Professional Documents

Culture Documents

An UPDATED FOR CBR250R 2013 Manual Service Book

Uploaded by

Faseeh Mhaskar0 ratings0% found this document useful (0 votes)

38 views23 pagesService Manual

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentService Manual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

38 views23 pagesAn UPDATED FOR CBR250R 2013 Manual Service Book

Uploaded by

Faseeh MhaskarService Manual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 23

This document and what is written in itis the result of a voluntary initiative,

without profit intentions, and has No connection of any kind to Honda.

It has nothing to do with the Honda,

An UPDATEs

FOR

Honda Manual Service Book CBR250R(USA) 2013

The Updates include: Notes, Fixing mistakes,

*

and Recommendations

Collected by: Common Knowledge

[Firs Edition 13-10-2022]

Ba .

Warning: This booklet is written ONLY for

entertainment purposes, and the writing in this booklet

should not be seen as a recommendation for any action.

Anyone using the information in this document does so at

their own risk. Regardless of what is written in this document,

it will be clarified that it does not intend to contradict the

manufacturer's instructions in the original motorcycle book.

The manufacturer's instructions are the ones that are binding.

Mechanical work of any kind requires a lot of knowledge that

is not found in this booklet. Mechanical work can be very

dangerous and even lead to DEATH! Anyone who does not

have the knowledge or the appropriate qualification in

motorcycle mechanics is not allowed to perform repairs on a

motorcycle.

https://www.cbr250.net/threads/honda-manual-service-book-for-cbr250r-usa-2013-

updates-firs-edition%FO%9F%94%A796FO%9F%493%901%SEFKBBUBFILE2%E83%A3-notes-

fixing-mistakes-and-recommendations.69491/

This document and what is written in it is the result of a voluntary initiative,

without profit intentions, and has No connection of any kind to Honda.

It has nothing to do with the Honda,

GENERAL INFORMATION

FUEL TANK BREATHER Hose

VACUUM HOSE

PAIR CONTROL SOLENOID VALVE

SECONDARY AIR

SUPPLY HOSE:

EVAP PURGE CONTROL,

SOLENOID VALVE

CANISTER to-EVAP PURGE CONTROL :

‘SOLENOID VALVE HOSE 7

"AIR CLEANER DRAIN PLUG

grercostienos

Owh dk USA models

ln cther model It's WE hose

(Ab ONIST, pee 1-1

@ CRANKCASE BREATHER HOSE,

GENERAL INFORMATION

EMISSION CONTROL SYSTEMS

EXHAUST EMISSION REQUIREMENT

The US. Endonmental Protection Aganey (EPA), Callomia Ar Resoutces Bond (CARB) and Tranapod Canats ete

TMamutectuer tocol tha thor mnoloeyeles samy rl apabin exaust emsson standards dung ther use We, when

NOISE EMISSION REQUIREMENT

‘The EPA aso requires hal motrcyetes bil ater January 1.1989 comply with appcable nolan emission standards fr one tee

Sno 00 sre 7 Teen ante roncegin a ale

provided

WARRANTY COMPLIANCE

Compliance with the fim of tho Distebulr's Lined Warranty for onda Moloreyte Emission Control Systems is necessary

‘order to keep the emissions system warranty in oflect

SOURCE OF EMISSIONS

‘The combustion process produces carbon monoxide (CO), oxides of ntgen (NOx) and hydrocarbons (HC) Foe) evaporation

laces hydrocarbon emissions ‘The contol of hytrocarhons and oxkos of agen 's wety imporors reset ‘under certain

produces hydrocana en pnoiochemsa smog whan subjected to sung Cerbon manosde doesnot reac in he Same way.

butitis toxic

Venide Meter Co, id ullzes vaous systems (page 148) o reduc carbon monaxde, oxides of open and hysroraivons

CRANKCASE EMISSION CONTROL SYSTEM

The engin s equinped with cased caankcaeosystom fo proven schorany crankcase omission ito ihe ‘almosphere.

fw by gas ened to the combustion chamber Hough the ar cleaner housing an twotle Body

[AIR CLEANER HOUSING

THROTTLE BODY

| GRANRCASE BREATHER HOSE

5-1

FUEL SYSTEM (PGM-FI)

DTC READOUT

Start the engine and check the ML

NOTE

When the ignition switch is turned ON and engine stop switch ""

twill stay on for a few seconds, then go off J cee

It the MIL stays on or blinks, connect the HDS pocket tester to th

ieee HDS pocket tester to the DLC

Read the DTC, freeze data and follow the troubleshooting in

Road he eshooting index.

To ead the DTC with the MIL blinking, refer to the following procedure.

ty

Reading DTC with the MIL.

‘Turn the ignition switch OFF

Remove the rear under cover (page 2-13).

Remove the dummy connector [1] from the DLC (2)

‘Short the DLC terminals using a special tool. i

TooL:

SCS Service connector 070PZ-230100

Connection: Blue ~ Green '

“Turn the igrition switch ON and engine stop switch "0", read. note the MIL |

blinks and refer to the DTC index (page 5-14). i

NOTE i

Ifthe ECM has any DTC in its memory. the MIL will start blinking,

ERASING DTC

Connect the HDS pocket tester fo the DLC (page 5-12)

Erase the DTC with the HDS packet tester while the engine is stopped.

To erase the DTC without HDS pocket tester, refer tothe folowing procedure,

How to erase the DTC with SCS Service connector

+ Tum the ignition switch OFF.

2. Remove the dummy connector from the DLC (1}

Short the DLC terminals using a special tool

TOOL:

SCS Sorvice connector [2] 070PZ-ZY30100

Connection: Blue ~ Green

3, Turn the ignition switch ON and engine stop switch *

4. Remove the special toot from the DLC.

“The MIL wil light for approximately § seconds. While the MIL lights.

tre Nhe DLC terminals again wilh a special ool, The sel-diagnostic

seenory is erased if the MIL. goes off and starts blinking.

a

NOTE

The DLC must be jumped while the MIL igh

1 Note that the selfdiagnostic memory cannot

Pago OTO p, 5-50

Lor JpSensom hese! P

hts. f not, the MIL will ot start blinking.

"be erased I the ignition switch is tuned OFF before the Mil. starts blinking,

5-13

FUEL SYSTEM (PGM-Fl)

FUEL TANK,

REMOVALJINSTALLATION

A, Relieve the fuel pressure and disconnect the quick

connect fiting (page 5:33),

we 2, Release the fuel fed hose [1] om the hose guide 2-

"SP conn

Rolease the clamp (3 from the setting plate,

$,Remove the bolts [4], collar [5], washers [6], mounting

nies food wey mh noes

note: ™(3)

W

Place the suitable support under the front side of the

removed fuel tank to avoid darmage the fuel fier.

Route the fioso ard Install the fuel tank in the reverse order of removal

"fe ropa eg Connect the quick connect fing (pag2 6-95),

FUEL PUMP UNIT

INSPECTION

‘Turn the ignition switch ON and engine stop switch °C)" Fy

‘and confirm thatthe fuel pump operates for 2 seconds.

Ifthe fuel pump does not operate, inspect as follows:

‘Turn the ignition switch OFF.

LL and suppor the fue tank (page 3-5).

Disconnect the fuel pump SP connector [1].

5-39

FUEL SYSTEM (PGM-Fl)

Start the engine and open the throttle sii

rl pen ightly 10 be

c2tain that a is sucked in through tho air supply hose,

the air is not dravm in, check the air supply hoses [1]

for clogs and PAIR control solenoid valve (2)

(page 5-59),

<= FRESH AR

<— EXHAUST GAS

PAIR CONTROL SOLENOID VALVE

REMOVALJINSTALLATION

Lift and support the fuel tank (page 3-5)

Disconnect the PAIR control solenoid valve 2P (Black)

connector [1]

Disconnect the air supply hoses [2] from the PAIR

control solencid vaive (3).

Remove the bolts [4], collars (5] and PAIR control

solenoid valve from the stay.

Installation isin the reverse order of removal

INSPECTION

Remove the PAIR control solenoid valve (page 5-59)

Check that air does not flow (A) to (B) when the 12 V |

battery is connected to the PAIR control solenoid valve

terminals. Alr should flow (A) to (B) when there is no |

Voltage applied to the PAIR control solenoid valve |

terminals. |

Hold FRONT WHEEL/SUSPENSION/STEERING

Hire he handlebar ‘weight (1),

Install and tighten a ‘New screw [2].

I the fet nandlevar

Heep pietebar emo.ed adh the cich ove

UT the right handlebar

Freeplay page sigbat FeMoved adjust the ttle gp

INNER WEIGHT REPLACEMENT

Remove the throttle pipe or ot

anttebar (pene s:7)gue eg ey ee oe

Straighten the retainer ring tab [1] b

er tn y the serewdriver or

Punch. Two tobs(¥2)

‘Apply usricant Temporariy install the handlebar weight [2] and screw.

spray through the then remove the inner weight assembly (3) by turning

{ab locking hole 4) the handlebar weight

to the rubber

cushions (5) for

‘easy removal

Remove the screw [1]. handlebar weight [2}, retainer

ring [3] and rubber cushions [4] from the inner weight

{5}.

Install the rubber cushions and new retainer ring onto

the inner weight

Install the handlebar weight to the inner weight align

with each cut-outs of the inner weight and handlebar

‘weight

Install and tighten the handlebar weight screw.

Jnt assembly [1] into the handlebar.

i and hook the weight retainer tab

{By wth the tb locking hole [3] in the hancleber.

Remove the screw and handlebar weight [4

Ital! the throtle pipe and grip rubber tothe handlebar

(page 13-9)

Install the inner weig

Turn the inner weight

ia 4

13-13

FRONT WHEEL/SUSPENSION/STEERING

Install the handlebars [1] to both fork pipes while [=

i

aligning the bosses on the handlebars wilh the cut outs (UJ)

; the handlebars wit

‘Tighten both handlebar pinch bots [1] to the spected |

torque. |

TORQUE:27 Nm (2.8 kgm, 20 1b) |

Instal the stopper rings [2 0 the grooves ofboth fork |

pipes. |

Instal the wire bands (9 tthe both fork ppes,

|

Nore

Route the wie propery (page 1-18) |

|

ti

Install the front brake caliperibracket assembly and [ CasZZoRK shown

tignien ‘new brake caliper mounting bols {1} to the | CORA BRASS

specified torque.

TORQUE: 30 Nim (3.1 kgf-m, 22 Ibftt)

Install the following:

— Front fender (page 2-12)

= Front wheel (page 13-19)

STEERING STEM

REMOVAL

Lift and support the fuel tank (page 2-5). ini

‘Open the rubber sheet.

Disconnect the ignition switch 3P connector (1)

Res( PRISM, B-2, 19-2)

gpaky, 24-1

FRONT WHEEL/SUSPENSION/STEERING

Remove the cap i} u

Loosen the steering stem nut (2).

Remove the fork legs (page 13-20),

Remove the

te jm |

Bridge (a) "2 teetng stem ut, washer {3} and |

Res: byniti ore switch

2,3-23

Straighten the lock washer [1] tabs

Remove the steering stom adjusting lock nut (2)

Loosen the steering stem adjusting nut [1] using a ————

special too |

TOOL:

‘Steering stem socket [2] 07916-3710101 or

0702-00200

(US.A. only)

Hold the steering stem and remove the steering stem

adjusting nut

Remove the following:

= Dust seal [1]

Upper bearing inner race [2]

Upper steering head bearing [3]

= Steering stem {4}

= Lower steering head bearing [5]

13-31

14. REAR WHEEL/SUSPENSION

COMPONENT LOCATIOr

SERVICE INFORMATIOI

TROUBLESHOOTIN

REAR WHEEL-~-~-~

SHOCK ABSORBER ~~

SHOCK LINKAGE

‘SWINGARM ~~ ee AAT

OkWE CHAN COVER, a3

DRIVE CHAW SLIDER 13,

14,28 0I¢), #y- 23

14-1

REAR WHEEL/SUSPENSION

Rome

savin f

savinganny pivot nut [1] pavet bolt [2] and

DISASSEMBLY

Cheek the dive chain sider for woar or damage.

The drive chain sti

the wear limit groove [1

rust be replaced i i is worn to

i

Remove the drive chain slider [1] by releasing the slider

slots from the swingarm tab [2}

m

j2

Remove tho pivot colar [1] and dust seal [2] trom the | ‘

right swingarm pivot ny

Cheek the colle for wear, damage or fatigue.

14-19

REAR WHEEL/SUSPENSION

ASSEMBLY

rod D> _ san oust sen

Si

NEEDLE BEARING Caled

DRIVE CHAIN ADJUSTER

DISTANCE COLLAR ® seannos a

mireaun SS Ss uONOOUAR

bust SEAL

DRIVE CHAIN SLIDER

Urn

P, 44-23

I[s

Apoly grease to anew dust sea (ips. i

Install the distance collar [2], dust seal and pivot collar | 1

{3} t0 the lef swingarm pivot |

NOTE: |

Insta the dust seal fush withthe pivot surtace |

| fe.

Apply grease to a new dust seal (1) rips, ~

Install the dust seal and pivot collar (2} 10 the right |

swingarm pivot.

NOTE: :

Install the dust seal flush withthe pivot surface, y

D _ cn) |

all the dl REAR WHEEL/SUSPENSION

pre ve toa Se whe algnng thes

Pua [i th he Ss (2) se swat hale th eo

GUT DER WSe0 wie [3]

INSTALLATION

‘Aol thin coat of re8s othe swingarm pe

outer surface. . eee

‘Set the drive chain onto the swingarm [2} and install the

swingarm to the frame.

Install the swingarm pivot bot from the left side,

Install and tighten the swingarm pivot nut [1] to the

specified torque.

‘TORQUE: 88 Nm (9.0 kgf'm, 65 Ibf-t)

Install both swingarm pivot caps {2}

im

Install the shock absorber lower mounting bol (1] and

rut (2) a

Tighten the nut to the specified torque,

TORQUE: 36 Nem (3.7 kgf-m, 27 Ibft)

wer

(CBR250R 2013 Honda Service Manual P. 17-5)*

TEM

BATTERYICHARGING. sys)

TROUBLESHOOTING

STEP-1; Look also at pages: 22-2 and 22-5

STEP-2: CURRENT LEAKAGE TEST ;

Check the battery cure eskage test (Leak test page 17-7)

1s the current leakage below 0.34 mA?

YES - GOTO STEPS.

No - GOTOSTEPS.

eee

NO — + Shorted wire harness

* Fauiyigaiton senteh

STEP-4; BarteRy rests tha ballory coninen using a recommended paiter/ fester

RRomove te ater (oage 17-6) Option B

only)

RECOMMENDED BATTERY TESTER: Micro 408xt (US Vex Tesb Enon OFF

esa Good Battery Charge q@am No of X > 12.3V $P Yes

Replace 1

t Volt Test Starter ON

Load fest / Dynamic test

a Good Battery ameB> GOTO STEP-5 x STEPS

‘Yes END

NEW Battery eS Problem Solved?

‘sal the baitery (0096 1 10

‘STEP-5: Battery Volt Test Engine ON (Dynamic Test)

At ~5000rpm

@ (The charging s¥stem)

is working properly

Atthis point yy

bulbs are burning! “9

pyes2

c= ES yest.

Re

‘STEP

(Yes1 + Yes2)

(’Static* test te 5 }ovnamic test t

Test each of the3_phases seperately for:

1. resistance within 0.1 ~ 1.0.0 (20°C/68"F)?

“oT 7? YES NO

NO Atv, £00 RPM At 5000+pn

18. IGNITION SYSTEM

‘SYSTEM LOCATION

IGNITION SYSTEM INSPECTION ~~

SYSTEM DIAGRAM

IGNITION TIMING ~~

SERVICE INFORMATION « IGNITION COIL ~~ 18-9

IGNITION SWLICH 20-43

(ee “25,18, 1-2 Af 2, D~1)

TROUBLESHOOTING:

ELECTRIC STARTER

GROUND LINE

Disconnect the starte

i 'e starter relay switch 4P (Red) connector

Check for ex ntinuity bet

eck or continay between the Greed wn

wire harass side (ground line) and ground. meotthe

1 there is continuity

inuity when the transmission isin neu |

cx when the lute is csengaged andthe stestond fs |

Tact, the ground cult of ho relay col is norma

eulral, there isa slight resistance due tothe diode)

STARTER RELAY INPUT VOLTAGE

Connect the starter relay switch 4P (Red) connector {1}.

‘Turn the ignition switch ON and engine stop switch “0”.

Measure the voltage between the Yellowired (+) wire

terminal at the starter relay switch 4P (Red) connector

and ground (-).

If the battery voltage appears only when the starter

switch is pushed with the ignition switch ON and engine

slop switch °C”, the starter relay input voltage is normal.

OPERATION CHECK

Remove the starter relay switch (oage 19-15).

Connect a 12 V battery to the starter relay switch as

shown.

“There should be continuily between the cable terminals

hen the baltery is connected. and not continuity when |

the battery is disconnected.

REMOVAL/INSTALLATION

4 Remove the rider seat (page 2-6)

Release the rubber cover [1

Disconnect the starter relay switch 4P (Red) connector

a

Braet as [and aes |

Laem Sy tt Fo te sys th

the shock rubber.

6 Remove the starter re

Installation is in the reverse order of removal

ty switch from the shock rubber.

You might also like

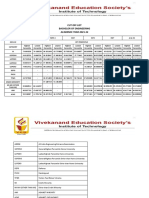

- Cut Off List For The Academic Year 21-22Document5 pagesCut Off List For The Academic Year 21-22Faseeh MhaskarNo ratings yet

- High Performance FilmsDocument1 pageHigh Performance FilmsFaseeh MhaskarNo ratings yet

- Fee Structure DSE 2022-23Document1 pageFee Structure DSE 2022-23Faseeh MhaskarNo ratings yet

- Typical Floor Plan - A2Document1 pageTypical Floor Plan - A2Faseeh MhaskarNo ratings yet

- New LL AcknowledgementDocument1 pageNew LL AcknowledgementFaseeh MhaskarNo ratings yet

- Mega Walk DriveDocument1 pageMega Walk DriveFaseeh MhaskarNo ratings yet

- 1 Copy of Layout Approval (In Case of Layout)Document1 page1 Copy of Layout Approval (In Case of Layout)Faseeh MhaskarNo ratings yet

- Unitplans A4Document5 pagesUnitplans A4Faseeh MhaskarNo ratings yet

- Instructions!Document1 pageInstructions!Faseeh MhaskarNo ratings yet

- Milind RukeDocument4 pagesMilind RukeFaseeh MhaskarNo ratings yet

- Honda CBR 250r Repsol Abs User ManualDocument137 pagesHonda CBR 250r Repsol Abs User ManualFaseeh MhaskarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)