Professional Documents

Culture Documents

PURICOMPACT Eng Rev01

Uploaded by

FernandoSanfigOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PURICOMPACT Eng Rev01

Uploaded by

FernandoSanfigCopyright:

Available Formats

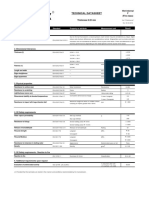

PURICOMPACT

MATERIAL PROPERTIES DATA SHEET

PURICOMPACT is a high pressure decorative laminates (HPL), having thickness 2 mm or greater, according to EN 438-1:2016, EN 438-2:2016 and EN 438-4:2016.

The core is composed of layers of kraft paper impregnated with thermosetting resins. The decorative surface in both sides is made of paper impregnated with aminoplastic

thermosetting resins. All the layers are bonded together by a high pressure and high temperature process to obtain a high density homogeneous non-porous material.

PURICOMPACT is available in standard CGS type and flame retardant CGF type according to EN 438-4:2016.

CGS - CGF

PROPERTIES TEST METHOD PROPERTY OR ATTRIBUTE VALUES UNIT

GENERAL PROPERTIES

Spots, dirt and similar surface defects ≤1 mm2/m2

Surface quality EN 438-2:2016 Par. 4

Fibers, hair and scratches ≤ 10 mm/m2

± 0,20 2,0 ≤ t < 3,0

± 0,30 3,0 ≤ t < 5,0

EN 438-2:2016 Par. 5 Thickness (1) ± 0,40 5,0 ≤ t < 8,0 mm

± 0,50 8,0 ≤ t < 12,0

± 0,60 12,0 ≤ t < 16,0

EN 438-2:2016 Par. 6 Length and width + 10 / - 0 mm

Dimensional tolerances

EN 438-2:2016 Par. 7 Straightness of edges ≤ 1,5 mm/m

EN 438-2:2016 Par. 8 Squareness ≤ 1,5 mm/m

≤ 8,0 2,0 ≤ t < 6,0

EN 438-2:2016 Par. 9 Flatness (measured on full-size sheet) ≤ 5,0 6,0 ≤ t < 10,0 mm/m

≤ 3,0 t ≥ 10,0

PHYSICAL PROPERTIES

≤5 2,0 ≤ t < 5,0

Mass increase %

≤2 t ≥ 5,0

≤6 2,0 ≤ t < 5,0

Thickness increase %

Resistance to immersion in boiling water EN 438-2:2016 Par. 12 ≤2 t ≥ 5,0

≥3 gloss finish

Surface appearance Rating

≥4 other finishes

Edge appearance ≥3 Rating

≤ 0,4 2,0 ≤ t < 5,0

Longitudinal % (2)

≤ 0,3 t ≥ 5,0

Dimensional stability at elevated temperatures EN 438-2:2016 Par. 17 Cumulative dimensional change

≤ 0,8 2,0 ≤ t < 5,0

Transversal % (2)

≤ 0,6 t ≥ 5,0

Drop height ≥ 1400 2,0 ≤ t < 6,0

Resistance to impact by large diameter ball EN 438-2:2016 Par. 21 ≥ 1800 t ≥ 6,0 mm

Indent diameter ≤ 10

Resistance to crazing EN 438-2:2016 Par. 24 Appearance ≥4 Rating

Density EN ISO 1183 Density ≥ 1,35 g/cm3

Flexural modulus EN ISO 178 Stress ≥ 9000 MPa

Flexural strength EN ISO 178 Stress ≥ 80 Mpa

SURFACE PROPERTIES

Resistance to surface wear EN 438-2:2016 Par. 10 Initial point ≥ 50 Revolutions

≥3 gloss finish

Resistance to water vapour EN 438-2:2016 Par. 14 Appearance Rating

≥4 other finishes

≥3 gloss finish

Resistance to dry heat (160°C) EN 438-2:2016 Par. 16 Appearance Rating

≥4 other finishes

≥3 gloss finish

Resistance to wet heat (100°C) EN 438-2:2016 Par. 18 Appearance Rating

≥4 other finishes

≥2 for smooth finishes

Resistance to scratching EN 438-2:2016 Par. 25 Force Rating

≥3 for textured finishes

5 groups 1 & 2

Resistance to staining EN 438-2:2016 Par. 26 Appearance Rating

≥4 group 3

Light Fastness (Xenon-arc) EN 438 -2:2016 Par. 27 Contrast ≥4 Grey scale rating

Page 1 of 2 | www.puricelli-group.com | Rev.0 26/03/20

PURICOMPACT

MATERIAL PROPERTIES DATA SHEET

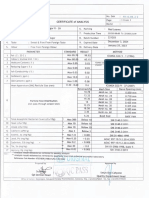

FIRE PERFORMANCES

Classification - CGS wood frame D-s2,d0

Reaction to fire (3) EN 13501 class

Classification - CGF metal frame B-s1,d0

FOOD & HYGIENE PROPERTIES

Acetic acid 3 % ≤ 10

Ethanol 50 % ≤ 10

Contact with food - overall migration EN 1186 mg/dm2

Ethanol 95 % ≤ 10

Isooctane ≤ 10

ENVIRONMENTAL PROPERTIES

Formaldehyde emission EN 13986 Formaldehyde emission rating E1 Rating

Classification A+ Rating

Volatile organic chemical emission AFNOR NF EN ISO 16000-9

TVOC emission ≤ 0,2 mg/m3

Phenol Free (4) AFNOR NF EN ISO 16000-9 Phenol emission < 0,002 mg/m3

Notes

(1) t: nominal thickness [mm]

(2) Longitudinal: parallel to the fiber direction (usually parallel to the direction of sanding). Transversal: at right angles to the fiber direction

(3) Please contact the manufacturer for more details on the fire tests performed and the certificates held

(4) Phenol is not used as raw material in PURICOMPACT production. 0,002 mg/m3 is the detection limit (DL) value of the test.

Note to PURICOMPACT sheets with adhesive protective film

The protective films are designed for temporary surface protection against dirt, scratches and tool marks; they are not designed for protection against corrosion, humidity or

chemicals. The laminates covered with the protective film shall be stored in a clean, dry place (40 to 60 RH%) at room temperature (20 to 25 °C), avoiding weathering and

UV exposure. In any case, the removal must be made within four months from the date of shipment by Puricelli. Puricelli cannot be responsible for the misuse of the laminates

covered with the protective film, nor for the consequences for non-recommended applications.

Page 2 of 2 | www.puricelli-group.com | Rev.0 26/03/20

You might also like

- FTD00078 enDocument2 pagesFTD00078 enGuilherme P MachadoNo ratings yet

- En 1090 2 Ex3 PDFDocument1 pageEn 1090 2 Ex3 PDFlai nguyenNo ratings yet

- Agriculture Agricultural Produce Biological Asset Bearer PlantDocument2 pagesAgriculture Agricultural Produce Biological Asset Bearer PlantGayle LalloNo ratings yet

- PTTEP Asset MalaysiaDocument19 pagesPTTEP Asset Malaysia2013246572100% (1)

- Yinlu Bicol Mining Corp Vs Trans-Asia OilDocument2 pagesYinlu Bicol Mining Corp Vs Trans-Asia OilmarvinNo ratings yet

- EN-GB8308 - TopLab Vertical Material Properties - 2.1Document2 pagesEN-GB8308 - TopLab Vertical Material Properties - 2.1OnebigunicornNo ratings yet

- Tu Kompakt-plita Arpa (Yadro v Kolіr)Document2 pagesTu Kompakt-plita Arpa (Yadro v Kolіr)wasyl.dawydenkoNo ratings yet

- KRONOSPANDocument1 pageKRONOSPANRely TokNo ratings yet

- Coa TotmDocument1 pageCoa TotmOsmar ContrerasNo ratings yet

- ASD Gama Lab TopDocument9 pagesASD Gama Lab Topdaniela ratuleaNo ratings yet

- GhoseDocument2 pagesGhoseRifqi RizqullahNo ratings yet

- Chloroprene Latex Cement Mortar CFLDDocument2 pagesChloroprene Latex Cement Mortar CFLDhjsassoNo ratings yet

- 06 Requirements For Polymer Modified Road Bitumens en PDFDocument2 pages06 Requirements For Polymer Modified Road Bitumens en PDFAnonymous R0VFaZQNo ratings yet

- Aisin Long Life Coolant Premixed 20 PDSDocument2 pagesAisin Long Life Coolant Premixed 20 PDSAmir AhmedNo ratings yet

- 2 酸性硅酮胶tds 模板Document2 pages2 酸性硅酮胶tds 模板QiChen GlueNo ratings yet

- CPE Bag TDS C-Top PDFDocument1 pageCPE Bag TDS C-Top PDFcuet cuetNo ratings yet

- CAR Abrasion Resistant AR Plus High Gloss Coloured Core Thin HPL StandardDocument1 pageCAR Abrasion Resistant AR Plus High Gloss Coloured Core Thin HPL StandardAnonymous FGzNDzIeJNo ratings yet

- JRG CapacitorsDocument2 pagesJRG Capacitorsmarina anastasovaNo ratings yet

- TDS - Insulation PressboardDocument2 pagesTDS - Insulation PressboardRoger FloresNo ratings yet

- Technical Datasheet: Tests Standard Property or Attribute Measurement Unit ResultDocument1 pageTechnical Datasheet: Tests Standard Property or Attribute Measurement Unit ResultRaul AntonieNo ratings yet

- SEAM 1210 (수정본)Document1 pageSEAM 1210 (수정본)Shyam SunderNo ratings yet

- Standard Specification: MHZ Crystals UnitsDocument1 pageStandard Specification: MHZ Crystals UnitsXJ YangNo ratings yet

- 5+MTC+Ultrafine Week+No.+27Document1 page5+MTC+Ultrafine Week+No.+27Mathi Vinoth PillaiNo ratings yet

- Fisa Tehnica Panouri Din Lemn Pentru Placari Exterioare-Parklex Facade FDocument1 pageFisa Tehnica Panouri Din Lemn Pentru Placari Exterioare-Parklex Facade FPopa MarianNo ratings yet

- Testing ReportDocument1 pageTesting ReportfaizNo ratings yet

- Ervin Germany GMBH - Rudower Chaussee 48 - 12489 Berlin - GermanyDocument2 pagesErvin Germany GMBH - Rudower Chaussee 48 - 12489 Berlin - GermanyreynaldoUHNo ratings yet

- MedanDocument1 pageMedannandatuahsyahalamNo ratings yet

- Specification Wood PelletDocument1 pageSpecification Wood PelletnandatuahsyahalamNo ratings yet

- Gas Oil Flowmeter SizingDocument4 pagesGas Oil Flowmeter SizingahmedNo ratings yet

- AluminizedDocument4 pagesAluminizedmarkengineerNo ratings yet

- Reliability Test Analogy The Seaside Salty EnvironmentDocument1 pageReliability Test Analogy The Seaside Salty EnvironmentIsmail MohammadNo ratings yet

- Line - Pipe - IS - TOLERANCE ON OUTSIDE DIAMETER, WALL THICKNESS, WEIGHT AND LENGTH OF PIPEDocument3 pagesLine - Pipe - IS - TOLERANCE ON OUTSIDE DIAMETER, WALL THICKNESS, WEIGHT AND LENGTH OF PIPECristi DemNo ratings yet

- G-Com TDSDocument2 pagesG-Com TDSSasi Kiran VundamatlaNo ratings yet

- Titanium Dioxide - R2Document1 pageTitanium Dioxide - R2Md Merajul IslamNo ratings yet

- C Si MN Thickness (MM) Yield Point (Mpa) Tensile Strength (Mpa) Elongation (%) Bend Test (In Radius) F S Applicable Thickness (MM) SpecDocument1 pageC Si MN Thickness (MM) Yield Point (Mpa) Tensile Strength (Mpa) Elongation (%) Bend Test (In Radius) F S Applicable Thickness (MM) SpecEri Dya FadliNo ratings yet

- Corning Fused Silica 7980Document4 pagesCorning Fused Silica 7980Mandi IndarsNo ratings yet

- General Regulations Part 3, Chapter 1: Table 1.8.5 Structural Misalignment and Fit (Steel and Aluminium)Document4 pagesGeneral Regulations Part 3, Chapter 1: Table 1.8.5 Structural Misalignment and Fit (Steel and Aluminium)khairulNo ratings yet

- Brief Introduction of UHMWPEDocument3 pagesBrief Introduction of UHMWPEFatima NusserNo ratings yet

- KoenigDocument14 pagesKoenigUday GurijalaNo ratings yet

- Gard Analog Transmitter: DescriptionDocument3 pagesGard Analog Transmitter: DescriptionÖzgürNo ratings yet

- Etd44 PDFDocument5 pagesEtd44 PDFChAmirShokatGujjarNo ratings yet

- Span Vs SPHTDocument1 pageSpan Vs SPHTNizar NazriNo ratings yet

- D Civ Cab Ldpe - 00Document5 pagesD Civ Cab Ldpe - 00HARINo ratings yet

- Coa 221203Document1 pageCoa 221203Asha Dicka Purchasing PT. Sin A 615No ratings yet

- Sandy Beach GranigliaDocument2 pagesSandy Beach GranigliaCamilo Ponce de LeonNo ratings yet

- FT 022 Sensor de Monoxido Carbono MSR Ma 0 1110 Carbon Monoxide Gas SensorDocument3 pagesFT 022 Sensor de Monoxido Carbono MSR Ma 0 1110 Carbon Monoxide Gas SensorAydee ArangurenNo ratings yet

- Technical Data - Epoxy Dotted PaperDocument1 pageTechnical Data - Epoxy Dotted PaperMly Saad BoudiafNo ratings yet

- 1050 Data Sheet: Chemical CompositionDocument1 page1050 Data Sheet: Chemical CompositionMiguel Angel Rocca HuaytaNo ratings yet

- Tech SpectDocument1 pageTech SpectLiezl FanoeNo ratings yet

- Test Report & Inspection CertificateDocument1 pageTest Report & Inspection CertificateAji HatmantoNo ratings yet

- NIC Components NRE-LS SeriesDocument5 pagesNIC Components NRE-LS SeriesNICCompNo ratings yet

- Akf392 Mems Digital AccelerometerDocument16 pagesAkf392 Mems Digital AccelerometerYudha Panji RahmanNo ratings yet

- Compare S355J2+N, St52-3, Fe510DDocument4 pagesCompare S355J2+N, St52-3, Fe510DGANESHNo ratings yet

- TSPP CoaDocument1 pageTSPP CoabcjskcNo ratings yet

- Aluminum Hydroxide Data SheetDocument1 pageAluminum Hydroxide Data Sheetjlvieira1994No ratings yet

- QF Qa 30 Visual Dimension Final Inspection ReportDocument8 pagesQF Qa 30 Visual Dimension Final Inspection ReportVikas Mani TripathiNo ratings yet

- Features: SLP Series Model 33Document2 pagesFeatures: SLP Series Model 33CarlosDíazPeñaNo ratings yet

- Sensirion SPS30 Particulate Matter Sensor v0.9 D1 1Document20 pagesSensirion SPS30 Particulate Matter Sensor v0.9 D1 1Jimmy PiñaNo ratings yet

- Direct-Hardening: Free-Cutting Steels 35S20Document1 pageDirect-Hardening: Free-Cutting Steels 35S20Biaizidi Abbou SamirNo ratings yet

- PBT TDS 190305Document1 pagePBT TDS 190305Carlos AgianiNo ratings yet

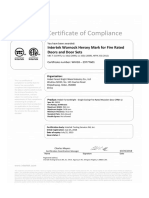

- D&D Hardware-Panic Device Catalogue-UL CertificateDocument27 pagesD&D Hardware-Panic Device Catalogue-UL CertificateFernandoSanfigNo ratings yet

- D&D Hardware-Door Closer UL-R40717Document2 pagesD&D Hardware-Door Closer UL-R40717FernandoSanfigNo ratings yet

- Automatic Hermetic Door Instruction - VERDocument32 pagesAutomatic Hermetic Door Instruction - VERFernandoSanfigNo ratings yet

- Catalog-Automatic Medical Door - OptDocument8 pagesCatalog-Automatic Medical Door - OptFernandoSanfigNo ratings yet

- 20 MIN To 90 MIN WH Fire Door Certificates - YUKIDocument7 pages20 MIN To 90 MIN WH Fire Door Certificates - YUKIFernandoSanfigNo ratings yet

- HAWA Junior 120 - 250 ADocument3 pagesHAWA Junior 120 - 250 AFernandoSanfigNo ratings yet

- Research Paper - Roles of Commercial Bank in IndiaDocument9 pagesResearch Paper - Roles of Commercial Bank in Indiasalman.wajidNo ratings yet

- 2023 - ECON422 - TURKISH ECONOMY - HOMEWORK - Final VersionDocument3 pages2023 - ECON422 - TURKISH ECONOMY - HOMEWORK - Final VersionsenaNo ratings yet

- Productivity o F Labor in The Cotton-Garm Ent Industry: United States Department of LaborDocument147 pagesProductivity o F Labor in The Cotton-Garm Ent Industry: United States Department of LaborZoya KhanNo ratings yet

- Factors Affecting Foreign Direct InvestmentDocument17 pagesFactors Affecting Foreign Direct Investmentbenki megeriNo ratings yet

- Chain RegisterDocument2 pagesChain RegisterAseem SinghNo ratings yet

- Bijahan Coal BlockDocument2 pagesBijahan Coal BlockPryas JainNo ratings yet

- Preferences For TNAU UG Admission 2019: Registration Number: Name of CandidateDocument3 pagesPreferences For TNAU UG Admission 2019: Registration Number: Name of CandidateRaja RajNo ratings yet

- North Perimeter Highway Public Engagement PresentationDocument22 pagesNorth Perimeter Highway Public Engagement PresentationChrisDcaNo ratings yet

- REINSURANCEDocument22 pagesREINSURANCENURUL AIN NAJIHAH TUKIRANNo ratings yet

- KPT G287 ORDR PASD 21.06.2016 Anx I SORDocument30 pagesKPT G287 ORDR PASD 21.06.2016 Anx I SORAbhishek KumarNo ratings yet

- Assesment Report 2Document27 pagesAssesment Report 2Mohd Shazwan DzulkefliNo ratings yet

- FRIGOMILK G9 From 2.000 LT To 30.000 LTDocument2 pagesFRIGOMILK G9 From 2.000 LT To 30.000 LTJorge PontonNo ratings yet

- Synthesis EssayDocument3 pagesSynthesis EssayGuruPrakash CNo ratings yet

- Group Assignment ECO162Document4 pagesGroup Assignment ECO162Noor SyazaniNo ratings yet

- Jimma UniversityDocument19 pagesJimma UniversityFirinsifNo ratings yet

- Agriculture Marketing in Bangladesh - FinalDocument27 pagesAgriculture Marketing in Bangladesh - FinalGopal Kumar DasNo ratings yet

- Class 12 Development ExperiencesDocument5 pagesClass 12 Development ExperiencesAryan ph vlogsNo ratings yet

- The Urban Game 2 0Document14 pagesThe Urban Game 2 0api-233855004No ratings yet

- Industrial Finance Corporation of India (Ifci)Document18 pagesIndustrial Finance Corporation of India (Ifci)Abhishek GuptaNo ratings yet

- Eisa Annex 02 Maps and DrawingsDocument73 pagesEisa Annex 02 Maps and Drawingscentaury2013No ratings yet

- MSMEDocument3 pagesMSMEPratik TandelNo ratings yet

- Ipa Summit Albania Presentation To Belgrade enDocument42 pagesIpa Summit Albania Presentation To Belgrade enab theproNo ratings yet

- 1-Well Completion I PDFDocument20 pages1-Well Completion I PDFHomam MohammadNo ratings yet

- NMMT - NMMC Types of Bus BusDocument3 pagesNMMT - NMMC Types of Bus Busharish guptaNo ratings yet

- Mine-Opening I Coal and Mineral Sector Opportunities: Home - Kpmg/inDocument40 pagesMine-Opening I Coal and Mineral Sector Opportunities: Home - Kpmg/inSuvamosmeNo ratings yet

- CARP Research Paper PDFDocument106 pagesCARP Research Paper PDFNatty ArcellaNo ratings yet

- Traffic in Towns Was An Influential Report and Popular Book OnDocument11 pagesTraffic in Towns Was An Influential Report and Popular Book OnmllabateNo ratings yet