Professional Documents

Culture Documents

RS8000 GBC46 MSDS

Uploaded by

Service DeskCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RS8000 GBC46 MSDS

Uploaded by

Service DeskCopyright:

Available Formats

Conforms to ANSI Z400.1-2004 Standard (United States, Canada).

Material Safety Data Sheet

R

Synthetic Gear, Bearing, Compressor Oil ISO-46

Date : 08/15/2012

Section 1. Product and company identification Version : 3

Product name Code

Synthetic Gear, Bearing, Compressor Oil ISO-46 GBC46

Material uses MSDS authored by

Lubricating Fluid. Not to be misted. SEVERUS INC.

Supplier/Manufacturer In case of emergency

SEVERUS INC. CHEMTREC, U.S. : 1-800-424-9300

2206 Winter Street International: +1-703-527-3887

Superior, WI 54880

Section 2. Hazards identification

Emergency overview

Color : Straw. [Light]

Physical state : Liquid.

Odor : Mild hydrocarbon.

Hazard statements : NOT EXPECTED TO PRODUCE SIGNIFICANT ADVERSE HEALTH EFFECTS WHEN

THE RECOMMENDED INSTRUCTIONS FOR USE ARE FOLLOWED.

Precautions : No known significant effects or critical hazards. Avoid prolonged contact with eyes, skin

and clothing.

OSHA/HCS status : While this material is not considered hazardous by the OSHA Hazard Communication

Standard (29 CFR 1910.1200), this MSDS contains valuable information critical to the

safe handling and proper use of the product. This MSDS should be retained and

available for employees and other users of this product.

Routes of entry : Dermal contact. Eye contact. Inhalation. Ingestion.

Potential acute health effects

Inhalation : No known significant effects or critical hazards.

Ingestion : No known significant effects or critical hazards.

Skin : No known significant effects or critical hazards.

Eyes : No known significant effects or critical hazards.

Potential chronic health effects

Chronic effects : No known significant effects or critical hazards.

Carcinogenicity : No known significant effects or critical hazards.

Mutagenicity : No known significant effects or critical hazards.

Teratogenicity : No known significant effects or critical hazards.

Developmental effects : No known significant effects or critical hazards.

Fertility effects : No known significant effects or critical hazards.

Over-exposure signs/symptoms

Inhalation : No specific data.

Ingestion : No specific data.

Skin : No specific data.

Eyes : No specific data.

1/6 Date of issue : 08/15/2012

Synthetic Gear, Bearing, Compressor Oil ISO-46 GBC46

Medical conditions : None known.

aggravated by overexposure

See toxicological information (Section 11)

Section 3. Composition/information on ingredients

There are no ingredients present which, within the current knowledge of the supplier and in the concentrations

applicable, are classified as hazardous to health or the environment and hence require reporting in this section.

Section 4. First aid measures

Eye contact : Immediately flush eyes with plenty of water for at least 20 minutes, occasionally lifting

the upper and lower eyelids. Get medical attention if symptoms occur.

Skin contact : After contact with skin, wash immediately with plenty of soap and water. Get medical

attention if symptoms occur.

Inhalation : Move exposed person to fresh air. Get medical attention if symptoms occur.

Ingestion : Wash out mouth with water. Do not induce vomiting unless directed to do so by medical

personnel. Never give anything by mouth to an unconscious person. Get medical

attention if symptoms occur.

Notes to physician : No specific treatment. Treat symptomatically. Contact poison treatment specialist

immediately if large quantities have been ingested or inhaled.

Section 5. Fire-fighting measures

Flammability of the product : No specific fire or explosion hazard.

Extinguishing media

Suitable : Use an extinguishing agent suitable for the surrounding fire.

Not suitable : None known.

Hazardous decomposition : Decomposition products may include the following materials:

products carbon dioxide

carbon monoxide

Special protective : No special protection is required.

equipment for fire-fighters

Section 6. Accidental release measures

Personal precautions : Put on appropriate personal protective equipment (see Section 8).

Environmental precautions : Avoid dispersal of spilled material and runoff and contact with soil, waterways, drains

and sewers. Inform the relevant authorities if the product has caused environmental

pollution (sewers, waterways, soil or air).

Methods for cleaning up

Small spill : Absorb with an inert dry material and place in an appropriate waste disposal container.

Dispose via a licensed waste disposal contractor.

Large spill : Prevent entry into sewers, water courses, basements or confined areas. Wash spillages

into an effluent treatment plant or proceed as follows. Contain and collect spillage with

non-combustible, absorbent material e.g. sand, earth, vermiculite or diatomaceous earth

and place in container for disposal according to local regulations (see Section 13).

Dispose via a licensed waste disposal contractor. Note: see section 1 for emergency

contact information and section 13 for waste disposal.

2/6 Date of issue : 08/15/2012

Synthetic Gear, Bearing, Compressor Oil ISO-46 GBC46

Section 7. Handling and storage

Handling : Put on appropriate personal protective equipment (see Section 8). Avoid contact with

used product. Eating, drinking and smoking should be prohibited in areas where this

material is handled, stored and processed. Workers should wash hands and face before

eating, drinking and smoking. Do not reuse container.

Storage : Store in accordance with local regulations. Store in original container protected from

direct sunlight in a dry, cool and well-ventilated area, away from incompatible materials

(see section 10) and food and drink. Keep container tightly closed and sealed until ready

for use. Containers that have been opened must be carefully resealed and kept upright

to prevent leakage. Do not store in unlabeled containers. Use appropriate containment

to avoid environmental contamination.

Section 8. Exposure controls/personal protection

Under conditions which may generate mists, the following exposure limits are recommended:

ACGIH TLV TWA: 5 mg/m³ ; STEL: 10 mg/m³.

Consult local authorities for acceptable exposure limits.

Recommended monitoring : Personal, workplace atmosphere or biological monitoring may be required to determine

procedures the effectiveness of the ventilation or other control measures and/or the necessity to use

respiratory protective equipment.

Engineering measures : No special ventilation requirements. Good general ventilation should be sufficient to

control worker exposure to airborne contaminants.

Hygiene measures : Wash hands, forearms and face thoroughly after handling chemical products, before

eating, smoking and using the lavatory and at the end of the working period.

Respiratory : Respirator selection must be based on known or anticipated exposure levels, the

hazards of the product and the safe working limits of the selected respirator. Not

required under normal conditions of use.

Hands : Not required under normal conditions of use. Use gloves appropriate for work or task

being performed.

Eyes : Not required under normal conditions of use. Safety eyewear should be used when

there is a likelihood of exposure. Recommended: Safety glasses with side shields.

Skin : No special protective clothing is required.

Environmental exposure : Emissions from ventilation or work process equipment should be checked to ensure they

controls comply with the requirements of environmental protection legislation.

Section 9. Physical and chemical properties

Physical state : Liquid. Odor : Mild hydrocarbon.

Color : Straw. [Light] pH : Not available.

Flash point : Open cup: 252°C (485.6°F) [Cleveland.] Auto-ignition : Not available.

temperature

Flammable limits : Not available. Melting point/ : -48°C (-54.4°F)

Pour point

Boiling point : Not available. Vapor pressure : Not available.

Relative density : 0.8408 Vapor density : Not available.

Volatility : Not available. Evaporation rate : Not available.

Viscosity : Kinematic: 0.073 cm2/s (7.3 cSt) (100oC) Solubility : Not available.

Kinematic: 0.429 cm2/s (42.9 cSt) (40oC)

3/6 Date of issue : 08/15/2012

Synthetic Gear, Bearing, Compressor Oil ISO-46 GBC46

Section 10. Stability and reactivity

Chemical stability : The product is stable.

Conditions to avoid : No specific data.

Materials to avoid : Reactive or incompatible with the following materials: oxidizing materials.

Hazardous decomposition : Under normal conditions of storage and use, hazardous decomposition products should

products not be produced.

Possibility of hazardous : Under normal conditions of storage and use, hazardous reactions will not occur.

reactions

Hazardous polymerization : Under normal conditions of storage and use, hazardous polymerization will not occur.

Section 11. Toxicological information

Acute toxicity

There is no data available.

Chronic toxicity

There is no data available.

Irritation/Corrosion

Skin : There is no data available.

Eyes : There is no data available.

Respiratory : There is no data available.

Sensitizer

Skin : There is no data available.

Respiratory : There is no data available.

Carcinogenicity

There is no data available.

Mutagenicity

There is no data available.

Teratogenicity

There is no data available.

Reproductive toxicity

There is no data available.

Section 12. Ecological information

Ecotoxicity : No known significant effects or critical hazards.

Aquatic ecotoxicity

There is no data available.

Persistence/degradability

There is no data available.

4/6 Date of issue : 08/15/2012

Synthetic Gear, Bearing, Compressor Oil ISO-46 GBC46

Section 13. Disposal considerations

Waste disposal : The generation of waste should be avoided or minimized wherever possible. Avoid

dispersal of spilled material and runoff and contact with soil, waterways, drains and

sewers. Empty containers or liners may retain some product residues. Dispose of

surplus and non-recyclable products via a licensed waste disposal contractor.

Disposal should be in accordance with applicable regional, national and local laws and regulations.

Refer to Section 7: HANDLING AND STORAGE and Section 8: EXPOSURE CONTROLS/PERSONAL PROTECTION for additional handling

information and protection of employees.

Section 14. Transport information

DOT/TDG/IMDG/IATA : Not regulated.

Section 15. Regulatory information

United States

HCS Classification : Not regulated.

U.S. Federal regulations : United States inventory (TSCA 8b): Not determined.

SARA 302/304/311/312 extremely hazardous substances: No products were found.

SARA 302/304 emergency planning and notification: No products were found.

SARA 302/304/311/312 hazardous chemicals: No products were found.

SARA 311/312 MSDS distribution - chemical inventory - hazard identification: No

products were found.

Clean Air Act Section : Not listed

112(b) Hazardous Air

Pollutants (HAPs)

Clean Air Act Section 602 : Not listed

Class I Substances

Clean Air Act Section 602 : Not listed

Class II Substances

DEA List I Chemicals : Not listed

(Precursor Chemicals)

DEA List II Chemicals : Not listed

(Essential Chemicals)

State regulations

Massachusetts : None of the components are listed.

New York : None of the components are listed.

New Jersey : The following components are listed: Distillates (petroleum), hydrotreated heavy

paraffinic

Pennsylvania : None of the components are listed.

California Prop. 65

WARNING: This product contains less than 0.1% of a chemical known to the State of California to cause cancer.

5/6 Date of issue : 08/15/2012

Synthetic Gear, Bearing, Compressor Oil ISO-46 GBC46

Ingredient name Cancer Reproductive No significant risk Maximum

level acceptable dosage

level

Ethyl acrylate Yes. No. No. No.

Canada

WHMIS (Canada) : Not controlled under WHMIS (Canada).

Canadian lists

Canadian NPRI : None of the components are listed.

CEPA Toxic substances : None of the components are listed.

Canada inventory : Not determined.

This product has been classified in accordance with the hazard criteria of the Controlled Products Regulations and the MSDS contains all the

information required by the Controlled Products Regulations.

Section 16. Other information

United States

Label requirements : NOT EXPECTED TO PRODUCE SIGNIFICANT ADVERSE HEALTH EFFECTS WHEN

THE RECOMMENDED INSTRUCTIONS FOR USE ARE FOLLOWED.

Hazardous Material :

Information System (U.S.A.)

Caution: HMIS® ratings are based on a 0-4 rating scale, with 0 representing

Health 0 minimal hazards or risks, and 4 representing significant hazards or risks

Although HMIS® ratings are not required on MSDSs under 29 CFR 1910.1200, the

Flammability 1 preparer may choose to provide them. HMIS® ratings are to be used with a fully

implemented HMIS® program. HMIS® is a registered mark of the National Paint &

Physical hazards 0 Coatings Association (NPCA). HMIS® materials may be purchased exclusively

from J. J. Keller (800) 327-6868.

The customer is responsible for determining the PPE code for this material.

National Fire Protection :

Association (U.S.A.)

1 Flammability

Health 0 0 Instability

Special

Date of issue : 08/15/2012

Date of previous issue : 07/30/2011

Version : 3

Notice to reader

To the best of our knowledge, the information contained herein is accurate. However, neither the above-named

supplier, nor any of its subsidiaries, assumes any liability whatsoever for the accuracy or completeness of the

information contained herein. Final determination of suitability of any material is the sole responsibility of the

user. All materials may present unknown hazards and should be used with caution. Although certain hazards are

described herein, we cannot guarantee that these are the only hazards that exist.

6/6 Date of issue : 08/15/2012

You might also like

- Multimodal Dangerous Goods FormDocument2 pagesMultimodal Dangerous Goods FormRavi Varma100% (1)

- Product Life Cycle in Automotive IndustryDocument7 pagesProduct Life Cycle in Automotive IndustryRidzuan Ahmad100% (2)

- Solisep MPT150Document8 pagesSolisep MPT150huyNo ratings yet

- MSDS York C Oil (En)Document9 pagesMSDS York C Oil (En)Jakeer hussain ShaikNo ratings yet

- 2021 Model XDocument96 pages2021 Model XSimon AlvarezNo ratings yet

- RS8000 GBC46 GHS SDSDocument10 pagesRS8000 GBC46 GHS SDSService DeskNo ratings yet

- ADVANTAGE EP GEAR OILS MsdsDocument6 pagesADVANTAGE EP GEAR OILS Msdsakhilesh12331No ratings yet

- Glycol MSDSDocument7 pagesGlycol MSDSPanya PurahongNo ratings yet

- Rooting gel-MSDS - Rootech1Document6 pagesRooting gel-MSDS - Rootech1Sinisa1709No ratings yet

- Becker Pumps Oil 3SVPODocument10 pagesBecker Pumps Oil 3SVPOcindy patriciaizquierdoRodriguezNo ratings yet

- Rad01-131 Ebt32c CLN Degreser Ang PDFDocument7 pagesRad01-131 Ebt32c CLN Degreser Ang PDFqwljalkdjNo ratings yet

- Msds - Mystik JT 6 HP Marine GreaDocument9 pagesMsds - Mystik JT 6 HP Marine GreaChinweNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument10 pagesSafety Data Sheet: Section 1. IdentificationFaizan NazirNo ratings yet

- GL-5 Gear Oil 85W-140 SDSDocument10 pagesGL-5 Gear Oil 85W-140 SDSDaniel Salazar CruzNo ratings yet

- Final A - PSDS - D8399629 (US) - Hea - Solid - Biofreeze Hot List Free Patch - 2022 - RTRID-25904Document12 pagesFinal A - PSDS - D8399629 (US) - Hea - Solid - Biofreeze Hot List Free Patch - 2022 - RTRID-25904Orkish100No ratings yet

- Safety Data Sheet: 1. IdentificationDocument7 pagesSafety Data Sheet: 1. IdentificationBrickArms WillNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument8 pagesSafety Data Sheet: Section 1. Identificationtsandeep1310No ratings yet

- Syn Gear Oil 680 - US GHS - SpanishDocument11 pagesSyn Gear Oil 680 - US GHS - Spanishleandro diazNo ratings yet

- Anderol 750: Material Safety Data SheetDocument6 pagesAnderol 750: Material Safety Data SheetOzan OğuzNo ratings yet

- Safety Data Sheet: 1. Identification of The Material and SupplierDocument5 pagesSafety Data Sheet: 1. Identification of The Material and SupplierRegan RidgeNo ratings yet

- GL-5 Gear Oil 80W-90 SDSDocument10 pagesGL-5 Gear Oil 80W-90 SDSDaniel Salazar CruzNo ratings yet

- Safety Data Sheet: in Case of EmergencyDocument3 pagesSafety Data Sheet: in Case of EmergencyJose Gilberto Cortez HernandezNo ratings yet

- Material Safety Data Sheet: Product and Company Identification 1Document6 pagesMaterial Safety Data Sheet: Product and Company Identification 1susiNo ratings yet

- Material Safety Data Sheet: Product and Company Identification 1Document7 pagesMaterial Safety Data Sheet: Product and Company Identification 1faisiiNo ratings yet

- Citric Acid, Anhydrous: Safety Data SheetDocument6 pagesCitric Acid, Anhydrous: Safety Data SheetPressesjg EllisNo ratings yet

- Grasa Sellante. Climax Spec Sheet 800 XH Lubricant SealantDocument7 pagesGrasa Sellante. Climax Spec Sheet 800 XH Lubricant SealantWilinton WilintonNo ratings yet

- Fuse Foam SDS 6-13-19Document7 pagesFuse Foam SDS 6-13-19jpinternational81No ratings yet

- MSDS CRB Monograde 40Document7 pagesMSDS CRB Monograde 40PetrusNo ratings yet

- Material Safety Data Sheet: (Acute and Chronic)Document4 pagesMaterial Safety Data Sheet: (Acute and Chronic)Ganjar Tri Gita AzhariNo ratings yet

- Safety Data Sheet: Nitobond Ep Slow Set BaseDocument3 pagesSafety Data Sheet: Nitobond Ep Slow Set Baseadil khanNo ratings yet

- Safety Data Sheet Fuse: Section 1: IdentificationDocument7 pagesSafety Data Sheet Fuse: Section 1: IdentificationKhaled BellegdyNo ratings yet

- Product and Company IdentificationDocument6 pagesProduct and Company IdentificationMichael rosoNo ratings yet

- Mercon LVDocument6 pagesMercon LVPEDRO laraNo ratings yet

- Material Safety Data Sheet: (Acute and Chronic)Document3 pagesMaterial Safety Data Sheet: (Acute and Chronic)KATHENo ratings yet

- Air Tool Lubricant - 2016 - 0Document8 pagesAir Tool Lubricant - 2016 - 0Cristhina LabraNo ratings yet

- SDS Citric AcidDocument6 pagesSDS Citric AcidZeeshan KhanNo ratings yet

- Arol GreaseDocument4 pagesArol GreasemahaprakashNo ratings yet

- BRIGHT N' CLEAN - Safety Data Sheet (SDS) - 2021 ENGDocument4 pagesBRIGHT N' CLEAN - Safety Data Sheet (SDS) - 2021 ENGSophie TranNo ratings yet

- Sod Hydrx 20 Aq Soln 500MLDocument8 pagesSod Hydrx 20 Aq Soln 500MLPutri Fadyanisa AnandaNo ratings yet

- Palm Fatty Acid Distillate SDSDocument6 pagesPalm Fatty Acid Distillate SDSАткр ЗеписNo ratings yet

- Sikagard 703W MSDS 1Document5 pagesSikagard 703W MSDS 1lir mNo ratings yet

- Safety Data Sheet: Safewing MP I LFD Ready To Use 55/45Document17 pagesSafety Data Sheet: Safewing MP I LFD Ready To Use 55/45Constanza CONTRERAS CASTILLONo ratings yet

- Safety Data Sheet: 1. IdentificationDocument6 pagesSafety Data Sheet: 1. IdentificationjpalauguillemNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument8 pagesSafety Data Sheet: 1. Product and Company IdentificationshoyebNo ratings yet

- Material Safety Data Sheet: Product and Company Identification 1Document6 pagesMaterial Safety Data Sheet: Product and Company Identification 1onejako12No ratings yet

- SDS - RO Syn 20W50 PDFDocument5 pagesSDS - RO Syn 20W50 PDFChemilomNo ratings yet

- Citric Acid, 10% W/V: Safety Data SheetDocument6 pagesCitric Acid, 10% W/V: Safety Data SheetCarreño AlejandroNo ratings yet

- Safety Data Sheet: in Case of EmergencyDocument4 pagesSafety Data Sheet: in Case of EmergencyJose Gilberto Cortez HernandezNo ratings yet

- Safety Sheet Castrol 20W50 PDFDocument9 pagesSafety Sheet Castrol 20W50 PDFmartin andoliniNo ratings yet

- Hoja de Seguridad Optimus TRANS HYD 68Document5 pagesHoja de Seguridad Optimus TRANS HYD 68Deylis Franyelis Osorio MaldonadoNo ratings yet

- SDS 800XHDocument7 pagesSDS 800XHHesam GhaffariNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument10 pagesSafety Data Sheet: Section 1. IdentificationFermanton SiagianNo ratings yet

- Sigma S-460 - EN - 45-29813Document9 pagesSigma S-460 - EN - 45-29813HKC EQUIPEMENTSNo ratings yet

- Meteq 2Document30 pagesMeteq 2Josman Pineda HernandezNo ratings yet

- Hoja de Seguridad Jabon Liq AxionDocument4 pagesHoja de Seguridad Jabon Liq AxionAlexis ArroyaveNo ratings yet

- Alamine 304 052523Document7 pagesAlamine 304 052523Loisse GrimaldoNo ratings yet

- SGP75984Document8 pagesSGP75984Ever LopezNo ratings yet

- Integral. 30714240 SDS CPA US en 7-1Document10 pagesIntegral. 30714240 SDS CPA US en 7-1Giancarlo Gianella GonzálezNo ratings yet

- Hoja de Seguridad - Aceite DielectricoDocument8 pagesHoja de Seguridad - Aceite DielectricoBELTCO CONVEYOR SYSTEM SOLUTIONSNo ratings yet

- GlycerinDocument6 pagesGlycerinmalcolmlow1No ratings yet

- Safety Data Sheet: 1. IdentificationDocument10 pagesSafety Data Sheet: 1. IdentificationGUADALUPE MATANo ratings yet

- All Purpose OilDocument5 pagesAll Purpose OilLee KooNo ratings yet

- Guidelines for Personal Protection When Handling and Applying Pesticides: International Code of Conduct on Pesticide ManagementFrom EverandGuidelines for Personal Protection When Handling and Applying Pesticides: International Code of Conduct on Pesticide ManagementNo ratings yet

- Sikaflex®-221: Safety Data SheetDocument15 pagesSikaflex®-221: Safety Data SheetJohn RamboNo ratings yet

- Clariant SDS PREVOL P Mexico EnglishDocument8 pagesClariant SDS PREVOL P Mexico Englishyanri cahyoNo ratings yet

- RT Freight Preparation PolicyDocument21 pagesRT Freight Preparation PolicyJohn KalvinNo ratings yet

- Mil B 85735Document11 pagesMil B 85735Márcio MatuckNo ratings yet

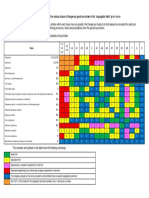

- 7.2.4 Segregation Table: Class 1.1 1.2 1.5 1.3 1.6 1.4 2.1 2.2 2.3 3 4.1 4.2 4.3 5.1 5.2 6.1 6.2 7 8 9Document1 page7.2.4 Segregation Table: Class 1.1 1.2 1.5 1.3 1.6 1.4 2.1 2.2 2.3 3 4.1 4.2 4.3 5.1 5.2 6.1 6.2 7 8 9ejrango74No ratings yet

- For-2009-06-08-602 11Document1 pageFor-2009-06-08-602 11amin mohNo ratings yet

- Safety Data Sheet Polurene Mt100Document9 pagesSafety Data Sheet Polurene Mt100sriatul2006No ratings yet

- MSDS-R170 Hangzhou Hongyan PigmentsDocument3 pagesMSDS-R170 Hangzhou Hongyan PigmentsJose E BatistaNo ratings yet

- GelHandbook Part2 eDocument84 pagesGelHandbook Part2 etankimsinNo ratings yet

- Sikaflex® PRO-3: Safety Data SheetDocument11 pagesSikaflex® PRO-3: Safety Data SheetdipinnediyaparambathNo ratings yet

- Dangerous Goods Panel (DGP) : Working PaperDocument2 pagesDangerous Goods Panel (DGP) : Working PaperMik AeilNo ratings yet

- Field Sampling Procedure ManualDocument574 pagesField Sampling Procedure Manualpetrus01idNo ratings yet

- Elastosil RT 601 ADocument8 pagesElastosil RT 601 AbilalaimsNo ratings yet

- Complete CMF Form Jan2014Document4 pagesComplete CMF Form Jan2014Mukul SoniNo ratings yet

- DLIML D-Limonene SDSDocument12 pagesDLIML D-Limonene SDSkokoNo ratings yet

- Material Safety Data Sheet Florida Chemical Company, IncDocument4 pagesMaterial Safety Data Sheet Florida Chemical Company, IncivonneNo ratings yet

- H2S Scavenger EvaluationDocument56 pagesH2S Scavenger EvaluationMufleh IdrisNo ratings yet

- Material Safety Data Sheet: November 2012 Page 1 of 7Document7 pagesMaterial Safety Data Sheet: November 2012 Page 1 of 7malaya tripathyNo ratings yet

- Msds N ButaneDocument6 pagesMsds N Butanenirmal_subudhiNo ratings yet

- Multimodal Dangerous Goods Form: Shipper'S DeclarationDocument2 pagesMultimodal Dangerous Goods Form: Shipper'S DeclarationCeDíazNo ratings yet

- AUTOTREAT English PDFDocument4 pagesAUTOTREAT English PDFMilan ChaddhaNo ratings yet

- Sika Saudi Arabia: Safety Data SheetDocument4 pagesSika Saudi Arabia: Safety Data Sheetusman khalid100% (1)

- Shippers Declaration Column Format FillableDocument1 pageShippers Declaration Column Format FillableDaffaNo ratings yet

- MSDS Al2O3Document7 pagesMSDS Al2O3Mas BagusNo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument7 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingEglė PuzelytėNo ratings yet

- Fluidum R11 MSDSDocument7 pagesFluidum R11 MSDSعبدالعزيز مقيطوفNo ratings yet

- Foam Chemguard C363 MSDSDocument6 pagesFoam Chemguard C363 MSDSHafiz AkhtarNo ratings yet