Professional Documents

Culture Documents

Standard Reference Material 1082 Cigarette Ignition Strength Standard

Uploaded by

selowestOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Standard Reference Material 1082 Cigarette Ignition Strength Standard

Uploaded by

selowestCopyright:

Available Formats

Date of Issue:

21 March 2022

Standard Reference Material 1082

Cigarette Ignition Strength Standard

C ERTIFICATE OF A NALYSIS

Purpose: The certified value delivered by this Standard Reference Material (SRM) is intended for use by test

laboratories to assess and control their testing of cigarette ignition strength in accordance with ASTM Standard

Methods E2187-16 (and earlier versions of this standard) [1] and with the nearly identical ISO 12863 [2].

Description: A unit of SRM 1082 consists of one (1) carton of cigarettes containing ten (10) packs of twenty (20)

cigarettes each.

Certified Value: The certified ignition strength value is given in Table 1. The certified value is traceable to

ASTM E2187-16 [1,3].

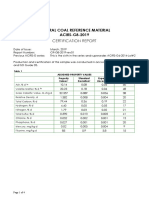

Table l. Certified Ignition Strength Value for SRM 1082

Measurand ASTM Method Certified Ignition

Strength Value

Ignition Strength ASTM E2187-16(a) 15.8 % ± 6.0 %

(on stainless steel plus one layer of filter paper) [4,5]

(a) Standard test method for measuring the ignition strength of cigarettes.

NOTICE OF VALUE CHANGE: THE ORIGINAL 2006 CERTIFICATE OF ANALYSIS VALUE FOR

SRM 1082 (12.6 % ± 3.3 %) IS NO LONGER VALID SINCE THE SUBSTRATE USED TO CONDUCT TESTING

HAS CHANGED SIGNIFICANTLY.

Period of Validity: The certified value delivered by SRM 1082 is valid within the measurement uncertainty specified

until 30 June 2027. The certified values are nullified if the material is stored or used improperly, damaged, disfigured,

contaminated, or otherwise modified.

Maintenance of Certified Value: NIST will monitor this SRM over the period of its validity. NIST will conduct

stability testing every five years to ensure the ignition strength of SRM 1082 has not changed substantially. In the

event that the results of the NIST stability tests indicate ignition strength may be lower than 5 % or greater than

24 % before the expiration of this certificate, NIST will issue an amended certificate through the NIST SRM website

(https://www.nist.gov/srm) and notify registered users. SRM users can register online from a link available on the

NIST SRM website or fill out the user registration form that is supplied with the SRM at the time of purchase.

Before making use of any of the values delivered by this material, users should verify they have the most recent

version of this documentation, available free of charge through the NIST SRM website.

Jiann C Yang, Chief (Acting) Steven J. Choquette, Director

Fire Research Division Office of Reference Materials

Certificate Revision History on Page 3

SRM 1082 Page 1 of 5

Safety: THERE ARE SUBSTANTIAL SAFETY HAZARDS ASSOCIATED WITH EXPOSURE TO BOTH

PRIMARY AND SECOND-HAND SMOKE FROM CIGARETTES. THESE CIGARETTES ARE ONLY TO BE

USED UNDER THE LABORATORY CONDITIONS DESCRIBED IN ASTM E2187-16.

Storage: ASTM E2187-16 and ISO 12863 state that cigarette test specimens are to be protected from physical or

environmental damage while in handling and storage. It is important that the specimens not be crushed or deformed

in any manner. Careful handling is needed to ensure that the specimens are not contaminated while in storage, and

that they are protected from degradation by insects. If test cigarettes are not to be used for more than one week, they

are to be stored in a freezer at 0 °C (32 °F) to –20°C (–4 °F).

Use: Prior to testing, the cigarettes are to be removed from the pack(s) and conditioned at a relative humidity

of 55 % ± 5 % and a temperature of 23 °C ± 3 °C (73 °F ± 5 °F) for at least 24 h. The cigarettes are to be

placed in a clean, open container, with the number of cigarettes being sufficiently small to enable free air access to

the specimens, for example, a maximum of 20 cigarettes in a 250 mL polyethylene or glass beaker.

Material Selection and Packaging: The United States, Canada, Australia, and the European Union have enacted

legislation requiring that all cigarettes sold in their jurisdictions must not exceed 25 % full-length burns using one of

these test methods. A test consists of 40 determinations, each on a substrate consisting of 10 layers of filter paper.

The filter paper is to meet the mass requirements in Section 9.4.1 of ASTM E2187-09 (ISO 12863 in Europe) and is

to be conditioned prior to testing, as described in the ASTM and ISO standards.

Beginning in approximately 2009, the values obtained with the specified filter paper changed significantly. Therefore,

a new substrate was developed that was not significantly dependent on the filter paper [4,5]. In 2016, this additional

substrate was added to the ASTM standard. This substrate consists of a sheet of full hard 302 stainless steel shim

stock, on top of which is placed a single sheet of filter paper. The specifications for the steel and filter paper are

contained in ASTM E2187-16 [1]. ISO 12863 DOES NOT CONTAIN THIS SUBSTRATE NOR THE

SPECIFICATIONS FOR ITS USE [2].

This SRM was developed because cigarette companies, the New York Office of Fire Prevention and Control, and

Health Canada indicated a need for a standard cigarette that could be used by testing laboratories and manufacturers

to assess and control ignition strength testing to assure regulatory compliance and quality control. The planned

cigarette was to have a target ignition strength near (a) the required pass/fail criterion and (b) the value to which

cigarette companies would need to design products in order to assure success during compliance testing, which is

somewhat lower than the pass/fail criterion.

After examining several prototypes, Philip Morris USA submitted the candidate standard cigarettes to NIST. The

packs and cartons were printed to NIST specifications at the factory. The cigarettes themselves bear no markings

other than “SRM 1082.”

REFERENCES

[1] ASTM E2187; Standard Test Method for Measuring the Ignition Strength of Cigarettes; Annual Book of ASTM

Standards, Vol. 04.07; ASTM International: West Conshohocken, PA (2016).

[2] ISO 12863:2010; Standard Test Method for Assessing the Ignition Propensity of Cigarettes; 1st ed.; International

Standards Organization, TC 92/SC 1: Geneva, Switzerland (2010).

[3] Beauchamp, C.R.; Camara, J.E.; Carney, J.; Choquette, S.J.; Cole, K.D.; DeRose, P.C.; Duewer, D.L.;

Epstein, M.S.; Kline, M.C.; Lippa, K.A.; Lucon, E.; Molloy, J.; Nelson, M.A.; Phinney, K.W.; Polakoski, M.;

Possolo, A.; Sander, L.C.; Schiel, J.E.; Sharpless, K.E.; Toman, B.; Winchester, M.R.; Windover, D.;

Metrological Tools for the Reference Materials and Reference Instruments of the NIST Material Measurement

Laboratory; NIST Special Publication (NIST SP) 260-136, 2021 edition; U.S. Government Printing Office:

Washington, DC (2021); available at https://nvlpubs.nist.gov/nistpubs/SpecialPublications/NIST.SP.260-136-

2021.pdf (accessed Mar 2022).

[4] Robbins, A.P.; Gann, R.G.; Guthrie, W.F.; Identification of an Alternate Substrate for Testing Reduced Ignition

Propensity Cigarettes (2013), Proceedings the 13th International Fire Science and Engineering Conference,

Interscience Communications: London; available at https://tsapps.nist.gov/publication/get_pdf.cfm?pub_id=9

13892 (accessed Mar 2022).

[5] Gann, R.G.; Bruns, M.C.; Hnetkovsky, E.J.; Guthrie, W.F.; Interlaboratory Study of An Alternate Substrate for

Use in ASTM E2187; NIST Technical Note 1874 (2016); available at

https://www.nist.gov/publications/interlaboratory-study-alternate-substrate-use-astm-e-2187

(accessed Mar 2022).

SRM 1082 Page 2 of 5

[6] Koepke, A.; Lafarge, T.; Possolo, A.; Toman, B.; NIST Consensus Builder User’s Manual (2017); available at

https://consensus.nist.gov/app/nicob (accessed Mar 2022).

[7] JCGM 100:2008; Evaluation of Measurement Data — Guide to the Expression of Uncertainty in Measurement

(GUM 1995 with Minor Corrections); Joint Committee for Guides in Metrology (JCGM) (2008); available at

https://www.bipm.org/en/publications/guides (accessed Mar 2022); see also Taylor, B.N.; Kuyatt, C.E.;

Guidelines for Evaluating and Expressing the Uncertainty of NIST Measurement Results; NIST Technical

Note 1297, U.S. Government Printing Office: Washington, DC (1994); available at

https://www.nist.gov/pml/nist-technical-note-1297 (accessed Mar 2022).

Certificate Revision History: 21 March 2022 (Removed shipping temperature specification based on updated information; updated format;

editorial changes); 26 October 2020 (Updated ignition strength value and uncertainty; editorial changes); 08 August 2019 (Change of ignition

strength value based on new substrate for testing per ASTM E2187-16; editorial changes); 28 September 2017 (Change of expiration date; editorial

changes); 02 September 2015 (Change of expiration date; editorial changes); 28 November 2012 (References added; editorial changes);

06 May 2008 (Editorial update); 01 February 2006 (Original certificate date).

Certain commercial equipment, instruments, or materials may be identified in this Certificate of Analysis to

adequately specify the experimental procedure. Such identification does not imply recommendation or endorsement

by the National Institute of Standards and Technology, nor does it imply that the materials or equipment identified

are necessarily the best available for the purpose.

Users of this SRM should ensure that the Certificate of Analysis in their possession is current. This can be accomplished

by contacting the Office of Reference Materials 100 Bureau Drive, Stop 2300, Gaithersburg, MD 20899-2300;

telephone (301) 975-2200; e-mail srminfo@nist.gov; or the Internet at https://www.nist.gov/srm.

* * * * * * * * * * * * End of Certificate of Analysis * * * * * * * * * * * *

SRM 1082 Page 3 of 5

A PPENDIX A

Certified Ignition Strength Value Analysis: The measurand is ignition strength as defined by ASTM

Method E2187-16. The certified value and its uncertainty interval were obtained using the DerSimonian-Laird

analysis (DLA) method within the NIST Consensus Builder [6], applied to testing results separately summarized from

each cigarette carton tested. This analysis is consistent with the Guide to the Expression of Uncertainty in

Measurement (GUM) [7], and the analysis indicates moderate carton-to-carton variability in ignition strength testing

results. The modeling approach and expanded uncertainty interval accounts for random variation both within- and

between-carton. The data from each carton was modeled using individual binomial likelihood functions, and a 95 %

confidence interval was formed for the ignition strength of each carton. The resulting proportions were transformed

𝑝𝑝

via logit function (i.e., 𝑓𝑓(𝑝𝑝) = log � � ). A DLA that accommodates potential between-carton variation was used

1−𝑝𝑝

to obtain an expanded uncertainty interval. The estimated logit of ignition strength obtained via the DLA was

x

transformed back to the scale of ignition strength via the logistic function (i.e., 𝑓𝑓(𝑥𝑥) = e x ) along with endpoints of

1+e

a 95 % confidence interval chosen so that the interval is symmetric around the estimated ignition strength. The

expanded uncertainty interval provided in Table 1 is intended to represent the range within which NIST scientists

would expect the ignition strength of a single randomly selected carton of SRM 1082 cigarettes to fall with 95 %

confidence when tested at the NIST laboratory by a trained NIST scientist.

The measurand is ignition strength as defined by ASTM Method E2187-16. The certified value and its uncertainty

interval were obtained using the DerSimonian-Laird analysis (DLA) method within the NIST Consensus Builder [3],

applied to testing results separately summarized from each cigarette carton tested. This analysis is consistent with the

Guide to the Expression of Uncertainty in Measurement (GUM) [7], and the analysis indicates moderate

carton-to-carton variability in ignition strength testing results. The modeling approach and expanded uncertainty

interval accounts for random variation both within- and between-carton. The data from each carton was modeled

using individual binomial likelihood functions, and a 95 % confidence interval was formed for the ignition strength

𝑝𝑝

of each carton. The resulting proportions were transformed via logit function (i.e., 𝑓𝑓(𝑝𝑝) = log � � ). A DLA that

1−𝑝𝑝

accommodates potential between-carton variation was used to obtain an expanded uncertainty interval. The estimated

logit of ignition strength obtained via the DLA was transformed back to the scale of ignition strength via the logistic

x

function (i.e., 𝑓𝑓(𝑥𝑥) = e x ) along with endpoints of a 95 % confidence interval chosen so that the interval is

1+e

symmetric around the estimated ignition strength. The expanded uncertainty interval provided in Table 1 is intended

to represent the range within which NIST scientists would expect the ignition strength of a single randomly selected

carton of SRM 1082 cigarettes to fall with 95 % confidence when tested at the NIST laboratory by a trained NIST

scientist.

* * * * * * * * * * * End of Appendix A * * * * * * * * * * *

SRM 1082 Page 4 of 5

A PPENDIX B

Coordination of the technical measurements leading to certification was performed by R.D. Davis of the NIST Fire

Research Division.

Ignition strength measurements at NIST were made by I. Kim of the NIST Fire Research Division.

Statistical consultation on experiment design and analysis of the certification data were performed by S.P. Lund of the

NIST Statistical Engineering Division.

Support aspects involved in the issuance of this SRM were coordinated through the NIST Office of Reference

Materials.

* * * * * * * * * * * End of Appendix B * * * * * * * * * * *

SRM 1082 Page 5 of 5

You might also like

- Certificate of Analysis: National Institute of Standards & TechnologyDocument3 pagesCertificate of Analysis: National Institute of Standards & TechnologyselowestNo ratings yet

- Safety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesFrom EverandSafety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesNo ratings yet

- GBT 8626-2007 FlamabilityDocument26 pagesGBT 8626-2007 Flamabilitytiruyam@gmail.comNo ratings yet

- Oil Content of Petroleum Waxes: Standard Test Method ForDocument7 pagesOil Content of Petroleum Waxes: Standard Test Method ForahmedNo ratings yet

- Oil Content of Petroleum Waxes: Standard Test Method ForDocument7 pagesOil Content of Petroleum Waxes: Standard Test Method ForHida Al-FithriNo ratings yet

- Astm D 2863 PDFDocument13 pagesAstm D 2863 PDFFLUTEF INDUSTRIES100% (2)

- Determining Inherent Viscosity of Poly (Ethylene Terephthalate) (PET) by Glass Capillary ViscometerDocument7 pagesDetermining Inherent Viscosity of Poly (Ethylene Terephthalate) (PET) by Glass Capillary ViscometerUlul ZimiNo ratings yet

- Astm D 4603 Viscosidad Intrinseca PetDocument7 pagesAstm D 4603 Viscosidad Intrinseca Petdayanara886No ratings yet

- Astm D 2863Document13 pagesAstm D 2863Ma PonyNo ratings yet

- Firetest BS en ISO 1182 GRCDocument10 pagesFiretest BS en ISO 1182 GRCSuraj RawatNo ratings yet

- Certificate of Analysis: National Institute of Standards & TechnologyDocument3 pagesCertificate of Analysis: National Institute of Standards & Technologyvipinkala1No ratings yet

- Astm E84 21Document12 pagesAstm E84 21Mariana Rodriguez IbarraNo ratings yet

- Control of Hazards and Risk in Oxygen Enriched SystemsDocument15 pagesControl of Hazards and Risk in Oxygen Enriched Systemskuraimund100% (1)

- CR G8 2019 Rev1Document4 pagesCR G8 2019 Rev1Andhika Manggal Putra PNo ratings yet

- P100J723Document5 pagesP100J723Dennis TranquilNo ratings yet

- Nist Dicromato de PotasioDocument2 pagesNist Dicromato de PotasioSandra Lara LaraNo ratings yet

- D 3241-14a Thermal Oxidation Stability of Aviation Turbine Fuels1Document21 pagesD 3241-14a Thermal Oxidation Stability of Aviation Turbine Fuels1Ruben Perez Ayo100% (1)

- ASTM-E84-21a Drafting The Hanges of RevisionDocument12 pagesASTM-E84-21a Drafting The Hanges of Revisionfalmubarak RnoNo ratings yet

- Epa Protocol 2012Document174 pagesEpa Protocol 2012Darby Wade CornelioNo ratings yet

- Standard Reference Material 1882a Calcium Aluminate Cement: Ertificate of NalysisDocument5 pagesStandard Reference Material 1882a Calcium Aluminate Cement: Ertificate of NalysisDerekNo ratings yet

- ASTM D1929 Core Test Report PDFDocument5 pagesASTM D1929 Core Test Report PDFaziz hNo ratings yet

- Astm D3276Document14 pagesAstm D3276Chris Mendoza100% (5)

- SRM 46h Sieve 45Document4 pagesSRM 46h Sieve 45Khairil HidayahNo ratings yet

- Astm D86 23Document13 pagesAstm D86 23a.daood404No ratings yet

- 1885 ADocument3 pages1885 Atatum29No ratings yet

- D 3895 - 02 OitDocument8 pagesD 3895 - 02 Oitגבריאל קליןNo ratings yet

- OSHA 2019 0001 0456 - Attachment - 4Document3 pagesOSHA 2019 0001 0456 - Attachment - 4Franky PankyNo ratings yet

- G88 1388261-1Document26 pagesG88 1388261-1hh774747No ratings yet

- Astm C868-85 (R95)Document4 pagesAstm C868-85 (R95)Ian HsuNo ratings yet

- Determination of Contaminants in Gas Turbine and Diesel Engine Fuel by Rotating Disc Electrode Atomic Emission SpectrometryDocument7 pagesDetermination of Contaminants in Gas Turbine and Diesel Engine Fuel by Rotating Disc Electrode Atomic Emission Spectrometryاتعلم ببساطةNo ratings yet

- Astm D - 127Document2 pagesAstm D - 127wjawichNo ratings yet

- Oil Content of Petroleum Waxes: Standard Test Method ForDocument7 pagesOil Content of Petroleum Waxes: Standard Test Method ForLalo RuizNo ratings yet

- Determination of Volatile and Semi-Volatile Organic Compounds From Vehicle Interior MaterialsDocument19 pagesDetermination of Volatile and Semi-Volatile Organic Compounds From Vehicle Interior MaterialsJefferson CruzNo ratings yet

- D 648 - 00 - Rdy0oc1sruqDocument15 pagesD 648 - 00 - Rdy0oc1sruqvongoctu2016No ratings yet

- Chemical and Mass Spectrometric Analysis of Nuclear-Grade Gadolinium Oxide Powder ASTM C889-11Document3 pagesChemical and Mass Spectrometric Analysis of Nuclear-Grade Gadolinium Oxide Powder ASTM C889-11Alex NovoNo ratings yet

- Reinforced and Filled Poly (Phenylene Sulfide) (PPS) Injection Molding and Extrusion Materials Using ASTM MethodsDocument6 pagesReinforced and Filled Poly (Phenylene Sulfide) (PPS) Injection Molding and Extrusion Materials Using ASTM MethodsJosé Miguel Palomino GarciaNo ratings yet

- Astm D5191 19Document9 pagesAstm D5191 19Claudia Barrera100% (1)

- Enseigne NF P92-507 M1Document5 pagesEnseigne NF P92-507 M1thierryethkNo ratings yet

- 1889 ADocument3 pages1889 Atatum29No ratings yet

- Glycol Impurities in Mono-, Di-, Tri-And Tetraethylene Glycol and in Mono - and Dipropylene Glycol (Gas Chromatographic Method)Document11 pagesGlycol Impurities in Mono-, Di-, Tri-And Tetraethylene Glycol and in Mono - and Dipropylene Glycol (Gas Chromatographic Method)iec iecNo ratings yet

- Iecex Certificate of ConformityDocument6 pagesIecex Certificate of ConformityPhan Cao An TruongNo ratings yet

- ASTM-D5800-21 Standard Test Method For Evaporation Loss of Lubricating Oil by Noack MethodDocument13 pagesASTM-D5800-21 Standard Test Method For Evaporation Loss of Lubricating Oil by Noack MethodjesusNo ratings yet

- 1880 BDocument5 pages1880 Btatum29No ratings yet

- Fogging Characteristics of Trim Materials: Worldwide Engineering StandardsDocument11 pagesFogging Characteristics of Trim Materials: Worldwide Engineering StandardsJefferson CruzNo ratings yet

- E 603 - 01 - Rtywmy0wmq - PDFDocument18 pagesE 603 - 01 - Rtywmy0wmq - PDFYogiIndraPrayogaNo ratings yet

- FPL 2012 White001Document17 pagesFPL 2012 White001Abbasi HussainNo ratings yet

- D 3002 - 97 - RdmwmditukveDocument3 pagesD 3002 - 97 - RdmwmditukveEmre DalgicNo ratings yet

- Astm d1945 ProDocument2 pagesAstm d1945 ProCaroldamNo ratings yet

- GMW 15634Document20 pagesGMW 15634Carlos Andrés Quevedo Fernández100% (1)

- D 3238 - 95 R00 RdmymzgDocument3 pagesD 3238 - 95 R00 RdmymzgEnrique Alejandro OvandoNo ratings yet

- D 6890 - 03 - Rdy4otatmdnbDocument14 pagesD 6890 - 03 - Rdy4otatmdnbDH BNo ratings yet

- G 76 - 02 - Rzc2lvjfraDocument8 pagesG 76 - 02 - Rzc2lvjfraEnriqe PuentesNo ratings yet

- Astm D4329 21Document5 pagesAstm D4329 21Maria Aparecida Pereira DamascenoNo ratings yet

- Astm G 128 - 95Document14 pagesAstm G 128 - 95AL DOMANo ratings yet

- Iso 9773 1998Document9 pagesIso 9773 1998Juliana BarrosNo ratings yet

- Vapor Pressure of Petroleum Products and Liquid Fuels (Mini Method)Document9 pagesVapor Pressure of Petroleum Products and Liquid Fuels (Mini Method)nenad.djuricNo ratings yet

- IGS-M-TP-014-3 (2) April. 2016: Heat Shrinkable Sleeve System (Hot Melt Adhesive) For Service Temperature Up To 80 CDocument17 pagesIGS-M-TP-014-3 (2) April. 2016: Heat Shrinkable Sleeve System (Hot Melt Adhesive) For Service Temperature Up To 80 CTa GiNo ratings yet

- E 2187 - 02 - RtixodctmdiDocument7 pagesE 2187 - 02 - RtixodctmdiYogiIndraPrayogaNo ratings yet

- Chapter 8 - Linkage, Crossing Over Chromosome Mapping in Eukaryotes 5 DecDocument44 pagesChapter 8 - Linkage, Crossing Over Chromosome Mapping in Eukaryotes 5 DecselowestNo ratings yet

- Teaching Methods in Practical Lab: 1.4 Theoretical/Conceptual FrameworkDocument5 pagesTeaching Methods in Practical Lab: 1.4 Theoretical/Conceptual FrameworkselowestNo ratings yet

- Lab Report 2Document8 pagesLab Report 2selowestNo ratings yet

- Recombinant DNA TechnologyDocument108 pagesRecombinant DNA TechnologyselowestNo ratings yet

- Genes and GenomesDocument66 pagesGenes and GenomesselowestNo ratings yet

- Arc Welding: Consumable ElectrodesDocument14 pagesArc Welding: Consumable ElectrodesselowestNo ratings yet

- En 50383-2010Document80 pagesEn 50383-2010hung311aNo ratings yet

- 0341-ID-A Practical Guide For The Estimation of Uncertainty in TestingDocument33 pages0341-ID-A Practical Guide For The Estimation of Uncertainty in TestinglthyaguNo ratings yet

- Experiment To Find The Value of Acceleration Due To Gravity: December 2019Document6 pagesExperiment To Find The Value of Acceleration Due To Gravity: December 2019Apoorv BelgundiNo ratings yet

- Ralat Dan Perambatan Ralat (Kuliah3)Document33 pagesRalat Dan Perambatan Ralat (Kuliah3)Cassandra FitriannaNo ratings yet

- F1lyon 0322Document6 pagesF1lyon 0322Muhammad SulaimanNo ratings yet

- Chapter 03 Radiation Dosimeters PDFDocument113 pagesChapter 03 Radiation Dosimeters PDFJose Ivan MejiaNo ratings yet

- Cambridge International AS & A Level: PHYSICS 9702/31Document12 pagesCambridge International AS & A Level: PHYSICS 9702/31sangdeepNo ratings yet

- Introduction To Risk: Learning OutcomesDocument22 pagesIntroduction To Risk: Learning OutcomesChristen CastilloNo ratings yet

- Volumetric Equation Approaches in Mishrif - Amara Oil FieldDocument10 pagesVolumetric Equation Approaches in Mishrif - Amara Oil FieldKalou BoniNo ratings yet

- KM66 CRD Project PDFDocument12 pagesKM66 CRD Project PDFHector Felix Gonzalez RamirezNo ratings yet

- TerrorismDocument89 pagesTerrorismMiguel CerdaNo ratings yet

- Chapter 5Document19 pagesChapter 5gasim kerimovNo ratings yet

- Qing Wu 2006 - Cost Overrun Risk AnalysisDocument77 pagesQing Wu 2006 - Cost Overrun Risk AnalysisTAHER AMMARNo ratings yet

- Bartlett Hong Zhou 2003Document12 pagesBartlett Hong Zhou 2003Luc ChiassonNo ratings yet

- AnyLogic Supply Chain Simulation and Optimization WhitepaperDocument23 pagesAnyLogic Supply Chain Simulation and Optimization WhitepaperSaid BasalimNo ratings yet

- Unit 1 Measurement and UncertaintiesDocument1 pageUnit 1 Measurement and UncertaintiesGajendraNo ratings yet

- Crisis and Crisis Management - A Contribution To A Conceptual & Terminological DelimitationDocument19 pagesCrisis and Crisis Management - A Contribution To A Conceptual & Terminological Delimitationroumaissaamrane06No ratings yet

- EURAMET Cg-12 V 2.0 Guidelines On EvaluationDocument24 pagesEURAMET Cg-12 V 2.0 Guidelines On EvaluationRichard FloresNo ratings yet

- Findling&Wyart - 2021 - Computation Noise in Human Learning Anddecision-Making Origin, Impact, FunctionDocument9 pagesFindling&Wyart - 2021 - Computation Noise in Human Learning Anddecision-Making Origin, Impact, FunctionBeth LloydNo ratings yet

- The Mental Block in TradingDocument5 pagesThe Mental Block in TradingAmbadnya-Amogh AnbhavaneNo ratings yet

- A Critical Review of Measurement Uncertainty in The Enumeration of Food Micro-Organisms - Pdf-Cdekey - DSLKOK4FQDJRD7OZ2ZGTG6FNJSRZAZ24Document24 pagesA Critical Review of Measurement Uncertainty in The Enumeration of Food Micro-Organisms - Pdf-Cdekey - DSLKOK4FQDJRD7OZ2ZGTG6FNJSRZAZ24Carolina MontoyaNo ratings yet

- Probability Theory: Uncertainty Measure: Lecture Module 23Document32 pagesProbability Theory: Uncertainty Measure: Lecture Module 23AdityaNo ratings yet

- Uncertainties and Errors LabDocument13 pagesUncertainties and Errors LabjulianaNo ratings yet

- ACCURACY AND PRECISION and PERCENT UNCERTAINTYDocument27 pagesACCURACY AND PRECISION and PERCENT UNCERTAINTYKrizthel RockwellNo ratings yet

- Applied Statistics: ProbabilityDocument14 pagesApplied Statistics: Probabilityiiyousefgame YTNo ratings yet

- Provision Contingent LiabilityDocument14 pagesProvision Contingent LiabilityAngelica IrincoNo ratings yet

- 0015 - Planning Using The Project Planning Matrix (PPM) - MethodDocument0 pages0015 - Planning Using The Project Planning Matrix (PPM) - MethodAndre SaputraNo ratings yet

- RRLDocument3 pagesRRLPaul Torrecampo100% (1)

- TH1018CDDocument73 pagesTH1018CDsaroj maharjanNo ratings yet

- DoigeDocument11 pagesDoigeHarikirshna ReddyNo ratings yet

- Analog Design and Simulation Using OrCAD Capture and PSpiceFrom EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNo ratings yet

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsFrom EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNo ratings yet

- Lean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsFrom EverandLean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsRating: 4 out of 5 stars4/5 (2)

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceFrom EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceRating: 4 out of 5 stars4/5 (19)

- Laws of UX: Using Psychology to Design Better Products & ServicesFrom EverandLaws of UX: Using Psychology to Design Better Products & ServicesRating: 5 out of 5 stars5/5 (9)

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsFrom EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsRating: 5 out of 5 stars5/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersFrom EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersRating: 4 out of 5 stars4/5 (13)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- Basic Electric Circuits: Pergamon International Library of Science, Technology, Engineering and Social StudiesFrom EverandBasic Electric Circuits: Pergamon International Library of Science, Technology, Engineering and Social StudiesRating: 3 out of 5 stars3/5 (1)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tFrom EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tRating: 4.5 out of 5 stars4.5/5 (27)