength, General UseislamakthamNo ratings yet

- MIL-STD-645B Dip Brazing of Aluminum AlloysDocument16 pagesMIL-STD-645B Dip Brazing of Aluminum AlloysRichard BennardoNo ratings yet

- A407-07 (2013) Standard Specification For Steel Wire, Cold-Drawn, For Coiled-Type SpringsDocument3 pagesA407-07 (2013) Standard Specification For Steel Wire, Cold-Drawn, For Coiled-Type Springstjt4779No ratings yet

- Aisi 1008 Carbon Steel (Uns g10080)Document3 pagesAisi 1008 Carbon Steel (Uns g10080)parasite01100% (1)

- Alloy Steel Socket Button and Flat Countersunk Head Cap ScrewsDocument5 pagesAlloy Steel Socket Button and Flat Countersunk Head Cap ScrewsAhmed AbdelazizNo ratings yet

- Astm A90Document5 pagesAstm A90Luis Jaramillo100% (1)

- A 148 - A 148M - 15a PDFDocument5 pagesA 148 - A 148M - 15a PDFphaindikaNo ratings yet

- Surface Vehicle Recommended Practice: 400 Commonwealth Drive, Warrendale, PA 15096-0001Document5 pagesSurface Vehicle Recommended Practice: 400 Commonwealth Drive, Warrendale, PA 15096-0001Leonardo Gonçalves GomideNo ratings yet

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363No ratings yet

- Astm A 913 - A913m - 04Document4 pagesAstm A 913 - A913m - 04Especialista AICONo ratings yet

- A 913 - A913m - 00 Qtkxmy0wmeeDocument4 pagesA 913 - A913m - 00 Qtkxmy0wmeedavNo ratings yet

- Update Presale JemberDocument17 pagesUpdate Presale JemberindityoNo ratings yet

- Perhitungan Struktur End Plate Sambungan Kolom Baja Dan BetonDocument4 pagesPerhitungan Struktur End Plate Sambungan Kolom Baja Dan BetonindityoNo ratings yet

- Naskah Publikasi Hendry Tri Wibowo PDFDocument6 pagesNaskah Publikasi Hendry Tri Wibowo PDFKriswantoWisanggeniNo ratings yet

- Naskah Publikasi Hendry Tri Wibowo PDFDocument6 pagesNaskah Publikasi Hendry Tri Wibowo PDFKriswantoWisanggeniNo ratings yet

- Tema 8 Texto LamptonDocument20 pagesTema 8 Texto LamptonKriseweteNo ratings yet

- Carlos TRABAJO FINAL INGLES 1 1Document7 pagesCarlos TRABAJO FINAL INGLES 1 1Greis sayuri Arellano AvendañoNo ratings yet

- Salary Loan Application Form: Do Not Write Below This Line - For Citysavings Use OnlyDocument2 pagesSalary Loan Application Form: Do Not Write Below This Line - For Citysavings Use OnlyRessieCabaneroNo ratings yet

- Dl-54b Photo ID Card ChangeDocument2 pagesDl-54b Photo ID Card ChangePA Work LicenseNo ratings yet

- 2008-2016 Persons Bar Q and ADocument75 pages2008-2016 Persons Bar Q and AAw Lapuz100% (2)

- BTS Planning Steps and RulesDocument955 pagesBTS Planning Steps and RulesLuthoPromiseNo ratings yet

- Banna Leisure Limited financial analysisDocument2 pagesBanna Leisure Limited financial analysisravinyseNo ratings yet

- A Zaidi Manual of Hisbah of The 3rd Cent, Author(s) R. B. SerjeantDocument35 pagesA Zaidi Manual of Hisbah of The 3rd Cent, Author(s) R. B. SerjeantZaydi LibraryNo ratings yet

- Debate Chairperson's FlowchartDocument1 pageDebate Chairperson's FlowchartChiew N Pang100% (1)

- Agrarian Reform Policies (Readings in The Philippine History)Document25 pagesAgrarian Reform Policies (Readings in The Philippine History)Cristine MamaradloNo ratings yet

- FDocument8 pagesFRam Kumar YadavNo ratings yet

- Ownership, Operation, Maintenance, and Inspection of Amusement Rides and DevicesDocument4 pagesOwnership, Operation, Maintenance, and Inspection of Amusement Rides and DevicesMarlon Piarpuito Enriquez0% (1)

- Stresses Faced by WomenDocument3 pagesStresses Faced by WomenIOSRjournalNo ratings yet

- Rizal's Essay on the Causes of Filipino IndolenceDocument3 pagesRizal's Essay on the Causes of Filipino IndolenceJazzy Mercado100% (1)

- LGU Budget Process GuideDocument3 pagesLGU Budget Process GuideDelfinNo ratings yet

- Money and The Central Bank SystemDocument9 pagesMoney and The Central Bank SystemKEZIAH REVE B. RODRIGUEZNo ratings yet

- Chapter 7Document11 pagesChapter 7Minh TúNo ratings yet

- 65 G.r.no. 204261, October 05, 2016 - Edward C. de Castro and Ma. Girlie F. Platon, Petitioners, V. CouDocument11 pages65 G.r.no. 204261, October 05, 2016 - Edward C. de Castro and Ma. Girlie F. Platon, Petitioners, V. CouCharlene MillaresNo ratings yet

- Christology and The Council of Chalcedon by Fr. Shenouda M. Ishak (OCR)Document727 pagesChristology and The Council of Chalcedon by Fr. Shenouda M. Ishak (OCR)TakeBack Constantinople50% (2)

- Crime & Punishment Essay #3Document1 pageCrime & Punishment Essay #3SarahJMWNo ratings yet

- Test Bank For Business Law Today Comprehensive 12th Edition Roger Leroy MillerDocument18 pagesTest Bank For Business Law Today Comprehensive 12th Edition Roger Leroy Millercooly.maharmahb89a8100% (46)

- LetterDocument3 pagesLetter6zbg98s2fmNo ratings yet

- Loan, Pledge & Mortgage - Mcqs Sy 2013-14 2nd SemDocument7 pagesLoan, Pledge & Mortgage - Mcqs Sy 2013-14 2nd Semincubus_yeahNo ratings yet

- Auditors' Qualified Opinion on Palli Sanchay Bank Financial StatementsDocument32 pagesAuditors' Qualified Opinion on Palli Sanchay Bank Financial StatementsFaysalAhmedNo ratings yet

- CIR vs San Roque Power Corp., 690 SCRA 336: CTA upholds claim for VAT refundDocument84 pagesCIR vs San Roque Power Corp., 690 SCRA 336: CTA upholds claim for VAT refundRonnie Garcia Del RosarioNo ratings yet

- TVM Problems SolvedDocument4 pagesTVM Problems SolvedCharlie Ercole Mercado0% (1)

- Colloquium Script - 1Document4 pagesColloquium Script - 1MinSU Bongabong Guidance OfficeNo ratings yet

- Philtranco Service v Court of Appeals: Liability for Damages Caused by Company Bus DriverDocument102 pagesPhiltranco Service v Court of Appeals: Liability for Damages Caused by Company Bus DriverPaulo BurroNo ratings yet

- Family Tree of Dacquel-MacabeoDocument31 pagesFamily Tree of Dacquel-MacabeoJimmy C. AndangNo ratings yet

- New job offer as Data Entry OperatorDocument2 pagesNew job offer as Data Entry OperatorSumesh SHNo ratings yet