Professional Documents

Culture Documents

UP201

UP201

Uploaded by

a0 ratings0% found this document useful (0 votes)

10 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views2 pagesUP201

UP201

Uploaded by

aCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

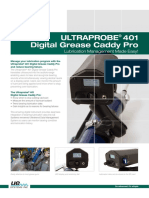

ULTRAPROBE 201 ®

A big step forward in condition based lubrication!

The Ultraprobe® 201 Grease Caddy is uniquely

designed to allow an individual operator to

simultaneously lubricate and monitor ultrasound

levels to prevent over-lubrication.

The Ultraprobe® 201 Grease Caddy will:

• Prolong the life of your equipment

• Prevent over lubrication

• Save on working hours

• Save on operation costs

• Improve maintenance efficiencies

Here's how it works:

As lubrication levels fall, friction levels rise, producing

ultrasonic waves, which are very directional and

localized. Easily attached to most standard grease

guns, or worn in an optional belt holster, the

Ultraprobe® 201 Grease Caddy translates high

frequency sounds into the audible range, where

users will hear and recognize bearing sounds. The

Ultraprobe® 201 Grease Caddy focuses in on these

sounds – even in the noisiest environment – and helps

users identify when to stop lubricating.

Additional useful features:

• Easy to read LED’s provide visual indication of ultra sound amplitude

• Built-in front-end lamp to illuminate dark areas

• Swivel base adjusts to odd angles

• Heavy duty headphones for high noise environments

• Magnetically mounted transducer for ease of operation

• Optional belt holster makes it even easier to carry

Mounting kit included LED display and sensitivity dial

Ultraprobe® 201 Grease Caddy Specifications

Housing Attaches directly to the grease gun, gives visual and audible indi-

cation for proper lubrication

Construction Aluminum housing

Dimensions 13.3 x 6.7 x 4.5 cm (LWH) (5.25" x 2.65" x 1.25")

Operating 0 °C to 60 °C (32 °F to 140 °F)

Temperature

Relative 10-95% non-condensing at up to 30 °C (86 °F)

Humidity

SMD/Solid State heterodyne receiver

Circuity

Transducer Magnetically mounted piezoelectric transducer

Frequency Peak response: centered around 38 kHz

Optional carry case Response

Indicator 10 Segment LED Bar Graph (red)

Bright white LED for illumination of test area

Sensitivity

8 position precision attenuation

Selection

Power Rechargeable nickel metal hydride

Power off Time delay after five (5) minutes

Low Battery

LED

indicator

Headset Deluxe noise isolating headset for hard hat use

Over 23 dB of noise attenuation

Meets or exceeds ANSI Specifications and OSHA standards

Attachment Universal: fits most commercially used cartridge grease guns

Weight 0.45 kg (16 oz)

Warranty 1-year parts/labor standard,

5 years with completed warranty registration card.

Built-in spotlight

Ultraprobe® 201 Grease Caddy

UE Systems Ultraprobe® 201 Grease Caddy is so sensitive, you will hear when

the grease enters the bearings and therefore, recognize when to stop applying

lubrication. With this one instrument, over lubrication and related bearing failure

problems will be reduced dramatically.

Holster for UP 201

www.uesystems.com

Headset for hardhat use

UE Systems Inc. • 14 Hayes St. • Elmsford, New York • USA 10523

T: +1 914 592 1220 • E: info@uesystems.com • www.uesystems.com

©UE Systems, Inc. Made in U.S.A.

Ultraprobe 201 Grease Caddy: Covered by one or more of the following patents: 0151115; 0303776; 0315199; 1206586; 1297576; 1881263; 2562758; 2689339; 4416145;

4823600; 5955670; 6122966; 6339961; 6341518; 6415645; 6655214; 6707762; 6804992; 8746068 UE Systems is committed to continual product improvement; therefore

specifications are subject to change without notice. Warranty details are available by request.

You might also like

- The Artist December 2020Document74 pagesThe Artist December 2020alftoy100% (2)

- MSI Product CatalogDocument89 pagesMSI Product CatalogAnil AbrahamNo ratings yet

- GTS 102N PDFDocument2 pagesGTS 102N PDFSaepullohNo ratings yet

- Kingmaker 1 Stat Blocks (Index Cards) (Excluding Happs)Document173 pagesKingmaker 1 Stat Blocks (Index Cards) (Excluding Happs)Brian McDanielNo ratings yet

- QrrecordermethodDocument37 pagesQrrecordermethodapi-239342890No ratings yet

- PC - VRF - Systems - PART IDocument18 pagesPC - VRF - Systems - PART Icarlos vasquezNo ratings yet

- Kabaddi Score SheetDocument1 pageKabaddi Score SheetKamala Devi69% (13)

- PTC - BSR.RVI.01 - BoreScope Visual Inspection Procedure (Rev.1)Document9 pagesPTC - BSR.RVI.01 - BoreScope Visual Inspection Procedure (Rev.1)Sang Nguyen QuangNo ratings yet

- Kodak Easyshare P850 ManualDocument106 pagesKodak Easyshare P850 ManualenjoytherideNo ratings yet

- Bodas de SangreDocument29 pagesBodas de SangreKarlos Efren Salinas HuechamilNo ratings yet

- LUBEChecker A4 EN PDFDocument2 pagesLUBEChecker A4 EN PDFJairNo ratings yet

- LUBEChecker Brochure ENDocument2 pagesLUBEChecker Brochure ENAnurag JhaNo ratings yet

- Pkt03 de Kenwood RadiosDocument2 pagesPkt03 de Kenwood RadiosLuis Alberto BelmonteNo ratings yet

- UP401 (+dielektrika)Document2 pagesUP401 (+dielektrika)milik bersamaNo ratings yet

- Product Leaflet CaptionDocument3 pagesProduct Leaflet Captionsamuel_menzelNo ratings yet

- GeoMax Zipp02 Data SheetDocument2 pagesGeoMax Zipp02 Data Sheetbbutros_317684077No ratings yet

- Crouse Hinds XPL Led BrochureDocument12 pagesCrouse Hinds XPL Led BrochureBrayan Galaz BelmarNo ratings yet

- Data0305 KX15EDDocument3 pagesData0305 KX15EDAbdelhamid SammoudiNo ratings yet

- EL-55 Luminaria LED Champ MLL Marca Crouse-Hinds Series EATON Cat. MLL4UNV1-TF-PDocument4 pagesEL-55 Luminaria LED Champ MLL Marca Crouse-Hinds Series EATON Cat. MLL4UNV1-TF-PManotas TorresNo ratings yet

- LM55-S400 Datasheet 2018.10.12Document2 pagesLM55-S400 Datasheet 2018.10.12Fredy Andres ValenciaNo ratings yet

- LM55-S400 Datasheet 2022.10.24Document2 pagesLM55-S400 Datasheet 2022.10.24Shukor AffandiNo ratings yet

- Product Leaflet CaptionDocument3 pagesProduct Leaflet Captionsamuel_menzelNo ratings yet

- DS-2CE56D1T-VFIR3: HD1080P Outdoor Vari-Focal IR Turret CameraDocument1 pageDS-2CE56D1T-VFIR3: HD1080P Outdoor Vari-Focal IR Turret CameraGermán Pinedo ChávezNo ratings yet

- Petrolux® LED: Wet Location For Demanding EnvironmentsDocument4 pagesPetrolux® LED: Wet Location For Demanding EnvironmentsJL Montero UbillusNo ratings yet

- AHD One Cable Selection 2017 0815Document11 pagesAHD One Cable Selection 2017 0815johnsgdNo ratings yet

- Data0305 KX15DQDocument3 pagesData0305 KX15DQAbdelhamid SammoudiNo ratings yet

- A World Leading Compact Pan and Tilt Camera With Ultra Low Light 4K VideoDocument5 pagesA World Leading Compact Pan and Tilt Camera With Ultra Low Light 4K VideoJuan PintoNo ratings yet

- ECG2 Product Highlights 01082021Document2 pagesECG2 Product Highlights 01082021Frank MartinNo ratings yet

- QuantumSplicer Q101CA PDFDocument2 pagesQuantumSplicer Q101CA PDFarturoNo ratings yet

- LU9245Document2 pagesLU9245mudassir.bukhariNo ratings yet

- PT 121 G c11 MPB PDFDocument9 pagesPT 121 G c11 MPB PDFlaboratorioelectroNo ratings yet

- T-Gage Iv MM: VersatilityDocument2 pagesT-Gage Iv MM: VersatilityPablo MondragónNo ratings yet

- Barco-RGB Laser ODL-721 - en - 1710164597.3761673Document3 pagesBarco-RGB Laser ODL-721 - en - 1710164597.3761673paulopspNo ratings yet

- Indicators LED & LED BuzzerDocument1 pageIndicators LED & LED Buzzerfahd.srslNo ratings yet

- A Fighter Keeps Strong Light Away!: Lightfighter Network CamerasDocument11 pagesA Fighter Keeps Strong Light Away!: Lightfighter Network CamerasQuocKhanh PhạmNo ratings yet

- Hand Held Ir BinocularDocument2 pagesHand Held Ir BinocularRahman PashariNo ratings yet

- Ds 2ce16d5t Vfit3Document1 pageDs 2ce16d5t Vfit3OnanNo ratings yet

- PC MultiV Indoor UnitsDocument28 pagesPC MultiV Indoor UnitscelsofortoulNo ratings yet

- Photo Indication Dimension Diagram: 3MP Indoor Mini Dome With Basic WDR, Fixed LensDocument2 pagesPhoto Indication Dimension Diagram: 3MP Indoor Mini Dome With Basic WDR, Fixed LensSemut GeniNo ratings yet

- HiLight B5 Plus ESF Zaragoza Product Training ENDocument48 pagesHiLight B5 Plus ESF Zaragoza Product Training ENaarizalNo ratings yet

- Uvled Curing Illuminant: Xiamen Sojet Electronics Co.,LtdDocument2 pagesUvled Curing Illuminant: Xiamen Sojet Electronics Co.,LtdYsabel Cristina Yaguaracuto TorrealbaNo ratings yet

- HATCHecker Brochure ENDocument2 pagesHATCHecker Brochure ENgustavoseseNo ratings yet

- When Hatch Cover Tightness Matters: T-Sonic9Document2 pagesWhen Hatch Cover Tightness Matters: T-Sonic9technical01No ratings yet

- Littelfuse Hall Effect Sensors 55110 Datasheet - pdf-938868Document4 pagesLittelfuse Hall Effect Sensors 55110 Datasheet - pdf-938868azer tyNo ratings yet

- cx-400 - e - Cata 2Document30 pagescx-400 - e - Cata 2York ThanaponNo ratings yet

- DH-SD52C225I-HC: 2MP 25x Starlight PTZ HDCVI CameraDocument3 pagesDH-SD52C225I-HC: 2MP 25x Starlight PTZ HDCVI CameraMarcelo VeraNo ratings yet

- 080 Frascold Chillventa-2020 1015Document46 pages080 Frascold Chillventa-2020 1015Dee RajaNo ratings yet

- PDF - N31 Series LED Display Manual 20210701Document6 pagesPDF - N31 Series LED Display Manual 20210701Hidayatullah sucahyoNo ratings yet

- Color Cameras: 420TVL, 1/3" Sony CCD, Color DSP, Weather Resistant IR Bullet CameraDocument1 pageColor Cameras: 420TVL, 1/3" Sony CCD, Color DSP, Weather Resistant IR Bullet CameraZedana Dwi.PNo ratings yet

- DX550 Series - PS v1.1Document2 pagesDX550 Series - PS v1.1paulaNo ratings yet

- Jaegar Radar Uk PDFDocument2 pagesJaegar Radar Uk PDFhulso gurionNo ratings yet

- Sonicision 2Document2 pagesSonicision 2Rinaldi SinagaNo ratings yet

- Shure SM89Document4 pagesShure SM89Jc C. GomezNo ratings yet

- Sony WX-C570R CHANGER Service ManualDocument70 pagesSony WX-C570R CHANGER Service Manualtm5u2rNo ratings yet

- Data0305 KX18DCDocument3 pagesData0305 KX18DCAbdelhamid SammoudiNo ratings yet

- Sounde and Beacon Combined - FLASHNIDocument1 pageSounde and Beacon Combined - FLASHNIrhomadonaNo ratings yet

- Catalog DentamericaDocument20 pagesCatalog DentamericaworrasidNo ratings yet

- Molykote BR-2 Plus High Performance GreaseDocument2 pagesMolykote BR-2 Plus High Performance GreaseRamonNo ratings yet

- DL I Series - 15W 5000K - NNP73429031Document1 pageDL I Series - 15W 5000K - NNP73429031Adi HardiansyahNo ratings yet

- 4401 ManualDocument4 pages4401 ManualBen RileyNo ratings yet

- SKF Ultrasound Lubrication Checker: Ultrasonic Sensor Improves Maintenance Practices When Re-Lubricating BearingsDocument2 pagesSKF Ultrasound Lubrication Checker: Ultrasonic Sensor Improves Maintenance Practices When Re-Lubricating BearingsNadia SalemNo ratings yet

- VTRDNSHEDocument2 pagesVTRDNSHEgratgecyassinNo ratings yet

- RRC 50w Light EngineDocument3 pagesRRC 50w Light EngineATUL PRASADNo ratings yet

- Viewz - Vz-55unbsDocument2 pagesViewz - Vz-55unbsjosev_3000No ratings yet

- Spesifikasi Detail & Jual Total Station Topcon GTS-102N (081297551995)Document2 pagesSpesifikasi Detail & Jual Total Station Topcon GTS-102N (081297551995)Rina Wahyuni100% (1)

- Voizecom - Brochure V836Document1 pageVoizecom - Brochure V836EHS Engineer0% (1)

- Noise and Signal Interference in Optical Fiber Transmission Systems: An Optimum Design ApproachFrom EverandNoise and Signal Interference in Optical Fiber Transmission Systems: An Optimum Design ApproachNo ratings yet

- China's Military Will Not Dance To US' Tune': Rising StarsDocument22 pagesChina's Military Will Not Dance To US' Tune': Rising StarsJackZhangNo ratings yet

- Media and Culture Mass Communication in A Digital Age 10th Edition Campbell Test BankDocument25 pagesMedia and Culture Mass Communication in A Digital Age 10th Edition Campbell Test Bankfreyaphuonghu8100% (23)

- Kaji Abdul MerajDocument2 pagesKaji Abdul MerajDRIVECURENo ratings yet

- Prince CharmingDocument18 pagesPrince CharmingIsabelleArthurNo ratings yet

- GA-Gaming B8: User's ManualDocument44 pagesGA-Gaming B8: User's ManualRommel LoayzaNo ratings yet

- HUL 239 AssignmentDocument5 pagesHUL 239 AssignmentVaibhav AgarwalNo ratings yet

- Have It All Hilton Grand VacationsDocument1 pageHave It All Hilton Grand Vacationsgt7nvvnvsjNo ratings yet

- Khalid Ali Shah Highlights and MemoriesDocument3 pagesKhalid Ali Shah Highlights and Memoriesgdrive.r859abNo ratings yet

- Flexjobs 87Document1 pageFlexjobs 87hjNo ratings yet

- Sample Match NarrativeDocument8 pagesSample Match Narrativeapi-234051459No ratings yet

- Colposcopio Con VideoDocument2 pagesColposcopio Con VideoMirna PS IvstoreNo ratings yet

- VMware Workstation Pro 4,5,6,7,8,9,10,11,12,14,15 Universal License Keys CollectionDocument8 pagesVMware Workstation Pro 4,5,6,7,8,9,10,11,12,14,15 Universal License Keys CollectionVinicius Jaguaraci LopesNo ratings yet

- VerbsDocument4 pagesVerbspmerrazurizNo ratings yet

- Soal Pas 1 Kls X 2021Document4 pagesSoal Pas 1 Kls X 2021riska andrianiNo ratings yet

- F&B QuestionsDocument6 pagesF&B QuestionsrednivnamNo ratings yet

- 103 at 8 O'clock: On Monday in AprilDocument2 pages103 at 8 O'clock: On Monday in AprilItzel Sauceda CoronadoNo ratings yet

- Badminton Court DimensionsDocument4 pagesBadminton Court DimensionsJayral Sidon PradesNo ratings yet

- Lyrics All SongsDocument75 pagesLyrics All SongsBacky CrisostomoNo ratings yet

- Predicting Round and Game Winners in CSGODocument10 pagesPredicting Round and Game Winners in CSGORopyNo ratings yet

- Brawn Agility Intellect Cunning Willpower Presence: Wound Threshold Strain Threshold M/R DefenseDocument4 pagesBrawn Agility Intellect Cunning Willpower Presence: Wound Threshold Strain Threshold M/R DefenseYek Chuen TanNo ratings yet

- Jackie's Closing Press ReleaseDocument1 pageJackie's Closing Press ReleaseAJ MetcalfNo ratings yet

- Ecom Midterm Finals ReviewerDocument13 pagesEcom Midterm Finals Reviewercindy licuanNo ratings yet