Professional Documents

Culture Documents

Ato ddc5 CHB Digital Controller Instruction Manual

Uploaded by

pongkkp0 ratings0% found this document useful (0 votes)

92 views2 pagesOriginal Title

ato-ddc5-chb-digital-controller-instruction-manual

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

92 views2 pagesAto ddc5 CHB Digital Controller Instruction Manual

Uploaded by

pongkkpCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

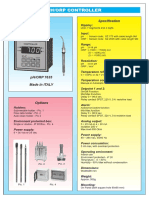

ATO-DDC5-CHB Group 2 parameters ⑤ Add key 1.

When measuring state, switch to gross

Weighing controller 3. Technical specifications value, net value, peak value and valley

Fi Coefficient 0.5000~3.0000 8.1

value.

Instruction ATO-DDC5-CHB

Power supply: AC 85~265V, 50Hz, 7.5W

Use environment: 0~50 ℃, 10~85%RH (no dewing)

F-r Range 100~45000 8.2 2. Increase the modification position

Digital display: 5 digit red LED display

in-b Zero point -19999~45000 8.3 value when setting.

Safety Caution Display range:-19999~45000, overload display . mv Sensitivity of sensor 0.8000~3.0000 8.4 ⑥Reduction 1. If the gross value does not exceed the

Decimal point position: 5 different positions can be selected Display the decimal point key zero range and the measurement value

in-d 5 modes 8.5

Sensor voltage: DC 10V/150mA position remains unchanged, press this key to

Incoming signal: 0~±25mV Automatic returning to

return to zero for 2 seconds.

Please be sure to comply with the following recorded notes in the Sampling speed: 10 times per second SZro zero selection when oFF / oN 8.6

2. Reduce the modification position value

product manual. There is a risk of serious injury or accident if you do Maximum display points: 10000 power on

when setting.

It will display countdown 9~0 in startup picture when power on.

not follow the note for use. Zror Zero setting range 0~10000 8.7

Auto returning to zero: The range is depended on the range of . 6.2 Parameter setting instructions

FLtr Digital filtering 1~20 8.8

Comparative control output: six ways to compare, select by setting. The parameters of the instrument are divided into two groups, each of

Please do not use in life-related equipment, such as atomic : when gross value > comparing setting value, controller outputs unit Unit 0~3 8.9 which is listed in Chapter 5, the parameter list.

energy, medical devices, etc. : when gross value < comparing setting value, controller outputs ★ The first group of parameters and the second group of parameters are

Std Stability judgment range 1~100 8.10

The meter has not power fuse, please install safety circuit : when positive deviation of gross value and setting value > controlled by the password. The password is not allowed to enter when the

tr-d Zero tracking range 0~4 8.11

breaker, such as fuse, etc., in the power supply circuit of the comparing setting value, controller outputs password is not set.

meter. Alarm setting value ★ Whether the , , parameters can be selected by

: when negative deviation of gross value and setting value >

Please do not use it outside the specifications provided by the oA1 selection control by oFF / oN 8.12 password control through the preferences of

comparing setting value, controller outputs

product. password When is set as OFF, and it is not controlled by it. When set to ON,

: when absolute value of deviation of gross value and setting value

Please do not use in flammable and explosive places. if it is not set, though it can be entered and modified, it cannot be stored.

> comparing setting values, controller outputs

Please avoid installing in the top of a high heating value meter : when absolute value of deviation of gross value and setting value

6. Operation 6.3 Setting method of comparison Control output

(heater, transformer, high-power resistance). < comparing setting values, controller outputs comparison value

When the ambient temperature is above 50℃, please use a 6.1 Panel and key instructions The comparison value is in the first set of parameters.

forced fan or cooler to cool, but do not let the cooling air blow 4. Installation and wiring 1. Press the setting key for 2 seconds to enter into setting state, and the

directly to the instrument. meter shows .

Wiring diagram: 2. You can select the other parameters of this group in order by single

For panel-mounted meters, in order to avoid user access to

high-voltage parts, such as power terminals, please take pressing the key.

necessary measures on the final equipment. 3. Press the key to call out the original set value of the current

The installation, commissioning and maintenance of the product parameter, and the flicker bit is a correction bit

4. Move the modification bit through the key, the key is for

shall be carried out by qualified engineers and technicians.

appreciation, and the key is for decrease in value, and modify the

If a failure or anomaly of the product is likely to cause the major Name Introductions parameter to the required value.

system accident, please set up an appropriate protective circuit 1. Display measured values respectively, 5. Press the key to save the modified parameter and automatically

externally to prevent the accident. such as gross value, net value, peak value go to the next parameter. If this is the last parameter, press the key

①Display

The company shall not bear any direct or indirect loss other than and valley value and then go to the first parameter.

the product itself. window

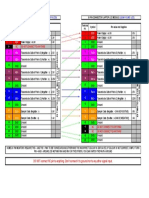

5. Parameter list 2. Displays parameter symbols and The other parameters of this group can be set up by repeating the Step 2

We reserve the right to change the product specification without parameter values in the parameter setting ~5.

notice. Group 1 parameters state ★ If the modified parameter cannot be stored, it is because the

1. out1, out2 are comparative output parameter is set to ON, so that the parameter is controlled by the

1. Overview Code Name Contents Value range Introduction

indicator light password, and the password should be set first.

ATO-DDC5-CHB is an economical digital weighing controller with Comparison value of the 1st 2. MOT light is on, measured value is

OUT1 -19999~45000 7 6.4 Password setting method

gross value, net value, peak value, valley value display, which can be comparison control output changed.

②Indicator 3. Zero light is on, measured value is zero. When the instrument is in the measurement state, the password can be set.

switched at any time. Comparison value of the 2nd

OUT2 -19999~45000 7 4. GROSS light is on, display gross value.

Two alarm outputs. comparison control output light 5. NET light is on, display net value.

1. Hold down the settings key until is displayed

Optional 6 alarm modes Target values of comparison 6. PEAK light is on, display peak value. 2. Press the key continuously and switch to

Au -19999~45000 7

The peak valley value uses 2 comparison values as threshold values. control output 7. VALLEY light is on, display valley value. 3. Press the key to enter the state of modification, in the

When the real-time weight exceeds the peak threshold value, the peak oA Password 0~9999 6.4 8. kN, g, kg, t are measurement unit cooperation of , , the key will be modified to

value is compared. When the real-time weight is below the threshold indicator lights

value of valley value, the valley value is compared.

Comparison mode of the 1st

1. Press it for 2 seconds to enter into the 4. Press the key to complete the password setup

ALo1 6 modes 7

Operational key

comparison control output 6.5 Setting method of other parameters

Digital weighing controller has the function of auto-tracking, stability setting state.

judgment, boot automatic zero-clearing, etc. Comparison mode of the 2nd ③Setting 2. Press it, and then press within 2 1. At first, set the password as 6.4

ALo2 6 modes 7

Indicator light definition: 12 indicator lights, such as, alarm 1, alarm 2, comparison control output seconds until showing , enter into the

key 2. The parameters after the parameters in the first set of parameters

MOT, zero, gross, net, peak, valley, t, kg, g, kN. Sensitivity of the 1st adjustment state.

HYA1 0~19999 7 3. Press it, and then press within 2 Press the key to select

comparison control output

2. Model specification seconds, after 2 seconds valley value will be 3. The parameters of the other groups are entered in sequence by

Sensitivity of the 2nd cleared.

HYA2 0~19999 7

Model: ATO-DDC5-CHB comparison control output holding down the setting key and the symbols of the first parameter of

Boundary dimension: horizontal type, 160×80×125(W×H×L)mm, 1. When the weight does not change, after

Detect threshold value of pressing the key controller notes the gross the group are displayed by the meter.

hole size 152*76mm AHH -19999~45000 7 value as the net minus deduction value, and

Display mode: Red LED single display 5 bits peak value ④Left key 4. After entering the group in which the parameters need to be set, press

transfers to the net value to show.

Input signal: ±25mV key in sequence to select the parameters that need to be set in this group

Detect threshold value of 2. Move the modification position when set.

ALL -19999~45000 7

Control output: two alarm outputs valley value 3. When setting a parameter, enter into 5. Press the key to call out the original set value of the current

External power supply: DC 10V/150mA parameter modification. parameter, and the flicker bit is a modified bit

Power supply: AC 220V

6. Move the modification bit through the key, add value to the Optional range is 1 / 20. The factory settings is 1.

key, reduce the value of the key, and modify the parameter to the 8.9 Unit selection Range 40000

desired value 0 - t,1 - kg,2 - g,3 - kN.

★ The parameter of parameter value is indicated by the form of 8.10 Stable range Transducer 2.0020

symbol. The flicker bit should be at the end of the modification. When the variation within 1 second of the measured value exceeds the sensitivity

7. Press the key to store the modified parameter and go to the value of the set parameters, the instrument considers the force value Display the 0.0000

next parameter indicates the deviation absolute value of gross value and set value At this time the Mot lights are on. decimal point

Repeat Step 4 ~ 7 to set other parameters of this group. < the output conductance in comparison value 8.11 Zero tracking range position

Exit setting: When the parameter symbol is displayed, hold down the If the force is in zero tracking range within 1 second or greater than

9.3User manual fine-tuning

settings key of until you exit the setting state of the parameter. or equal, the reading will be tracked to zero. Zero tracking range is 0 ~

4, and if it’s not tracking when 0. When the weighing material is full, it can be achieved by adjusting the

7. The description of output comparison value

8.12 Password control selection for comparing zero and coefficient when the calibration condition is not met. Notice:

parameter is controlled output settings please record the values of the parameters of and , which

Each control output comparison value has three parameters, which are This parameter determines whether the comparison output settings cannot be recovered after calibration.

used to control the output comparison value, select the comparison are controlled by the password: 9.3.1Fine-tuning zero point

mode and compare the sensitivity of the comparison value. 、 Sensitivity setting for comparison output of point 1 and 2. - Comparison output settings are controlled by passwords

The sensitivity is the extended region of output recovery set according to For example,

and are the comparison of the 1st and 2nd control - Comparison output settings are not controlled by

outputs, respectively the need to prevent the gross value from fluctuating near the comparison passwords In a large storage tank, the zero point is changed greatly due to the

value resulting in frequent output ON,OFF mechanical structure or the change of the mechanical state of the sensor.

is the target value of the comparative control output.

For example: when the comparison way is 9. Calibration Instructions

~ are two selection and comparison methods, The display weight is not correct, and the tank can not clear the

Notice: before calibration, the zero tracking points is closed; it

respectively calibrated zero point, so it can be adjusted by manual input of the zero

All comparison values are equal to the gross value. can not be cleared by ZERO key; If the power is turned on to clear the

internal code.

Each comparative output control point is correlated with three zero automatically, please set the parameters to OFF, then

power on again before calibrating. The material in the tank is estimated to be 20 000 kg according to the

parameters of , ,

If the third to sixth comparisons are used, they are also related to 9.1 Automatic calibration volume, but it can actually be shown to be 21 000 kg. If the 1000kg

the parameters. When it leave the factory, the parameter is set to =10000 material is added, the display will also increase 1000 kg at the same

, : Point 1, point 2, compare the output of the peak value judgment threshold value =2.0000 time, then the weight is not allowed to be caused by the zero point

comparison value set. When the real time weight exceeds the peak threshold, the new peak value 9.1.1Automatic zero adjustment: change, and the zero parameter can be modified to and the zero

, : The first and second point comparison output comparison is performed, and the new peak value is retained until the weight Press for 2 seconds then press for 2 seconds to enter into the point can be adjusted up to 1000kg.

comparison mode setting. exceeds the peak threshold value again. adjustment state, showing . Press the button to enter into the

Zero adjustment formula:

indicates gross value > the output conductance in zero calibration. After the zero-position calibration is completed, it is

valley threshold value Adjusted display value = Display value before zero adjustment -

comparison value shown that there is a scintillation at the end.

When the real time weight is below the threshold of the valley value, the ( )

If you only adjust to zero, do not adjust the range, press the key to

new valley value is compared, and the new valley value is kept until the weight 9.3.2Fine-tuning coefficient

exit adjustment, and return to normal measurement.

is lower than the threshold value of the valley value again. 9.1.2Automatic range adjustment For example,

8. Parameter specification Press for 2 seconds then press for 2 seconds to enter into the Assuming that the weight of the weighing platform is 1000kg and the

adjustment state, showing . meter shows 997kg, the calibration coefficient needs to increase by

8.1 coefficient ①Press the

indicates gross value > the output conductance in button to enter into the zero calibration. After the

The coefficient is a full scale calibration coefficient, and the factory has 1000÷997, which is equal to 1.00301. The original calibration

comparison value zero-position calibration is completed, it is shown to enter

been calibrated. When users do not modify, they can not be calibrated. coefficient is =2.1672, and it is necessary to expand the coefficient

range calibration.

8.2 range ②The standard weight is placed on the force measuring device, and the 2.1672 by 1.00301 times, that is, =2.1737.

The sensor range is the sum of n sensor ranges. The user sets the display value is set to the standard value of the standard weight by Coefficient correction formula:

parameter according to the actual range, indicating that the sensor's range is means of the cooperation of the key, and the calibration of the Adjusted display value = Display value before coefficient correction ×

. The factory settings is 10000. measuring range is completed by pressing the , and key.

8.3 null point -( )

③If zero is not calibrated, press the key to enter the range

indicates positive deviation between gross value and given Zero values range is from-1999 to 45000, the factory settings is 10000. ★ : the automatic calibration range can be calibrated up to

calibration directly after displaying . Press the key to enter the

value > the output conductance in comparison value 8.4 transducer sensitivity numerical modification. The display value will be set as the standard 10000. if it exceeds 10000, can be shown.

The unit of sensor sensitivity is MV/v, and the factory settings is 2.0000. value of the standard weight. Press the key to confirm the exit after the ★ : when calibrating the measuring range automatically, the

8.5 scaling position modification. Press the key to enter the numerical modification. input signal number value exceeds the limit. It may be that the value of

There are 5 decimal places, respectively are .、 . 、 The display value will be set as the standard value with the ,

. 、 . 、 . . The factory settings is the parameter is too large.

and key . Press the key to confirm the exit after the

8.6 Automatic zero clearing selection modification.

★ : When zero is adjusted, the input signal exceeds 50% of the

indicates positive deviation between gross value and given Automatic zero clearing parameters of meter. When it’s = oN, it ★ Press before withdrawal to make sure MOT lights are not on total range

value > the output conductance in comparison value will automatic clearing; when it’s = oFF, the automatic clearing is 9.2 User has not weights calibration ★ . :

invalid, and the factory settings is oN。 When the instrument leaves the factory, it has been calibrated according When the product of input signal and coefficient, range, and sensitivity

8.7 zero setting to the sensitivity and range. The user only needs to set up the sensitivity of the instrument is out of range, . is shown.

When the measured value is within zero range, press the button for 2 of the sensor, display the decimal point and the range, and then make

seconds to make the display zero. In measuring condition. The factory settings When the measured value of the instrument is greater than 45000 or less

sure that the range is not calibrated when the input of the range and

is 1000. than -19999, showing .

sensitivity is correct.

indicates the deviation absolute value of gross value and 8.8 digital filtering For example: the sensitivity of the sensor is 2.002 MV/v, and the

When the peak value or valley value exceeds the limit, . will

The force measurement device is affected by its own natural frequency be displayed. and the peak and valley value will be cleared to show the

set value > the output conductance in comparison value measuring range of 4 sensors is 1 t. total range 4t

and the external vibration conduction will produce random vibration, which normal value.

Unable code correction parameter setting:

makes the display value of the instrument unstable. The appropriate digital

filter is selected according to the size of its vibration to make the display

stable. The smaller digital filter is selected for vibration hours, and the larger

number is chosen for large vibration. www.ato.com

You might also like

- CB92 Load Cell IndicatorDocument4 pagesCB92 Load Cell IndicatortharlesNo ratings yet

- CB92Document10 pagesCB92hipolito.bautistaNo ratings yet

- DS100S AC Servo Drive ManualDocument23 pagesDS100S AC Servo Drive ManualJuan Francisco Sanchez MassadiNo ratings yet

- Thor CATV Cable or ATSC Off Air RF Auto Redundancy Failover Switch 5-1000Mhz ManualDocument8 pagesThor CATV Cable or ATSC Off Air RF Auto Redundancy Failover Switch 5-1000Mhz ManualthorbroadcastNo ratings yet

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- 5x7mm Precision TCXO in Stock at Digi-Key: Description: FeaturesDocument2 pages5x7mm Precision TCXO in Stock at Digi-Key: Description: FeaturessergeyNo ratings yet

- InteliLite 4 AMF 8 DatasheetDocument4 pagesInteliLite 4 AMF 8 DatasheetDieselmotors ManNo ratings yet

- 4912 - Autocompute LCR-Q Meter SorterDocument2 pages4912 - Autocompute LCR-Q Meter SortertarandsNo ratings yet

- Supmea SUP-ZP InstruccionesDocument22 pagesSupmea SUP-ZP InstruccionesJhon Sanchez ChNo ratings yet

- SYL-1813 Multifunction Automotive Gauge Instruction Manual: Auber InstrumentsDocument3 pagesSYL-1813 Multifunction Automotive Gauge Instruction Manual: Auber InstrumentsPuruf PufNo ratings yet

- Inteligen 1000 3.0.2 DatasheetDocument6 pagesInteligen 1000 3.0.2 DatasheetjuadogonNo ratings yet

- MULTIMETER MANUALDocument2 pagesMULTIMETER MANUALAbel Elías Ledo AmachiNo ratings yet

- FT CostDocument4 pagesFT CostSupriyaNathRayNo ratings yet

- InteliLite 4 AMF 20 Datasheet - 2Document4 pagesInteliLite 4 AMF 20 Datasheet - 2Cj BongNo ratings yet

- InteliLite 4 AMF 20 Datasheet - 2Document4 pagesInteliLite 4 AMF 20 Datasheet - 2Cj BongNo ratings yet

- UT94 - Quick - User - Guide Masibus IsolatorDocument2 pagesUT94 - Quick - User - Guide Masibus IsolatorShigilNo ratings yet

- InteliLite 4 AMF 20 Datasheet - 2Document4 pagesInteliLite 4 AMF 20 Datasheet - 2Cj BongNo ratings yet

- InteliLite 4 AMF 20 Datasheet - 2Document4 pagesInteliLite 4 AMF 20 Datasheet - 2Cj BongNo ratings yet

- FG 7000L ManualDocument8 pagesFG 7000L ManualEsmeralda MariscalNo ratings yet

- Operation Manual: 1. Technical SpecificationDocument2 pagesOperation Manual: 1. Technical SpecificationAbdo AshrafNo ratings yet

- Operator'S Manual: Model: 41RDocument14 pagesOperator'S Manual: Model: 41Rarad electronicNo ratings yet

- V 5 DuyDocument2 pagesV 5 Duyarad electronicNo ratings yet

- RISHMax 10 Operating Elements User's ManualDocument11 pagesRISHMax 10 Operating Elements User's ManualAsian InternationalNo ratings yet

- 3039-I - Cable Fault LocatorDocument2 pages3039-I - Cable Fault Locatorhemantgupta226No ratings yet

- Digital Tachometer InstructionsDocument10 pagesDigital Tachometer InstructionsMARCOSNo ratings yet

- Level Sensor ManualDocument7 pagesLevel Sensor ManualSatyasrinivas PulavarthiNo ratings yet

- C628 AWESOME Rate Meter: Dynapar Veeder-RootDocument1 pageC628 AWESOME Rate Meter: Dynapar Veeder-RootnayhatNo ratings yet

- Flow Indicator Totalizer: Electronics Systems and DevicesDocument2 pagesFlow Indicator Totalizer: Electronics Systems and DevicesAnand BagadeNo ratings yet

- YHT7E WeighingDocument11 pagesYHT7E Weighingmohsin bilalNo ratings yet

- Introducing FineTek's Highest-End Temperature ControllerDocument23 pagesIntroducing FineTek's Highest-End Temperature ControllerWilly TurdoNo ratings yet

- InteliLite 4 AMF 8 Datasheet - 2Document4 pagesInteliLite 4 AMF 8 Datasheet - 2Bikash Das100% (1)

- PLC-K7 Series (K7M-DR60U)Document2 pagesPLC-K7 Series (K7M-DR60U)Suresh MNo ratings yet

- Operating Instructions: LCD Display Counters E5024C SeriesDocument20 pagesOperating Instructions: LCD Display Counters E5024C SeriesFernando BarraganNo ratings yet

- 879 DatasheetDocument1 page879 DatasheetRoozbeh BNo ratings yet

- 180.0 ° 50.01 HZ 49.99 HZ 230.2 V 228.1 V: Multi Function MeterDocument2 pages180.0 ° 50.01 HZ 49.99 HZ 230.2 V 228.1 V: Multi Function MeterMAYCON KOPELVSKINo ratings yet

- Cam Operated Rotary Switches TimerDocument7 pagesCam Operated Rotary Switches TimerImamul HaqueNo ratings yet

- Master K120 SDocument11 pagesMaster K120 SYudi MalangNo ratings yet

- 4-20 Ma Control/Alarm/Indicator: ISO-9001, CE, IEC1010Document2 pages4-20 Ma Control/Alarm/Indicator: ISO-9001, CE, IEC1010vishadkapadiaNo ratings yet

- InteliGen 1000 2 2 2 Datasheet - 2Document5 pagesInteliGen 1000 2 2 2 Datasheet - 2刘金星No ratings yet

- PI Digital Panel Indicator - B0Document7 pagesPI Digital Panel Indicator - B0dtoxidNo ratings yet

- Mitsubhishi Cop ProgrameDocument61 pagesMitsubhishi Cop ProgrameSunil KumarNo ratings yet

- M2 User ManualDocument36 pagesM2 User ManualDmitri Matveev . гр.No ratings yet

- LOGO! 8 Soft Comfort Online-Hilfe English Sides 300-303Document4 pagesLOGO! 8 Soft Comfort Online-Hilfe English Sides 300-303Abdullah TalibNo ratings yet

- Power Genius Meters PDFDocument2 pagesPower Genius Meters PDFAritheertham SaravananNo ratings yet

- Digital Process Indicator Selectron PIC101Document1 pageDigital Process Indicator Selectron PIC101industrialindiaNo ratings yet

- KM-PFR-S-9 - 04-08-12Document7 pagesKM-PFR-S-9 - 04-08-12Asra NtNo ratings yet

- HM 8018Document2 pagesHM 8018nicolae ratescuNo ratings yet

- 24VDCDocument6 pages24VDCAB-S ELECTRO MECHANICAL INDUSTRIAL AUTOMATIONNo ratings yet

- B&C - 2015Document6 pagesB&C - 2015Tư vấn môi trườngNo ratings yet

- Suitable To A Wide Range of Weighing ApplicationsDocument2 pagesSuitable To A Wide Range of Weighing ApplicationsFawzul AleemNo ratings yet

- Digital Display Voltmeter (Ammeter) Anual Operational Instruction MDocument4 pagesDigital Display Voltmeter (Ammeter) Anual Operational Instruction MCaterine CrespoNo ratings yet

- Ex840 UmDocument12 pagesEx840 Umasonenshine6385No ratings yet

- Document Change Record: Calibration SheetDocument7 pagesDocument Change Record: Calibration Sheetmikedlt100% (2)

- lxc900 VDocument1 pagelxc900 VGaurav MahajanNo ratings yet

- 3 Phase Intelligent Energy Meter User Manual: ES925 SeriesDocument4 pages3 Phase Intelligent Energy Meter User Manual: ES925 SeriesMbgardNo ratings yet

- Manual CNT Asl51Document4 pagesManual CNT Asl51Jhoompieer VFNo ratings yet

- Turbo Plus PDFDocument27 pagesTurbo Plus PDFAnonymous iDJw3bDEW2No ratings yet

- How To Install Blue PrismDocument2 pagesHow To Install Blue PrismRanjith NarayanNo ratings yet

- HistoryDocument13 pagesHistoryMuhamed Zimić ZimaNo ratings yet

- LCD PinoutsDocument1 pageLCD PinoutsPablo Daniel MagallanNo ratings yet

- Wa0031 PDFDocument1 pageWa0031 PDFAnaNo ratings yet

- Consultants DirectoryDocument36 pagesConsultants DirectoryAnonymous yjLUF9gDTSNo ratings yet

- Nikita Rajput: Anchor/Host/Master of CeremoniesDocument21 pagesNikita Rajput: Anchor/Host/Master of CeremoniesnamanNo ratings yet

- Sap AbapDocument7 pagesSap Abapidrees aliNo ratings yet

- Triumph Spitfire MK4 - 1500Document108 pagesTriumph Spitfire MK4 - 1500Ricardo100% (1)

- Hedonomics: Bridging Decision Research With Happiness ResearchDocument20 pagesHedonomics: Bridging Decision Research With Happiness ResearchgumelarNo ratings yet

- Safety and Quality of Health Care System in IndiaDocument18 pagesSafety and Quality of Health Care System in IndiaKNOWLEDGE FeedNo ratings yet

- Operation Manuals HCWA10NEGQ - Wired ControllerDocument2 pagesOperation Manuals HCWA10NEGQ - Wired Controllerchamara wijesuriyaNo ratings yet

- CPAR Summary - WK 144Document6 pagesCPAR Summary - WK 144NagarajNo ratings yet

- Engine Tune-UpDocument43 pagesEngine Tune-UpЮра ПетренкоNo ratings yet

- Understanding The American Education SystemDocument6 pagesUnderstanding The American Education SystemCastor JavierNo ratings yet

- Certified Elder Law Attorney Middletown NyDocument8 pagesCertified Elder Law Attorney Middletown NymidhudsonlawNo ratings yet

- How Nokia Failed to Adapt to Market ChangesDocument5 pagesHow Nokia Failed to Adapt to Market ChangesRiangelli ExcondeNo ratings yet

- Answer Key Determinants & Matrices: B C C B B C D A B CDocument2 pagesAnswer Key Determinants & Matrices: B C C B B C D A B CElbert EinsteinNo ratings yet

- Etextbook 978 0078025884 Accounting Information Systems 4th EditionDocument61 pagesEtextbook 978 0078025884 Accounting Information Systems 4th Editionmark.dame383100% (49)

- IB Urban Environments Option G (Latest 2024)Document154 pagesIB Urban Environments Option G (Latest 2024)Pasta SempaNo ratings yet

- The 2012 FedEx Ketchum Social Business StudyDocument40 pagesThe 2012 FedEx Ketchum Social Business StudyEric PrenenNo ratings yet

- Test IMO EnglezaDocument4 pagesTest IMO EnglezaCristina PopovNo ratings yet

- Manual Equus 810 070Document10 pagesManual Equus 810 070Juan Ramón100% (1)

- Port Er's Nat Iona L Dia Mon D Co Mpe Titiv Ea Dva Ntag Eof Natio NS'Document45 pagesPort Er's Nat Iona L Dia Mon D Co Mpe Titiv Ea Dva Ntag Eof Natio NS'Soha KhanNo ratings yet

- Chandler V MillerDocument2 pagesChandler V MillerJay Cezar100% (1)

- Presentation On Tutorial Question On Promissory EstoppelDocument13 pagesPresentation On Tutorial Question On Promissory EstoppelNaqeeb NexerNo ratings yet

- Oracle ASMDocument46 pagesOracle ASMWaqas ChaudhryNo ratings yet

- Function-Answer (2016-2018)Document9 pagesFunction-Answer (2016-2018)朱瑞霖No ratings yet

- Clinical Practice Guidelines For Acute Otitis Media in Children: A Systematic Review and Appraisal of European National GuidelinesDocument3 pagesClinical Practice Guidelines For Acute Otitis Media in Children: A Systematic Review and Appraisal of European National GuidelinesusmfdocNo ratings yet

- Last Minute Reviewer for 2019 Bar ExamDocument19 pagesLast Minute Reviewer for 2019 Bar ExamFrances Ann Teves100% (1)