Professional Documents

Culture Documents

TW 100 Maintenance Schedule

Uploaded by

Evandro Jva compressoresOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TW 100 Maintenance Schedule

Uploaded by

Evandro Jva compressoresCopyright:

Available Formats

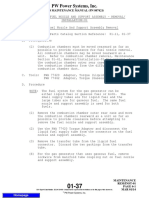

MAINTENANCE SCHEDULE

TW 100

Operating Hours

Part No. Part Name Quantity First

2.000 4.000 6.000

500

2602310620 Inlet Valve Ass’y(1st.) 2 ○ ○ ●

2602310680 Inlet Valve Ass’y(2nd.) 1 ○ ○ ●

2602022520 Guide Ring(1st.) 4 ●

2602022630 Guide Ring(2nd.) 2 ●

2602022500 Compression Ring(1st.) 4 ●

2602022610 Compression Ring(2nd.) 3 ●

2602022540 Piston Pin Sleeve(1st.) 4 ●

2602022650 Piston Pin Sleeve(2nd.) 2 ●

2110090034 Bearing 3 ●

2110020055 Bearing 1 ●

2110020051 Bearing 1 ●

2110020067 Bearing 3 ●

2109010002 Bearing Seal 6 ●

2602310660 I. V. Seat Gasket(1st.) 2 ● ● ●

2602310730 I. V. Seat Gasket(2nd.) 1 ● ● ●

2602022270 Cylinder Head Packing(1st.) 2 ●

2602022300 Cylinder Head Packing(2nd.) 1 ●

2602022320 Cylinder Case Packing(1st.) 2 ●

2602022340 Cylinder Case Packing(2nd.) 1 ●

2602490480 Connect Flange Packing 5 ●

2601540560 Air Strainer Ass’y 2 ◎ ◎ ◎ ●

2113010158 Belt (60Hz)

3 ○ ○ ○ ●

2113010130 Belt (50Hz)

2100050180 Bearing Grease 30g ○ ○ ○ ○

Note:

1) ● replace ○ inspection △ calibration ◎ clean

2) The above sheet is calculated based on 6,000 operating hours per year or every 12 months period. Maintenance should

be conducted according to which term comes first.

3) Adjust cleaning cycle according to your operation.

You might also like

- W Series Maintenance ScheduleDocument13 pagesW Series Maintenance ScheduleEvandro Jva compressoresNo ratings yet

- E35 Parts List CAP934Document6 pagesE35 Parts List CAP934robertNo ratings yet

- CURTIS E23 PumpDocument8 pagesCURTIS E23 PumprobertNo ratings yet

- Series: Single Stage Reciprocating CompressorDocument8 pagesSeries: Single Stage Reciprocating CompressorrobertNo ratings yet

- CURTIS E15 Pump PartsDocument8 pagesCURTIS E15 Pump PartsrobertNo ratings yet

- Curtis E50 Pump Parts ListDocument8 pagesCurtis E50 Pump Parts ListrobertNo ratings yet

- Linde HPV105 PartsDocument153 pagesLinde HPV105 PartsJustin83% (12)

- CHICAGO 90KW Spare Parts Manual 2011Document32 pagesCHICAGO 90KW Spare Parts Manual 2011UbanAirlanggaNo ratings yet

- CURTIS E71 Pump Parts LISTDocument10 pagesCURTIS E71 Pump Parts LISTrobertNo ratings yet

- UntitledDocument37 pagesUntitledDiesel RuizNo ratings yet

- 空压机 WD6系列不同机型的用量Document7 pages空压机 WD6系列不同机型的用量MAX MAXNo ratings yet

- C80 Element Overhaul PDFDocument26 pagesC80 Element Overhaul PDFMohamed Saied100% (6)

- Compressor 20201128 174612Document5 pagesCompressor 20201128 174612Vicente PorrasNo ratings yet

- POW63753 - POW 63757 EngineDocument13 pagesPOW63753 - POW 63757 EngineDOMINGOS VELHONo ratings yet

- CSH8581-125 - Piese de SchimbDocument27 pagesCSH8581-125 - Piese de SchimbLiviu PopaNo ratings yet

- Spare Parts KYDR203CD-23 EnglishDocument18 pagesSpare Parts KYDR203CD-23 EnglishHuy Lễ NguyễnNo ratings yet

- 1 Part Sino 2021 Order Emergency AddDocument8 pages1 Part Sino 2021 Order Emergency AddheruNo ratings yet

- Hitachi Osp-11m5arnDocument1 pageHitachi Osp-11m5arnUbanAirlanggaNo ratings yet

- HPV105!02!2640002621 - Power Unit and HousingDocument3 pagesHPV105!02!2640002621 - Power Unit and HousingSarah DelloNo ratings yet

- 2QJ 5系列绞车零件图册(英文)okDocument10 pages2QJ 5系列绞车零件图册(英文)okRiad RaddawiNo ratings yet

- BITZERDocument8 pagesBITZERalef mezaNo ratings yet

- L100AEDocument15 pagesL100AEGileno MotaNo ratings yet

- F - K0S35-30001 - Brake & Clutch Control 83Document3 pagesF - K0S35-30001 - Brake & Clutch Control 83JOAO BIANCHININo ratings yet

- Boom / Bucket HydraulicsDocument30 pagesBoom / Bucket HydraulicsEdgarNo ratings yet

- Prüfpumpe TP 25 EN 0716Document2 pagesPrüfpumpe TP 25 EN 0716Leandro GomesNo ratings yet

- First Rear Axle HousingDocument24 pagesFirst Rear Axle HousingMantenimiento Mecanico BiddleNo ratings yet

- Recommended PartsC1400D5 (KTA50) PCC3100Document2 pagesRecommended PartsC1400D5 (KTA50) PCC3100saifulNo ratings yet

- Lh517 Catalgo de PartesDocument503 pagesLh517 Catalgo de PartesEsteban San Martín MaulénNo ratings yet

- Manual Power GenerationDocument1 pageManual Power Generationmarlon073050No ratings yet

- Injector Specification: Assembly No: 32144Document1 pageInjector Specification: Assembly No: 32144Miguel RojasNo ratings yet

- J320 Maintenance Spare Parts ListDocument1 pageJ320 Maintenance Spare Parts ListKeith ChengNo ratings yet

- Compressor - Version 1 - Until 03.2013 - 20211129 - 154248Document10 pagesCompressor - Version 1 - Until 03.2013 - 20211129 - 154248عابر سبيلNo ratings yet

- PercussionDocument3 pagesPercussionaugustoNo ratings yet

- L100N-DE Parts DiagramDocument19 pagesL100N-DE Parts DiagramSameh FayedNo ratings yet

- Manual Partes Martillo Pb420Document3 pagesManual Partes Martillo Pb420PD Jose JuanNo ratings yet

- 2 MainstreetDocument25 pages2 MainstreetyoNo ratings yet

- Corona (Sinotruk) Howo PDFDocument17 pagesCorona (Sinotruk) Howo PDFmetal1xNo ratings yet

- L100N6CA1T1AAMS - MANUAL DE PARTES - 0CR10-M84400 - enDocument31 pagesL100N6CA1T1AAMS - MANUAL DE PARTES - 0CR10-M84400 - enAugusto BellezaNo ratings yet

- Compressor - Version 2 - From 04.2013 - 20230125 - 141828Document8 pagesCompressor - Version 2 - From 04.2013 - 20230125 - 141828Mosleh AbdelkaderNo ratings yet

- 4tnv106t GgehcDocument22 pages4tnv106t GgehcDzmitryNo ratings yet

- XYZ Compact Turn: CNC Turning Center Parts ManualDocument23 pagesXYZ Compact Turn: CNC Turning Center Parts ManualJayakrishnaNo ratings yet

- 86785888-15 - Man - Piec.v32 - D MontabertDocument24 pages86785888-15 - Man - Piec.v32 - D Montabertjacques PerronNo ratings yet

- BITZER 4P.2Y - Part ListDocument6 pagesBITZER 4P.2Y - Part Listаа аааNo ratings yet

- Fig.2. Gear Housing: (E) (D) (C) (B) (A) 4TNE106T-TBLDocument1 pageFig.2. Gear Housing: (E) (D) (C) (B) (A) 4TNE106T-TBLComercial AlfaOmega LimitadaNo ratings yet

- L100w6-Gey Parts ManualDocument28 pagesL100w6-Gey Parts ManualFlavio MedranoNo ratings yet

- Rear FrameDocument24 pagesRear FrameYuriPasenkoNo ratings yet

- SSSDocument14 pagesSSSFeroz GullNo ratings yet

- Flygt Basic Repair Kit. Kit CatalogueDocument44 pagesFlygt Basic Repair Kit. Kit Cataloguebezabih tegegnNo ratings yet

- CPG Spare Parts Manual 2009Document36 pagesCPG Spare Parts Manual 2009RUN GONo ratings yet

- 07montabert V2500 KR ET Liste Ser V250A50000 2012Document32 pages07montabert V2500 KR ET Liste Ser V250A50000 2012dmm tgctpNo ratings yet

- Compressor - 20230208 - 144342 Parts ListDocument7 pagesCompressor - 20230208 - 144342 Parts ListEdduin RodriguezNo ratings yet

- Parts Manual V45 MontabertDocument24 pagesParts Manual V45 Montabertjacques PerronNo ratings yet

- Eclate 129970-51000Document6 pagesEclate 129970-51000Theo HuqueleuxNo ratings yet

- F - G0U25-40001C - Wet Type Brake & Inching ControlDocument3 pagesF - G0U25-40001C - Wet Type Brake & Inching ControlJOAO BIANCHININo ratings yet

- L100V6C (0CR10-G63100)Document19 pagesL100V6C (0CR10-G63100)André LuisNo ratings yet

- 2tne68c-Bg Parts ManualDocument21 pages2tne68c-Bg Parts ManualflajemeNo ratings yet

- 517-100-Discos de Freio A Oleo PDFDocument2 pages517-100-Discos de Freio A Oleo PDFWalter FormigoniNo ratings yet

- CT65 Parts ListDocument26 pagesCT65 Parts ListJayakrishnaNo ratings yet

- K 350 1 2560 20290-01 01useDocument40 pagesK 350 1 2560 20290-01 01useEvandro Jva compressoresNo ratings yet

- 1 2810 2-000 00useDocument160 pages1 2810 2-000 00useEvandro Jva compressoresNo ratings yet

- 7 - 7740 - 0 - 14E SIGMA AIR CONTROL PlusDocument85 pages7 - 7740 - 0 - 14E SIGMA AIR CONTROL PlusEvandro Jva compressoresNo ratings yet

- Service Manual Sigma Air Control Plus: Article Number: 7.7740.0 7.7741.0 7.7742.0Document47 pagesService Manual Sigma Air Control Plus: Article Number: 7.7740.0 7.7741.0 7.7742.0Evandro Jva compressoresNo ratings yet

- 9 - 9450 - 01USE Steuerung Zu ASD.2CDocument182 pages9 - 9450 - 01USE Steuerung Zu ASD.2CEvandro Jva compressoresNo ratings yet

- Technical Description Sigma Air Manager: GSM Modem Retrofit KitDocument20 pagesTechnical Description Sigma Air Manager: GSM Modem Retrofit KitEvandro Jva compressoresNo ratings yet

- Service Manual: Sigma Air Manager 16/8Document192 pagesService Manual: Sigma Air Manager 16/8Evandro Jva compressoresNo ratings yet

- Asd 2C 10224114 10-000 00useDocument136 pagesAsd 2C 10224114 10-000 00useEvandro Jva compressoresNo ratings yet

- 7 - 5250 - 01880 - 01E NachrüstsatzDocument11 pages7 - 5250 - 01880 - 01E NachrüstsatzEvandro Jva compressoresNo ratings yet

- EMP2Document6 pagesEMP2Evandro Jva compressoresNo ratings yet

- Model:: AE4425Y-GS1ADocument8 pagesModel:: AE4425Y-GS1AEvandro Jva compressoresNo ratings yet

- GS Setup Table (ABB ACS550) 2010.09.15Document1 pageGS Setup Table (ABB ACS550) 2010.09.15Evandro Jva compressoresNo ratings yet

- Tcw413y Ds8eDocument2 pagesTcw413y Ds8eEvandro Jva compressoresNo ratings yet

- Performance: Technical Leaflet Pressure Transmitters, Type AKS 32 and AKS 33Document3 pagesPerformance: Technical Leaflet Pressure Transmitters, Type AKS 32 and AKS 33Evandro Jva compressoresNo ratings yet

- THB1548AG Ventilador InversorDocument11 pagesTHB1548AG Ventilador InversorEvandro Jva compressoresNo ratings yet

- CPF-175-200-CPVS-200-250 ManualDocument28 pagesCPF-175-200-CPVS-200-250 ManualEvandro Jva compressoresNo ratings yet

- Tubulacao Dimensioes Globais Valvulas e ConexoesDocument3 pagesTubulacao Dimensioes Globais Valvulas e ConexoesEvandro Jva compressoresNo ratings yet

- Cpe100, Cpe120, CPVS100, CPVS120 - A Partir Api170897 - 05-2013Document108 pagesCpe100, Cpe120, CPVS100, CPVS120 - A Partir Api170897 - 05-2013Evandro Jva compressores100% (1)

- Pressure Controls, Type KP, With Enclosure IP 33, IP 44 or IP 54Document8 pagesPressure Controls, Type KP, With Enclosure IP 33, IP 44 or IP 54Evandro Jva compressoresNo ratings yet

- Characteristic Value: Product SpecificationsDocument1 pageCharacteristic Value: Product SpecificationsEvandro Jva compressoresNo ratings yet

- Thermostats,: Type KPDocument12 pagesThermostats,: Type KPEvandro Jva compressoresNo ratings yet

- LT 4041 Aam Deere BrochureDocument28 pagesLT 4041 Aam Deere Brochurechristian vergaray gonzalesNo ratings yet

- T-2.973.758 (2003) Inspection and Testing of GasketsDocument6 pagesT-2.973.758 (2003) Inspection and Testing of Gaskets김창배No ratings yet

- PW Power Systems, Inc.: Gg8 Maintenance Manual (PN 807421)Document9 pagesPW Power Systems, Inc.: Gg8 Maintenance Manual (PN 807421)JHONNATTAN RODRIGUEZNo ratings yet

- Catalago Pá Lonking CDM 816Document138 pagesCatalago Pá Lonking CDM 816Diego ValensuelaNo ratings yet

- Caja RTXDocument92 pagesCaja RTXLuis Alberto Gutierrez LeyvaNo ratings yet

- Pam Cijevi DuctilDocument20 pagesPam Cijevi DuctilLejla BuljetovicNo ratings yet

- Shurjoint Catalog2008Document131 pagesShurjoint Catalog2008pdiagne1No ratings yet

- Catalogo Comercial RootsDocument28 pagesCatalogo Comercial Rootsfernando MedinaNo ratings yet

- Blue-White Pitot Tube Insertion MeterDocument2 pagesBlue-White Pitot Tube Insertion MeterbaysidepddNo ratings yet

- Z1212 - Hoja de InstalacionDocument2 pagesZ1212 - Hoja de InstalacionBenjamin ChavezNo ratings yet

- Manual Book Dindan 2400W - 70ACU005 - New - EnglishDocument23 pagesManual Book Dindan 2400W - 70ACU005 - New - EnglishDeriNo ratings yet

- Meritor MS15 - Manual de PartesDocument68 pagesMeritor MS15 - Manual de PartesJorge Arrieta Torres100% (1)

- Filler Info For 4200 ProductDocument2 pagesFiller Info For 4200 ProductRichard CleeNo ratings yet

- 01 Samss 025 PDFDocument18 pages01 Samss 025 PDFCherukunnon JubuNo ratings yet

- PVP2008 61708Document7 pagesPVP2008 61708DeclanNo ratings yet

- AWWA-C207 (2018) - Steel Pipe Flanges For Waterworks ServiceDocument40 pagesAWWA-C207 (2018) - Steel Pipe Flanges For Waterworks ServicePubcrawlNo ratings yet

- Workshop Manual - 20-26 - 7748841Document350 pagesWorkshop Manual - 20-26 - 7748841Wayne Sharkett100% (1)

- Pamphlet 95-Gaskets For Chlorine Service PDFDocument17 pagesPamphlet 95-Gaskets For Chlorine Service PDFJUNAID RAFEYNo ratings yet

- BMW E60 Engine Seals NotebookDocument24 pagesBMW E60 Engine Seals NotebookPeter McCracken100% (6)

- Design of Pressure Vessels by B.Raghunathan: TUV INDIA, Member of TÜV NORD GroupDocument135 pagesDesign of Pressure Vessels by B.Raghunathan: TUV INDIA, Member of TÜV NORD Groupp s rajuNo ratings yet

- Ed D 02.00 I 01Document25 pagesEd D 02.00 I 01joseellargoNo ratings yet

- OVENS - CatalogDocument15 pagesOVENS - Catalogdéborah_rosalesNo ratings yet

- US Army Plumbing IV Plumbing FixturesDocument96 pagesUS Army Plumbing IV Plumbing FixturesSpace_Hulker100% (1)

- Phe M3Document2 pagesPhe M3Vishnu Vardhan . CNo ratings yet

- Transmissao 938Document58 pagesTransmissao 938Jose De Moura CamaraNo ratings yet

- Flush Seals Foxboro PDFDocument6 pagesFlush Seals Foxboro PDFruzzo2003No ratings yet

- Volume3A Mech PDFDocument321 pagesVolume3A Mech PDFSayee Krishnan100% (1)

- Gee Valve SealsDocument28 pagesGee Valve SealsHARSHANo ratings yet

- 113c2b Iveco Stock Clearance AstraDocument72 pages113c2b Iveco Stock Clearance AstrarrNo ratings yet

- VUCG Guia de Mantenimiento 1ZSC000498-ABD en (VUCG)Document36 pagesVUCG Guia de Mantenimiento 1ZSC000498-ABD en (VUCG)armandoa71565No ratings yet